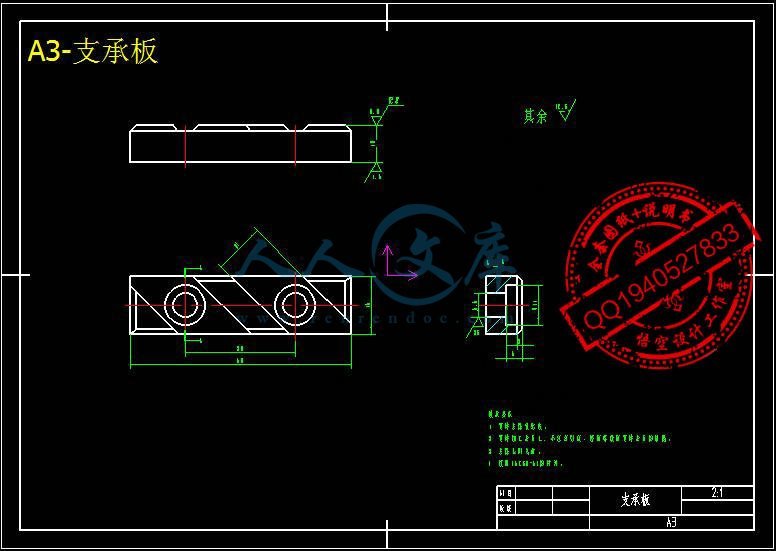

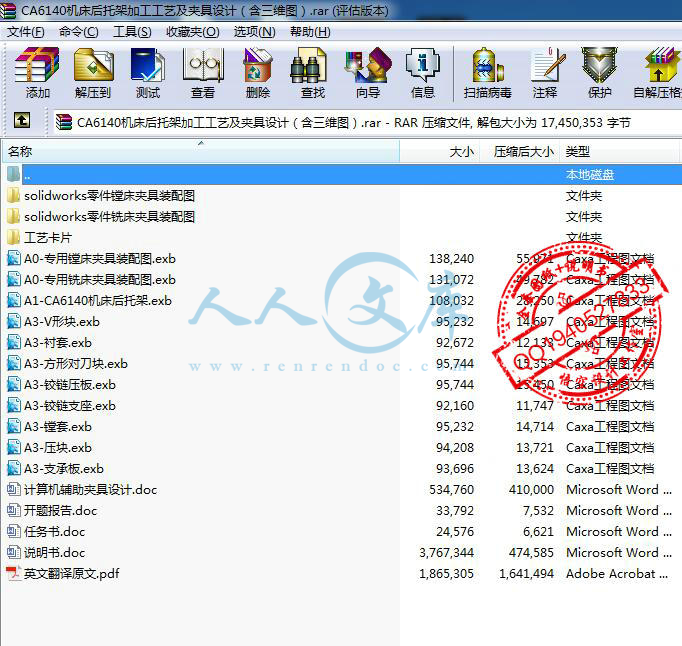

CA6140机床后托架加工工艺及夹具设计(含solidworks三维图)

收藏

资源目录

压缩包内文档预览:(预览前8页/共47页)

编号:6975943

类型:共享资源

大小:6.86MB

格式:RAR

上传时间:2018-01-05

上传人:优***

认证信息

个人认证

罗**(实名认证)

广西

IP属地:广西

55

积分

- 关 键 词:

-

ca6140

机床

托架

加工

工艺

夹具

设计

solidworks

三维

- 资源描述:

-

摘 要

机械加工工艺是实现产品设计,保证产品质量,节约能源,降低消耗的重要手段,本课题研究CA6140车床后托架加工工艺规程。首先通过对零件图的分析,了解工件的结构形式,明确具体的技术要求,从而对工件各组成表面选择合适的加工方法,再拟定较为合理的工艺规程,在制订工艺过程中,需要确定各工序的安装工位和该工序需要的工步,加工该工序的机车及机床的进给量,切削深度,主轴转速和切削速度,该工序的夹具,刀具及量具,还有走刀次数和走刀长度,最后计算该工序的基本时间,辅助时间和工作地服务时间,以验证达到生产要求。

机床夹具设计是工艺装备设计中的一个重要组成部分,在整个机械加工过程中,夹具除了夹紧固定被加工零件,所以需要选择相应的零部件来实现定位;还要求保证加工零件的位置精度,提高加工生产率,所以需要计算夹紧装置夹紧力,并按要求加工出零件的部分。

