小型自发电照明系统-手压式发电机构系统设计【4张CAD图纸和说明书】

收藏

资源目录

压缩包内文档预览:

编号:6092580

类型:共享资源

大小:1.75MB

格式:ZIP

上传时间:2017-11-14

上传人:俊****计

认证信息

个人认证

束**(实名认证)

江苏

IP属地:江苏

40

积分

- 关 键 词:

-

小型

自发

照明

系统

手压式

发电

机构

设计

cad

图纸

以及

说明书

仿单

- 资源描述:

-

- 内容简介:

-

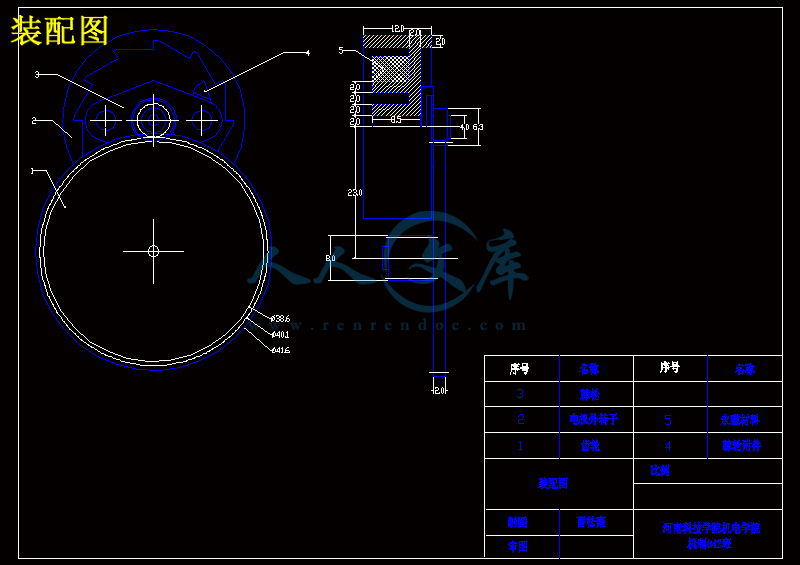

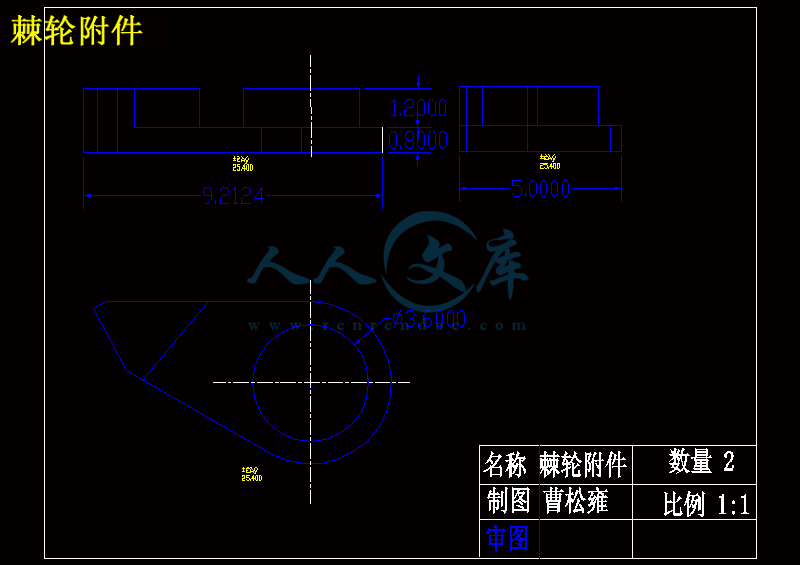

,毕业设计答辩,学生:,曹松雍,小型自发电照明系统-发电机构系统设计,小型自发电照明系统总体框架研究,手压式自发电照明系统传动系统设计与分析,传动系统设计,电机部分设计,前言,目录,前言,本文讨论了机械能供电系统及如何用手摇发电机来对可储电池进行充电,从而带动LED灯泡进行日常照明的工作原理,成为照明系统的电力源。阐述了充电电路设计,LED发光原理,发电机构材料选择,发电机构的设计,及齿轮的参数计算,以二级增速传动为机械转换机构。动力将从手柄传至原动系,带动发电机运转 。,手压式供电照明系统的分析,发电机结构原理分析,发电机材料选择与应用,LED的发光原理分析,供电电池选择,手压式照明电路分析统,1,2,3,4,5,手压式机械能供电LED灯系统设计与分析,1,图5 手压式机械能供电系统分析概图,小型发电机结构分析,转子,手柄,齿轮,棘轮,电机转子,传动系统结构图,主传动齿轮正面反面侧面效果图,传动外援有81个齿,外径44.6毫米,齿轮根为1.5毫米。中部有直径2毫米的贯通孔。主传动齿轮上部有同心齿轮,外缘有10个齿,齿轮厚1.2毫米,直径2.2毫米,齿轮根为3.4毫米。,齿轮,两铁质定子片呈45度角交叉。定子轴直径2毫米,长35毫米。线圈绕在两铁质定子片内部,线圈上下有绝缘塑料片垫称,装配过的定子底部固定。,定子,定子设计的效果图,转子正面有12个棘轮巢,棘轮附件零件匹配棘轮转子巢。转子正中有贯通孔,直径为2毫米。转子内镶嵌永久磁铁,磁铁内径4毫米,外径11.6毫米,厚度8毫米,磁铁有一定重量,在压动时动力转化为惯性动量,再加上转子本身有质量,根据质量与惯性的关系,质量越大惯性愈大,惯性动能才能长时间持续。,转子,转子设计的效果图,棘轮上部有与转子同心的贯通孔,直径为2毫米。棘轮镶嵌有从动齿轮,外缘有10个轮齿,直径1.2毫米,厚10毫米,齿轮根为1.5毫米。,棘轮与棘轮附件,设计的效果图,系统转速:主动齿轮81个齿直接驱动棘轮上的10个齿,线速度为8.1比1。,装配系统,设计的效果图,照明电路的设计,1,电路有自发电机,整流桥,储电电容C1是100F的,电池是可充电的三节CR2032电池,电池是可拆卸的,单刀单控开关,当接通时,压动电机电流瞬时能对储能电容充电,电容是超大容量的,能满足对电池组的充电。可以持续点亮LED灯。是15欧母的降压电阻。改进的概念型照明系统的特点是储能大电容对电池自充电,有利于再没有市电对电池补充电能的情况长时间的使用。,转子由机壳、磁环和轴组成。磁环采用磁性能较强的粘结铁硼( NdFeB )材料,注塑成型,工艺简单而价格便宜。内圆充磁l2个极,表面磁场可达0. l9 T以上。定于铁心为9槽结构,采用熔槽绝缘或绝缘片均可。齿上绕制三相集中绕组.采用人型接法。铁心内孔压人含油轴承。,电机部分设计,设计的效果图,发电机定子与含油轴承是压配台,通过轴承铆接将定子固定到安装板上,如图所示。安装板上有四个孔用以与整机固定,还有两个齿轮轴用以装配增速齿轮。齿轮采用塑料注塑成型,用卡圈固定到轴上。发电机轴身端装有粉末冶金齿轮。安装板上齿轮轴之间及与轴齿轮之间的中心距应保证足够的加工精度以确保齿轮的啮合质量,发电机的结构特点,发电机的额定转速为3000rmin,若变为适合手摇的速度就需要增加两级增速齿轮。轴齿轮的技术参数Z1=10,m=0.6mm 两个增速齿轮为Z2=45,m=0.6mm ,增速比t=20.2,手动转速则为148rmin=2.5rs,通过齿轮组将手动的速度变为25rs,正好适合人的操作 。,发电机的使用特点,学生:,曹松雍,谢谢各位老师,河南科技学院本科毕业论文(设计)中期进展情况检查表学生姓名 曹松雍 班级 042 班 指导教师 丛晓霞论文(设计)题目 小型自发电照明系统-发电机构系 统设计1.从图书馆、网上查找相关毕业设计 的资料,能 够自己独立的 阅读部分资料,毕业设计的过程建立整体概念;2.进行发电机构的设计、电器元件的 选择,充 电电路的设计 等工作;3.传动系统设计 传动系统简图 齿轮相关参数设计 电机部分设计 电机参数及相关计算;4.发电机的结构特点 发电机的使用特点等。目前已完成任务是否符合任务书要求进度: 符合1.用 pore 画出具体的电路图及发电机构图、元件联接图;2.做出实物进行试验。尚需完成的任务能否按期完成论文(设计):能够按期完成毕业论文。存在问题1.进行发电机构的设计、电器元件的 选择,充 电电路的设计 等工作;2.画出具体的电路图及发电机构图、元件 联接图。存在问题和解决办法拟采取的办法1.在老师和同学帮助下,尽快完成 结构设计;2.加快进度,画出图形; 3.及时和老师交流,按时完成 毕业设计任务、提交 毕业设计报 告。指导教师签 字 日期 年 月 日教学院长(主任)意 见 负责人签字: 年 月 日河南科技学院本科生毕业论文(设计)任务书题目名称 小型自发电照明系统-手压式发电机构系统设计学生姓名 曹松雍 所学专业 机械设计制造及其自动化 学号 20040114019指导教师姓名 丛晓霞 所学专业 机械 职称 副教授完成期限 2008 年 12 月 12 日至 2009 年 6 月 5 日一、论文(设计)主要内容及主要技 术指标1.主要内容熟悉自发电照明系统的工作原理,了解 现有的自发电照明系 统的结构和原理, 综合自发电照明系统的结构与原理, 进行发电机构的设计、 电器元件的 选择,充电电路的设计等工作,并进行电器元器件的选择,画出具体的 电路图及发电机构图 、元件 联接图。2.技术指标进行发电机系统的结构设计、电器元件的选择、充 电电路的 设计等工作,画出具体的电路图及发电机构图、元件连接图。、 毕业论文(设计)的基本要求1.实现 PLC 控制编程。1.