资源目录

压缩包内文档预览:

编号:8155154

类型:共享资源

大小:3.06MB

格式:ZIP

上传时间:2018-02-08

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

数控

火焰

切割机

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

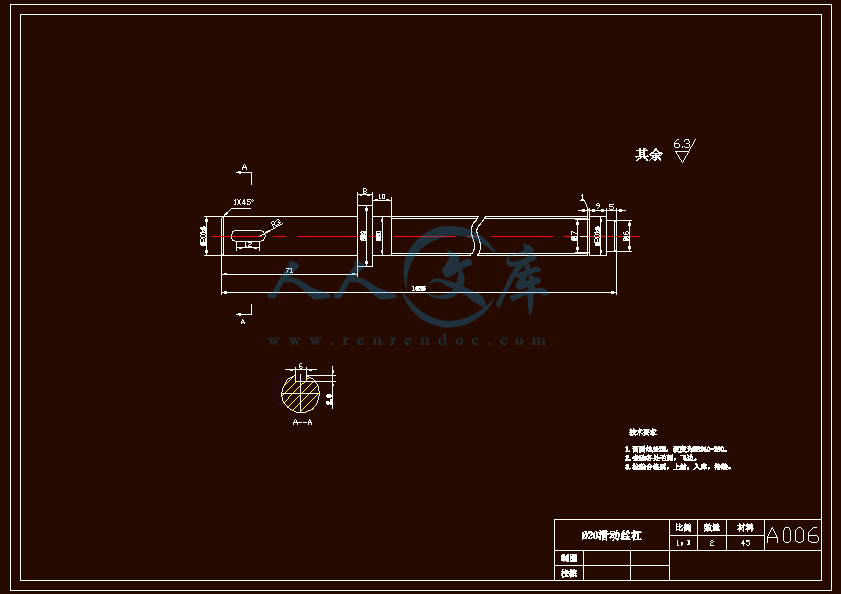

英文原文CNCFLAMECUTTINGBASICCOMMONSENSETHEBASICKNOWLEDGEOFCNCFLAMEGASCUTTINGATHEBASICWORKINGPRINCIPLEOFGASCUTTINGANDGASCUTTINGPROCESSHEATUSINGAGASFLAMECUTTINGTHEWORKPIECEISPREHEATEDTOATACERTAINTEMPERATURE,THEDISCHARGESPEEDCUTTINGOXYGENSTREAM,SOTHATCOMBUSTIONANDGIVESOFFHEATTOACHIEVECUTTINGMETHODISCALLEDTORCHCUTTINGTHEOXYGENCUTTINGPROCESSHASTHEFOLLOWINGTHREESTAGES1,THEBEGINNINGOFTHEPREHEATINGGASCUTTING,USINGAGASFLAMEOXYGENACETYLENEFLAME,OXYGEN,PROPANEFLAMEOFTHEWORKPIECETOBECUTATTHEIGNITIONOFTHEMETALMATERIALISPREHEATEDTOAPPROXIMATELY1100TO1150CFORLOWCARBONSTEELCOMBUSTIONEMITHIGHSPEEDCUTTINGOXYGENFLOWREACHEDLIGHTEDMETALINTENSEBURNINGINANOXYGENSTREAM3,BLOWINGSLAGMETALOXIDECOMBUSTIONGENERATEDBYTHEOXYGENSTREAMTOBLOWOFFTHEINCISIONISFORMED,SOTHATTHEMETALSEPARATION,THECOMPLETIONOFTHECUTTINGPROCESSBGASWELDING,GASCUTTINGEQUIPMENTUSEDINTHECOMPOSITIONOFTHEGASWELDING,GASCUTTINGEQUIPMENT,OXYGENBOTTLES,OXYGENREGULATOR,ACETYLENEBOTTLESACETYLENEGENERATOR,ACETYLENEREGULATOR,THETEMPERINGINSURANCE,TORCHTORCHANDRUBBERTUBECWHATISGOODNOTCHEDCUTTINGTHEMIDDLEOFTHENOTCHEDSURFACEAFTERTHEWHITENINGDIDNOTBURNSCARNOTCHEDWITHOUTWASTESIDEOFTHEPHENOMENONDGASCUTTINGMETALSHALLCOMPLYWITHTHEFOLLOWINGCONDITIONS1THEMELTINGPOINTOFTHEMETALOXIDESHOULDBELESSTHANTHEMELTINGPOINTOFTHEMETALTABLE11ARESOMECOMMONMELTINGPOINTOFTHEMETALANDITSOXIDE2METALWITHOXYGENCOMBUSTIONCANRELEASEALOTOFHEAT,ANDTHETHERMALCONDUCTIVITYOFTHEMETALITSELFTHEGASCUTTINGCONDITIONSMETALIRON,LOWCARBONSTEEL,MEDIUMCARBONSTEELANDLOWALLOYSTEELANDTITANIUMOTHERCOMMONLYUSEDMETALSSUCHASCASTIRON,STAINLESSSTEEL,ALUMINUMANDCOPPER,ETC,MUSTUSESPECIALMETHODORMELTINGMETHODOFOXYFUELCUTTING8MMSHEET,ITISNOTEASYTOCNCGASCUTTINGCNCFLAMECUTTINGGASCUTTINGACCURACYISTHEERRORBETWEENAFTERCUTTINGGEOMETRYWITHITSDRAWINGSIZECOMPARISON,CUTTINGTHEQUALITYOFTHEWORKPIECEISCUTOFFTHESURFACEROUGHNESSOFTHESURFACE,THEMELTINGDEGREEOFCOLLAPSESECTIONONTHEEDGEOFTHEINCISION,THEINCISIONEDGEISDROSSANDTHEUNIFORMITYOFKERFWIDTHFIRST,THEIMPACTOFSTEELFLAMECUTTINGQUALITYTHREEBASICELEMENTSGAS,CUTTINGSPEED,CUTTINGNOZZLEHEIGHT1GASESOXYGEN,COMBUSTIBLEGASANDTHEFLAMEADJUSTED1OXYGENOXYGENISNECESSARYFORCOMBUSTIONOFTHECOMBUSTIBLEGAS,INORDERTOPROVIDETHEENERGYREQUIREDFORSTEELREACHESTHEIGNITIONTEMPERATUREADDITION,OXYGENISCARRIEDOUTAFTERTHESTEELISPREHEATEDACHIEVEIGNITIONCOMBUSTIONASNECESSARYCUTTINGSTEELWITHOXYGENMUSTHAVEAHIGHPURITYOFMORETHAN995,THEGENERALREQUIREMENTS,SOMEADVANCEDCOUNTRIESBYINDUSTRYSTANDARDS,THEOXYGENPURITYOF997THEOXYGENPURITYDECREASINGBY05,STEELPLATECUTTINGSPEEDSHOULDBEREDUCEDBYABOUT10IFTHEOXYGENPURITYISREDUCEDBY08TO1,NOTONLYCUTTINGSPEEDDECREASEDBY1520,WHILETHESLOTTEDALSOWILLBEWIDER,HANGINGATTHEBOTTOMOFTHEINCISIONTHERESIDUEANDCLEANDIFFICULT,SIGNIFICANTDETERIORATIONOFTHEQUALITYOFTHECUTTINGSECTION,GASCONSUMPTIONALSOINCREASESOBVIOUSLY,THISREDUCESTHEPRODUCTIONEFFICIENCYANDCUTTINGQUALITY,THEPRODUCTIONCOSTSAREALSOSIGNIFICANTLYINCREASEDSEEFIGURE91FIGURE91UNDERTHESAMEOXYGENPRESSURE,OXYGENPURITYOFCUTTINGTIMEANDOXYGENCONSUMPTIONTHEUSEOFLIQUIDOXYGENCUTTING,ALTHOUGHTHEONETIMEINVESTMENT,BUTINTHELONGRUN,ITSCOMPREHENSIVEECONOMICINDICATORSAREMUCHBETTERTHANIMAGINEDTHESTABILITYOFTHEGASPRESSUREONTHECUTTINGQUALITYOFTHEWORKPIECEISALSOESSENTIALTHEOXYGENPRESSUREFLUCTUATIONSWILLCUTTHEAPPARENTDETERIORATIONOFTHEQUALITYOFCROSSSECTIONTHEAIRPRESSUREISADJUSTEDACCORDINGTOTHETYPEOFTHECUTTINGNOZZLE,THECUTTINGOFTHEPLATETHICKNESSCUTTINGIFTHEOXYGENPRESSUREEXCEEDSAPREDETERMINEDVALUE,DOESNOTIMPROVETHECUTTINGSPEED,BUTTHECUTTINGSECTIONDECLINEINTHEQUALITYOFTHEDROSSISDIFFICULTTOBECLEARED,INCREASINGTHEPROCESSINGTIMEANDCOSTOFCUTTINGTABLE91ISCOMMONLYUSEDINGASWELDINGMACHINEFACTORYPRODUCTIONTHEGK1SERIESOFFASTCUTTINGNOZZLEIETHELAVALNOZZLESTRUCTURECUTTINGNOZZLEUSINGTHEPARAMETERMANUFACTURERSMAYATANYTIMEMODIFYTHEPARAMETERSSHOULDBECUTTINGNOZZLESUBJECTTOTHEATTACHEDDOCUMENT,THISTABLEISFORREFERENCE2FLAMMABLEGASFLAMECUTTING,COMMONLYUSEDFLAMMABLEGASESSUCHASACETYLENE,GAS,NATURALGAS,PROPANE,SOMEFOREIGNMANUFACTURERSALSOUSEMAPP,NAMELYMETHANEETHANEPROPANEGENERALLY,THECOMBUSTIONSPEED,HIGHCOMBUSTIONVALUEOFTHEGASISSUITABLEFORSHEETMETALCUTTINGLOWCOMBUSTIONVALUE,THESLOWCOMBUSTIONOFFLAMMABLEGASISMORESUITABLEFORCUTTINGSLAB,ESPECIALLYSTEELSHEETOFATHICKNESSOFMORETHAN200MM,SUCHASAGASORGASBECUT,YOUWILLGETTHEDESIREDCUTQUALITY,BUTTHECUTTINGSPEEDWILLBESLIGHTLYLOWERINCOMPARISON,THEACETYLENEISMUCHMOREEXPENSIVETHANNATURALGAS,OWINGTORESOURCECONSTRAINTSINTHEACTUALPRODUCTION,THEGENERALUSEOFACETYLENEGAS,BUTATTHESAMETIMECUTTINGTHESLABREQUIREHIGHCUTTINGQUALITYANDADEQUACYOFRESOURCES,ITWILLCONSIDERTHEUSEOFNATURALGAS3THEFLAMECANBEADJUSTEDBYADJUSTINGTHEPROPORTIONOFTHEOXYGENANDACETYLENETHETHREECUTTINGFLAMENEUTRALFLAMEIE,NORMALFLAME,OXIDIZINGFLAME,REDUCINGFLAME,ASSHOWNINFIGURE92THENORMALFLAMECHARACTERIZEDINTHATNOFREEOXYGENINTHEREDUCTIONZONEANDTHEACTIVATEDCARBON,THEREARETHREEDISTINCTREGIONS,THEFLAMECOREDISTINCTIVEOUTLINEAPPROXIMATELYCYLINDRICALTHEFLAMECORECOMPONENTOFACETYLENEANDOXYGEN,ANDITSENDSWEREUNIFORMLYROUNDANDSHINYSHELLTHEHOUSINGISMADEOFREDHOTCARBONPARTICLESFLAMECORETEMPERATUREUPTO1000CREDUCINGZONEINTHEFLAMECORE,ASIGNIFICANTDIFFERENCEWITHTHEFLAMECOREISITSBRIGHTNESSISDARKERREDUCTIONZONEBYTHEPRODUCTOFINCOMPLETECOMBUSTIONOFACETYLENECARBONMONOXIDEANDHYDROGEN,THEREDUCTIONZONETEMPERATUREUPTO3000CORSOCOMPLETELYWAIYANIETHECOMBUSTIONZONEISLOCATEDOUTSIDEOFTHEREDUCINGZONE,ITISCOMPOSEDOFCARBONDIOXIDEANDWATERVAPOR,NITROGEN,ITSTEMPERATUREVARIESBETWEEN1200TO2500COXIDIZINGFLAMEISGENERATEDINTHECASEOFEXCESSOXYGEN,THEFLAMECORECONICAL,LENGTHSHORTENEDSIGNIFICANTLY,THEOUTLINEISNOTCLEAR,THEBRIGHTNESSISDIMSIMILARLY,THEREDUCTIONZONEANDOUTERFLAMEHASBEENSHORTENED,THEFLAMEWASPURPLEBLUECOMBUSTIONACCOMPANIEDBYSOUND,THESOUNDOFTHESIZEOFTHEPRESSUREOFOXYGEN,OXIDIZINGFLAMETEMPERATUREISHIGHERTHANNORMALFLAMEIFYOUAREUSINGTHEOXIDIZINGFLAMECUTTINGWILLMAKETHECUTQUALITYSIGNIFICANTLYDETERIORATEDREDUCINGFLAMEISGENERATEDINTHECASEOFEXCESSACETYLENEFLAMECOREISNOOBVIOUSSILHOUETTEGREENEDGE,THEFLAMEENDOFTHECORE,TODETERMINETHEEXCESSOFACETYLENEINACCORDANCEWITHTHEGREENEDGEREDUCINGZONEISUNUSUALLYBRIGHT,ALMOSTTHEFLAMECORELUMPEDTOGETHERWAIYANTHEYELLOWWHENTHEEXCESSACETYLENEISTOOFAR,BLACKSMOKE,WHICHISCAUSEDBECAUSEOFTHELACKOFNECESSARYOXYGENACETYLENEFLAMEINCOMBUSTIONPREHEATTHEENERGYOFTHEFLAMESIZEANDCUTTINGSPEED,CUTQUALITYAREALLVERYCLOSEWITHTHECUTWORKPIECETHICKNESSINCREASESANDTHECUTTINGSPEEDTOACCELERATE,THEENERGYOFTHEFLAMEALSOSHOULDINCREASEAS,BUTNOTTOOSTRONG,PARTICULARLYWHENTHESLABISCUT,THETHEMETALCOMBUSTIONHEATOFREACTIONGENERATEDINCREASES,STRENGTHENINGTHECUTTINGPOINTPREHEATCAPABILITIES,CUTTINGEDGE,THEN,TOOSTRONGPREHEATINGFLAMEWILLMAKESERIOUSMELTINGCOLLAPSEDONTHEEDGEOFTHECUTEDGETOOWEAKTOPREHEATFLAME,THESTEELWILLNOTGETENOUGHENERGYTOFORCETOREDUCETHECUTTINGSPEED,EVENCUTTINGPROCESSISINTERRUPTEDSOPREHEATINGFLAMESTRENGTHANDCUTTINGSPEEDRELATIONSHIPOFMUTUALRESTRAINTINGENERAL,THESTEELCUTTING200MMNEUTRALFLAMECANGETABETTERCUTQUALITYUSEDINTHECUTTINGOFSTEELPLATESSHOULDRESTOREPREHEATFLAMECUTTING,BECAUSETHEREDUCINGFLAMEOFTHEFLAMELENGTH,FLAMELENGTHSHOULDBEATLEASTATHICKNESSOF12TIMESORMORE2CUTTINGSPEEDTHECUTTINGSPEEDOFTHESTEELSHEETISCORRESPONDINGWITHTHEBURNINGRATEOFTHESTEELINANOXYGENINTHEACTUALPRODUCTIONSHOULDBEBASEDONTHEPERFORMANCEPARAMETERSOFTHECUTTINGNOZZLE,GASTYPEANDPURITY,STEELPLATETHICKNESSTOADJUSTTHECUTTINGSPEEDCUTTINGSPEEDDIRECTLYAFFECTSTHESTABILITYOFTHECUTTINGPROCESSANDTHEQUALITYOFCUTTINGSECTIONIFYOUWANTTOARTIFICIALLYINCREASETHECUTTINGSPEEDTOIMPROVEPRODUCTIONEFFICIENCYANDSLOWDOWNTHECUTTINGSPEEDTOBESTIMPROVETHEQUALITYOFTHECUTTINGSECTION,ITISIMPOSSIBLE,ONLYMAKETHEPOORQUALITYOFTHECUTTINGSECTIONTOOFASTCUTTINGSPEEDCANCAUSETHECUTTINGSECTIONSWITHQUALITYDEFECTSSUCHASDENTSANDDROSS,SERIOUSMAYRESULTINCUTTINGINTERRUPTTOOSLOWCUTTINGSPEEDMAKETHEINCISIONONTHEEDGEOFTHEMELTINGEDGEOFCOLLAPSE,THELOWEREDGEROUNDED,CUTTINGCROSSSECTIONINTHESECONDHALFPARTOFTHEFLUSHSHAPEDDEEPGROOVEPITBYOBSERVINGTHECHARACTERISTICSOFTHESLAGDISCHARGEDFROMTHEINCISION,ADJUSTTOTHEAPPROPRIATECUTTINGSPEEDINTHENORMALFLAMECUTTINGPROCESS,CUTTINGOXYGENSTREAMRELATIVETOTHEVERTICALCUTTINGTORCHSLIGHTLYATANANGLE,ANDITSCORRESPONDINGOFFSETISCALLEDDRAGAMOUNTSEEFIGURE93SPEEDISTOOLOW,THEREISNOAMOUNTOFPOSTDRAG,OFFSETTHEWORKPIECECUTBELOWTHEMOUTHOFTHEFIREBOUQUETSTOTHECUTTINGDIRECTIONIMPROVETHERUNNINGSPEEDOFTHETORCH,THEFIREBOUQUETWILLBEOFFSETINTHEOPPOSITEDIRECTION,WHENTHEFIREBOUQUETANDCUTTINGOXYGENFLOWPARALLELTOTHECUTTINGSPEEDSPEEDISTOOHIGH,THEFIREBOUQUETSIGNIFICANTLYAFTERPARTIAL,ASSHOWNINFIGURE94CUTTINGNOZZLEANDCUTTHEHEIGHTOFTHEWORKPIECESURFACESTEELPLATEFLAMECUTTINGPROCESS,THECUTTINGNOZZLETOCUTTHEHEIGHTOFTHEWORKSURFACEISONEOFTHEMAINFACTORSINDECISIONNOTCHQUALITYANDCUTTINGSPEEDDIFFERENTTHICKNESSOFTHEPLATE,USINGDIFFERENTPARAMETERSOFTHECUTTINGNOZZLE,ADJUSTTHEHEIGHTINORDERTOOBTAINHIGHQUALITYCUTS,THECUTTINGNOZZLETOTHEHEIGHTOFTHEWORKPIECESURFACETOBECUTINTHECUTTINGPROCESSMUSTBEKEPTBASICALLYTHESAMESECOND,THETHERMALDEFORMATIONOFTHECONTROLWILLALLOWTOBECUTDUETOTHEUNEVENNESSOFTHESTEELSHEETHEATINGANDCOOLING,THEMATERIALOFINTERNALSTRESSTHEROLEOFTHEWORKPIECEINTHECUTTINGPROCESS,DIFFERENTDEGREESOFBENDINGORDISPLACEMENTOFIEHEATDEFORMATION,THESPECIFICPERFORMANCEISTHEDEVIATIONOFTHESHAPEOFTHETWISTINGANDCUTTINGSIZEMATERIALINTERNALSTRESSCANNOTBEBALANCEDANDCOMPLETELYELIMINATED,ITCANONLYTAKESOMEMEASURESTOTRYTOREDUCETHETHERMALDEFORMATIONTHIRD,THESTEELSURFACEPREPARATIONTHESTEELFROMTHESTEELPLANTTHROUGHASERIESOFINTERMEDIATELINKSTOTHECUTTINGWORKSHOP,DURINGTHATTIME,THESTEELSURFACEWILLINEVITABLYPRODUCEALAYEROFOXIDEFURTHERMORE,THESTEELSHEETISALSOPRODUCEDDURINGTHEROLLINGPROCESSTHELAYEROFOXIDEISATTACHEDTOTHESURFACEOFTHESTEELSHEETTHESEOXIDEHASAHIGHMELTINGPOINT,ISNOTEASYTOBURNANDMELT,WARMUPTIME,REDUCINGTHECUTTINGSPEEDHEATEDATTHESAMETIME,SCALESPLASH,CANEASILYCAUSECONGESTION,REDUCETHESERVICELIFEOFTHECUTTINGNOZZLECUTTINGNOZZLETHEREFORE,PRIORTOCUTTING,ITISNECESSARYONTHESURFACEOFTHESTEELSHEETRUSTPRETREATMENTTHECOMMONMETHODISTOSHOTBLASTING,RUSTAFTERPAINTINGUPCOMINGSMALLIRONSANDBLASTINGMACHINESPRAYEDINTOTHESURFACEOFTHESTEELPLATE,RELYONTHEIMPACTOFIRONORETOSTEELDESCALING,THENSPRAYEDFLAMERETARDANT,ELECTRICALCONDUCTIVITYANDGOODANTIRUSTPAINTRUSTPAINTPRETREATMENTBEFORESTEELCUTTINGHASBECOMEANINDISPENSABLEPARTINTHEPRODUCTIONOFMETALSTRUCTURESFOURTH,CNCFLAMECUTTINGQUALITYDEFECTSCAUSEANALYSISINTHEACTUALPRODUCTIONPROCESS,OFTENONEWAYORANOTHERQUALITYPROBLEMS,GENERALLYTHEREARESEVERALDEFECTSEDGEDEFECTS,CUTTINGCROSSSECTIONDEFECTS,DROSS,CRACKS,ETCANDQUALITYACCIDENTSCAUSEDBYMANYREASONS,IFTHEOXYGENPURITYTOENSURENORMAL,NORMALOPERATIONOFEQUIPMENT,CAUSINGFLAMECUTTINGQUALITYDEFECTSISMAINLYMANIFESTEDINTHEFOLLOWINGASPECTSCUTTINGTORCH,CUTTINGNOZZLE,THEQUALITYOFTHESTEELITSELF,STEELPLATE1ONTHECUTTINGEDGEOFQUALITYDEFECTSTHISISCAUSEDDUETOMELTINGOFQUALITYDEFECTS1ONTHEEDGEOFCOLLAPSEEDGEPHENOMENONTHEEDGEOFTHEMELTINGTOOQUICKLY,RESULTINGINAROUNDEDEDGECOLLAPSEREASONS1CUTTINGSPEEDISTOOSLOW,TOOPREHEATFLAME2CUTTINGHEIGHTBETWEENTHENOZZLEANDTHEWORKPIECEISTOOHIGHORTOOLOWCUTTINGNOZZLENUMBERISTOOLARGE,EXCESSOXYGENINTHEFLAME2TEARDROPSHAPEDMELTINGSTRINGBEANSSEEFIGURE99PHENOMENONTHEUPPEREDGEOFTHECUTTOFORMASERIESOFTEARDROPSHAPEDMELTBEANSREASONS1THESURFACEOFTHESTEELCORROSIONOROXIDE2CUTTINGHEIGHTBETWEENTHEMOUTHANDTHESTEELISTOOSMALL,PREHEATFLAMEISTOOSTRONG3CUTTINGHEIGHTBETWEENTHEMOUTHANDTHESTEELISTOOLARGE3THEUPPEREDGEOFTHEMATSECTIONANDPRESENTSTHETHEEAVESSHAPESEEFIGURE910PHENOMENAINTHEUPPEREDGEOFTHECUTFORMINGTHEEAVESLIKEPROJECTINGEDGECOLLAPSEREASONS1PREHEATTHEFLAMEISTOOSTRONGTHECUTTOOLOWANALTITUDEBETWEENTHEMOUTHANDSTEEL3CUTTINGSPEEDISTOOSLOWCUTTINGHEIGHTBETWEENTHENOZZLEANDTHEWORKPIECEISTOOLARGE,THECUTTINGNOZZLENUMBERISTOOLARGE,THETHEPREHEATFLAMEINOXYGENEXCESS4THEUPPEREDGEOFTHECUTTINGSECTIONOFDROSSSEEFIGURE911PHENOMENONONTHEEDGEOFTHEINCISIONDEPRESSIONANDDROSSREASONS1CUTTINGHEIGHTBETWEENTHENOZZLEANDTHEWORKPIECEISTOOLARGE,CUTTINGOXYGENPRESSUREISTOOHIGH2PREHEATTHEFLAMEISTOOSTRONG2THECUTTINGSECTIONRUGGEDFLATNESS1CUTTINGTHESECTIONBELOWTHEUPPEREDGE,ACONCAVEDEFECTSEEFIGURE912PHENOMENONTHERECEIVINGDEPRESSION,ONTHEEDGEOFTHECUTTINGSECTIONATTHEUPPEREDGETHEREAREDIFFERENTDEGREESOFMELTINGMATSECTIONREASONS1CUTTINGOXYGENPRESSUREISTOOHIGH2CUTTINGHEIGHTBETWEENTHENOZZLEANDTHEWORKPIECEISTOOLARGETHECUTTINGNOZZLEBECOMESCLOGGED,THEWINDLINEDISTURBEDDEFORMATION2SLOTTEDBECONTRACTEDFROMTOPTOBOTTOMSEEFIGURE913PHENOMENONSLOTTEDWIDERATTHETOPREASONS1CUTTINGOXYGENPRESSUREISTOOHIGH2CUTTINGHEIGHTBETWEENTHENOZZLEANDTHEWORKPIECEISTOOLARGETHECUTTINGNOZZLEBECOMESCLOGGED,THEWINDLINEDISTURBEDDEFORMATIONPHENOMENONSLOTTEDTHENARROWWIDTH,BELLSHAPEDREASONS1THECUTTINGSPEEDISTOOFAST,CUTTINGOXYGENPRESSUREISTOOHIGHCUTTINGNOZZLENUMBERISTOOLARGE,TOOMUCHCUTTINGOXYGENFLOW3CUTTINGHEIGHTBETWEENTHENOZZLEANDTHEWORKPIECEISTOOLARGE4CUTTINGSECTIONRECESSSEEFIGURE915PHENOMENONTHECUTTINGSECTION,ESPECIALLYTHEMIDDLEPARTWITHDEPRESSIONREASONS1CUTTINGSPEEDISTOOFAST2TOUSETHECUTTINGNOZZLEISTOOSMALL,THECUTTINGPRESSUREISTOOLOW,CUTTINGNOZZLEISCLOGGEDORDAMAGED3CUTTINGOXYGENPRESSUREISTOOHIGH,THEWINDLINEBLOCKEDDETERIORATION5CUTTINGSECTIONSHOWINGACORRUGATEDSHAPESEEFIGURE916PHENOMENONCUTTINGSECTIONUNEVEN,SHOWINGALARGECORRUGATEDSHAPEREASONS1CUTTINGSPEEDISTOOFAST2CUTTINGOXYGENPRESSUREISTOOLOW,CUTTINGNOZZLECLOGGINGORDAMAGE,DETERIORATIONOFAIRLINE3USINGTHECUTTINGNOZZLENUMBERISTOOLARGE6THEANGULARDEVIATIONOFTHEVERTICALDIRECTIONOFTHEINCISIONSEEFIGURE917PHENOMENONAVERTICALINCISION,ABEVELREASONSTORCHANDTHEWORKPIECESURFACEISNOTPERPENDICULARTOTHEWINDLINEISNOTCORRECT7UNDERTHEEDGEOFTHEINCISIONINTOROUNDEDCORNERSSEEFIGURE918PHENOMENONTHELOWEREDGEOFTHEINCISIONHAVEDIFFERENTDEGREESOFMELTING,ROUNDEDSHAPEREASONSCUTTINGNOZZLECLOGGINGORDAMAGE,DETERIORATIONOFAIRLINECUTTINGSPEEDISTOOFAST,CUTTINGOXYGENPRESSUREISTOOHIGH8THERECESSANDTHELOWEREDGEOFTHELOWERPARTOFTHEINCISIONINTOTHEROUNDEDCORNERSSEEFIGURE919PHENOMENONCLOSETOTHELOWEREDGEOFTHEDEPRESSIONANDTHELOWEREDGEISMELTEDINTOAFILLETCAUSETHECUTTINGSPEEDISTOOFAST,THECUTTINGNOZZLECLOGGINGORDAMAGETO,DETERIORATIONOFAIRLINEBLOCKED3ROUGHNESSDEFECTSOFTHECUTTINGSECTIONCUTTINGCROSSSECTIONOFTHEROUGHNESSOFTHEDIRECTLYAFFECTSUBSEQUENTSTEP,THEPROCESSINGQUALITYOFTHECUTSURFACEROUGHNESSANDAHEADOFTHEAMOUNTOFITSDEPTHOFCUTPATTERN1EXCESSIVEDRAGCUTTINGSECTIONFIGURE920PHENOMENONTHECUTTINGSECTIONCUTPATTERNOFFSETBACKWARDS,ATTHESAMETIMEASTHESIZEOFTHEOFFSETANDVARYINGDEGREESOFDEPRESSIONREASONS1CUTTINGSPEEDISTOOFAST2TOUSETHECUTTINGNOZZLEISTOOSMALL,TOOSMALLCUTTINGOXYGENFLOW,CUTTINGOXYGENPRESSUREISTOOLOW3CUTTINGHEIGHTOFTHENOZZLEANDTHEWORKPIECEISTOOLARGE2INTHEUPPERHALFOFTHECUTTINGSECTION,ACUTADVANCEAMOUNTSEEFIGURE921PHENOMENONACUTNEARTHEUPPEREDGE,THEFORMATIONOFACERTAINDEGREEOFADVANCEAMOUNTREASONS1CUTTINGTORCHISNOTPERPENDICULARTOTHECUTTINGDIRECTION,CUTTINGNOZZLECLOGGINGORDAMAGETHEWINDLINEBLOCKEDDETERIORATEPHENOMENONTHESECTIONCLOSETOTHECUTTINGEDGEOFACUTAHEADTOOMUCHREASONSCUTTINGNOZZLECLOGGINGORDAMAGE,THEWINDLINEBLOCKEDDETERIORATIONTORCHVERTICALORCUTTINGNOZZLE,THEWINDLINEISNOTRIGHT,TILT4DROSSONTHECUTTINGSECTIONORTHELOWEREDGEOFDIFFICULTTOREMOVETHEDROSS1THELOWEREDGEOFTHEDROSSSEEFIGURE923PHENOMENONTHELOWEREDGEOFTHECUTTINGSECTIONTOPRODUCEACONTINUOUSDROSSREASONSCUTTINGSPEEDISTOOFASTORTOOSLOW,THECUTTINGNOZZLENUMBERISTOOSMALL,CUTTINGOXYGENPRESSUREISTOOLOW2PREHEATINGFLAMEGASEXCESSSTEELSURFACEOXIDERUSTORUNCLEAN3CUTTINGHEIGHTBETWEENTHENOZZLEANDTHEWORKPIECEISTOOLARGE,TOOPREHEATINGFLAME2CUTTINGSECTIONDROSSPHENOMENONTHEDROSSONTHECUTTINGSECTION,ESPECIALLYINTHELOWERHALFOFTHEDROSSCAUSETHECONTENTOFALLOYCOMPOSITIONISTOOHIGH5CRACKPHENOMENONAVISIBLECRACKONTHECUTTINGSECTION,ORPULSATIONINTHECUTTINGSECTIONNEARINTERNALCRACK,ORJUSTCRACKSCANBESEENINCROSSSECTIONREASONSTHEAMOUNTOFCARBONORALLOYCOMPOSITIONCONTAININGTOOHIGH,THEUSEOFWARMUPCUTTINGMETHOD,THEPREHEATINGTEMPERATUREOFTHEWORKPIECEISNOTENOUGH,THETHEWORKPIECECOOLINGTIMEISTOOFAST,THEMATERIALWORKHARDENING中文译文数控火焰气割的基本常识(一)气割的基本工作原理及气割的过程利用气体火焰的热能将工件切割处预热到一定温度后,喷出高速切割氧流,使其燃烧并放出热量实现切割的方法,叫气割。氧气切割过程有下列三个阶段1、预热气割开始时,利用气体火焰氧乙炔焰、氧丙烷焰将工件待切割处预热到该种金属材料的燃点对于低碳钢约为11001150。2、燃烧喷出高速切割氧流,使已达燃点的金属在氧流中激烈燃烧。3、吹渣金属燃烧生成的氧化物被氧流吹掉,形成切口,使金属分离,完成切割过程。