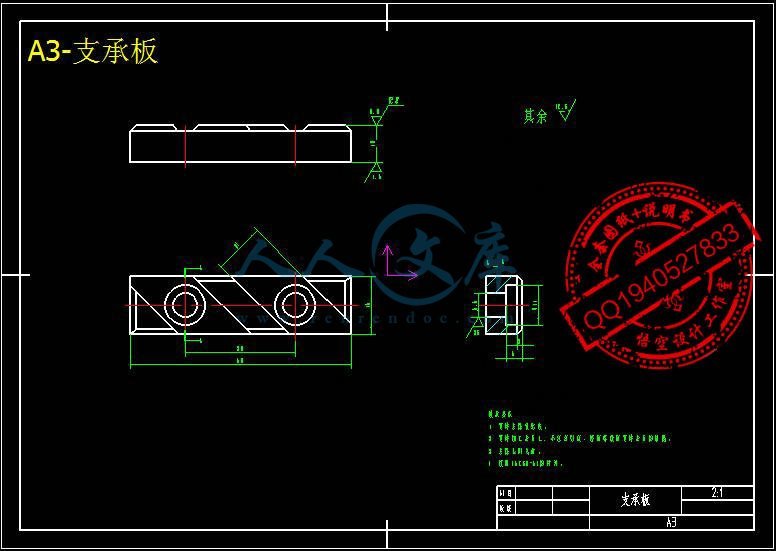

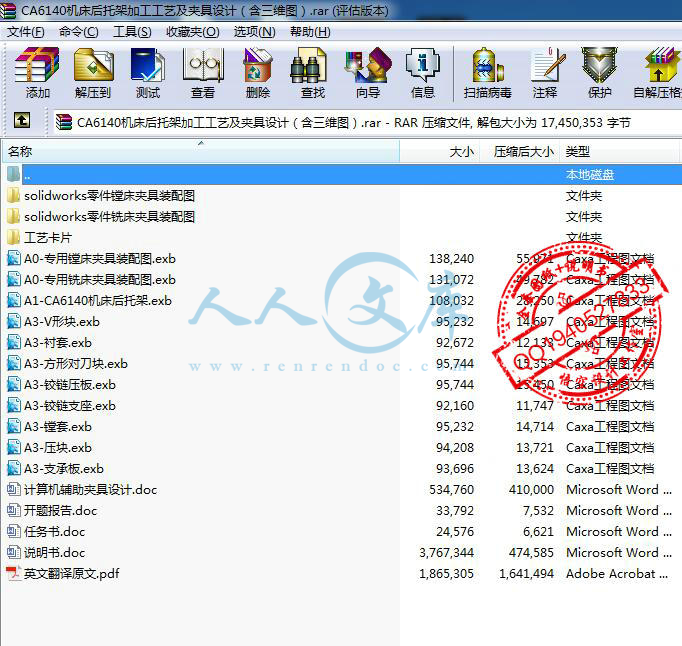

CA6140机床后托架加工工艺及夹具设计(含solidworks三维图)

收藏

资源目录

压缩包内文档预览:(预览前8页/共14页)

编号:6975943

类型:共享资源

大小:6.86MB

格式:RAR

上传时间:2018-01-05

上传人:优***

认证信息

个人认证

罗**(实名认证)

广西

IP属地:广西

55

积分

- 关 键 词:

-

ca6140

机床

托架

加工

工艺

夹具

设计

solidworks

三维

- 资源描述:

-

摘 要

机械加工工艺是实现产品设计,保证产品质量,节约能源,降低消耗的重要手段,本课题研究CA6140车床后托架加工工艺规程。首先通过对零件图的分析,了解工件的结构形式,明确具体的技术要求,从而对工件各组成表面选择合适的加工方法,再拟定较为合理的工艺规程,在制订工艺过程中,需要确定各工序的安装工位和该工序需要的工步,加工该工序的机车及机床的进给量,切削深度,主轴转速和切削速度,该工序的夹具,刀具及量具,还有走刀次数和走刀长度,最后计算该工序的基本时间,辅助时间和工作地服务时间,以验证达到生产要求。

机床夹具设计是工艺装备设计中的一个重要组成部分,在整个机械加工过程中,夹具除了夹紧固定被加工零件,所以需要选择相应的零部件来实现定位;还要求保证加工零件的位置精度,提高加工生产率,所以需要计算夹紧装置夹紧力,并按要求加工出零件的部分。