毕业设计 (论文)一份:有 400 字左右的中英文摘要,正文后有 20 篇左右的参考文献,正文中要引用 5 篇以上文献,并注明文献出 处。2.有不少于 2000 汉字的与本课题有关的外文翻译资料;3.毕业设计总字数在 20000 字以上;4. 具体的图纸与单片机控制程序。三、毕业论文(设计)进度安排1.2008 年 12 月 16 日-2008 年 12 月 21 日,下达毕业设计任务书;寒假期间完成英文资料翻译和开题报告。2. 2009 年 2 月 16-2 月 27 日(第 1-2 周),指 导教师审核开 题报告、设计方案和英文资料翻译。3. 2009 年 3 月 2 日-4 月 24 日(第 3-10 周), 毕业设计单元部分 设计。4. 2009 年 4 月 20 日-4 月 30 日(第 10-11 周), 毕业设计中期 检查。5. 2009 年 5 月 4 日-5 月 22 日(第 12-14 周), 设计仿真、程序调试、线路板制作调试,整理、撰写毕业设计报告。6. 2009 年 5 月 25-6 月 5 日(第 15-16 周)上交毕业设计报告,指导教师、 评阅教师审查评阅设计报告,毕业设计答辩资格审查 。毕业设计答辩,学生修改整理 设计报告。河南科技学院2009 届本科毕业论文(设计)论文题目:小型自 发电照明系统- 手压式发电机构系统设计学生姓名: 曹松雍所在院系: 机电学院所学专业: 机械设计制造及其自动化导师姓名: 丛晓霞完成时间:2009 年 5 月 20 日摘 要随着各种器件对供电电源的长时间供电和结构小型化的要求日益迫切,而物理电源具有无损检测、可重复使用、可长期储存和良好的高低温特性,又由于高性能永磁体的出现,使得微型自 发电电源受到了广泛的关注。本文讨论了机械能供电系统及如何用手摇发电机来对可储电池进行充电,从而带动 LED 灯泡进行日常照明的工作原理,成 为照明系 统的电力源。首先阐述了充电电路设计,LED 发光原理,发电机构材料选择,发电机构的设计,及齿轮的参数计算,以二级增速传动为 机械转换机构。 动力将从手柄传至原动系, 带动发电机运转。发电机是一种微型的直流发电机,通过对转子的转动速度来计算此发电系统最终能产生多大功率和提供多大供电电压,将计算结果和实际上所能产生的功率和电压作比较,分析各种影响关系,得出制作此微型自 发电系统的最佳设计尺寸。关键词:机械转换机构,发电机, LED,充电电路AbstractWith the power supply device for a long period of power supply and the demands of small-scale structure of the increasingly urgent, and the physical power of nondestructive testing, re-use, it can be a good long-term storage and high and low temperature properties, and because high-performance Wing The emergence of magnet, making micro-generating power since it has been widely concern.This paper discusst machine ability power supply system and how by hand shake generator to come to rightness can keep battery to carry on refresh, arouse a LED lamp bulb to carry on thus daily illuminate of work principle, become lighting system of electric power source.Elaborated to refresh an electric circuit design first, the LED gave out light principle, generate electricity organization material a choice and generate electricity organization of design, and the parameter of the wheel gear calculation, with second class increase to soon spread to move for machine conversion organization.The motive will spread from the hand handle to original move to fasten, arouse generator an operation.Generator is a miniature DC generator, through the rotational speed of the rotor to calculate the ultimate power generation system can produce much more power and supply voltage, and the calculated results can actually have the power and voltage for comparison and analysis all kinds of influences, that produced this micro-power generation system since the best design dimensions.Key word: Machine conversion organization, generator, Refresh electric circuitFigure 9-12 Tool-nose radius compensation allows us toprogram the part, not the tool path. The mathematicalcalculations that are needed to program a part profilewith angles and radii, without the aid of cutterdiameter