关键词: 工艺过程的制订;工序;工步;加工余量;时间配额;夹具;定位方案;夹紧力

目 录

一 CA6140 机床后托架加工工艺 6

1.1 CA6140 机床后托架的作用 6

1.2 CA6140 机床后托架的工艺分析 6

1.3 CA6140 机床后托架的工艺要求及技术要求 7

1.4 确定后托架零件的生产类型及制造方法 7

1.5 确定各表面加工方案 7

1.5.1在选择各表面及孔的加工方法时,要综合考虑以下因素 7

1.5.2平面的加工 8

1.5.3 孔的加工方案 8

1.6 工艺路线的拟订 8

1.6.1粗基准的选择 8

1.6.2精基准选择的原则 8

1.6.3加工经济精度与加工方法的选择 9

1.6.4工艺顺序的安排 9

1.6.5工序的集中与分散 10

1.6.6加工阶段的划分 10

1.7 加工工艺路线方案的比较 11

1.8 CA6140 机床后托架的偏差,加工余量,工序尺寸及毛坯尺寸的确定 13

1.8.1毛坯的结构工艺要求 13

1.8.2 CA6140 机床后托架的偏差计算 14

1.9 确定切削用量及基本工时(机动时间) 16

1.9.1工序1 粗、精铣底面 16

1.9.2工序2 粗、半精、精镗 CA6140 侧面三杠孔 17

1.9.3工序3 钻顶面四孔 24

1.9.4工序4 钻侧面两孔 28

2.0 时间定额计算及生产安排 30

2.0.1粗、精铣底面 30

2.0.2镗侧面三杠孔 30

2.0.3钻顶面四孔 31

2.0.4钻左侧面两孔 31

2.0.5 M 6的螺纹孔攻丝 32

二 机床夹具设计 32

2.1夹具的功能 32

2.2 机床夹具的分类 32

2.3 机床夹具的组成 33

2.4 常用定位方法与定位元件 33

2.4.1六点定位原理 33

2.4.2工件以平面定位,主要形式是支承定位。 34

2.4.3工件以圆柱孔定位 34

2.4.4工件以外圆表面定位 34

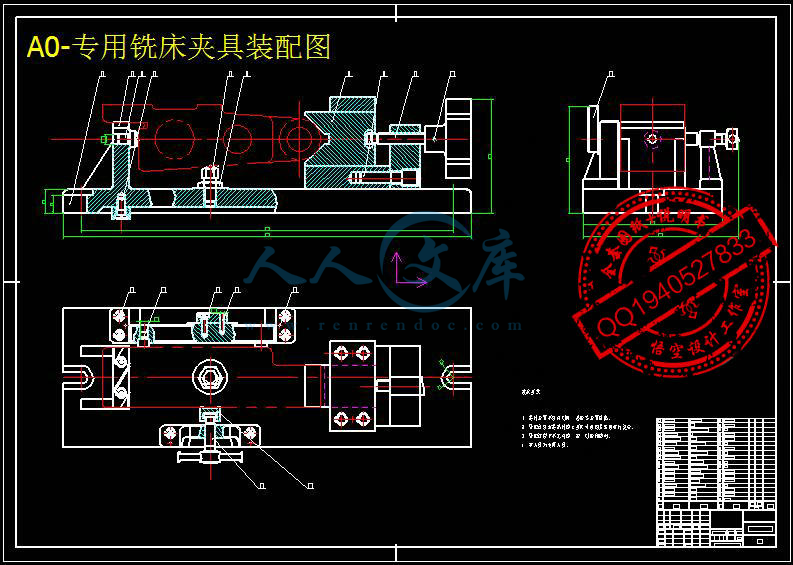

2.5铣平面夹具设计 34

2.5.1研究原始材料 34

2.5.2定位基准的选择 34

2.5.3切削力及夹紧分析计算 35

2.5.4误差分析与计算 36

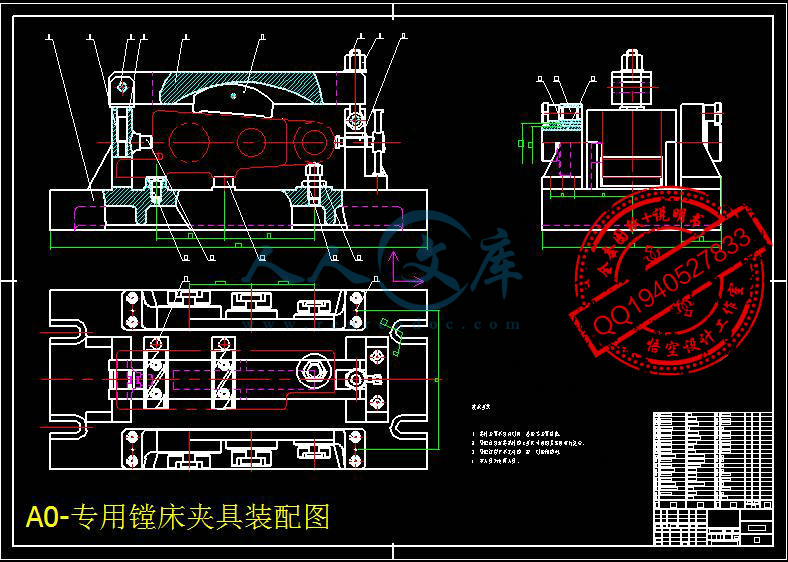

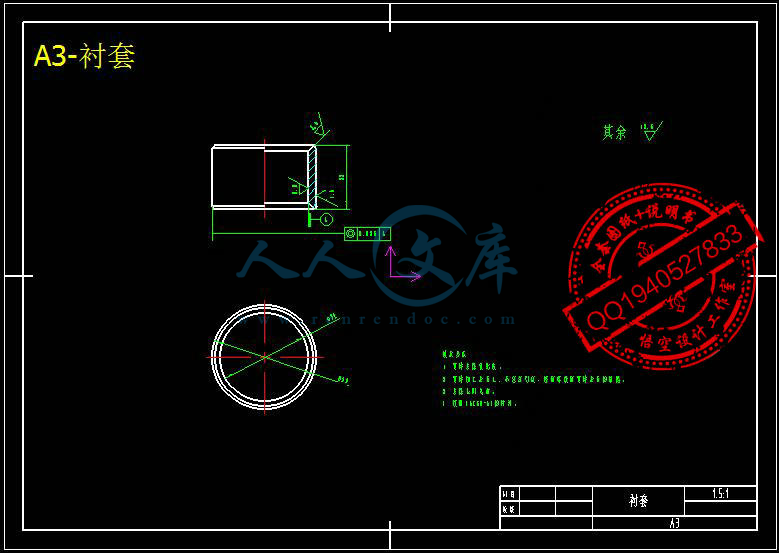

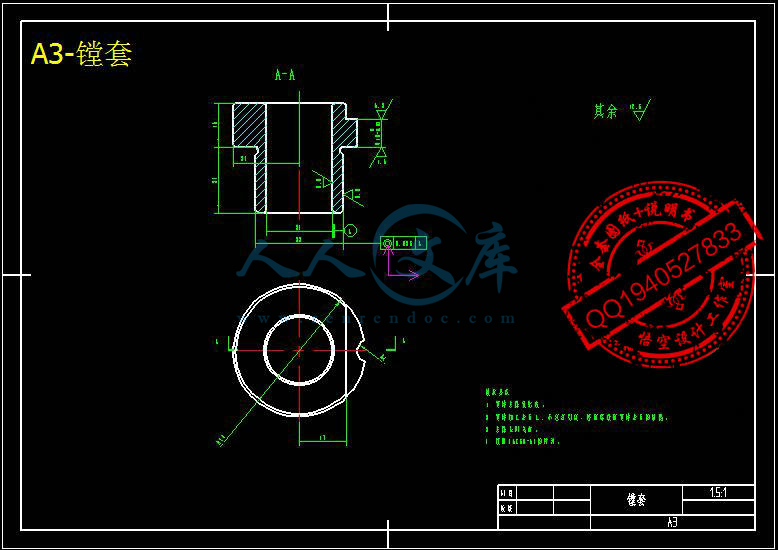

2.6 镗孔夹具设计 37

2.6.1研究原始质料 37

2.6.2定位基准的选择 37

2.6.3切削力及夹紧力的计算 38

2.6.4误差分析与计算 39

结论 39

致 谢 41

参考文献 42

- 内容简介:

-

机械加工工艺卡片产品名称及型号零件名称零件图号名称HT200种类毛重第1页牌号毛坯尺寸零件重量净重305KG第1页机械加工工艺卡片材料性能每料件数每台件数每批件数切削用量工艺装备名称及编号工时定额工序号工序内容同时加工零件数背吃刀量/MM切削速度/M/MIN主轴转速/R/MIN或/N/MIN进给量/MM/R设备名称及编号夹具刀具量具技术等级单件/MIN准备终结050粗铣1372370084双立轴圆工作台铣床KX52专用夹具硬质合金端铣刀游标卡尺IT12033060精铣1159046009双立轴圆工作台铣床KX52专用夹具硬质合金端铣刀游标卡尺IT7033编制抄写校对审核批准机械加工工艺卡片产品名称及型号零件名称零件图号名称种类毛重第页牌号毛坯尺寸零件重量净重第页机械加工工艺卡片材料性能每料件数每台件数每批件数切削用量工艺装备名称及编号工时定额工序号工序内容同时加工零件数背吃刀量/MM切削速度/M/MIN主轴转速/R/MIN或/N/MIN进给量/MM/R或/MM/MIN设备名称及编号夹具刀具量具技术等级单件/MIN准备终结070粗镗0352孔1221320035卧式镗床68T专用镗床夹具硬质合金镗刀游标卡尺IT11062080粗镗023孔1221260045卧式镗床68T专用镗床夹具硬质合金镗刀游标卡尺IT11059090粗镗孔0254122422005卧式镗床68T专用镗床夹具硬质合金镗刀游标卡尺IT11063100半精镗0352孔112198270035卧式镗床68T专用镗床夹具硬质合金镗刀游标卡尺IT10072110半精镗023孔112204250035卧式镗床68T专用镗床夹具硬质合金镗刀游标卡尺IT10077120半精镗0254孔11224200042卧式镗床68T专用镗床夹具硬质合金镗刀游标卡尺IT1008130精镗0352孔10818250028卧式镗床68T专用镗床夹具硬质合金镗刀塞规IT7096140精镗023孔10820425003卧式镗床68T专用镗床夹具硬质合金镗刀塞规IT7090150精镗孔025410821200035卧式镗床68T专用镗床夹具硬质合金镗刀塞规IT7096编制抄写校对审核批准产品名称及型号零件名称零件图号名称种类毛重第页牌号毛坯尺寸零件重量净重第页机械加工工艺卡片材料性能每料件数每台件数每批件数切削用量工艺装备名称及编号工时定额工序号工序内容同时加工零件数背吃刀量/MM切削速度/M/MIN主轴转速/R/MIN或/N/MIN进给量/MM/R或/MM/MIN设备名称及编号夹具刀具量具技术等级单件准备终结160钻孔,132以及的0锥孔15216700033钻床3025Z专用钻床夹具硬质合金锥柄麻花钻头游标卡尺IT11087170扩孔13211522255009钻床3025Z专用钻床夹具硬质合金锥柄麻花钻头游标卡尺IT1105180锪孔2011518300015钻床3025Z专用钻床夹具硬质合金锥柄麻花钻头游标卡尺IT11069190锪孔131321500015钻床3025Z专用钻床夹具硬质合金锥柄麻花钻头游标卡尺IT1107200铰孔102102519262002钻床3025Z专用钻床夹具硬质合金锥柄麻花钻头游标卡尺IT903编制抄写校对审核批准机械加工工艺卡片产品名称及型号零件名称零件图号名称种类毛重第页牌号毛坯尺寸零件重量净重第页机械加工工艺卡片材料性能每料件数每台件数每批件数切削用量工艺装备名称及编号工时定额工序号工序内容同时加工零件数背吃刀量/MM切削速度/M/MIN主轴转速/R/MIN或/N/MIN进给量/MM/R或/MM/MIN设备名称及编号夹具刀具量具技术等级单件准备终结210钻6132161200025钻床3025Z专用钻床夹具硬质合金锥柄麻花钻头游标卡尺IT11022220钻6M螺孔1262161300025钻床3025Z专用钻床夹具硬质合金锥柄麻花钻头游标卡尺IT11006230攻螺6M纹孔126693501组合攻丝机专用钻床夹具高速钢机动丝锥游标卡尺IT9008编制抄写校对审核批准编号任务书题目CA6140机床后托架加工工艺及夹具设计学院专业学生姓名学号指导教师单位姓名职称题目类型理论研究实验研究工程设计工程技术研究软件开发注1、本任务书一式两份,一份院办留存,一份发给学生,任务完成后附在说明书内。2、任务书均要求打印,打印字体和字号按照本科生设计(设计)统一格式的规定执行。3、以下标题为四号仿宋体、加粗,正文中文用小四宋体,英文用小四TIMESNEWROMAN,日期采用阿拉伯数字。4、“一、设计(设计)的内容、要求”位于页面最顶端,“任务下达时间”位于新页面最顶端。5、请不要修改最后一页(即“任务下达时间”所在页的内容)一、设计(设计)的内容在生产过程中,使生产对象(原材料,毛坯,零件或总成等)的质和量的状态发生直接变化的过程叫工艺过程,如毛坯制造,机械加工,热处理,装配等。在制定工艺过程中,要确定各工序的安装工位和该工序需要的工步,加工该工序的机车及机床的进给量,切削深度,主轴转速和切削速度,该工序的夹具,刀具及量具,还有走刀次数和走刀长度,最后计算该工序的基本时间,辅助时间和工作地服务时间。1、查阅相关资料,了解零件加工工艺的制定方法和夹具设计原理、方法等,2、分析所给题目的零件结构工艺性,编排出该零件的合理的加工工艺过程,选择各加工工序的合理的切削用量,计算各工序的定额,填写零件的加工工艺卡片;3、制订年产5000台CA6140机床后托架的加工工艺,设计零件主视图中的三孔的加工夹具、设计铣底面的夹具;4、绘制装配图、零件图,编制工艺卡及夹具设计计算说明书。二、设计(设计)的要求与数据1、设计思路清晰,结构合理;2、按给出零件图完成上述设计任务;3、设计说明书应包含中英文摘要、零件结构的工艺分析,各工序切削用量与定额的制定,工艺卡的编制,夹具设计应能满足工艺要求;4、提交夹具装配图、主要零件图、加工工艺卡、设计说明书等三、设计(设计)应完成的工作1、完成二万字左右的设计说明书(设计);在设计说明书(设计)中必须包括300500个单词的英文摘要;2、独立完成与课题相关,不少于四万字符的英文资料翻译(附英文原文);3、完成折合三张A0幅面的绘图工作量,其中包含两张A3以上的计算机绘图量。4、完成零件结构的工艺分析,各工序切削用量与定额的制定,工艺卡的编制,夹具设计等。四、应收集的资料及主要参考文献1符炜等机构设计学长沙湖南大学出版社,20012徐耀信机械加工工艺及现代制造技术M西安交通大学出版社,200523吴宗泽机械设计实用手册M北京机械工业出版社,20024许晓旸专用机床设备设计M重庆重庆大学出版社20035孟少龙机械加工工艺手册第1卷M北京机械工业出版社19916朱启明机械加工工艺手册第2卷第10章钻削、扩削、铰削、挤光加工M北京机械工业出版社199197王靖东金属切削加工方法与设备M高等教育出版社200678王晓霞等机床夹具设计M黑龙江科技出版社,200629徐鸿本机床夹具设计手册M辽宁科学技术出版社2004310JLALTHEORYOFMECHANISMSMACHINESMMETROPLITANBOOKCO,1993五、试验、测试、试制加工所需主要仪器设备及条件计算机、CAD软件任务下达时间2012年01月09日设计开始与完成时间2012年01月09日至2012年06月03日组织实施单位教研室主任意见签字2011年12月30日院领导小组意见签字2012年01月05日编号开题报告题目CA6140机床后托架加工工艺及夹具设计院(系)专业学生姓名学号指导教师单位姓名职称题目类型理论研究实验研究工程设计工程技术研究软件开发01设计的主要内容、重点和难点等1设计的主要内容(1)根据要求编排出零件的合理的加工工艺过程;(2)选用各加工工序的合理的切削用量,计算各工序的定额,填写工艺卡片;(3)制订CA6140机床后托架的加工工艺,并设计零件主视图中的三孔的加工夹具、设计铣底面的夹具。(4)绘制装配图、零件图和设计说明书。2设计的重点及难点重点(1)了解零件加工工艺的制定方法和夹具设计的基本原理、方法等。(2)合理设计各工序的切削用量和定额并制订相关工艺。(3)合理设计零件主视图中的三孔的加工夹具和铣底面的夹具。