关键词: 工艺过程的制订;工序;工步;加工余量;时间配额;夹具;定位方案;夹紧力

目 录

一 CA6140 机床后托架加工工艺 6

1.1 CA6140 机床后托架的作用 6

1.2 CA6140 机床后托架的工艺分析 6

1.3 CA6140 机床后托架的工艺要求及技术要求 7

1.4 确定后托架零件的生产类型及制造方法 7

1.5 确定各表面加工方案 7

1.5.1在选择各表面及孔的加工方法时,要综合考虑以下因素 7

1.5.2平面的加工 8

1.5.3 孔的加工方案 8

1.6 工艺路线的拟订 8

1.6.1粗基准的选择 8

1.6.2精基准选择的原则 8

1.6.3加工经济精度与加工方法的选择 9

1.6.4工艺顺序的安排 9

1.6.5工序的集中与分散 10

1.6.6加工阶段的划分 10

1.7 加工工艺路线方案的比较 11

1.8 CA6140 机床后托架的偏差,加工余量,工序尺寸及毛坯尺寸的确定 13

1.8.1毛坯的结构工艺要求 13

1.8.2 CA6140 机床后托架的偏差计算 14

1.9 确定切削用量及基本工时(机动时间) 16

1.9.1工序1 粗、精铣底面 16

1.9.2工序2 粗、半精、精镗 CA6140 侧面三杠孔 17

1.9.3工序3 钻顶面四孔 24

1.9.4工序4 钻侧面两孔 28

2.0 时间定额计算及生产安排 30

2.0.1粗、精铣底面 30

2.0.2镗侧面三杠孔 30

2.0.3钻顶面四孔 31

2.0.4钻左侧面两孔 31

2.0.5 M 6的螺纹孔攻丝 32

二 机床夹具设计 32

2.1夹具的功能 32

2.2 机床夹具的分类 32

2.3 机床夹具的组成 33

2.4 常用定位方法与定位元件 33

2.4.1六点定位原理 33

2.4.2工件以平面定位,主要形式是支承定位。 34

2.4.3工件以圆柱孔定位 34

2.4.4工件以外圆表面定位 34

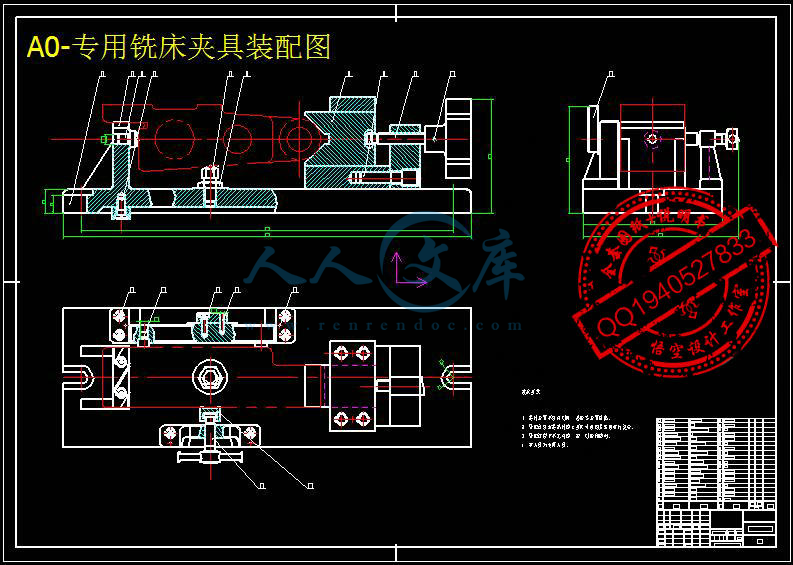

2.5铣平面夹具设计 34

2.5.1研究原始材料 34

2.5.2定位基准的选择 34

2.5.3切削力及夹紧分析计算 35

2.5.4误差分析与计算 36

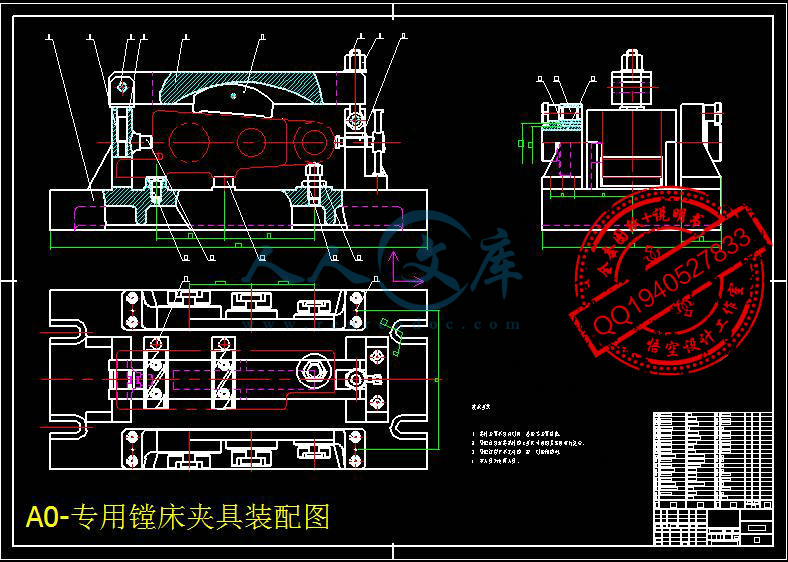

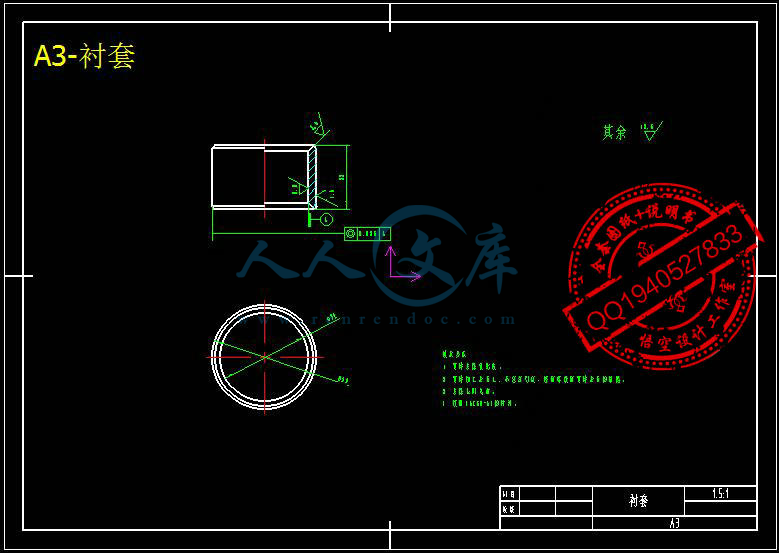

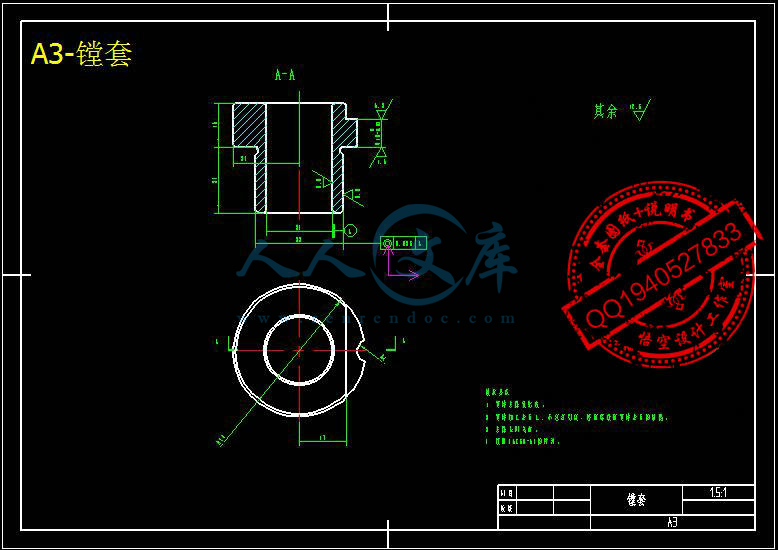

2.6 镗孔夹具设计 37

2.6.1研究原始质料 37

2.6.2定位基准的选择 37

2.6.3切削力及夹紧力的计算 38

2.6.4误差分析与计算 39

结论 39

致 谢 41

参考文献 42

- 内容简介:

-

0JOURNALOFMANUFACTURINGSYSTEMSWVOL2UNO1D2002TRENDSANDPERSPECTIVESCOMPUTERAIDEDFIXTUREDESIGNUSINGINFORMATIONINTENSIVEFUNCTIONMODELSINTHEDEVELOPMENTOFAUTOMATEDFIXTUREDESIGNSYSTEMSJCECIL,ASSISTANTPROFESSOR,VIRTUALENTERPRISEENGINEERINGLABVEEL,INDUSTRIALENGINEERINGDEPT,NEWMEXICOSTATEUNIVERSITY,LASCRUCES,NEWMEXICO,USAABSTRACTINTHISPAPER,THEDEVELOPMENTOFANINFORMATIONINTENSIVEFUNCTIONMODELIIFMOFFIXTUREDESIGNACTIVITIESISDISCUSSEDTHISFUNCTIONMODELWASDEVELOPEDUSINGTHEIDEF0INTEGRATEDDEFINITIONMETHODOLOGYANDWASBUILTPRIMARILYAFTERINTERACTINGWITHEXPERTFIXTUREDESIGNERSINADDITION,KNOWLEDGEFROMFIXTUREDESIGN,TOOLDESIGN,ANDMETALCUTTINGHANDBOOKSANDFROMJOURNALPAPERSWASUSEDTOLENDAHOLISTICFLAVORTOTHEDEVELOPEDIDEF0MODELANIDEF0MODELINGSOFTWARETOOL,AI0WIN,WASUSEDTOBUILDTHISMODELATVARIOUSLEVELSOFDECOMPOSITIONTHISPAPERALSODISCUSSESTHEIMPORTANCEOFILFMSINTHECURRENTANDFUTUREDESIGNOFCOMPUTERAIDEDFIXTUREDESIGNCAFDSYSTEMSKEYWORDSFIXTUREDESIGN,COMPUTERAIDEDFIXTUREDESIGN,FUNCTIONMODELING,CAD/CAM,INFORMATIONINTENSIVEFUNCTIONMODELSINTRODUCTIONFIXTUREDESIGNISACOMPLEXTASKTHATHASBEENVIEWEDBYINDUSTRIALPRACTITIONERSANDRESEARCHERSASAVITALLINKBETWEENDESIGNANDMANUFACTURINGACTIVITIESSAKURAI1990SENTHILKUMAR,SUBRAMANIAM,SEOW1997COMPUTERAIDEDFIXTUREDESIGNCAFDISACRUCIALTASKWHOSEREALIZATIONWILLENABLETHEINTEGRATEDACCOMPLISHMENTOFCOMPUTERAIDEDDESIGNCADANDCOMPUTERAIDEDMANUFACTURINGCAMACTIVITIESINMODERNMANUFACTURINGENVIRONMENTSTHEREHAVEBEENNUMEROUSEFFORTSTOAUTOMATEFIXTUREDESIGNACTIVITIESANDDEVELOPCAFDMETHODSFORROTATIONALANDPRISMATICPARTSMANUFACTURINGSEEREFERENCESL22,2439,41,42,45,46HOWEVER,THEREHASBEENALACKOFEFFECTIVECAFDTECHNIQUESTOFILLTHEVOIDBETWEENCADANDCAM,ANDAUTOMATEDFIXTUREDESIGNTECHNIQUESCONTINUETOBETHEFOCUSOFMANUFACTURINGRESEARCHEFFORTSTHEREISANEEDTOBETTERUNDERSTANDTHECOMPLEXTASKSANDSUBTASKSWITHINTHEFIXTUREDESIGN58ACTIVITYBYDEVELOPINGAFUNCTIONMODELOFOVERALLACTIVITIESSUCHAMODELWOULDNOTONLYHELPTHEUNDERSTANDINGOFTHECOMPLEXFUNCTIONSANDTASKACCOMPLISHMENTSWITHINFIXTUREDESIGNBUTWOULDRESULTINAMODELOFWHATWASBEINGACCOMPLISHEDBYTHEVARIOUSFUNCTIONSINGENERAL,AFUNCTIONMODELCANBEDESCRIBEDASAREPRESENTATIONOFACTIVITIESWITHINATARGETFOCUSAREAORSYSTEMANDTHERELATIONSHIPSBETWEENTHEMAFUNCTIONMODELCANALSOENABLEUNDERSTANDINGOFTHEIMPACTANDROLEOFVARIOUSINFORMATIONINPUTSANDCONTROLSINTHEACCOMPLISHMENTOFACTIVITIESPASTEFFORTSHAVENOTEMPHASIZEDTHEUSEOFFORMALMODELSORREPRESENTATIONSASABASISFORDESIGNINGANDDEVELOPINGCAFDSYSTEMSTHERESEARCHACTIVITYDISCUSSEDHEREEXPLORESTHEROLEOFINFORMATIONINTENSIVEFUNCTIONMODELSIIFM,WHICHCANBEAVALUABLETOOLINOBTAININGABETTERUNDERSTANDINGOFCOMPLEXACTIVITIESANDTASKSINADOMAINSUCHASFIXTUREDESIGNFURTHER,THESEMODELSPROVIDEASTRUCTUREDBASISOFCOMMUNICATIONTOCONCURRENTENGINEERINGCETEAMS,WHOWILLBEIMPACTEDBYANDWHOIMPACTTHEACTIVITIESWITHINFIXTUREDESIGNFUNCTIONMODELSCANALSOBEUSEDASAREQUIREMENTSDEFINITIONMAPBYSOFTWAREENGINEERSWHOSUPPORTTHEIMPLEMENTATIONOFSOFTWARESYSTEMSTHATACCOMPLISHCAFDAFORMALLYSTRUCTUREDMODELCANMOREEFFECTIVELYCONVEYTHECOMPLEXRELATIONSHIPSANDDEPENDENCIESAMONGSUBACTIVITIESOTHERENGINEERSSUCHASPRODUCTDESIGNERSORMACHINISTSINVOLVEDINTHELIFECYCLEOFAPRODUCT,ANDWHOARENOTFAMILIARWITHFIXTUREDESIGNACTIVITIES,CANGETABETTERUNDERSTANDINGOFTHEINTERRELATIONSHIPSANDTHENEEDFORFEEDBACKANDTIMELYCOMMUNICATIONAMONGTHEIRRESPECTIVECETEAMSBEFOREANINFEASIBLEDESIGNIDEAPROGRESSESTOWARDOTHERDOWNSTREAMJOURNALOFMANUFACTURINGSYSTEMSVOL21/NO12002ACTIVITIESTHEPOWEROFIIFMSLIESINTHEIRABILITYTODESCRIBEWHATCANORWILLBEACCOMPLISHEDBYASYSTEM,HUMANTEAMMEMBERS,ANDOTHERRESOURCESIIFMSEXPLICITLYCAPTUREINTRICATERELATIONSHIPSBETWEENINFORMATIONSOURCES,BOTTLENECKORIENTEDCONSTRAINTSFOREXAMPLE,AVAILABILITYOFDATAORSOMEOTHERINTERNALATTRIBUTE,ANDTHESOFTWAREORHARDWAREMECHANISMSTHATWORKTOGETHERTOACCOMPLISHAGIVENACTIVITYINTODAYSINFORMATIONTECHNOLOGYORIENTEDMANUFACTURINGENVIRONMENT,THEDESIGNOFMANUFACTURINGRELATEDSOFTWARESYSTEMSMUSTBEACCOMPLISHEDTAKINGINTOCONSIDERATIONSUCHINFORMATIONATTRIBUTESTHATARECAPTUREDINIIFMSFIXTUREDESIGNISACOMPLEXTASK,ANDUNDERSTANDINGTHERELATIONSHIPSEXPLICITLYANDBUILDINGANIIFMOFTHESEATTRIBUTESLAYSTHEFOUNDATIONFORIMPLEMENTINGEFFECTIVECAFDAPPROACHESITALSOPROVIDESACOMMONLANGUAGEFORREASONINGASPECIFICAPPROACH,ENABLESCETEAMMEMBERSTOUNDERSTANDANDCOMMUNICATEPOTENTIALPROBLEMSININFORMATIONAVAILABILITYMOREEFFECTIVELY,ANDPROPOSESWAYSTOACCOMPLISHACORESETOFACTIVITIESINAMOREINTEGRATEDMANNERUSINGTHEFUNCTIONMODELOFFIXTUREDESIGNACTIVITIES,APRELIMINARYVERSIONOFACAFDSYSTEMCALLEDTAMILTOWARDSAMANUFACTURINGINTEGRATIONLINKHASBEENDEVELOPEDCECIL2001THEIIFMPROVIDEDAFUNDAMENTALBASISTOUNDERSTANDANDMAPCOMPLEXRELATIONSHIPS,STUDYINFORMATIONFLOW,ANDTHENDESIGNANDBUILDASYSTEMTOAUTOMATEFIXTUREDESIGNACTIVITIESIDEF0METHODOLOGYWASUSEDTOBUILDTHEIIFMTHEIDEF0MODELRESULTINGFROMTHEUSEOFTHISMETHODOLOGYPROVIDEDAFOUNDATIONFORUNDERSTANDINGTHECOMPLEXACTIVITIESINFIXTUREDESIGNANDFACILITATEDTHEDEFINITIONOFACTIVITIESANDINFORMATIONSURROUNDINGTHESEFUNCTIONSINOTHERINITIATIVES,THEIDEF0METHODHASBEENUSEDASAPOWERTILMODELINGTOOLFORANALYSIS,SPECIFICATION,ANDDESIGNOFMANUFACTURINGANDOTHERSYSTEMSCECIL1995MAYER,KEEN,BLINN1990THEFOURBASICATTRIBUTESMODELEDFOREACHACTIVITYANDSUBTASKSINCLUDEINPUTS,CONTROLS,OUTPUTS,ANDMECHANISMSTERMEDICOMS,SEEFIGUREITHEIDEF0METHODINCLUDESAGRAPHICALLANGUAGETHATENABLESTHEUSERTODESCRIBETHEACTIVITIESBEINGMODELEDINAPOWERFULHIERARCHICALMANNERTHEROOTORHIGHESTLEVELINTHISHIERARCHICALSTRUCTUREHASLOWERLEVEL,ORCHILDREN,NODESTHATDETAILTHEFUNCTIONAACTIVITYBEINGMODELEDATRAVERSALOFTHISHIERARCHYUNFOLDSTHEDETAILSOFTHECHILDRENACTIVITIESANDTHEOBJECTSTHATFORMTHERELATIONSBETWEENTHESEACTIVITIESINPUTCONTROLMECHANISMOUTPUTFIGUREIICOMATTRIBUTESILLUSTRATEDINANIDEF0MODELFUNCTIONMODELDEVELOPMENTANDDESCRIPTIONSTHEIDEF0FUNCTIONMODELDISCUSSEDWASBUILTAFTERSTUDYINGTHEACCOMPLISHMENTOFFIXTUREDESIGNACTIVITIESBYEXPERTFIXTUREDESIGNERSANDPROCESSPLANNERSKNOWLEDGEANDINFORMATIONFROMFIXTUREDESIGN,TOOLDESIGN,ANDMETALCUTTINGHANDBOOKSANDFROMJOURNALPAPERSHASALSOBEENUSEDTODEVELOPAMOREHOLISTICIDEF0MODELADDITIONALDISCUSSIONOFTHEINFORMATIONREPRESENTEDINANIDEF0MODELISPROVIDEDINTHESECTIONENTITLEDIDEF0FUNCTIONMODELOFFIXTUREDESIGNDOMAINEXPERTSINCLUDEDAPROCESSPLANNEREXPERTA