compensation, can be very involved.on a turning center. When we set the X and Z axes of the tool, we create a square point on the tool. Most of the tools we use for turning have radii. To compensate for the radii, we need to use TNR compensation, which saves us from having to mathematically calculate the cutter path (see Figure 9-12).TNR compensation also lets us use the same program for a variety of tool types. With TNR compensation capabilities, the insert radius size can be ignored and the part profile can be programmed. The exact size of the cutting tool to be used is entered into the offset file, and when the offset is called, the tool path will automatically be offset by the tool radius.Tool-nose radius compensation can be to the right or left of the part profile.To determine which offset you need, imagine yourself walking behind the cutting tool. Do you want the tool to the left of the programmed path or to the right (see Figure 9-13)? Figure 9-13 Tool-nose compensation.Compensation direction is controlled by a G-code. When a compensation to the left is desired, a G41 is used. When a compensation to the right is needed,a G42 is used. When using these cutter compensation codes, you need to specify how much the controller is to offset. The size of the radius is placed in the nose radius offset table, which is typically located adjacent to the tool file under the tool number being used. Tool-nose radius information can be determined from catalogs or the insert package.Other information needed to insure proper compensation is the tool nose direction vector. The tool tip or imaginary tool tip of turning tools has a specificlocation or direction from the center of the tool-nose radius. The tool nose vector tells the control which direction it must compensate for individual types of tools.Standard tool-nose direction vectors are shown in Figure 14. The direction vector number is usually placed in the same tool offset table as the radius value. Figure 9-14 Tool-nose radius direction vectors.To invoke compensation, the programmer will have to make a machine move (ramp on). This move allows the control to evaluate its present position and make the necessary adjustment from tool-edge positioning to tool-nose radius positioning. This adjustment move must be greater than the radius value of the tool. To cancel the cutter compensation and return to cutter-edge programming, the programmer must make a linear move (ramp off) to invoke a cutter compensation cancellation (G40).Figure 9-15 illustrates a typical part that uses tool-nose radius compensation.The program for the part follows the figure.N0001 G90 G20;N0005 G40;N0010 T0101;N0015 G92 X5.800 Z10.250;N0020 G96 S400 M03;N0025 GOO G42 Xl .30 Z.100; (Rapid position ramp on move and