Vertical Turning Center of NC.doc

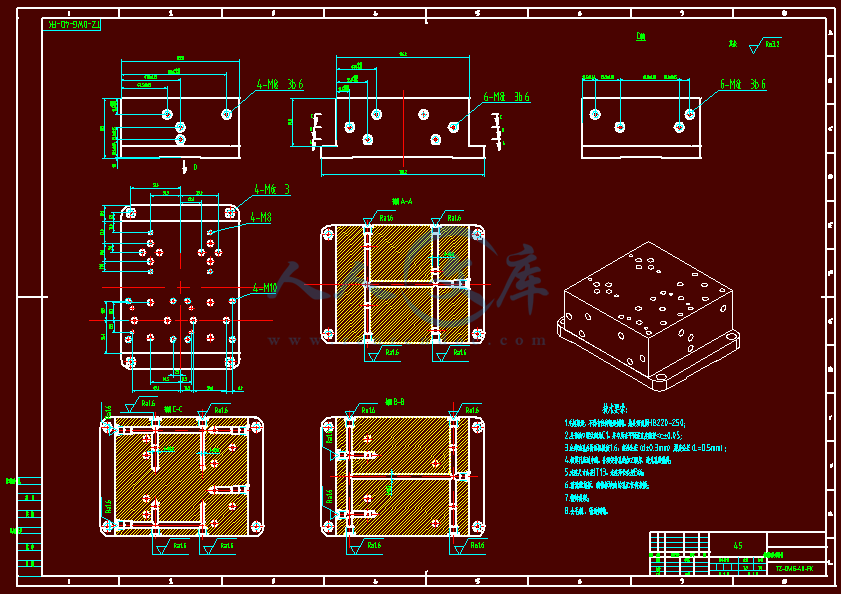

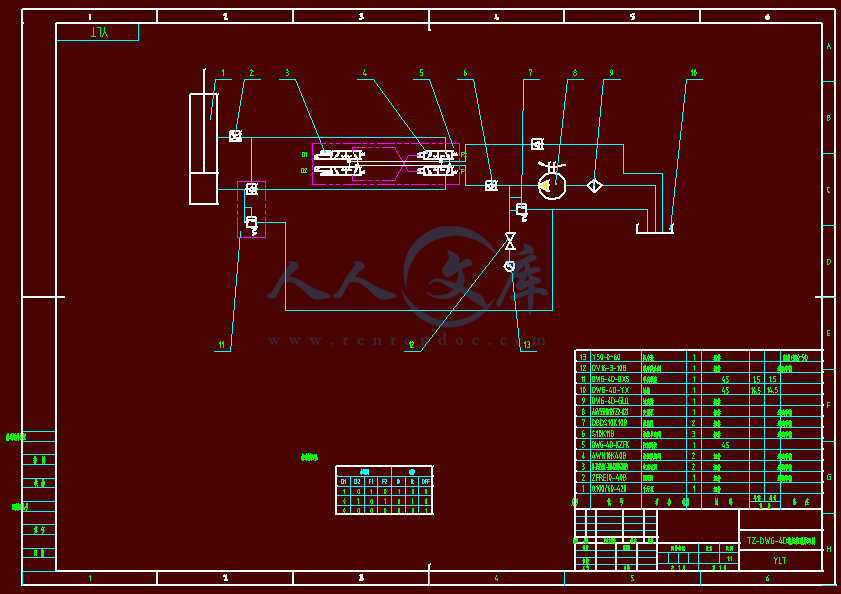

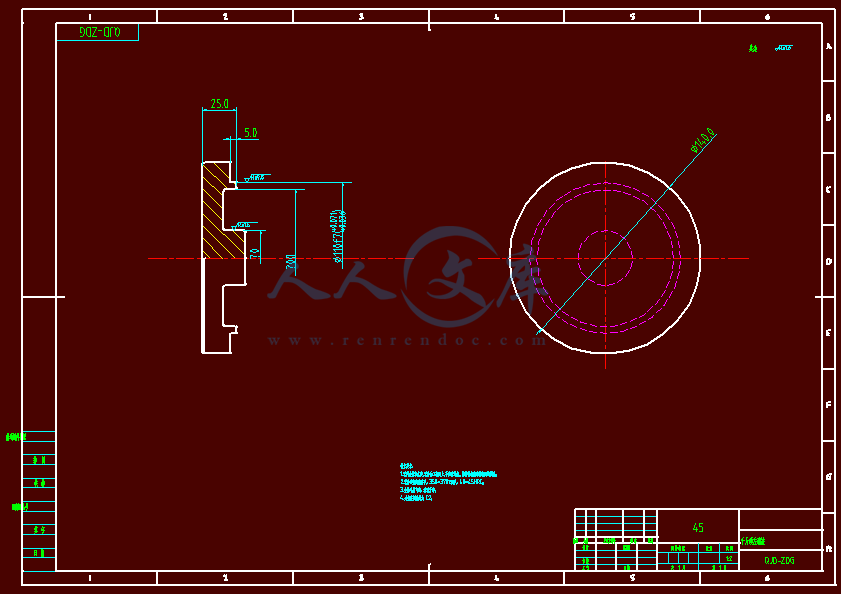

DWG-4D推弯式小型液压弯管机设计(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:9596627

类型:共享资源

大小:2.03MB

格式:ZIP

上传时间:2018-03-16

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

dwg

推弯式

小型

液压

弯管

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

1VERTICALTURNINGCENTEROFNCNEWSINUMERIK802DCNCSYSTEMONTHEUSEOFMORETHAN10YEARSOFSKIQ16CNCBVERTICALTURNINGCENTEROFNC,NCMACHINETOOLPOWERFULFEATURESGREATLYBROADENEDTHESCOPEOFMACHININGPARTS,ANDBETTERENSURINGTHEPROCESSINGOFPARTSTHECONSISTENCYANDQUALITYOFPRODUCTSTHISARTICLEWASTHESECONDSINUMERIKNCAPPLICATIONESSAYACTIVITIESANDTHETRANSFORMATIONOFAPRIZESECONDPRIZEKIQ16CNCBVERTICALTURNINGCENTERINTHECZECHHULINCOMPANIESINTHE1990SMANUFACTURE,USEFANUCBASK6TCNCSYSTEMSINCETHEMACHINEHADBEENINUSEFORMORETHAN10YEARS,ANDTHENCSYSTEMUPGRADING,BASK6TFANUCCNCSYSTEMHASBEENSHUTDOWN,SYSTEMBOARDOFAGING,EXPENSIVESPAREPARTSANEWCNCMACHINETOOLSTOTRANSFORMTHESYSTEMISIMPERATIVESOTHATTHEMACHINECANRESTOREVITALITY,ANDGIVEBETTERPLAYTOTHEPOTENTIALOFMACHINETOOLSTRANSFORMATIONPROGRAMMEDEVELOPMENTTHEORIGINALFULLFEATUREDMACHINE,INCLUDINGSPINDLETABLEANDTHEROTATIONAXISMILLINGCAMPAIGN,X,ZAXISCOORDINATESOFMOVEMENT,15KNIVESINAKNIFELIBRARYSYSTEMS,ANDSUCHASTHECOOLINGSYSTEM,HYDRAULICSYSTEM,LUBRICATIONSYSTEM,PAIXIESYSTEMFUNCTIONALMACHINESPINDLEAXISANDMILLINGBYDCANDDCMOTORSPEEDREGULATORXANDZAXISALSOCOORDINATESBYDCSERVOMOTORANDDCSERVOGOVERNORTHEKNIFEUSEDORDINARYTHREEPHASEASYNCHRONOUSACMOTORFROMTHEFIVEBINARYCAMPOSITIONINGTHEMECHANICALPARTOFTHEMACHINEALLGOODMECHANICALPROPERTIESOFSTABILITY,ACCURACYFAIRANDNORMALHYDRAULICSYSTEM,THEPARTOFTHECAPITALREMAINUNCHANGEDNCSYSTEMANDTHEREPLACEMENTOFELECTRICALCONTROLPART,BYSIEMENSSINUMERIK802DCNCSYSTEMXANDZAXESANDKNIVESCOORDINATESTHESERVODRIVESYSTEMUSESSIIMODRIVE611UEVARIABLEFREQUENCYDRIVESYSTEMANDAFK7SERVOMOTOR,ENCODERPULSECHOSENASALOCATIONDETECTIONDEVICES,DIGITALSERVODRIVESYSTEMTOACHIEVECLOSEDLOOPCONTROLANDMILLINGSPINDLEAXISDRIVESYSTEMBYTHEBRITISHCOMPANYS590EUROTHERMSERIESDCMOTORSPEEDCONTROLDEVICEMACHINECONTROLOFOTHERELECTRICALLINES,THEREPLACEMENTOFELECTRICALCONTROLDEVICESTOENSURETHATALLKINDSOFMACHINECONTROLFUNCTIONANDOPERATIONOFTHEREALIZATIONOFTHE2ELECTRICALCONTROLMACHINETOOLSGUARANTEEALONGTERMRELIABLEWORKAPARTFROMINCREASINGMCPMACHINECONTROLPANEL,WEMUSTALSOREDESIGNEDMACHINEOPERATORPANELWITHALLTYPESOFMACHINEFUNCTIONBUTTONSANDLIGHTSNCSYSTEMANDTHESERVODRIVESYSTEMCOORDINATESSIEMENSSINUMERIK802DCNCSYSTEMISALLCNC,PLC,HMIANDCOMMUNICATIONSTASKSINTEGRATION,ISBASEDONTHENCSYSTEMOFPROFIBUSMAINTENANCEFREEHARDWAREINTEGRATIONPROFIBUSINTERFACEUSEDTODRIVEANDI/OMODULEANDINSTALLEDASPEEDOFTHEOPERATIONPANELSINUMERIK802DCNCCONTROLSYSTEMX,ZAXESANDKNIVESTOTHETHREEFIGURESINTOASPINDLEAXISANDTHEMACHINEUSEDTWOI/OMODULESANDMACHINEOPERATORPANELPP72/48MCPTOOLBOX802DUSEINPROGRAMMINGTOOLPLC802SOFTWAREDEVELOPMENTPLCCONTROLPROCEDURES,CALLTHESUBROUTINELIBRARYPLCSBR32PLCINIPLCINITIALIZATION,SBR33EMGSTOPEXIGENCYSTOPPROCESSING,TRANSMISSIONSBR34MCP802DMACHINECONTROLPANELCORRESPONDINGI/OSTATUS,NCKSBR38MCPMCPMACHINECONTROLPANELSIGNAL,SIGNALSENTTOTHEOPERATIONPANELHMINCKINTERFACE,SBR39HANDWHLFROMTHEOPERATIONPANELHMIINTHEMACHINECOORDINATESORWORKPIECECOORDINATESYSTEMSELECTIONHANDWHEEL,SBR40AXISCTLFEEDSPINDLEAXISANDENABLECONTROLTHESUBROUTINEISTHESTANDARDLATHECONTROLPROCEDURES,ANDSODIFFERENTFROMTHEACTUALSITUATIONOFTHEMACHINE,THEDIGITALKNIFEAXIS,ANINCREASEOFTHENUMBEROFDIGITALAXISINTHEMACHINECONTROLPANELANDFEEDAXISANDTHESPINDLECANCONTROLSUBROUTINEWILLBEDONEINCERTAINMODIFICATIONSVERTICALTURNINGCENTERUNLIKEORDINARYHORIZONTALLATHE,COORDINATESADIFFERENTDIRECTION,ITISALSONECESSARYTODOSUBROUTINEAMENDEDACCORDINGLYSIIMODRIVE611UEVARIABLEFREQUENCYDRIVESYSTEMISAFUNCTIONOFTHEDRIVESYSTEMCANBECONFIGUREDWITHSINUMERIK802DCNCSYSTEMCONSTITUTESANIDEALCOMBINATIONSIIMODRIVE611UEVARIABLEFREQUENCYDRIVESYSTEMINTHEMACHINETOMEETTHEDYNAMICRESPONSEANDSPEEDADJUSTMENTRANGEANDROTATIONACCURACYCHARACTERISTICSOFTHEREQUIREMENTTOUSEMODULARDESIGNCANBEOPTIMIZEDTOBESTINDEPENDENTSTATEDEBUGGINGCANDRIVEONAPCUSINGSIMOCOMUORUSEOFTHEFRONTOFTHEDRIVERMODULESFORDISPLAYANDKEYBOARDSIMOCOMUCANBESETUSINGDRIVESANDMOTORSANDPOWERMODULESMATCHINGTHEBASICPARAMETERSOFACTUALUNDERSERVO3MOTORDRIVEMECHANICALPARTS,THESIIMODRIVE611UESPEEDCONTROLLERFORAUTOMATICOPTIMIZATIONOFTHEPARAMETERSCANMONITORTHEOPERATIONALSTATUSOFDRIVERS,INCLUDINGACTUALMOTORCURRENTANDTHEACTUALTORQUEAXISMILLINGSPINDLEANDDRIVESYSTEMANDMILLINGSPINDLEAXISDRIVESYSTEMUSINGTHEBRITISHCOMPANYS590EUROTHERMSERIESDCMOTORSPEEDCONTROLDEVICE590SERIESOFDCMOTORSPEEDCONTROLDEVICEASSUPPORTINGANDCONTROLEQUIPMENTINSTALLEDINTHESTANDARDBOXCOMPONENTSANDDESIGNAC380VCONTROLDEVICESUSINGTHESTANDARDTHREEPHASEVOLTAGE,PROVIDINGDCOUTPUTVOLTAGEANDCURRENTFORTHEARMATUREANDEXCITING,APPLICABLETODCMOTORCONTROLANDPERMANENTMAGNETMOTOR590SERIESOFDCMOTORSPEEDDEVICEISUSEDTOACHIEVE32BITMICROPROCESSOR,HASMANYADVANCEDFEATURESCOMPLEXCONTROLALGORITHMSSTANDARDSOFTWAREMODULESANDSOFTWARECONFIGURATIONCANCONTROLCIRCUITINTEGRATIONOFTHESERIALLINK,ANDNCTRANSMISSIONDEVICESOROTHERCOMMUNICATIONSSYSTEMS,ADVANCEDTOAPROCESSSYSTEMAXISMILLINGSPINDLEMOTORANDNOTREPLACED,THEORIGINALANALOGVOLUMECONTROLTHESPINDLEMOTORANDNONSPINDLEBETWEEN11DIRECTCONNECT,SPINDLESIEMENSINSTALLEDONTHE5000LINETTLPULSEINCREMENTALENCODERSIIMODRIVE611UEBUSWILLADDRESSTHEBIAXIAL12AFEEDCHANNELMODULEWITHTHESPINDLE,SETASTACKAXISTHROUGHTHESINUMERIK802DCNCSYSTEMPARAMETERSETTINGS,THEUSEOFSIMOCOMUDRIVERDEBUGGINGTOOLSADJUSTMENTSIIMODRIVE611UEBUSCONFIGURATIONPARAMETERSANDANALOGOUTPUT,ANALOGOUTPUTINTERFACEFORAGIVENOUTPUTSPINDLESPEED10V,DIGITALOUTPUTCANBEUSEDTOSIMULATETHESPINDLECONTROL,WSGINTERFACEUSEDTOCONNECTASPINDLESPEEDENCODERFEEDBACK,ANDCOMPLETECONTROLOFSPINDLECONFIGURATIONKNIFELIBRARYSYSTEMKNIFEBECAUSETHEORIGINALSYSTEMUSEDFORGENERALMOTORS,MECHANICALTRANSMISSIONRATIO1360THEMECHANICALSTRUCTUREOFSPECIALKNIVES,KNIFEDISCINTHEVERTICALZAXISRAM,ITSDIRECTIONANDTHEBAXISROTATIONDIRECTIONOFTHESAMEAFTERTRANSFORMATION,USINGSIIMODRIVE611UEANDAVARIABLEFREQUENCYDRIVESYSTEMFK7SERVOMOTOR,AKNIFETOTHENCCOORDINATEAXIS,ASINCREASEDPULSEENCODERPOSITIONDETECTIONDEVICES,DIGITALSERVODRIVESYSTEMTOACHIEVECLOSEDLOOPCONTROL4THEREMOVALOFTHEORIGINALFIVEBINARYCAMPOSITIONINGMECHANISMASTHEKNIFEAFTERTHEFULLGRAVITYKNIVES,KNIFETHEDISKCANNOTACHIEVEBALANCEGRAVITYALTHOUGHTHEMOVEMENTCANKNIFEPRECISEPOSITIONING,BUTTHEREASONSFORTHEDEVIATIONOFTHEACTUALLOCATION,LOCATIONISSTILLUSEDAFTERPOSITIONINGCOORDINATESMOVEMENTPININSERTEDACCURATEPOSITIONINGMETHODSTHESPECIALMACHINETOOLCHANGEPROCESS,WITHDIFFERENTVERTICALLATHEGENERALPLCCONTROLATCPROCEDURESARECOMPLETEDTHEFOLLOWINGPROCESSWHENTHEKNIFEWITHXANDZAXISMOVEMENTASAFEPLACE,ZAXIS,NOKNIFE,AMACHINETOOLRELAXEDSTATEPLCCONTROLMANIPULATOROUTTOPROMOTEVERTICALLATHETOOLTOZAXISMACHINETOOLAFTERTHECOMPLETIONOFTHATPROCESSFINISHEDWITHKNIVESSHIRKINGKNIFE,XANDZAXISMOVEMENTASAFEPLACE,ZAXIS,AKNIFE,AMACHINETOOLCLAMPINGSTATEPLCCONTROLMECHANICALHANDOUTSTRETCHED,THISTOOLTORELAX,MANIPULATORDRIVENVERTICALLATHETOOLRETRACTABLEKNIFEWASBACKON,MACHINETOOL,KNIFEDISPOSALPROCESSISCOMPLETESINUMERIK802DCNCSYSTEMSUPPORTFORTHEUSEOFMCODEORUSERCALLSTCODECYCLECANBEUSEDFORMACHINETOOLEXCHANGEBYSETTINGPARAMETERSMACTIVATIONCODE,THEUSEOFTHEPROCEDURECALLEDM06FIXEDEXCHANGECYCLEENFORCEMENTTOOLPROCEDURESFORTHEPREPARATIONOFUSERSCYCLETHROUGHEACHALGORITHMTODETERMINETHEKNIFEKNIFEAXISBAXISROTATIONANGLE,USEOFTHEDEFINITIONOFMATCACTIVATIONPLCLOGICPLCNCSYSTEMWILLBE“READTOPROHIBIT“BUYSIGNALSOTHATTHECYCLEOFAFIXEDSTOPATCWILLBEMECHANICALMOVEMENTSMCODEWITHACUSTOMIMPLEMENTATIONOFDECOMPOSITION,SUCHASM12DUMPINGKNIVES,M13WITHKNIVESATCCOMPLETED,THEPLCWILLBE“READPROHIBITS“RESETSIGNALSOTHATTHEFIXEDCYCLECONTINUEINTHEFIXEDCYCLESHOWNINTHEPREPARATIONOFCNCSYSTEMPROMPTSONTHESCREENTOATCBYSTEPMACHINEDEBUGGINGNCSYSTEMCONNECTINGTHEVARIOUSCOMPONENTSAFTERTHECOMPLETIONOFTHEINSTALLATION,COMMISSIONINGSTARTPLCCONTROLPROCEDURESSINCETHEEQUIPMENTISVERTICALLATHE,UNLIKEPLCSUBROUTINELIBRARYINTHELATHEAPPLICATIONS,ITMUSTADDRESSTHESPECIFICCONDITIONSOFTHEMACHINETOAMENDPLCSUBROUTINESETTHEKNIFEFORBAXIS,ANDTHESTANDARDPROCEDURESONLYXANDZAXIS,ANDTHE5NEEDTOINCREASETHEBAXISINTHEMCPPLUSORMINUSADDINGBAXISDIRECTIONTOMOVETHEBUTTON,THENEEDFORSBR34,SBR38,SBR40SUCHASSUBROUTINEBECAUSEITISVERTICALLATHE,X,ZAXISDIRECTIONTOMOVETHEPLUSORMINUSKEYMCPANDSETDIFFERENTSTANDARDSALSONEEDSTOBEREVISEDACCORDINGTOMCPONTHEMACHINENEEDTODESIGNUSERDEFINEDKEYS,SUCHASHYDRAULICLAUNCH,HYDRAULICSTOP,RELAXBEAMS,ANDLIGHTBEAMSLOCKINGDESIGNMCPANDMACHINEOPERATORPANELSPLCCONTROLPROCEDURESANDDEBUGGINGFEATURESTOACHIEVEFULLYTESTEDBYTHEUSEOFTHESUBROUTINELIBRARYOFSUBROUTINESTOENSURETHATTHESUBROUTINEWITHTHEFUNCTIONSOFPLCCONTROLPROCEDURESLINKED,ARECORRECTALARMUSERSEDITPLCDESIGN,MACHINEPARAMETERSPROVIDEDBYSETTINGTHEPROPERTIESOFEACHALARMMACHINESETBASICPARAMETERSINCLUDEPROFIBUSBUSCONFIGURATION,POSITIONINGSERVODRIVEMODULE,THESPINDLEAXISPOSITIONCONTROLANDCOORDINATEENABLERATIOANDTRANSMISSIONPARAMETERSINTHEMACHINEUNDERGONEASERIESOFADJUSTMENTS,NCMACHINETOOLSHASBASICALLYCANBEINNORMALOPERATIONBUTTOMAKETHEWHOLESYSTEMINTOTHEBESTRUNNINGSTATE,BUTALSOASYSTEMPARAMETEROPTIMIZATIONWORKWHENTHENORMALOPERATIONOFTHESYSTEMASAWHOLE,SHOULDALSOCOORDINATEAXISCORRESPONDINGPARAMETERSSUCHASOPTIMALADJUSTMENT,SUCHASSPEED,GAIN,ANDTHEACCELERATIONOFTHECONTROLPARAMETERS,INORDERTOENABLEACCESSTOTHEBESTSYSTEMOFTHESTATEINTHENORMALOPERATIONOFMACHINETOOLS,MACHINETOOLSSHOULDALSOMECHANICALPARTS,SUCHASTHEVERTICALAXIS,THEREVERSEGAP,TRANSMISSIONPRECISIONMEASUREMENTADJUSTMENTS,THEMECHANICALSYSTEMTOTHEBESTOFCOURSE,THEMECHANICALADJUSTMENTS,SHOULDALSOFINETUNESYSTEMPARAMETERSTOENABLETHEMACHINERUNNINGINTHEBESTCONDITIONWHENTHEPARTOFTHEADJUSTMENTAFTERTHEENDOFTHEMACHINETHROUGHMECHANICALPRECISIONMEASUREMENT,CNCMACHINETOOLSNEEDEDFORTHEPOSITIONCONTROLSYSTEMFORPRECISIONCOMPENSATIONREVERSECLEARANCECOMPENSATIONFORPOSITIONFEEDBACKENCODERMOUNTEDONTHELEADSCREWDRIVEHEAD,ALTHOUGHTHESLOWDOWNINBINSELIMINATEMECHANICALPARTOFTHEREVERSEGAP,BUTTHEREVERSEITSELFLEADSCREWGAPSTILLEXISTS,THEVALUEOFTHECORRESPONDINGINPUTSYSTEMPARAMETERS,EACHREVERSEOPERATION,THESYSTEMOFCOMPENSATIONBECAUSELONGTERMUSEOFTHELEADSCREWWEAR,THELOCATIONOFTHELEADSCREWPITCHANDWILLHAVEANOMINAL6VALUEERROR,TOIMPROVEPOSITIONINGACCURACY,THESYSTEMPARAMETERSCOMPENSATIONACCORDINGTOTHEPRODUCTIONNEEDSOFUSERSWITHTHEPROCESSOFTRANSFORMINGMACHINETOOLS,FROMSINUMERIK802DCNCSYSTEMFORTHEANALYSIS,DESIGNANDIMPLEMENTATIONATPRESENT,AGAINSTTHEMACHINEMECHANICAL,ELECTRICAL,VARIOUSASPECTSOFTHESYSTEMTRANSFORMATION,INSTALLATION,COMMISSIONINGWORKHASBEENCOMPLETED,SAMPLESWEREPROCESSEDFULLYACHIEVETHEDESIREDRESULTSMACHINETOOLHASBEENTRANSFORMEDINTONORMALUSE,THEPROGRESSIVECOMPLETIONOFANUMBEROFMACHININGTASKSFROMTHEUSEOFTHEMACHINERUNNINGTHESTATE,THEMODIFIEDMACHINECOMPAREDWITHTHEORIGINALMACHINE,GREATLYENHANCINGTHEFUNCTIONALITY,AHIGHDEGREEOFAUTOMATIONNCPOWERFULFEATURESGREATLYBROADENEDTHESCOPEOFMACHININGPARTSBETTERGUARANTEETHECONSISTENCYOFTHEPARTSPROCESSING,ANDPRODUCTQUALITYATTHESAMETIMEAHIGHDEGREEOFAUTOMATIONHASGREATLYREDUCEDTHELABORINTENSITYOPERATIONSWORKERS,BUTINTHEOPERATIONOFTHEOVERALLQUALITYOFWORKERSHASALSOPUTFORWARDHIGHERREQUIREMENTSFROMTHEMACHINEOPERABLE,COMPACTSTRUCTUREREASONABLE,DISPLAYS,SWITCHESANDINDICATOROFTHELAYOUTMORESUITABLEFORTHEUSEOFOPERATORSATTHESAMETIMEINCREASEDBYASMALLHANDHELDUNITOPERATIONS,INORDERTOOPERATEINDIFFERENTSTATEOFTHEOPERATIONOFAMOREAPPROPRIATECHOICEOFLOCATIONTHEHOISTINGOFTHEENTIREOPERATINGSYSTEM

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

|

2:不支持迅雷下载,请使用浏览器下载

3:不支持QQ浏览器下载,请用其他浏览器

4:下载后的文档和图纸-无水印

5:文档经过压缩,下载后原文更清晰

|

川公网安备: 51019002004831号

川公网安备: 51019002004831号