难点(1)各工序切削用量与定额的制定(2)工艺卡的编制(3)夹具设计2准备情况(查阅过的文献资料及调研情况、现有设备、实验条件等)1查阅过的文献资料有1符炜等机构设计学长沙湖南大学出版社,20012徐耀信机械加工工艺及现代制造技术M西安交通大学出版社,200523吴宗泽机械设计实用手册M北京机械工业出版社20024许晓旸,专用机床设备技术M,重庆重庆大学出版社,20035孟少龙机械加工工艺手册第1卷M北京机械工业出版社19916朱启明机械加工工艺手册第2卷第10章钻削、扩削、绞削、挤光加工M北京机械工业出版社199197王靖冬,金属切削加工方法与设备M,高等教育出版社,200678王晓霞等机床夹具设计M黑龙江科技出版社200629徐鸿本,机床夹具设计手册M辽宁科学技术出版社2004310JLALTHEORYOFMECHANISMSMACHINESMMETROPLITANBOOKCO,1993所需设备一台计算机、CAD软件和SOLIDWORKS三维绘图软件。3、实施方案、进度实施计划及预期提交的设计资料装订线2实施方案根据目前所掌握的资料,以制订CA6140机床后托架加工工艺为主线,设计合理的夹具和切削用量以生产出相应的零件,最后通过装配后来实现指定的功能。进度实施计划315321查找相关资料,并把各种资料汇总322328对比各个资料,筛选出结构最简单,实用,易于实现的一种结构329411计算各个参数值并绘制草图412419初步绘制其机械图419425进行详细的机械设计,并校验各个参数。425517绘制三维图形517524撰写设计说明书预期提交的设计资料设计说明书(设计)及设计图等。指导教师意见指导教师(签字)2012年月日开题小组意见开题小组组长(签字)32012年月日院(系、部)意见主管院长(系、部主任)签字2012年月日0JOURNALOFMANUFACTURINGSYSTEMSWVOL2UNO1D2002TRENDSANDPERSPECTIVESCOMPUTERAIDEDFIXTUREDESIGNUSINGINFORMATIONINTENSIVEFUNCTIONMODELSINTHEDEVELOPMENTOFAUTOMATEDFIXTUREDESIGNSYSTEMSJCECIL,ASSISTANTPROFESSOR,VIRTUALENTERPRISEENGINEERINGLABVEEL,INDUSTRIALENGINEERINGDEPT,NEWMEXICOSTATEUNIVERSITY,LASCRUCES,NEWMEXICO,USAABSTRACTINTHISPAPER,THEDEVELOPMENTOFANINFORMATIONINTENSIVEFUNCTIONMODELIIFMOFFIXTUREDESIGNACTIVITIESISDISCUSSEDTHISFUNCTIONMODELWASDEVELOPEDUSINGTHEIDEF0INTEGRATEDDEFINITIONMETHODOLOGYANDWASBUILTPRIMARILYAFTERINTERACTINGWITHEXPERTFIXTUREDESIGNERSINADDITION,KNOWLEDGEFROMFIXTUREDESIGN,TOOLDESIGN,ANDMETALCUTTINGHANDBOOKSANDFROMJOURNALPAPERSWASUSEDTOLENDAHOLISTICFLAVORTOTHEDEVELOPEDIDEF0MODELANIDEF0MODELINGSOFTWARETOOL,AI0WIN,WASUSEDTOBUILDTHISMODELATVARIOUSLEVELSOFDECOMPOSITIONTHISPAPERALSODISCUSSESTHEIMPORTANCEOFILFMSINTHECURRENTANDFUTUREDESIGNOFCOMPUTERAIDEDFIXTUREDESIGNCAFDSYSTEMSKEYWORDSFIXTUREDESIGN,COMPUTERAIDEDFIXTUREDESIGN,FUNCTIONMODELING,CAD/CAM,INFORMATIONINTENSIVEFUNCTIONMODELSINTRODUCTIONFIXTUREDESIGNISACOMPLEXTASKTHATHASBEENVIEWEDBYINDUSTRIALPRACTITIONERSANDRESEARCHERSASAVITALLINKBETWEENDESIGNANDMANUFACTURINGACTIVITIESSAKURAI1990SENTHILKUMAR,SUBRAMANIAM,SEOW1997COMPUTERAIDEDFIXTUREDESIGNCAFDISACRUCIALTASKWHOSEREALIZATIONWILLENABLETHEINTEGRATEDACCOMPLISHMENTOFCOMPUTERAIDEDDESIGNCADANDCOMPUTERAIDEDMANUFACTURINGCAMACTIVITIESINMODERNMANUFACTURINGENVIRONMENTSTHEREHAVEBEENNUMEROUSEFFORTSTOAUTOMATEFIXTUREDESIGNACTIVITIESANDDEVELOPCAFDMETHODSFORROTATIONALANDPRISMATICPARTSMANUFACTURINGSEEREFERENCESL22,2439,41,42,45,46HOWEVER,THEREHASBEENALACKOFEFFECTIVECAFDTECHNIQUESTOFILLTHEVOIDBETWEENCADANDCAM,ANDAUTOMATEDFIXTUREDESIGNTECHNIQUESCONTINUETOBETHEFOCUSOFMANUFACTURINGRESEARCHEFFORTSTHEREISANEEDTOBETTERUNDERSTANDTHECOMPLEXTASKSANDSUBTASKSWITHINTHEFIXTUREDESIGN58ACTIVITYBYDEVELOPINGAFUNCTIONMODELOFOVERALLACTIVITIESSUCHAMODELWOULDNOTONLYHELPTHEUNDERSTANDINGOFTHECOMPLEXFUNCTIONSANDTASKACCOMPLISHMENTSWITHINFIXTUREDESIGNBUTWOULDRESULTINAMODELOFWHATWASBEINGACCOMPLISHEDBYTHEVARIOUSFUNCTIONSINGENERAL,AFUNCTIONMODELCANBEDESCRIBEDASAREPRESENTATIONOFACTIVITIESWITHINATARGETFOCUSAREAORSYSTEMANDTHERELATIONSHIPSBETWEENTHEMAFUNCTIONMODELCANALSOENABLEUNDERSTANDINGOFTHEIMPACTANDROLEOFVARIOUSINFORMATIONINPUTSANDCONTROLSINTHEACCOMPLISHMENTOFACTIVITIESPASTEFFORTSHAVENOTEMPHASIZEDTHEUSEOFFORMALMODELSORREPRESENTATIONSASABASISFORDESIGNINGANDDEVELOPINGCAFDSYSTEMSTHERESEARCHACTIVITYDISCUSSEDHEREEXPLORESTHEROLEOFINFORMATIONINTENSIVEFUNCTIONMODELSIIFM,WHICHCANBEAVALUABLETOOLINOBTAININGABETTERUNDERSTANDINGOFCOMPLEXACTIVITIESANDTASKSINADOMAINSUCHASFIXTUREDESIGNFURTHER,THESEMODELSPROVIDEASTRUCTUREDBASISOFCOMMUNICATIONTOCONCURRENTENGINEERINGCETEAMS,WHOWILLBEIMPACTEDBYANDWHOIMPACTTHEACTIVITIESWITHINFIXTUREDESIGNFUNCTIONMODELSCANALSOBEUSEDASAREQUIREMENTSDEFINITIONMAPBYSOFTWAREENGINEERSWHOSUPPORTTHEIMPLEMENTATIONOFSOFTWARESYSTEMSTHATACCOMPLISHCAFDAFORMALLYSTRUCTUREDMODELCANMOREEFFECTIVELYCONVEYTHECOMPLEXRELATIONSHIPSANDDEPENDENCIESAMONGSUBACTIVITIESOTHERENGINEERSSUCHASPRODUCTDESIGNERSORMACHINISTSINVOLVEDINTHELIFECYCLEOFAPRODUCT,ANDWHOARENOTFAMILIARWITHFIXTUREDESIGNACTIVITIES,CANGETABETTERUNDERSTANDINGOFTHEINTERRELATIONSHIPSANDTHENEEDFORFEEDBACKANDTIMELYCOMMUNICATIONAMONGTHEIRRESPECTIVECETEAMSBEFOREANINFEASIBLEDESIGNIDEAPROGRESSESTOWARDOTHERDOWNSTREAMJOURNALOFMANUFACTURINGSYSTEMSVOL21/NO12002ACTIVITIESTHEPOWEROFIIFMSLIESINTHEIRABILITYTODESCRIBEWHATCANORWILLBEACCOMPLISHEDBYASYSTEM,HUMANTEAMMEMBERS,ANDOTHERRESOURCESIIFMSEXPLICITLYCAPTUREINTRICATERELATIONSHIPSBETWEENINFORMATIONSOURCES,BOTTLENECKORIENTEDCONSTRAINTSFOREXAMPLE,AVAILABILITYOFDATAORSOMEOTHERINTERNALATTRIBUTE,ANDTHESOFTWAREORHARDWAREMECHANISMSTHATWORKTOGETHERTOACCOMPLISHAGIVENACTIVITYINTODAYSINFORMATIONTECHNOLOGYORIENTEDMANUFACTURINGENVIRONMENT,THEDESIGNOFMANUFACTURINGRELATEDSOFTWARESYSTEMSMUSTBEACCOMPLISHEDTAKINGINTOCONSIDERATIONSUCHINFORMATIONATTRIBUTESTHATARECAPTUREDINIIFMSFIXTUREDESIGNISACOMPLEXTASK,ANDUNDERSTANDINGTHERELATIONSHIPSEXPLICITLYANDBUILDINGANIIFMOFTHESEATTRIBUTESLAYSTHEFOUNDATIONFORIMPLEMENTINGEFFECTIVECAFDAPPROACHESITALSOPROVIDESACOMMONLANGUAGEFORREASONINGASPECIFICAPPROACH,ENABLESCETEAMMEMBERSTOUNDERSTANDANDCOMMUNICATEPOTENTIALPROBLEMSININFORMATIONAVAILABILITYMOREEFFECTIVELY,ANDPROPOSESWAYSTOACCOMPLISHACORESETOFACTIVITIESINAMOREINTEGRATEDMANNERUSINGTHEFUNCTIONMODELOFFIXTUREDESIGNACTIVITIES,APRELIMINARYVERSIONOFACAFDSYSTEMCALLEDTAMILTOWARDSAMANUFACTURINGINTEGRATIONLINKHASBEENDEVELOPEDCECIL2001THEIIFMPROVIDEDAFUNDAMENTALBASISTOUNDERSTANDANDMAPCOMPLEXRELATIONSHIPS,STUDYINFORMATIONFLOW,ANDTHENDESIGNANDBUILDASYSTEMTOAUTOMATEFIXTUREDESIGNACTIVITIESIDEF0METHODOLOGYWASUSEDTOBUILDTHEIIFMTHEIDEF0MODELRESULTINGFROMTHEUSEOFTHISMETHODOLOGYPROVIDEDAFOUNDATIONFORUNDERSTANDINGTHECOMPLEXACTIVITIESINFIXTUREDESIGNANDFACILITATEDTHEDEFINITIONOFACTIVITIESANDINFORMATIONSURROUNDINGTHESEFUNCTIONSINOTHERINITIATIVES,THEIDEF0METHODHASBEENUSEDASAPOWERTILMODELINGTOOLFORANALYSIS,SPECIFICATION,ANDDESIGNOFMANUFACTURINGANDOTHERSYSTEMSCECIL1995MAYER,KEEN,BLINN1990THEFOURBASICATTRIBUTESMODELEDFOREACHACTIVITYANDSUBTASKSINCLUDEINPUTS,CONTROLS,OUTPUTS,ANDMECHANISMSTERMEDICOMS,SEEFIGUREITHEIDEF0METHODINCLUDESAGRAPHICALLANGUAGETHATENABLESTHEUSERTODESCRIBETHEACTIVITIESBEINGMODELEDINAPOWERFULHIERARCHICALMANNERTHEROOTORHIGHESTLEVELINTHISHIERARCHICALSTRUCTUREHASLOWERLEVEL,ORCHILDREN,NODESTHATDETAILTHEFUNCTIONAACTIVITYBEINGMODELEDATRAVERSALOFTHISHIERARCHYUNFOLDSTHEDETAILSOFTHECHILDRENACTIVITIESANDTHEOBJECTSTHATFORMTHERELATIONSBETWEENTHESEACTIVITIESINPUTCONTROLMECHANISMOUTPUTFIGUREIICOMATTRIBUTESILLUSTRATEDINANIDEF0MODELFUNCTIONMODELDEVELOPMENTANDDESCRIPTIONSTHEIDEF0FUNCTIONMODELDISCUSSEDWASBUILTAFTERSTUDYINGTHEACCOMPLISHMENTOFFIXTUREDESIGNACTIVITIESBYEXPERTFIXTUREDESIGNERSANDPROCESSPLANNERSKNOWLEDGEANDINFORMATIONFROMFIXTUREDESIGN,TOOLDESIGN,ANDMETALCUTTINGHANDBOOKSANDFROMJOURNALPAPERSHASALSOBEENUSEDTODEVELOPAMOREHOLISTICIDEF0MODELADDITIONALDISCUSSIONOFTHEINFORMATIONREPRESENTEDINANIDEF0MODELISPROVIDEDINTHESECTIONENTITLEDIDEF0FUNCTIONMODELOFFIXTUREDESIGNDOMAINEXPERTSINCLUDEDAPROCESSPLANNEREXPERTA,ATOOLENGINEEREXPERTB,ANDANENGINEERINGINSTRUCTOREXPERTCEXPERTAWORKSINAMACHINESHOPANDHASMORETHAN20YEARSOFEXPERIENCEPERFORMINGPROCESSPLANNING,FIXTUREDESIGN,ANDMACHININGINAJOBSHOP,WHICHPRODUCESBOTHROTATIONALANDPRISMATICPARTSEXPERTBISATOOLENGINEERINTHEAUTOMOBILEINDUSTRYWITHADECADEOFINDUSTRIALEXPERIENCEWHODESIGNSJIGSANDFIXTURESFORPARTSUSEDINTHEPRODUCTIONOFCARSANDTRUCKSEXPERTCISAMECHANICALENGINEERINGINSTRUCTORWHOTEACHESFIXTUREDESIGNRELATEDCOURSESANDHADPREVIOUSLYWORKEDASAFIXTUREDESIGNERINTHEAUTOMOBILEINDUSTRYVERBALPROTOCOLANALYSISWASUSEDASTHEMETHODOFACQUIRINGDETAILEDKNOWLEDGEFROMTHEDOMAINEXPERTSAFTERBEINGGIVENAPRODUCTDESIGNANDDESIGNINGTHEFIXTURE,EACHEXPERTPROVIDEDEXPLANATIONSOFALISTOFPOSSIBLEDESIGNSORCONCLUSIONSAFTERTHEEXPERTSCOMPLETEDTHENECESSARYEXPLANATIONS,THEMODELDEVELOPERREVIEWEDTHEDESCRIPTIONOFTHEPROTOCOLORSTEPSUSEDTOARRIVEATTHEFIXTUREDESIGNSANDADDEDMOREDETAILSIFNECESSARYCECIL200059JOURNALOFMANUFACTURINGSYSTEMSVOL21RNO12002ANOTHERPROTOCOLUSEDINKNOWLEDGEACQUISITIONFORTHEFIXTUREDESIGNACTIVITYWASBLINDPROBLEMDISCUSSIONTUTHILL1990FIXTUREDESIGNSFROMANOTHERKNOWLEDGEEXPERT,ASWELLASFROMBOOKSANDPAPERS,WEREUSEDINTHEDISCUSSIONEACHFIXTUREDESIGNEXPERTWASPRESENTEDWITHAPARTDESIGNDESIGNAANDASKEDTODESIGNAFIXTUREFORTHATPARTDESIGNEACHEXPERTSORGANIZATIONOFKNOWLEDGE,THEHYPOTHESESCONSIDEREDTHEINFLUENCEOFVARIOUSFACTORSDURINGANALYSIS,ANDTHEDETERMINATIONOFTHEOVERALLDETAILEDDESIGNWERERECORDEDTHISRECORDEDAPPROACHWASCOMPAREDWITHTHEAPPROACHDESCRIBEDBYOTHERFIXTUREDESIGNEXPERTSFORTHESAMEPARTDESIGNBYCOMPARINGANDCONTRASTINGTHEAPPROACHESOFTHESEFIXTUREDESIGNERS,ABETTERUNDERSTANDINGOFTHEFIXTUREDESIGNACTIVITYWASOBTAINEDTHISTECHNIQUEWASREPEATEDWITHAPPROACHESDETAILEDINBOOKSANDMANUALSNUMEROUSQUESTIONSWEREASKEDTOCLARIFYWHYCERTAINTASKSWEREPERFORMEDANDWHATROLESPECIFICFACTORSORINPUTSPLAYEDINTHEFIXTUREDESIGNTHEINTENTWASTOOBTAINANUNDERSTANDINGOFANALYSISCRITERIAINFIXTUREDESIGNTYPICALQUESTIONSEXPLOREDBYTHEMODELDEVELOPERINCLUDEDWHATTYPESOFINFORMATIONWEREREQUIREDTODETERMINEPROBLEMBOUNDARIESWHATLEVELOFDETAILINTHESOLUTIONORDESIGNWASREQUIREDHOWTODECOMPOSEAPROBLEMINTOSUBPROBLEMSANDWHATTYPESOFANALYTICALANDHEURISTICRULESWERETYPICALLYUSEDORREQUIREDTOVALIDATETHEFINALDESIGNSOLUTIONWITHOUTHAVINGTOBUILDANACTUALFIXTUREOFTHEDEVELOPEDFIXTUREDESIGNTHEDOMAINEXPERTSCONCLUSIONSWEREANALYZEDFURTHERBYPOSINGWHATIFSCENARIOSTOUNDERSTANDMOREABOUTTHEPROBLEMSOLUTIONAFOLLOWUPPOSTSESSIONDISCUSSIONHELPEDEXPLOREEACHFACTORANDATTRIBUTETHATSEEMEDTOINFLUENCEDEVELOPMENTOFTHEPROBLEMSOLUTIONTHISDISCUSSIONHELPEDESTABLISHINDIVIDUALCONTRIBUTIONSOFTHEVARIOUSINPUTSORFACTORSSUCHASTOLERANCES,FEATUREATTRIBUTES,ETCTOTHEOVERALLFIXTUREDESIGNACTIVITYIDEF0FUNCTIONMODELOFFIXTUREDESIGNINTHISSECTION,THEIDEF0MODELOFFIXTUREDESIGNISPRESENTEDANDABRIEFDISCUSSIONOFEACHACTIVITYPERFORMEDINFIXTUREDESIGNISPROVIDEDINGENERAL,ANIDEF0MODELINCLUDESASUMMARYPURPOSE,VIEWPOINT,CONTEXT,DECOMPOSITIONDIAGRAMS,DESCRIPTIONSOFTHEMODELEDACTIVITIES,ANDAGLOSSARYFIXTUREDYIGNPRINCIPLES/CONCEPTSPRODUCTDESIQNDATAINITIALRAWWORKPIECESPECIFICATIONSTENTATIVEMACHININGSEQUENCESDEVELOPFIXTUREDESIGNSTFIXTUREDESIGNERFIGURE2AOLEVELDIAGRAMOFFIXTUREDESIGNACTIVITYOFTHEICOMATTRIBUTESCAPTUREDINTHEMODELINTHISPAPER,THETOPLEVELANDDECOMPOSITIONDIAGRAMSAREILLUSTRATEDINFIGURES2,3,4,6,8,9,AND13THEPURPOSEOFBUILDINGTHISIDEF0MODELWASTOPROVIDEABETTERUNDERSTANDINGOFTHEVARIOUSACTIVITIESANDSUBACTIVITIESANDTASKSPERFORMEDWITHINFIXTUREDESIGNANDCAPTURETHECOMPLEXINTERRELATIONSHIPSAMONGTHESEACTIVITIESANDTHEIRDECOMPOSITIONSTHISFUNCTIONMODELWASUSEDTOBUILDANAUTOMATEDFIXTUREDESIGNSYSTEMTOSERVEASALINKBETWEENCADANDCAMACTIVITIESTHEMODELINGVIEWPOINTWASFROMANINDUSTRIALENGINEERWITHASTRONGBACKGROUNDINBOTHDESIGNANDMANUFACTURINGWHOHASPERFORMEDFIXTUREDESIGNACTIVITIESANDISFAMILIARWITHFUNDAMENTALFIXTUREDESIGNTASKSTHECONTEXTFORBUILDINGANYIDEF0FUNCTIONMODELISPROVIDEDINADIAGRAMREFERREDTOASACONTEXTDIAGRAMSHOWNINFIGURE1THESPECIFICCONTEXTLEVELDIAGRAMFORTHEMODELEDFIXTUREDESIGNACTIVITIESISSHOWNINFIGURE2FORTHEFIXTUREDESIGNACTIVITIES,INPUTSASSUMEDTOBEAVAILABLETOTHEFIXTUREDESIGNERINCLUDEPRODUCTDESIGNINFORMATIONSUCHASDESIGNDRAWINGS/CADMODELS,TOLERANCESPECIFICATIONS,ETCANDWORKPIECEMATERIALINPUTSCANBEREALOBJECTSORDATANEEDEDTOPERFORMALTHEFIXTUREDESIGNERIDENTIFIESTHETOLERANCEPLANESORDATUMREFERENCEPLANESFOREACHFEATURETHISACTIVITYISAPRECURSORTOIDENTIFYINGTHEDATUMORFACEF2FIGURE5EXAMPLEOFAPARTDESIGNDECOMPOSITIONOFACTIVITYA2ANALYZEMACHININGREQUIREMENTSREFERENCEPLANESINEACHSETUP,WHICHISPERUNDERTHECATEGORYANALYZEMACHININGFORMEDLATERFIGURE5ILLUSTRATESANEXAMPLEOFAREQUIREMENTSFIGURE6THEFIRSTACTIVITYINVOLVESPARTDESIGNWITHTOLERANCESUNITSINMMANDTWOIDENTIFYINGMACHININGREQUIREMENTSA21THEFIXFEATURESSTEPANDABLINDHOLETHEDATUMPLANESTUREDESIGNERSTUDIESTHEMACHININGREQUIREMENTSOFGIVENAREFACESF5,F7,ANDFLEACHFEATUREINTHEGIVENPARTDESIGNANYMACHININGMLDECOMPOSITIONOFANALYZEMACHININGREQUIREMENTSACTIVITYA263JOURNALOFMANUFACTURINGSYSTEMSVOL21MO12002CONSTRAINTTHATMAYINFLUENCETHEDESIGNOFTHEFIXTUREISIDENTIFIEDTHEMACHININGCONSTRAINTSINFLUENCINGFIXTUREDESIGNDEPENDONTHETYPEOFFEATUREBEINGMACHINEDANEXAMPLEOFTHISWOULDBEWHETHERTHEMACHININGOFAFEATURESUCHASATHROUGHHOLEORSLOTINFLUENCESTHEDESIGNOFASUPPORTORLOCATORMACHININGATHROUGHHOLEREQUIRESTHATCAREBETAKENWHILEDESIGNINGASUPPORTAKEYASPECTTOBEADDRESSEDISENSURINGTHATTHEMACHINECUTTINGTOOLSUCHASADRILLISABLETODRILLTHROUGHTHEBOTTOMFACEANDCLEARTHEBOTTOMFACEINREFERENCETHISWOULDREQUIRETHATTHESUPPORTDEVICEUSEDBEDESIGNEDTOPROVIDEARELIEFFORTHEDRILLTOOLTOCLEARTHEBOTTOMFACEWHILEMACHININGTHETHROUGHHOLEINREFERENCETHEMACHININGOFASLOTORANYOTHERFEATURETHATSTRADDLESTWOFACESOROCCURSACROSSTWOFACESALSONEEDSTOBESTUDIEDMACHININGOFSLOTSNECESSITATESASIDEHEIGHTCLEARANCETOALLOWTHEMILLINGCUTTERTOMACHINETHEENTRANCEOFTHESLOTTHEFACEPOSSESSINGTHEENTRANCEOFASLOTCANBEUSEDASALOCATINGORADDITIONALLOCATINGSURFACEASLONGASTHELOCATINGDEVICEDOESNOTOBSTRUCTTHEMACHININGOFTHESLOTFIGURE7ISSUESRELATEDTOTHEMACHININGOFFEATURESAREIDENTIFIEDINTHISACTIVITYANDAREUSEFULWHENTHEFIXTUREDESIGNERPERFORMSDETAILEDLOCATOR,SUPPORT,ANDCLAMPDESIGNINTHELATERSTAGESTHENEXTACTIVITY,IDENTIFYCHIPREMOVALREQUIREMENTSASINDICATEDINFIGURE6,ISCLOSELYRELATEDTOACTIVITYA21THEACCUMULATIONOFCHIPSDURINGMACHININGOFFEATURESSUCHASTHROUGHHOLESNEEDSTOBEADDRESSEDTHETYPEOFMACHINETOOLUSEDALSOINFLUENCESTHECHIPACCUMULATIONPROBLEMFOREXAMPLE,IFAMACHINETOOLSUCHASAGUNDRILLISUSED,CHIPACCUMULATIONISNOTAPROBLEMBECAUSEAGUNDRILLCOLLECTSTHECHIPSWITHTHEUSEDCOOLANTDURINGDRILLINGANDDISPOSESTHEMUSINGASUCTIONMECHANISMWHENOTHERDRILLTOOLSAREUSED,THEFIXTUREDESIGNERHASTOINCORPORATEARELIEFDESIGNINTHESUPPORTDEVICETOMINIMIZETHEACCUMULATIONOFCHIPSDURINGMACHININGANOTHERACTIVITYRELATESTOGROUPINGPOSSIBLEOPERATIONSA23INFIGURE6THEMAJORMACHININGCONSTRAINTADDRESSEDBYTHEFIXTUREDESIGNERISINTHEGENERATIONOFSETUPSTHEGOALINTHISACTIVITYISTOENABLETHEMACHININGOFASMANYFEATURESASPOSSIBLEINASETUPTHEMAJORCONSTRAINTISTHECAPABILITYOFTHEMACHINESAVAILABLEONTHESHOPFLOORTENTATIVELYSPECIFIEDBYTHEPROCESSPLANNERSEEFIGURE2VARIOUSSETUPSTOMACHINETHEFEATURESONTHEHORIZONTALDIMENSIONSOFLOCATORSHOULDALLOWFORMACHINETOOLCLEARANCETOMACHINETHESLOTFIGURE7ANALYZINGMACHININGREQUIREMENTSGIVENPARTDESIGNAREGENERATEDBASEDONTHEDIRECTIONOFMACHINING,THEPROCESSSEQUENCE,ANDTHEMACHININGCAPABILITIESOFAVAILABLEMACHINESONTHESHOPFLOORTHEFIXTUREDESIGNERIDENTIFIESTHEMACHININGDIRECTIONSTOPRODUCEEACHOFTHEFEATURESONAGIVENPARTDESIGNFEATURESTHATPOSSESSTHESAMEMACHININGDIRECTIONTHATCANBEMACHINEDONANASSIGNEDMACHINEPERTHEPROCESSSEQUENCEPROVIDEDAREGROUPEDTOGETHERANDFORMONESETUPFORTHEPARTDESIGNSHOWNINFIGURE5,BOTHOFTHEFEATURESCANBEMACHINEDINTHESAMESETUPTHELASTACTIVITYOFA2SEEFIGUREISTOIDENTIFYPOTENTIALREFERENCEPLANESA24AFTERDETERMININGTHEVARIOUSMACHININGSETUPS,THEFIXTUREDESIGNERATTEMPTSTOIDENTIFYREFERENCEPLANESORFEATURESFOREACHSETUPTHEGUIDINGTHEMEINTHISACTIVITYISTOACCURATELYLOCATEVARIOUSFEATURESTOBEMACHINEDINASETUPINGENERAL,FIXTUREDESIGNERSPREFERTHEUSEOFPREMACHINEDORPREEXISTINGTHROUGHHOLESANDAPAIROFADJACENTPERPENDICULARFACESDOWELPINSINSERTEDINTOTHROUGHHOLESPOSITIONTHEWORKPIECEACCURATELYANDHOLDTHATPOSITIONWELLDURINGMACHININGAPAIROFFLATPLATELOCATORSBUTTINGAGAINSTACORRESPONDINGPAIROFRIGHTANGLEDSURFACESRIGIDLYENSURESACCURATEWORKPIECELOCATIONDURINGMACHININGFORTHEFEATURESTOBEMACHINEDINFIGURE5,FACES1,5,AND7CANSERVEASPOTENTIALREFERENCEPLANESDECOMPOSITIONOFACTIVITYA3PERFORMSKELETALFIXTUREDESIGNTHEACTIVITYPERFORMINGASKELETALFIXTUREDESIGNACTIVITYA3INFIGURE3CANBEDECOMPOSEDASSHOWNINFIGURE8THETERMSKELETALFIXTUREDESIGNREFERSTOTHEGENERALDESIGNIDEATOSUPPORT,LOCATE,ANDCLAMPAWORKPIECEINASETUPFORINSTANCE,AFIXTUREDESIGNER64JOURNALOFMANUFACTURINGSYSTEMVOL21/NO12002MLFIGURE8DECOMPOSITIONOFPERFORMSKELETALFIXTUREDESIGNA3MAYINITIALLYDECIDEON1USINGASUPPORTAGAINSTTHEBOTTOMFACEOFAPART2USINGAPREMACHINEDHOLETOLOCATEALLFEATURESTOBEMACHINEDINTHATSETUPAND3ADOPTINGASIDECLAMPINGMETHODTOHOLDAWORKPIECETHISINITIALDESIGNISBASEDONTHEFIXTUREDESIGNERSUNDERSTANDINGOFTHEFEATURESTOBEPRODUCED,THEDATUMPLANESINTHATSETUP,ANDTHENATURE,OFTHEBASEANDSIDEFACESTHATIS,ARETHEYPLANARANDDOTHEYPOSSESSENOUGHAREAFORACLAMPTOBEUSED,AMONGOTHERISSUESASMENTIONEDEARLIER,EXPERIENCEDFIXTUREDESIGNERSUSUALLYFOCUSONTHEDETAILEDFIXTUREDESIGNWITHOUTDEVELOPINGASKELETALFIXTUREDESIGNTHEDOMAINEXPERTSOPINEDTHATDURINGTHEIRINITIALYEARSTHEYPERFORMEDSKELETALFIXTUREDESIGNBEFOREDETAILINGTHEDESIGNHOWEVER,ASTHEIREXPERIENCEINCREASEDTHEYBECAMEMORESKILLEDATPRODUCINGAFEASIBLEFIXTUREDURINGTHEIRFIRSTATTEMPTANDGRADUALLYSTOPPEDDEVELOPINGTHESKELETALFIXTUREDESIGNALTOGETHERASINDICATEDBYACTIVITIESA31,A32,ANDA33INFIGURE8,OTHERFIXTUREDESIGNERSPREFERAMOREORGANIZEDAPPROACHTHEYINITIALLYFORMAMENTALPICTUREOFEACHOFTHESUPPORTING,LOCATING,ANDCLAMPINGTECHNIQUESTHEYTHINKAREFEASIBLETOHOLD,SUPPORT,ANDLOCATETHEWORKPIECEDURINGMACHININGCECIL2000,CECIL1995AGENERALOUTLINEOFTHEFIXTUREISPRODUCEDAFTERDISCARDINGINFEASIBLEDESIGNSORRESOLVINGCONFLICTINGDESIGNPROBLEMSASINA34CONFLICTINGDESIGNPROBLEMSINCLUDEISSUESSUCHASDETERMININGWHETHERTHETENTATIVELYSELECTEDDOWNCLAMPINGMETHODINA33AGREESWITHTHELOCATIONAPPROACHINA32,SUCHASUSINGARADIALLOCATIONTECHNIQUEIFTHEYAREINFEASIBLE,THENTHISCONFLICTISRESOLVEDITERATIVELYASINDICATEDBYTHEFEEDBACKLOOPANALYSISFEEDBACKFROMACTIVITYA34ASINDICATEDINACTIVITYA3,ONEOFTHECONTROLLINGINFLUENCESISTHETERMFIXTURINGDESIGNPRINCIPLESTHISREFERSTOTHEEMBEDDEDFIXTURINGKNOWLEDGEOFTHEDESIGNERINCLUDINGHEURISTICSANDEXPERTISEGAINEDINTHISAREAWHENPERFORMINGTHEFIXTUREDESIGNTASKKNOWLEDGEOFTHEFUNDAMENTALSOFFIXTUREDESIGN,COUPLEDWITHTHEHEURISTICBASE,ISANIMPORTANTINFLUENCEORCONTROLLINGFACTORDURINGTHE65JOURNALOFMANUFACTURINGSYSTEMSVOL21MO12002RGUREYDECOMPOSITIONOFDETAILANDCONSOLIDATEFIXTUREDESIGNA4ACCOMPLISHMENTOFTHEFIXTUREDESIGNSUCHKNOWLEDGEINCLUDESIDENTIFYINGTHEPREFERREDCHOICEOFLOCATINGSURFACESANDWHETHERTHEREISANEEDFORRADIALLOCATION,FAMILIARITYWITHDIFFERENTCLAMPINGMETHODSRANGINGFROMDOWNCLAMPINGTOSIDECLAMPING,ANDSOONDECOMPOSITIONOFACTIVITYA4DETAILANDCONSOLIDATEFIXTUREDESIGNACTIVITYA4,WHICHISTODETAILANDCONSOLIDATETHEFIXTUREDESIGN,ISDECOMPOSEDINTOFOURSUBACTIVITIESASINFIGURE9PERFORMSUPPORTDESIGNINTHEFIRSTSUBACTIVITYESTABLISHSUPPORTPLANEANDSELECTSUPPORTA41,THEFIXTUREDESIGNERDETERMINESTHESUPPORTFACEINEACHSETUPANDSELECTSTHETYPEOFSUPPORTDEVICETOBEUSEDINTHEFIXTUREINFLUENCESONTHISACTIVITYINCLUDEPARTDESIGN,TYPEOFFEATURETOBEMACHINEDINTHATSETUP,ANDMACHININGCONSTRAINTSIFMACHININGISTOBEPERFORMEDALONGAZAXIS,THENTHEFIXTUREDESIGNERPREFERSTOUSEAFLATSURFACEWHOSEOUTERGEOMETRICALENVELOPEALONGTHEXYAXISCONTAINSGEOMETRICALPROFILESOFTHEFEATURESTOBEMACHINEDINTHATSETUPFIGUREIOTHISINCREASESTHESTABILITYOFTHEWORKPIECEDURINGMACHININGWHICHISASUPPORTDESIGNHEURISTICIFATHROUGHHOLENEEDSTOBEDRILLEDINTHATSETUP,THENTHEMACHININGCONSTRAINTSINFORMATIONWILLINFLUENCETHEFIXTUREDESIGNERTOSELECTAFLATPLATEWITHARELIEFINCORPORATEDINITINFIGURE10,ASUPPORTBLOCKWITHARELIEFENABLEST

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号