TNRcompensation to the right)N0035 GOO X.375; (Profile of the part)N0045 G01 Z0.0 F.01; (Profile of the part)N0050 G01 X.500 Z-.0625; (Profile of the part)N0055 G01 Z-1.00; (Profile of the part)N0060 G02 Xl .00 Z-1.25 1.25 K0.0; (Profile of the part)N0065 G01 X1.25; (Profile of the part)N0070 G40 G00 X2.0 Z2.0; (TNR compensation cancel and rapid positionramp off move)N0075 G28;N0080 T0100;N0085 M30; Figure 9-15 Program that utilizes tool-nose radius compensation.CANNED CYCLES FOR TURNING CENTERSCanned cycles (fixed) cycles are used to simplify the programming of repetitive turning operations, such as rough turning, threading, and grooving. Canned cycles are sets of preprogrammed instructions that eliminate the need for many lines of programming. Programming a simple part without the use of a canned cycle can take up to four or five times the number of lines needed for a part programmed with canned cycles. Think of the lines that are needed to produce a thread: (1) position the X and Z axes to the proper coordinates with a rapid traverse move (G00), (2) position the tool for the proper lead angle, (3) feed the tool across, (4) rapid position the tool back to the clearance plan, (5) feed the tool across. That is only two threading passes. With a canned threading cycle, a thread can be done with one line of programming. Standard canned cycles, or fixed cycles, are common to most CNC machines. See Figure 9-4 for a general list of the most commonly used canned cycles for turning centers. ROUGHING OR TURNING CYCLE (G71)The G71 automatically takes roughing passes to turn down a workpiece to a specific diameter at a specified depth of cut. The G71 cycle reads a specified number of blocks to determine the part profile and determines each pass, the depth of cut for each pass, and the number of repeat passes for the cycle. Cutting is accomplished through parallel moves of the tool in the Z axis direction. A certain procedure needs to be followed when using canned cycles. In the first procedure, the tool needs to be positioned to the rough stock boundaries.This procedure has a two-fold purpose: it tells the control how big the stock is, and it creates a Z clearance position that the tool rapids back to on each pass.The G71 uses letters to give the controller information on the part profile, the amount of stock we are going to leave for finishing, the depth of cut, and the feed rate. A G71 roughing cycle command follows.N0010 G71 P40 Q85 U.03 W.010 D750 F.012;G71 is the roughing cycle call.P40 is the block or line number that designates the start of the part profile.Q85 is the block or line number that designates the end of the part profile.U.03 tells the controller that we want to leave .03 of an inch stock on the X axis of the profile for