,ATOOLENGINEEREXPERTB,ANDANENGINEERINGINSTRUCTOREXPERTCEXPERTAWORKSINAMACHINESHOPANDHASMORETHAN20YEARSOFEXPERIENCEPERFORMINGPROCESSPLANNING,FIXTUREDESIGN,ANDMACHININGINAJOBSHOP,WHICHPRODUCESBOTHROTATIONALANDPRISMATICPARTSEXPERTBISATOOLENGINEERINTHEAUTOMOBILEINDUSTRYWITHADECADEOFINDUSTRIALEXPERIENCEWHODESIGNSJIGSANDFIXTURESFORPARTSUSEDINTHEPRODUCTIONOFCARSANDTRUCKSEXPERTCISAMECHANICALENGINEERINGINSTRUCTORWHOTEACHESFIXTUREDESIGNRELATEDCOURSESANDHADPREVIOUSLYWORKEDASAFIXTUREDESIGNERINTHEAUTOMOBILEINDUSTRYVERBALPROTOCOLANALYSISWASUSEDASTHEMETHODOFACQUIRINGDETAILEDKNOWLEDGEFROMTHEDOMAINEXPERTSAFTERBEINGGIVENAPRODUCTDESIGNANDDESIGNINGTHEFIXTURE,EACHEXPERTPROVIDEDEXPLANATIONSOFALISTOFPOSSIBLEDESIGNSORCONCLUSIONSAFTERTHEEXPERTSCOMPLETEDTHENECESSARYEXPLANATIONS,THEMODELDEVELOPERREVIEWEDTHEDESCRIPTIONOFTHEPROTOCOLORSTEPSUSEDTOARRIVEATTHEFIXTUREDESIGNSANDADDEDMOREDETAILSIFNECESSARYCECIL200059JOURNALOFMANUFACTURINGSYSTEMSVOL21RNO12002ANOTHERPROTOCOLUSEDINKNOWLEDGEACQUISITIONFORTHEFIXTUREDESIGNACTIVITYWASBLINDPROBLEMDISCUSSIONTUTHILL1990FIXTUREDESIGNSFROMANOTHERKNOWLEDGEEXPERT,ASWELLASFROMBOOKSANDPAPERS,WEREUSEDINTHEDISCUSSIONEACHFIXTUREDESIGNEXPERTWASPRESENTEDWITHAPARTDESIGNDESIGNAANDASKEDTODESIGNAFIXTUREFORTHATPARTDESIGNEACHEXPERTSORGANIZATIONOFKNOWLEDGE,THEHYPOTHESESCONSIDEREDTHEINFLUENCEOFVARIOUSFACTORSDURINGANALYSIS,ANDTHEDETERMINATIONOFTHEOVERALLDETAILEDDESIGNWERERECORDEDTHISRECORDEDAPPROACHWASCOMPAREDWITHTHEAPPROACHDESCRIBEDBYOTHERFIXTUREDESIGNEXPERTSFORTHESAMEPARTDESIGNBYCOMPARINGANDCONTRASTINGTHEAPPROACHESOFTHESEFIXTUREDESIGNERS,ABETTERUNDERSTANDINGOFTHEFIXTUREDESIGNACTIVITYWASOBTAINEDTHISTECHNIQUEWASREPEATEDWITHAPPROACHESDETAILEDINBOOKSANDMANUALSNUMEROUSQUESTIONSWEREASKEDTOCLARIFYWHYCERTAINTASKSWEREPERFORMEDANDWHATROLESPECIFICFACTORSORINPUTSPLAYEDINTHEFIXTUREDESIGNTHEINTENTWASTOOBTAINANUNDERSTANDINGOFANALYSISCRITERIAINFIXTUREDESIGNTYPICALQUESTIONSEXPLOREDBYTHEMODELDEVELOPERINCLUDEDWHATTYPESOFINFORMATIONWEREREQUIREDTODETERMINEPROBLEMBOUNDARIESWHATLEVELOFDETAILINTHESOLUTIONORDESIGNWASREQUIREDHOWTODECOMPOSEAPROBLEMINTOSUBPROBLEMSANDWHATTYPESOFANALYTICALANDHEURISTICRULESWERETYPICALLYUSEDORREQUIREDTOVALIDATETHEFINALDESIGNSOLUTIONWITHOUTHAVINGTOBUILDANACTUALFIXTUREOFTHEDEVELOPEDFIXTUREDESIGNTHEDOMAINEXPERTSCONCLUSIONSWEREANALYZEDFURTHERBYPOSINGWHATIFSCENARIOSTOUNDERSTANDMOREABOUTTHEPROBLEMSOLUTIONAFOLLOWUPPOSTSESSIONDISCUSSIONHELPEDEXPLOREEACHFACTORANDATTRIBUTETHATSEEMEDTOINFLUENCEDEVELOPMENTOFTHEPROBLEMSOLUTIONTHISDISCUSSIONHELPEDESTABLISHINDIVIDUALCONTRIBUTIONSOFTHEVARIOUSINPUTSORFACTORSSUCHASTOLERANCES,FEATUREATTRIBUTES,ETCTOTHEOVERALLFIXTUREDESIGNACTIVITYIDEF0FUNCTIONMODELOFFIXTUREDESIGNINTHISSECTION,THEIDEF0MODELOFFIXTUREDESIGNISPRESENTEDANDABRIEFDISCUSSIONOFEACHACTIVITYPERFORMEDINFIXTUREDESIGNISPROVIDEDINGENERAL,ANIDEF0MODELINCLUDESASUMMARYPURPOSE,VIEWPOINT,CONTEXT,DECOMPOSITIONDIAGRAMS,DESCRIPTIONSOFTHEMODELEDACTIVITIES,ANDAGLOSSARYFIXTUREDYIGNPRINCIPLES/CONCEPTSPRODUCTDESIQNDATAINITIALRAWWORKPIECESPECIFICATIONSTENTATIVEMACHININGSEQUENCESDEVELOPFIXTUREDESIGNSTFIXTUREDESIGNERFIGURE2AOLEVELDIAGRAMOFFIXTUREDESIGNACTIVITYOFTHEICOMATTRIBUTESCAPTUREDINTHEMODELINTHISPAPER,THETOPLEVELANDDECOMPOSITIONDIAGRAMSAREILLUSTRATEDINFIGURES2,3,4,6,8,9,AND13THEPURPOSEOFBUILDINGTHISIDEF0MODELWASTOPROVIDEABETTERUNDERSTANDINGOFTHEVARIOUSACTIVITIESANDSUBACTIVITIESANDTASKSPERFORMEDWITHINFIXTUREDESIGNANDCAPTURETHECOMPLEXINTERRELATIONSHIPSAMONGTHESEACTIVITIESANDTHEIRDECOMPOSITIONSTHISFUNCTIONMODELWASUSEDTOBUILDANAUTOMATEDFIXTUREDESIGNSYSTEMTOSERVEASALINKBETWEENCADANDCAMACTIVITIESTHEMODELINGVIEWPOINTWASFROMANINDUSTRIALENGINEERWITHASTRONGBACKGROUNDINBOTHDESIGNANDMANUFACTURINGWHOHASPERFORMEDFIXTUREDESIGNACTIVITIESANDISFAMILIARWITHFUNDAMENTALFIXTUREDESIGNTASKSTHECONTEXTFORBUILDINGANYIDEF0FUNCTIONMODELISPROVIDEDINADIAGRAMREFERREDTOASACONTEXTDIAGRAMSHOWNINFIGURE1THESPECIFICCONTEXTLEVELDIAGRAMFORTHEMODELEDFIXTUREDESIGNACTIVITIESISSHOWNINFIGURE2FORTHEFIXTUREDESIGNACTIVITIES,INPUTSASSUMEDTOBEAVAILABLETOTHEFIXTUREDESIGNERINCLUDEPRODUCTDESIGNINFORMATIONSUCHASDESIGNDRAWINGS/CADMODELS,TOLERANCESPECIFICATIONS,ETCANDWORKPIECEMATERIALINPUTSCANBEREALOBJECTSORDATANEEDEDTOPERFORMALTHEFIXTUREDESIGNERIDENTIFIESTHETOLERANCEPLANESORDATUMREFERENCEPLANESFOREACHFEATURETHISACTIVITYISAPRECURSORTOIDENTIFYINGTHEDATUMORFACEF2FIGURE5EXAMPLEOFAPARTDESIGNDECOMPOSITIONOFACTIVITYA2ANALYZEMACHININGREQUIREMENTSREFERENCEPLANESINEACHSETUP,WHICHISPERUNDERTHECATEGORYANALYZEMACHININGFORMEDLATERFIGURE5ILLUSTRATESANEXAMPLEOFAREQUIREMENTSFIGURE6THEFIRSTACTIVITYINVOLVESPARTDESIGNWITHTOLERANCESUNITSINMMANDTWOIDENTIFYINGMACHININGREQUIREMENTSA21THEFIXFEATURESSTEPANDABLINDHOLETHEDATUMPLANESTUREDESIGNERSTUDIESTHEMACHININGREQUIREMENTSOFGIVENAREFACESF5,F7,ANDFLEACHFEATUREINTHEGIVENPARTDESIGNANYMACHININGMLDECOMPOSITIONOFANALYZEMACHININGREQUIREMENTSACTIVITYA263JOURNALOFMANUFACTURINGSYSTEMSVOL21MO12002CONSTRAINTTHATMAYINFLUENCETHEDESIGNOFTHEFIXTUREISIDENTIFIEDTHEMACHININGCONSTRAINTSINFLUENCINGFIXTUREDESIGNDEPENDONTHETYPEOFFEATUREBEINGMACHINEDANEXAMPLEOFTHISWOULDBEWHETHERTHEMACHININGOFAFEATURESUCHASATHROUGHHOLEORSLOTINFLUENCESTHEDESIGNOFASUPPORTORLOCATORMACHININGATHROUGHHOLEREQUIRESTHATCAREBETAKENWHILEDESIGNINGASUPPORTAKEYASPECTTOBEADDRESSEDISENSURINGTHATTHEMACHINECUTTINGTOOLSUCHASADRILLISABLETODRILLTHROUGHTHEBOTTOMFACEANDCLEARTHEBOTTOMFACEINREFERENCETHISWOULDREQUIRETHATTHESUPPORTDEVICEUSEDBEDESIGNEDTOPROVIDEARELIEFFORTHEDRILLTOOLTOCLEARTHEBOTTOMFACEWHILEMACHININGTHETHROUGHHOLEINREFERENCETHEMACHININGOFASLOTORANYOTHERFEATURETHATSTRADDLESTWOFACESOROCCURSACROSSTWOFACESALSONEEDSTOBESTUDIEDMACHININGOFSLOTSNECESSITATESASIDEHEIGHTCLEARANCETOALLOWTHEMILLINGCUTTERTOMACHINETHEENTRANCEOFTHESLOTTHEFACEPOSSESSINGTHEENTRANCEOFASLOTCANBEUSEDASALOCATINGORADDITIONALLOCATINGSURFACEASLONGASTHELOCATINGDEVICEDOESNOTOBSTRUCTTHEMACHININGOFTHESLOTFIGURE7ISSUESRELATEDTOTHEMACHININGOFFEATURESAREIDENTIFIEDINTHISACTIVITYANDAREUSEFULWHENTHEFIXTUREDESIGNERPERFORMSDETAILEDLOCATOR,SUPPORT,ANDCLAMPDESIGNINTHELATERSTAGESTHENEXTACTIVITY,IDENTIFYCHIPREMOVALREQUIREMENTSASINDICATEDINFIGURE6,ISCLOSELYRELATEDTOACTIVITYA21THEACCUMULATIONOFCHIPSDURINGMACHININGOFFEATURESSUCHASTHROUGHHOLESNEEDSTOBEADDRESSEDTHETYPEOFMACHINETOOLUSEDALSOINFLUENCESTHECHIPACCUMULATIONPROBLEMFOREXAMPLE,IFAMACHINETOOLSUCHASAGUNDRILLISUSED,CHIPACCUMULATIONISNOTAPROBLEMBECAUSEAGUNDRILLCOLLECTSTHECHIPSWITHTHEUSEDCOOLANTDURINGDRILLINGANDDISPOSESTHEMUSINGASUCTIONMECHANISMWHENOTHERDRILLTOOLSAREUSED,THEFIXTUREDESIGNERHASTOINCORPORATEARELIEFDESIGNINTHESUPPORTDEVICETOMINIMIZETHEACCUMULATIONOFCHIPSDURINGMACHININGANOTHERACTIVITYRELATESTOGROUPINGPOSSIBLEOPERATIONSA23INFIGURE6THEMAJORMACHININGCONSTRAINTADDRESSEDBYTHEFIXTUREDESIGNERISINTHEGENERATIONOFSETUPSTHEGOALINTHISACTIVITYISTOENABLETHEMACHININGOFASMANYFEATURESASPOSSIBLEINASETUPTHEMAJORCONSTRAINTISTHECAPABILITYOFTHEMACHINESAVAILABLEONTHESHOPFLOORTENTATIVELYSPECIFIEDBYTHEPROCESSPLANNERSEEFIGURE2VARIOUSSETUPSTOMACHINETHEFEATURESONTHEHORIZONTALDIMENSIONSOFLOCATORSHOULDALLOWFORMACHINETOOLCLEARANCETOMACHINETHESLOTFIGURE7ANALYZINGMACHININGREQUIREMENTSGIVENPARTDESIGNAREGENERATEDBASEDONTHEDIRECTIONOFMACHINING,THEPROCESSSEQUENCE,ANDTHEMACHININGCAPABILITIESOFAVAILABLEMACHINESONTHESHOPFLOORTHEFIXTUREDESIGNERIDENTIFIESTHEMACHININGDIRECTIONSTOPRODUCEEACHOFTHEFEATURESONAGIVENPARTDESIGNFEATURESTHATPOSSESSTHESAMEMACHININGDIRECTIONTHATCANBEMACHINEDONANASSIGNEDMACHINEPERTHEPROCESSSEQUENCEPROVIDEDAREGROUPEDTOGETHERANDFORMONESETUPFORTHEPARTDESIGNSHOWNINFIGURE5,BOTHOFTHEFEATURESCANBEMACHINEDINTHESAMESETUPTHELASTACTIVITYOFA2SEEFIGUREISTOIDENTIFYPOTENTIALREFERENCEPLANESA24AFTERDETERMININGTHEVARIOUSMACHININGSETUPS,THEFIXTUREDESIGNERATTEMPTSTOIDENTIFYREFERENCEPLANESORFEATURESFOREACHSETUPTHEGUIDINGTHEMEINTHISACTIVITYISTOACCURATELYLOCATEVARIOUSFEATURESTOBEMACHINEDINASETUPINGENERAL,FIXTUREDESIGNERSPREFERTHEUSEOFPREMACHINEDORPREEXISTINGTHROUGHHOLESANDAPAIROFADJACENTPERPENDICULARFACESDOWELPINSINSERTEDINTOTHROUGHHOLESPOSITIONTHEWORKPIECEACCURATELYANDHOLDTHATPOSITIONWELLDURINGMACHININGAPAIROFFLATPLATELOCATORSBUTTINGAGAINSTACORRESPONDINGPAIROFRIGHTANGLEDSURFACESRIGIDLYENSURESACCURATEWORKPIECELOCATIONDURINGMACHININGFORTHEFEATURESTOBEMACHINEDINFIGURE5,FACES1,5,AND7CANSERVEASPOTENTIALREFERENCEPLANESDECOMPOSITIONOFACTIVITYA3PERFORMSKELETALFIXTUREDESIGNTHEACTIVITYPERFORMINGASKELETALFIXTUREDESIGNACTIVITYA3INFIGURE3CANBEDECOMPOSEDASSHOWNINFIGURE8THETERMSKELETALFIXTUREDESIGNREFERSTOTHEGENERALDESIGNIDEATOSUPPORT,LOCATE,ANDCLAMPAWORKPIECEINASETUPFORINSTANCE,AFIXTUREDESIGNER64JOURNALOFMANUFACTURINGSYSTEMVOL21/NO12002MLFIGURE8DECOMPOSITIONOFPERFORMSKELETALFIXTUREDESIGNA3MAYINITIALLYDECIDEON1USINGASUPPORTAGAINSTTHEBOTTOMFACEOFAPART2USINGAPREMACHINEDHOLETOLOCATEALLFEATURESTOBEMACHINEDINTHATSETUPAND3ADOPTINGASIDECLAMPINGMETHODTOHOLDAWORKPIECETHISINITIALDESIGNISBASEDONTHEFIXTUREDESIGNERSUNDERSTANDINGOFTHEFEATURESTOBEPRODUCED,THEDATUMPLANESINTHATSETUP,ANDTHENATURE,OFTHEBASEANDSIDEFACESTHATIS,ARETHEYPLANARANDDOTHEYPOSSESSENOUGHAREAFORACLAMPTOBEUSED,AMONGOTHERISSUESASMENTIONEDEARLIER,EXPERIENCEDFIXTUREDESIGNERSUSUALLYFOCUSONTHEDETAILEDFIXTUREDESIGNWITHOUTDEVELOPINGASKELETALFIXTUREDESIGNTHEDOMAINEXPERTSOPINEDTHATDURINGTHEIRINITIALYEARSTHEYPERFORMEDSKELETALFIXTUREDESIGNBEFOREDETAILINGTHEDESIGNHOWEVER,ASTHEIREXPERIENCEINCREASEDTHEYBECAMEMORESKILLEDATPRODUCINGAFEASIBLEFIXTUREDURINGTHEIRFIRSTATTEMPTANDGRADUALLYSTOPPEDDEVELOPINGTHESKELETALFIXTUREDESIGNALTOGETHERASINDICATEDBYACTIVITIESA31,A32,ANDA33INFIGURE8,OTHERFIXTUREDESIGNERSPREFERAMOREORGANIZEDAPPROACHTHEYINITIALLYFORMAMENTALPICTUREOFEACHOFTHESUPPORTING,LOCATING,ANDCLAMPINGTECHNIQUESTHEYTHINKAREFEASIBLETOHOLD,SUPPORT,ANDLOCATETHEWORKPIECEDURINGMACHININGCECIL2000,CECIL1995AGENERALOUTLINEOFTHEFIXTUREISPRODUCEDAFTERDISCARDINGINFEASIBLEDESIGNSORRESOLVINGCONFLICTINGDESIGNPROBLEMSASINA34CONFLICTINGDESIGNPROBLEMSINCLUDEISSUESSUCHASDETERMININGWHETHERTHETENTATIVELYSELECTEDDOWNCLAMPINGMETHODINA33AGREESWITHTHELOCATIONAPPROACHINA32,SUCHASUSINGARADIALLOCATIONTECHNIQUEIFTHEYAREINFEASIBLE,THENTHISCONFLICTISRESOLVEDITERATIVELYASINDICATEDBYTHEFEEDBACKLOOPANALYSISFEEDBACKFROMACTIVITYA34ASINDICATEDINACTIVITYA3,ONEOFTHECONTROLLINGINFLUENCESISTHETERMFIXTURINGDESIGNPRINCIPLESTHISREFERSTOTHEEMBEDDEDFIXTURINGKNOWLEDGEOFTHEDESIGNERINCLUDINGHEURISTICSANDEXPERTISEGAINEDINTHISAREAWHENPERFORMINGTHEFIXTUREDESIGNTASKKNOWLEDGEOFTHEFUNDAMENTALSOFFIXTUREDESIGN,COUPLEDWITHTHEHEURISTICBASE,ISANIMPORTANTINFLUENCEORCONTROLLINGFACTORDURINGTHE65JOURNALOFMANUFACTURINGSYSTEMSVOL21MO12002RGUREYDECOMPOSITIONOFDETAILANDCONSOLIDATEFIXTUREDESIGNA4ACCOMPLISHMENTOFTHEFIXTUREDESIGNSUCHKNOWLEDGEINCLUDESIDENTIFYINGTHEPREFERREDCHOICEOFLOCATINGSURFACESANDWHETHERTHEREISANEEDFORRADIALLOCATION,FAMILIARITYWITHDIFFERENTCLAMPINGMETHODSRANGINGFROMDOWNCLAMPINGTOSIDECLAMPING,ANDSOONDECOMPOSITIONOFACTIVITYA4DETAILANDCONSOLIDATEFIXTUREDESIGNACTIVITYA4,WHICHISTODETAILANDCONSOLIDATETHEFIXTUREDESIGN,ISDECOMPOSEDINTOFOURSUBACTIVITIESASINFIGURE9PERFORMSUPPORTDESIGNINTHEFIRSTSUBACTIVITYESTABLISHSUPPORTPLANEANDSELECTSUPPORTA41,THEFIXTUREDESIGNERDETERMINESTHESUPPORTFACEINEACHSETUPANDSELECTSTHETYPEOFSUPPORTDEVICETOBEUSEDINTHEFIXTUREINFLUENCESONTHISACTIVITYINCLUDEPARTDESIGN,TYPEOFFEATURETOBEMACHINEDINTHATSETUP,ANDMACHININGCONSTRAINTSIFMACHININGISTOBEPERFORMEDALONGAZAXIS,THENTHEFIXTUREDESIGNERPREFERSTOUSEAFLATSURFACEWHOSEOUTERGEOMETRICALENVELOPEALONGTHEXYAXISCONTAINSGEOMETRICALPROFILESOFTHEFEATURESTOBEMACHINEDINTHATSETUPFIGUREIOTHISINCREASESTHESTABILITYOFTHEWORKPIECEDURINGMACHININGWHICHISASUPPORTDESIGNHEURISTICIFATHROUGHHOLENEEDSTOBEDRILLEDINTHATSETUP,THENTHEMACHININGCONSTRAINTSINFORMATIONWILLINFLUENCETHEFIXTUREDESIGNERTOSELECTAFLATPLATEWITHARELIEFINCORPORATEDINITINFIGURE10,ASUPPORTBLOCKWITHARELIEFENABLESTOOLCLEARANCEDURINGTHEDRILLINGOFATHROUGHHOLEPERFORMLOCATORDESIGNTHESECONDSUBACTIVITYINA4FIGURE9ISTOESTABLISHLOCATIONPLANESANDSELECTLOCATORSA42THEFIXTUREDESIGNERUSESTHEIDENTIFIEDREFERENCEPLANE,PARTDESIGNINFORMATION,ANDLOCATIONDESIGNHEURISTICSGAINEDFROMHISORHEREXPERIENCETODETERMINEAFEASIBLELOCATIONFACEONTHEWORKPIECETHELOCATIONDEVICEISTHENSELECTEDBASEDONTHE66JOURNALOFMANUFACTURINGSYSTEMSVOL21MO12002VETHUS,ASUPPORTPLATEOFAL

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号