(二)气焊、气割用设备的组成气焊、气割用设备由氧气瓶、氧气减压器、乙炔瓶乙炔发生器、乙炔减压器、回火保险器、焊炬割炬和橡胶管等组成。(三)什么样的割口是好的切割后的割口面中间泛白没有疤痕割口不带废渣没有烧边现象(四)可以气割的金属应符合下述条件1)金属氧化物的熔点应低于金属熔点。是一些常用的金属及其氧化物的熔点。2)金属与氧气燃烧能放出大量的热,而且金属本身的导热性要低。符合上述气割条件的金属有纯铁、低碳钢、中碳钢和低合金钢以及钛等。其它常用的金属如铸铁、不锈钢、铝和铜等,必须采用特殊的氧燃气切割方法或熔化方法切割。对于8MM以下的板材,不易采用数控气割。数控火焰切割气割精度是指被切割完的工作几何尺寸与其图纸尺寸对比的误差关系,切割质量是指工件切割断面的表面粗糙度、切口上边缘的熔化塌边程度、切口下边缘是否有挂渣和割缝宽度的均匀性等。一、影响钢板火焰切割质量的三个基本要素(气体、切割速度、割嘴高度)气体(氧气,可燃性气体,火焰的调整)氧气氧气是可燃气体燃烧时所必须的,以便为达到钢材的点燃温度提供所需的能量;另外,氧气是钢材被预热达到燃点后进行燃烧所必须的。切割钢材所用氧气必须要有较高的纯度,一般要求在995以上,一些先进国家的工业标准要求氧气纯度在997以上。氧气纯度每降低05,钢板的切割速度就要降低10左右。如果氧气纯度降低081,不仅切割速度下降1520,同时,割缝也随之变宽,切口下端挂渣多并且清理困难,切割断面质量亦明显劣变,气体消耗量也随着增加。显然,这就降低了生产效率和切割质量,生产成本也就明显地增加了。采用液氧切割,虽然一次性投资大,但从长远看,其综合经济指标比想象的要好得多。气体压力的稳定性对工件的切割质量也是至关重要的。波动的氧气压力将使切割断面质量明显劣变。气压压力是根据所使用的割嘴类型、切割的钢板厚度而调整的。切割时如果采用了超出规定数值的氧气压力,并不能提高切割速度,反而使切割断面质量下降,挂渣难清,增加了切割后的加工时间和费用。2)可燃性气体火焰切割中,常用的可燃性气体有乙炔、煤气、天然气、丙烷等,国外有些厂家还使用MAPP,即甲烷乙烷丙烷。一般来说,燃烧速度快、燃烧值高的气体适用于薄板切割;燃烧值低、燃烧速度缓慢的可燃性气体更适用于厚板切割,尤其是厚度在200MM以上的钢板,如采用煤气或天然气进行切割,将会得到理想的切割质量,只是切割速度会稍微降低一些。相比较而言,乙炔比天然气要贵得多,但由于资源问题,在实际生产中,一般多采用乙炔气体,只是在切割大厚板同时又要求较高的切割质量以及资源充足时,才考虑使用天然气。(3)火焰的调整通过调整氧气和乙炔的比例可以得到三种切割火焰中性焰(即正常焰),氧化焰,还原焰。正常火焰的特征是在其还原区没有自由氧和活性碳,有三个明显的区域,焰芯有鲜明的轮廓(接近于圆柱形)。焰芯的成分是乙炔和氧气,其末端呈均匀的圆形和光亮的外壳。外壳由赤热的碳质点组成。焰芯的温度达1000。还原区处于焰芯之外,与焰芯的明显区别是它的亮度较暗。还原区由乙炔未完全燃烧的产物氧化碳和氢组成,还原区的温度可达3000左右。外焰即完全燃烧区,位于还原区之外,它由二氧化碳和水蒸气、氮气组成,其温度在12002500之间变化。氧化焰是在氧气过剩的情况下产生的,其焰芯呈圆锥形,长度明显地缩短,轮廓也不清楚,亮度是暗淡的;同样,还原区和外焰也缩短了,火焰呈紫蓝色,燃烧时伴有响声,响声大小与氧气的压力有关,氧化焰的温度高于正常焰。如果使用氧化焰进行切割,将会使切割质量明显地恶化。还原焰是在乙炔过剩的情况下产生的,其焰芯没有明显的轮廓,其焰芯的末端有绿色的边缘,按照这绿色的边缘来判断有过剩的乙炔;还原区异常的明亮,几乎和焰芯混为一体;外焰呈黄色。当乙炔过剩太多时,开始冒黑烟,这是因为在火焰中乙炔燃烧缺乏必须的氧气造成的。预热火焰的能量大小与切割速度、切口质量关系相当密切。随着被切工件板厚的增大和切割速度的加快,火焰的能量也应随之增强,但又不能太强,尤其在割厚板时,金属燃烧产生的反应热增大,加强了对切割点前沿的预热能力,这时,过强的预热火焰将使切口上边缘严重熔化塌边。太弱的预热火焰,又会使钢板得不到足够的能量,逼使减低切割速度,甚至造成切割过程中断。所以说预热火焰的强弱与切割速度的关系是相互制约的。一般来说,切割200MM以下的钢板使用中性焰可以获得较好的切割质量。在切割大厚度钢板时应使用还原焰预热切割,因为还原焰的火焰比较长,火焰的长度应至少是板厚的12倍以上。2切割速度钢板的切割速度是与钢材在氧气中的燃烧速度相对应的。在实际生产中,应根据所用割嘴的性能参数、气体种类及纯度、钢板材质及厚度来调整切割速度。切割速度直接影响到切割过程的稳定性和切割断面质量。如果想人为地调高切割速度来提高生产效率和用减慢切割速度来最佳地改善切割断面质量,那是办不到的,只能使切割断面质量变差。过快的切割速度会使切割断面出现凹陷和挂渣等质量缺陷,严重的有可能造成切割中断;过慢的切割速度会使切口上边缘熔化塌边、下边缘产生圆角、切割断面下半部分出现水冲状的深沟凹坑等等。通过观察熔渣从切口喷出的特点,可调整到合适的切割速度。在正常的火焰切割过程中,切割氧流相对垂直的割炬来说稍微偏后一个角度,其对应的偏移叫后拖量。速度过低时,没有后拖量,工件下面割口处的火花束向切割方向偏移。如提高割炬的运行速度,火花束就会

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号