finishing.W.O1 tells the controller that we want to leave .01 of an inch stock on the Z axis of the profile for finishing.D750 tells the controller we want to take .0750 of an inch per pass per side depth of cut. Notice that the decimal point was left off. No decimal point input is possible for depth of cut. When the D is commanded the controller reads from the right and decides what the depth of cut will be. Each number in each decimal position gets a value. If we wanted to take .0500 depth of cut per side, we would write it as D500. The first zero from the right has 0 tenths of a thousandths value. The next zero from the right has 0 thousandths of an inch value. The 5 in the third position from the right has 5 ten-thousandths of an inch value or 50 thousandths of an inch.F.O12 is the feed rate of the roughing passes.Next we take the example program from Figure 9-15 and convert it to a program that utilizes a roughing canned cycle (see Figure 16). We will eliminate the TNR compensation just for ease of understanding.N0001 Gg0 G20;N0005 G40;N0010 T0101;N0015 G92 X5,800 Z10.2.50;N0020 G96 S400 M03;N0025 GOO Xl .30 Z.100; (Rapid position that indicates to the controllerour stock size and Z clearance point)N0030 G71 P35 Q65 U.03 W.01 D600 R010; (Canned roughing cycle call)N0035 GOO X.375; (Profile of the part)N0045 G01 Z0.0 1:.01; (Profile of the part)N0050 G01 X,500 Z-.0625; (Profile of the part)N0055 G01 Z-1.00; (Profile of the part)N0060 G02 Xl .00 Z-1.25 1.25 KO.O; (Profile of the part)N0065 G01 X1.25; (Profile of the part)N0070 GOO X2.0 Z2.0;N0075 G28;N0080 T0100;N0085 M30;Figure 9-16 Roughing cycle exampleFINISHING CYCLE (G70)The G70 command calculates the finish part profile, then executes a finish pass on the part. The finishing cycle is called with a G70, followed by a letter address P for the start line of the finish part profile and the letter address Q for the end line of the part profile. A finishing feed rate can also be included in this block. When the finish cycle is commanded, it reads the program blocks designated by the P and Q and formulates a finishing cycle. As in the roughing cycle, the tool needs to be positioned to a Z clearance plane or stock boundary prior to the calling of the G70 finishing cycle. Next we will finishthe program shown in Figure 9-15.N0001 G90 G20;N0005 G40;N0010 T0101;N0015 G92 X5.800 Z10.250;N0020 G96 S400 M03;N0025 GOO X1.30 Z.100; (Rapid position that indicates to the controllerour stock size and Z clearance point)N0030 G71 P35 Q65 U,03 W.01 D600 F.010; (Canned roughing cycle call)N0035 GOO X,375; (Profile of the part)N0045 G01 Z0.0 1:,01; (Profile of the part)N0050 G01 X.S00 Z-.0625; (Profile of the part)N0055 G01 Z-1.00; (Profile of the part)N0060 G02 Xl .00 Z-1,25 1.25 KO.O; (Profile