翻译原文-Moldflow Software in a Complex Plastic Shell Injection Mold Design.pdf

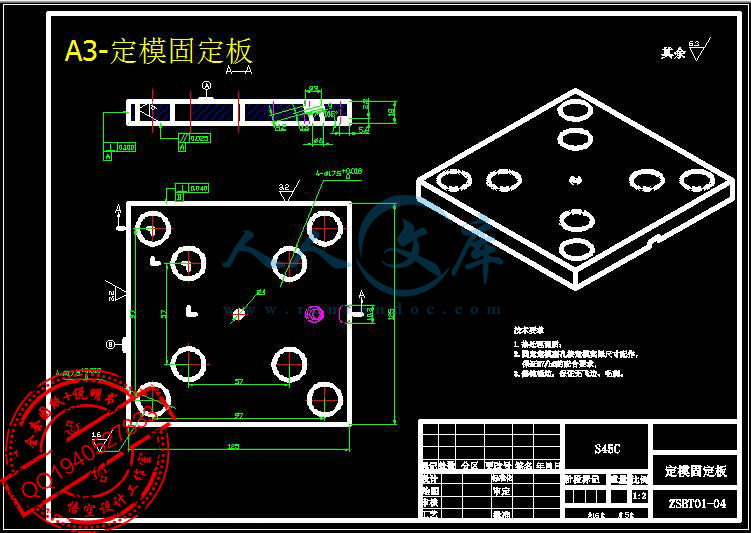

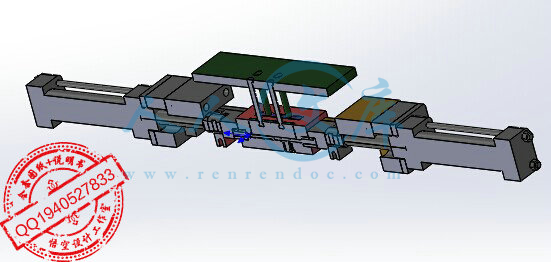

笔筒注塑工艺分析与模具设计(含ProE三维图)

收藏

资源目录

压缩包内文档预览:

编号:7010229

类型:共享资源

大小:41.03MB

格式:RAR

上传时间:2018-01-06

上传人:优***

认证信息

个人认证

罗**(实名认证)

广西

IP属地:广西

60

积分

- 关 键 词:

-

笔筒

注塑

工艺

分析

模具设计

proe

三维

- 资源描述:

-

- 内容简介:

-

MOLDFLOWSOFTWAREINACOMPLEXPLASTICSHELLINJECTIONMOLDDESIGNZHENYUZHAO1,A,LONGLIAO1,B,FEITANG1,C,BAILIU1,D1SHENZHENINSTITUTEOFINFORMATIONTECHNOLOGY,SHENZHEN,CHINAAYXPZZY01163COM,BLIAOLSZIITCOMCN,CTANGFSZIITCOMCN,DLIUBENYTOMCOMKEYWORDSINJECTIONMOLD,MOLDFLOW,MOLDDESIGN,MPIABSTRACTTHEPAPERDESCRIBESTHEIMPORTANTROLEOFMOLDFLOWTECHNOLOGYANDSTATUSTHROUGHTHEAPPLICATIONOFMOLDFLOW/MPIMOLDFLOWPLASTICSINSIGHTSOFTWAREFORCAEUNDERACOMPREHENSIVEANALYSISOFTHESHELLMOLDS,INJECTIONMOLDINGPARAMETERSSUCHASMOLDTEMPERATURE,MELTTEMPERATURE,INJECTIONTIMEANDINJECTIONPRESSUREAREUSEDTOSIMULATETHEACTUALPRODUCTIONPROCESSTHISSHOWSTHEMOLDFLOWTECHNOLOGYPLAYSASIGNIFICANTROLEINTHEMOLDDEVELOPMENTPROCESSFOROPTIMIZINGPLASTICPRODUCTSDESIGN,PLASTICMOLDDESIGNANDINJECTIONPROCESSPARAMETERS,ETCINTRODUCTIONATPRESENT,MOSTINJECTIONMOLDDESIGNERSAREBASEDMAINLYONTHEIRYEARSOFEXPERIENCEINMOLDDESIGNDUETOTHEDIVERSITY,COMPLEXITYOFPLASTICWORKPIECESANDTHELIMITEDEXPERIENCEOFDESIGNERS,ITISDIFFICULTTOACCURATELYDESIGNALOWCOST,SHORTCYCLE,GOODQUALITYPRODUCTS,QUALIFIEDHIGHRATEOFMOLDANDCRAFTPROGRAMS,ANDDESIGNERSOFTENREQUIRESREPEATEDCONTINUOUSLYINORDERTOTRYOUTWITHTHEREVISEDMODELFORMALLYPUTINTOPRODUCTION,SOMEBEYONDREPAIRDUETOTHEPRECISIONDIESCRAPMOLDFLOWTECHNOLOGY1HASAGREATADVANTAGETOIMPROVINGPRODUCTIVITY,ENSUREPRODUCTQUALITY,ORREDUCECOSTS,REDUCELABORINTENSITYANDSOONMOLDFLOWTECHNOLOGYCANBEUSEDINMOLDPROCESSINGPRIORTOUSECOMPUTERSTOSIMULATETHEENTIREINJECTIONMOLDINGPROCESSANALYSIS,TOPREDICTTHEMELTFILLING,PACKING,AIRTRAPS,WELDLINES,TEMPERATUREATFLOWFRONTANDWARPAGE,ETC26,SOTHATDESIGNERSCANEARLYDETECTIONOFPROBLEMS,REVISEPLASTICPARTSANDMOLDDESIGN,REDUCEANDEVENAVOIDMOLDREWORKSCRAP,IMPROVEQUALITYANDREDUCETHECOSTOFPLASTICPARTSANDSOONMOLDFLOWTECHNOLOGYHASSIGNIFICANTTECHNICALANDECONOMICSIGNIFICANCEINTHEPAPER,APLASTICSHELLINJECTIONMOLDISSELECTEDASANFLOWANALYSISEXAMPLE,MOLDFLOWSOFTWARETOOPTIMIZETHEDESIGNOFMOLDSFORPLASTICINJECTIONPRODUCTS,MOLDFILLING,COOLING,WARPAGEANDOTHERBEHAVIOROFTHEDYNAMICSIMULATIONFORTHEPRODUCTS,MOLDDESIGNANDDETERMINATIONOFINJECTIONMOLDINGPROCESSPARAMETERSPROVIDESATHEORETICALBASISINORDERTOIMPROVETHEQUALITYOFMOLDINGPRODUCTSMOLDINGPROCESSANALYSISTHEPRODUCTFORTHEPLASTICSHELLPARTSISSHOWNINFIG1,USINGABSPLASTIC,ANDTHEOUTERSURFACEHASTHEHIGHERQUALITYREQUIREMENTSINTHEPAPER,MPIMODULEISUSEDTOPROCESSTHEPRODUCTFLOWANALYSISINTHEANALYSIS,THROUGHTHEPROCESSFLOWSIMULATIONANALYSISISDETERMINEDTHEGATELOCATION,QUANTITYANDPROCESSCONDITIONS,ANDTHEPROCESSFLOWSIMULATIONISPREDICTEDTHECAVITYPRESSUREDISTRIBUTION,TEMPERATUREDISTRIBUTION,CLAMPINGFORCESIZE,ETC,FORTHEACTUALMOLDINGTOPROVIDEMOLDINGPROCESSPARAMETERSAFTERCOMPLETINGTHEABOVEANALYSIS,THEINJECTIONMOLDINGMATERIALISSELECTEDINTHESOFTWARE,THEREAREMANYLARGECOMPANIESOFPRODUCTSTOCHOOSEFROMINTHECASEMATERIALSELECTABSTYPE,PARAMETERSETTINGISINTAB1TAB1MOLDFLOWANALYSISPARAMETERSETTINGSINJECTIONMOLDINGTEMPERATURE230G263FORMINGCONTROLFILLINGCONTROLPRESSURE90MPAMOLDTEMPERATUREPUNCH55G263SPEED/PRESSURECONVERSIONAUTOMATICDIE80G263PACKINGPRESSURECONTROL80INJECTIONPRESSURE6SAPPLIEDMECHANICSANDMATERIALSVOLS29322010PP646650ONLINEAVAILABLESINCE2010/AUG/13ATWWWSCIENTIFICNET2010TRANSTECHPUBLICATIONS,SWITZERLANDDOI104028/WWWSCIENTIFICNET/AMM2932646ALLRIGHTSRESERVEDNOPARTOFCONTENTSOFTHISPAPERMAYBEREPRODUCEDORTRANSMITTEDINANYFORMORBYANYMEANSWITHOUTTHEWRITTENPERMISSIONOFTTP,WWWTTPNETID58175214,THEUNIVERSITYOFMANCHESTER,MANCHESTER,UNITEDKINGDOM11/01/14,031949MPIWILLAUTOMATICALLYGENERATETHEBESTGATELOCATIONOFRELEVANTINFORMATIONANDTOGRAPHICALLYDISPLAYTHEBESTGATEREGION,THEDEEPERTHECOLORTHEMORESUITABLEAREASELECTEDASAGATEACCORDINGTOFIG1THEPLASTICMODELSHOWSASYMMETRICALSTRUCTURE,ANDTHEBESTLOCATIONISTHEMIDDLEREGIONINTHEPAPERFIG1PLASTICSHELLMODELFIG2FILLTIMEMOLDFLOWANALYSISINTHEPAPERMPISOFTWAREISUSEDTOANALYSISTHEFILLTIMEANDFILLINGPRESSURE,WELDLINES,AIRTRAPS,MAXIMUMCLAMPINGFORCEANDWARPAGETHROUGHTHEANALYSISOFTHESEPARAMETERS,THEBESTINJECTIONPROGRAMSARESELECTEDFILLTIMEGATINGSYSTEMDESIGNDIRECTLYAFFECTSTHEMELTFILLINGBEHAVIOR,WHILETHEFILLINGANALYSISOFTHEIRULTIMATEGOALISTOGETTHEBESTGATINGSYSTEMDESIGNFILLANALYSISISFROMTHEBEGINNINGTOTHECAVITYTHATISFILLEDWITHINJECTIONOFTHEENTIREPROCESSOFANALYSISOFTHEFLOWFRONTLOCATIONTHEANALYSISUSEDTOPREDICTTHEFILLINGBEHAVIOROFWORKPIECEISREASONABLE,WHETHERTHEBALANCEOFFILLING,WHETHERTOCOMPLETETHEWHOLEWORKPIECEFILLFILLINGTHEPURPOSEOFTHEANALYSISISTOOBTAINTHEBESTGATELOCATION,GATENUMBERANDTHEBESTCASTINGSYSTEMLAYOUTFIG2SHOWSTHERESULTSOFTHEANALYSISOFFILLINGTIMETHROUGHTHEDIFFERENTSHADESOFCOLOR,THECHANGEOFSTATEASWELLASTHEMELTFLOWDURINGFILLINGISREFLECTED,FROMWHICHCANSEEWHETHERTHECAVITYISFILLED,ANDWHETHERTHEPROCESSOFFILLINGISBALANCEASCANBESEEFROMFIG2,FILLINGTIMEIS2825S,ANDTHECOLORSHADEISSOFTERTRANSITIONTHEINDICATESTHATTHEFILLINGPROCESSISRELATIVELYFLAT,ANDTHATTHEENTIREINJECTIONMOLDEDPARTSCANBEFILLEDWITHINASHORTPERIODOFTIME,LIQUIDITYBALANCEOFGOODANDFILLINGANDREASONABLESITUATIONTHUSTHEANALYSISCANBEPROVEDTHATGATINGSYSTEMDESIGNSHOWNINFIGURE2ISFEASIBLEAIRTRAPSTHECIRCLESHOWNINFIG3ISAIRTRAPAIRTRAPLOCATIONMAPISSHOWNINTHEFIGUREMELTFRONTBUBBLESGATHEREDININJECTIONPARTSWITHINORCAVITYSURFACEAREBASICALLYAROUNDTHELATERALSIDEOFTHEINJECTIONPARTS,ANDCONCENTRATEDINTHEPARTINGSURFACEINTHECASEAIRTRAPSMAINLYINTHEINNERSURFACEOFPLASTICSHELL,ANDMOSTAPPEARINTHEPARTINGSURFACE,ASSHOWNINFIG3SOAIRINTHEMELTFILLINGWILLAUTOMATICALLYDISCHARGE,THEAIRTRAPSDOESNOTAFFECTTHEAPPEARANCEOFTHEQUALITYOFTHEPRODUCTTHEREFORE,THECASEOFGASVERYEASILYTHROUGHTHEMOLDPARTINGSURFACEGAPDISCHARGE,THEREISNOTRAPPEDAIRPHENOMENON,WHICHCANEFFECTIVELYPREVENTTHEFORMATIONOFAIRTRAPSINJECTIONMOLDEDPARTS,ANDSCORCHTHESURFACEDEFECTSSUCHASDEFECTIVEFIG3AIRTRAPSFIG4WELDLINESAPPLIEDMECHANICSANDMATERIALSVOLS2932647WELDLINESWHENTWOORMOREOFTHEFLOWFRONTINTEGRATION,ITWILLFORMAWELDLINEINTHEWELDLINEPOSITIONTHEMOLECULESARETENDTOCHANGESTRONGLY,SOTHATTHEMECHANICALSTRENGTHSIGNIFICANTLYWEAKENEDINTHEPOSITION,ANDWELDLINEISNOTVISUALLYOBVIOUSINTHISCASE,INCREASINGTHEMOLDTEMPERATUREANDMELTTEMPERATUREMAKETWOMELTENCOUNTERSMERGEBETTERITISADVISABLETOINCREASETHESCREWSPEEDORIMPROVETHEDESIGNOFGATINGSYSTEMTOREDUCETHEFRICTIONGENERATEDHEAT,WHILEMAINTAININGMELTFLOWRATETOREDUCEFLOWCHANNELDIMENSIONSIFWELDLINESCANNOTELIMINATED,THENTHEYSHOULDBELOCATEDTHEPLACETHATITISLESSSENSITIVEONTHEWORKPIECEAREATOPREVENTTHEIMPACTOFTHEMECHANICALPROPERTIESANDAPPEARANCEOFWORKPIECEQUALITYBYCHANGINGTHEGATELOCATION,ORTOCHANGETHEWORKPIECETHICKNESSCANCHANGETHELOCATIONOFWELDLINESTHEWELDLINESPOSITIONISSHOWNONTHEPLASTICPIECESINFIG4AFTERAMOLDFLOWOPTIMIZATIONANALYSIS,IMPROVINGTHEDIETEMPERATURE,INCREASINGADEQUATETHEGATEANDREDUCINGAPPROPRIATELYCLAMPINGFORCE,OPENINGOFTHEEXHAUSTSYSTEMINTHEWELDINGSEAM,THEPRODUCTWELDLINESWILLBECOMEOBVIOUS,REDUCEDSCRAPRATES,TOMEETACTUALPRODUCTIONNEEDSTHERESULTSFROMFIG4CANBESEENTHATTHEREISNOLARGEAREAANDCONTINUOUSWELDLINES,SOWORKPIECESURFACEQUALITYWILLNOTBEAFFECTEDSINKINDEXSHRINKAGELINESREFERTOTHEPHENOMENONOFSURFACEDEPRESSIONSINTHEMOLDINGSALTHOUGHTHESEDEPRESSIONSARESMALL,BUTASLONGASVIEWINGFROMDIFFERENTANGLES,BUTITISVISIBLESHRINKAGELINESVISIBILITYANDITSSURFACETEXTUREISTHEROLEOFTHECOLORCOMPONENTS,SODEEPISTHEDISTINGUISHINGCRITERIATHEMAINREASONOFLINESAPPEARANCEISTHATINTHECOOLINGPROCESSHEATISCONTRACTEDFIGURE5SHOWSTHEDEPTHOFSHRINKAGELINESINTHECASELINESDEPTHISVERYSMALL,SHRINKLINESVERYCLEARLYDOESNOTAFFECTTHEPRODUCTSAPPEARANCEFIG5SINKINDEXFIG6CLAMPFORCECLAMPFORCEINTHEINJECTIONPROCESS,DUETOEXPANSIONFORCEOFMELTWITHINTHEMOLD,MOLDPARTINGSURFACEMAYSEPARATE,RESULTINGINTHEFLYINGSIDE,ITISNECESSARYFORTHEINJECTIONMOLDMACHINETOPROVIDEALOCKINGFORCE,ANDTHEFORCEKNOWNASTHECLAMPINGFORCEWITHTHEFORCECANOFFSETTHECAVITYEXPANSIONFORCEGENERATEDBYMELTUSUALLYCLAMPFORCESHOULDBEASSMALLASPOSSIBLETHESMALLERCLAMPINGFORCECANNOTONLYSAVEENERGY,REDUCECOSTS,BUTALSOTOEXTENDTHESERVICELIFEOFINJECTIONMOLDINGMACHINESANDMOLD,WHILETHEMOLDISALSOANEXHAUSTCANBECARRIEDOUTSMOOTHLY,SOTHATTHEMOLDFILLINGSTATEISMOREEASILYCONTROLLEDININJECTIONMOLDINGTHECLAMPINGFORCEDISTRIBUTIONISSHOWNINFIG6THEMAXIMUMCLAMPINGFORCEIS86KN,THERESULTSOFTHEANALYSISCANBEUSEDTOHELPDESIGNERSTOCHOOSEDIFFERENTTYPESOFINJECTIONMOLDINGMACHINEASCANBESEENFROMFIG5,THEMACHINERYCANMEETTHEREQUIREMENTSANDISCAPABLEOFNORMALPRODUCTIONRECOMMENDEDRAMSPEEDFIG7ISTHERECOMMENDEDRAMOFTHEPROGRAMGRAPH,ANDITSROLEINTHEREGULATIONOFRAMINTOTHECAVITYOFTHEINJECTIONSPEED,SPEEDOFINJECTIONMOLDFILLINGPROCESSTOENSURECONSISTENT,WILLHELPTOIMPROVETHESURFACEQUALITYOFWORKPIECESANDTOAVOIDEXCESSIVESHEARSTRESSTHEINJECTIONSPEEDISRECOMMENDEDTOMAKEAMOREUNIFORMRATEOFFLOWFRONT,WHICHWILLHELPTOELIMINATETHEPRESSUREPEAK,ANDATTHESAMETIMECANIMPROVEWORKPIECESURFACEFINISHINFIG7XYPOSITIONBYINJECTIONPRESSUREMAPCANEASILYSHOWTHECHANGESINPRESSURETEMPERATURETEMPERATUREMAINLYINCLUDESTEMPERATUREATFLOWFRONTANDBULKTEMPERATUREATTHEENDOFFILLINGTHEINTEGRATEDUSEOFTEMPERATUREATFLOWFRONTANDTHEWELDLINEGRAPHCANBEANALYZED648APPLIEDMECHANICSANDMECHANICALENGINEERINGWHETHERWELDLINEQUALITYISGOODORBADTHENARROWERTHESIZERANGEOFTEMPERATUREDISTRIBUTIONISATTHEENDOFFILLING,THEBETTERMOLDQUALITYISTWOKINDSOFTHERMALANALYSISRESULTSARESHOWNINFIG8ANDFIG9THERMOPLASTICPOLYMERFLOWANALYSISISUSUALLYUSEDTOPREDICTTHEFLOWBEHAVIORINSIDETHEDIEMOLDFLOWSIMULATIONBEGINSTOMELTFROMTHEINJECTIONSITESPREADTOTHEADJACENTPOINTOFTHEFLOWFRONT,UNTILTHEFLOWFRONTTOSPREADANDFILLWORKPIECEANDTHELASTPOINTTOCOMPLETETHEFLOWANALYSISANDCALCULATIONTHEOBJECTIVEISTOOBTAINTHEBESTPACKINGSTAGESETTIME,THEREBYREDUCINGASMUCHASPOSSIBLECAUSEOFTHEWORKPIECEBYTHEHOLDINGPRESSURECONTRACTION,WARPINGANDOTHERQUALITYDEFECTSAREASONABLETEMPERATUREDISTRIBUTIONATFLOWFRONTSHOULDBEUNIFORM,ANDTHEMODELCANNOTBEMUCHDIFFERENCEINTEMPERATUREASCANBESEENFROMFIG8,THEMODELISMOREUNIFORMTEMPERATUREDISTRIBUTIONMODELSHOWSTHATTHEMELTTEMPERATUREINTHEFLOWOFSLOWDECLINE,WHICHWILLHELPFILL,ANDASMALLERDROPINTHETEMPERATUREOFTHEPRODUCT,WHICHMEANSTHATTHESURFACEQUALITYOFPLASTICPARTSWILLBEGUARANTEEDFIGURE8SIMULATIONRESULTSFORTHEFLOWFRONTTEMPERATUREASCANBESEENFROMFIG8,MATERIALFLOWANALYSISCANBESEENTHATTHEMAXIMUMTEMPERATURETHEFOREFRONTIS2306,THELOWESTTEMPERATUREIS2238,INJECTIONMOLDEDPARTSOFTHETEMPERATUREDIFFERENCEIS68,THERECOMMENDEDVALUESOFTHECONTROLVALUE20WITHININDICATEDTHATASMALLERTEMPERATUREDIFFERENCE,WHICHMEANSTHEQUALITYOFTHESURFACEOFINJECTIONMOLDEDPARTSAREGUARANTEED,WORKPIECESCANBEFILLEDFIG8SHOWSTHATWHENTHEMATERIALFUSIONTEMPERATUREIS22892306,THELOWESTMELTTEMPERATUREISONLYLOWERTHANTHEINJECTIONTEMPERATUREOF2238SOMATERIALSCANBEAVERYGOODFUSION,ANDDOESNOTAPPEARWELDCAVITATIONSARESEENINTHEFUSIONLINEANDPARTINGSURFACE,ANDEXHAUSTDUCTSARESETATTHEOPENINGOFWELDLINETHISISNOTONLYCONVENIENTTOEXHAUST,BUTALSOINCREASETHEFUSIONLINEOFFASTNESSFROMTHEFIG8FLOWFRONTTEMPERATUREGRAPHANDFIG4WELDLINEGRAPH,WECANSEETHEFORMATIONOFWELDLINESWHENTHEMELTTEMPERATUREISABOUT230THEWELDLINEISNOTOBVIOUS,ANDTHERESULTSAREBESTBULKTEMPERATUREHASREFLECTEDTHESHEARHEATPRODUCEDINSIDETHEWORKPIECEIFTHEWORKPIECEHASASTRONGSHEARWITHINTHEROLE,WORKPIECETEMPERATUREWILLRISEINTHEMOLDFILLINGSTAGE,THEVOLUMECANBESEENFROMFIG9THATTHETEMPERATUREDIAGRAMSPEEDWEIGHTEDAVERAGETEMPERATURESHOULDBEVERYUNIFORMTHEMINIMUMTEMPERATUREIS1773C,ANDTHEMAXIMUMTEMPERATUREIS2343CTHECHANGESMEETTHEBULKTEMPERATURECONTROLLEDRANGEFIG7RECOMMENDEDRAMSPEEDFIG8TEMPERATUREATFLOWFRONTFIG9BULKTEMPERATUREFIG10PRESSUREATTHEENDOFFILLINGAPPLIEDMECHANICSANDMATERIALSVOLS2932649PRESSUREASCANBESEENFROMFIG10,THEPRESSUREDISTRIBUTIONISOBTAINEDATTHEENDOFFILLING,ANDANALYSISOFFILLINGPRESSUREDISTRIBUTIONISBALANCEDINTHEFINALFILLINGPRESSUREONTHELOWERPARTOFTHEBLUE,THEENTIREPLASTICPRESSUREDIFFERENCEISBELOW35MPAVOLUME/PRESSURECONVERSIONDATAANDFILLINGPRESSUREDATAATTHEENDOFFILLINGMOLDARETHESAMEEFFECTUSUALLY,THEVOLUMEANDPRESSURECONVERSIONTHROUGHOUTTHEINJECTIONMOLDINGCYCLEISTHEHIGHESTATTHISTIMETHESIZEANDDISTRIBUTIONOFPRESSURETHROUGHTHEPRESSUREPROFILECANBEOBSERVED,ANDWORKPIECEFILLBASICALLYREACH100ATTHECONVERSIONASCANBESEENFROMFIG11,THELARGESTINJECTIONPRESSUREIS5337MPAINMOLDINGPROCESS,ANDITISTHEREDINTHEDIAGRAMPOSITIONTHEGREYPARTINTHEFIGUREINDICATESTHATTHEWORKPIECE100FILLEDWITHGOODEFFECTPRESSUREATTHEINJECTIONLOCATIONPACKINGPROCESSBASEDONTHEFILLINGPROCESSISSIMULATEDBYOPTIMIZINGTHEINJECTIONOFREASONABLEFORCEANDPACKINGPRESSUREFORPRODUCTIONPREPARATIONFIG12SHOWSTHEPACKINGPROCESSOFSIMULATIONRESULTSINJECTIONPRESSUREFLOWISALSOKEYPARAMETERS,ADIRECTIMPACTONMOLDFILLINGGOODORBADASCANBESEENFROMFIG12,THEENDOFINJECTIONMOLDINGPRESSUREREACHESTHEMAXIMUM55MPA,LESSTHANTHEMAXIMUMINJECTIONMOLDINGMACHINE,PACKINGPRESSURECURVEANDSETTHEBASICLINEFIG11VOLUME/PRESSURECONVERSIONFIG12INJECTIONFORCEANDPACKINGPROCESSCONCLUSIONINTHEPAPER,MOLDFLOWSOFTWARETHROUGHTHEFLOWBEHAVIORISUSEDINTHESIMULATION,PREDICTION,ANDDISPLAYTHEFOREFRONTOFMEL

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

|

2:不支持迅雷下载,请使用浏览器下载

3:不支持QQ浏览器下载,请用其他浏览器

4:下载后的文档和图纸-无水印

5:文档经过压缩,下载后原文更清晰

|

川公网安备: 51019002004831号

川公网安备: 51019002004831号