of the part)N0065 G01 1.25; (Profile of the part)N0070 GOO X2.0 Z2.0;PECK DRILLING CYCLE (G74)The G74 peck drilling cycle will peck drill holes with automatic retract and incremental depth of cut. The G74 command relays to the controller the incremental depth of cut, the full depth of the hole, and the feed rate through the command variables K, Z, and E The next command shows the proper format for peck drilling.N0010 G74 X0.0 Z-1 25 K.125 F.010;G74 is the peck drill cycle call.X0.0 is the center of the workpiece (X is always zero).Z-1.25 is the full depth of the drilled hole.K.125 is the depth of each peck.F.01 is the drilling feed rate.The drill must be positioned to a clearance plane in the Z axis and also to X0.0 prior to the calling of the G74 peck drilling cycle. The spindle should also be reprogrammed for direct RPM input using a G97 when drilling. Examine the sample peck drilling cycle in Figure 9-17.N0001 Gg0 G20;N0005 G40;N0010 T0606; (Tool #6, .500 diameter drill)N0015 G92 X5.800 Z10.250;N0020 G97 S800 M03; (RPM 800)N0025 GOO X0.0 Z.200; (Rapid position the drill to the center of the stockand .200 of an inch in front of the work face)N00B0 G74 X0.0 Z-1.25 F0.01 K.125; (Peck drilling cycle call)N0035 G28 Z1.00; (Return to home through Z1.00)N0040 T0600;N0045 M30;Figure 9-17 Peck drilling cycle.GROOVING CYCLE (G75)The grooving cycle is used to cut grooves of varying widths automatically. To use the grooving cycle, the tool must be positioned to the start of the groove prior to calling the grooving cycle. Through a series of letter addresses, the controller can be commanded to cut a groove of varying width and depth.The next example shows the proper format for the grooving cycle.NO010 G7S X.750 Z-.S0 FO.125 DO 1.125 K.125;G75 is the grooving cycle call.X.750 is the diameter at the bottom of the groove.Z-.50 is the end position of the groove.F0.125 is the incremental retract of the grooving tool.I is the depth of cut on the X axis.K is the depth of cut on the Z axis.The controller looks at the position of the tool prior to the calling of the grooving cycle and uses that information to establish the groove width and depth positions. The programmer, when positioning the grooving tool, will have to take into consideration which corner of the tool is the leading edge. She/he may have to make adjustments for the width of the tool. Note that the last feed rate that was active prior to the grooving cycle will be the grooving feed rate. It is not possible to express a feed rate within a grooving cycle. Take a look at a sample grooving cycle in Figure 9-18.Figure 9-18 This figure shows a part that wouldbe appropriate for a G75 grooving cycle.N0001 G90 G20;N0005 G40;N0010 T0505; (Tool #5, .125 wide grooving tool)N0015 G92 X5.800 Z10.250;N0020 G96 S200 M03;N0025 GOO Xl .250 Z-1.125; (Rapid position that indicates to the controller our stock diameter at the groove location and the Z position of the start of the groove)N0030 G75 X.750 Z-1.375 F0.125 1.125 K.125; (Grooving cycle call)N0035 G28 X2.00 (Return to home through X2.00)N0040 T0500;N0045 M30;The grooving cycle is primarily used to cut a groove that is wider than the tool. If the groove is the same width as the tool it may be just as easy to program the groove in linear blocks.THREAD-CUTTING CYCLE (G76)The G76 thread-cutting cycle can cut multi-pass threads with one block of information. By using several letter address parameters, the control will automatically calculate the correct number of cut passes, depth of cut for each pass, and the starting point for each pass. To use the G76 thread-cutting canned cycle, the following commands need to be programmed:N00010 G76 X.712 Z-1.125 10.0 K.076 D0.012 E0147 A60;X.712 is the minor diameter of the thread.Z-1.125 is the absolute Z position of the end of the thread.10.0 is the radial difference between the thread starting point and the thread ending point. The I is used for cutting tapered threads. For cutting straight threads a zero should be programmed.K.076 is the thread height expressed as a radius value (i.e., major diameter minor diameter divided by 2).D0.012 is the depth of cut for the first pass (in a radius value). Note: Every pass after the first pass will be decreasing in depth.F is the thread lead (i.e., 1 divided by the number of threads per inch). Note: The F can sometimes be substituted with E.A is the included angle of the thread.Prior to calling the G76 thread-cutting cycle, the tool must be positioned to the major diameter of the thread. The tool should also be positioned in front of the thread Z axis start position by a distance of at least double the thread lead. This insures that the proper lead will be cut throughout the length of the thread. The spindle should be running in direct RPM (G97), not constant surface footage control. Consider the sample G76 thread-cutting cycle in Figure 9-19.N0001 G90 G20;N000S G40;N0010 T0505; (Tool/45, 60-degree threading tool)N0015 G92 X5.800 Z10.250;N0020 G97 5300 M03; (Direct RPM input)N0030 GOO Z.200; (Z axis rapid position in front of the thread start point).N0040 GOO ;(1.00; (X axis rapid position to major thread diameter)NO050 G76 X.897 Z-t .25 K.051 D120 F. 0833 A60; (Threading cycle)N0060 G28; (Return home)N0070 T0500;NO080 M30;Figure 9-19 This part would be appropriatefor a G76 thread-cutting cycle.Now that we have an understanding of canned cycles and how they are used,we need to put our knowledge to work. After the chapter questions there are some part prints. Use the part prints and the tool table shown in Figure 9-20 to program these parts. The programs should include canned cycles and tool-nose radius compensation where appropriate.Part #1 Written by: Kellv Curran Machine: Mazak Q10N Date 07/03/95 Sheet 1 of 1 Notes: PaM Datum XO Center ZO Right end Tool #Tool Description Operation 1 80-degree diamond Rough turn 2 35-degree diamond Finish profile3 .125 grooving tool Groove 4 60-degree threading toolThread 5 1 diameter drill 1 hole FIGURE 9-20 Tool tableCHAPTER QUESTIONS1. Which turning center axis controls the diameter of the part?2. What are the potential drawbacks of using hardened chuck jaws?3. Define constant surface footage control.4. What secondary axes addresses are used to define the centerpointposition when cutting radii on a turning center?5. Explain why tool-nose radius compensation is needed when cuttingtapers or radii.6. Which letter address controls the depth of cut when using canned cycles?7. What is the letter address command to take .100 of an inch off the diameter of the part per pass when using a roughing cycle?8. Describe when a grooving cycle would be used.9. What letter address controls the pitch or lead of the thread when using a G76 thread cutting cycle?10. What must be done prior to the calling of a G76 thread cutting cycle?11. Program the part shown in Figure 9-21. Use canned cycles where appropriate and the tooling shown in Figure 9-20.12Program the part shown in Figure 9-22Figure 9-22 Use with question 12.13. Program the part shown in Figure 9-23Figure 9-23 Use with question 13.14.Program the part shown in Figure 9-24Figure 9-24 Use with question 13.翻译部分图 9-12 刀具的实际走刀路线并不是我们编程时写的那 样,如果不使用刀尖半径补偿的话,就得需要大量的数学计算当我们设置了 X 和 Z 轴的工具,我们就为机床上的刀具建立了一个点。大部分的刀具,我们使用的时候有半径误差。以补偿为半径,我们需要使用 tnr补偿,从而节省了我们不必在数学上计算刀具轨迹(见图 9-12).TNR 补偿,我们也可以使用到各种刀具上。TNR 补偿能力,插入半径大小可以被忽略,以及部分可以编程。确切的大小刀具将要采用时需要调入,当补偿调入后,刀具路径将自动抵销刀具半径。刀尖半径补偿,可以是左刀补也可以是右刀补。先确定自己的走刀路线,再决定是采用左刀补还是右刀补。你想让自己的程序是左刀补还是右刀补呢(见图9-13)?图 9-13 刀尖半径补偿补偿的方向是由 G 代码控制。当应该是左刀补时,就应该调用 g41 指令。当应该采用右刀补时,就应该调用 g42。当使用这些刀具补偿代码时,您需要指定多少控制器,大小半径,来进行刀尖半径补偿,这是通常被使用的方法。文件下工具的数据正在使用时,刀尖半径的资料才能确定。其他必要的信息,为了保证是正确的补偿是刀尖的方向向量。该刀具提示或假想车刀的刀尖有一个特定位置或方向,从中心的刀尖半径。该刀尖半径告诉矢量控制哪个方向,它必须弥补个别类型的刀具。标准刀尖半径的方向向量如图14 。方向向量的数目通常是放置同样的刀具,抵销了车床上的作为半径数值。图 9-14 刀尖半径方向矢量引用补偿,程序将不得不作出定点移动。以确定其目前的位置,并作出必要的调整,从刀具的优势定位,以刀尖半径定位。这个调整动必须大于半径价值的刀具。取消刀具补偿,程序员必须作出定点移动,调用刀具补偿取消指令( G40 ) 。 9-15 的数据是普通的刀尖半径补偿实例。其程序如下:N0001 G90 G20;N0005 G40;N0010 T0101;N0015 G92 X5.800 Z10.250;N0020 G96 S400 M03;N0025 GOO G42 Xl .30 Z.100; N0035 GOO X.375; N0045 G01 Z0.0 F.01;N0050 G01 X.500 Z-.0625;N0055 G01 Z-1.00; N0060 G02 Xl .00 Z-1.25 1.25 KO.O; N0065 G01 X1.25; N0070 G40 GOO X2.0 Z2.0; N0075 G28;N0080 T0100;N0085 M30;图 9-15 刀尖半径补偿的程序使用固定循环固定循环的使用,可以简化重

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号