基于UG的齿轮泵体零件机械工艺规程及铣床夹具的虚拟设计及运动仿真【UG】-[机械毕业设计论文]

收藏

资源目录

压缩包内文档预览:

编号:965123

类型:共享资源

大小:24.94MB

格式:RAR

上传时间:2016-12-31

上传人:木***

认证信息

个人认证

高**(实名认证)

江苏

IP属地:江苏

50

积分

- 关 键 词:

-

基于

ug

齿轮泵

零件

机械

工艺

规程

铣床

夹具

虚拟

设计

运动

仿真

毕业设计

论文

- 资源描述:

-

文档包括:

说明书一份。41页。14600字左右。

任务书一份。

开题报告一份。

计划周记进度检查表一份。

外文翻译一份。

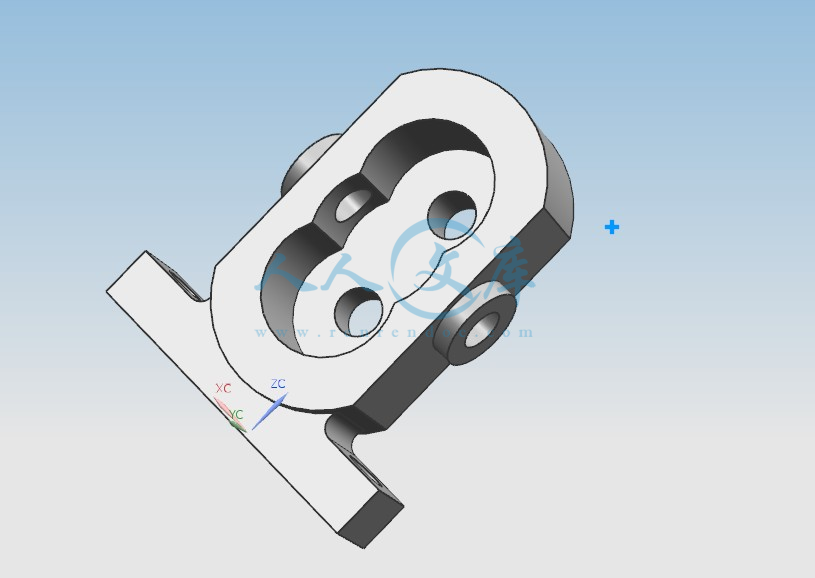

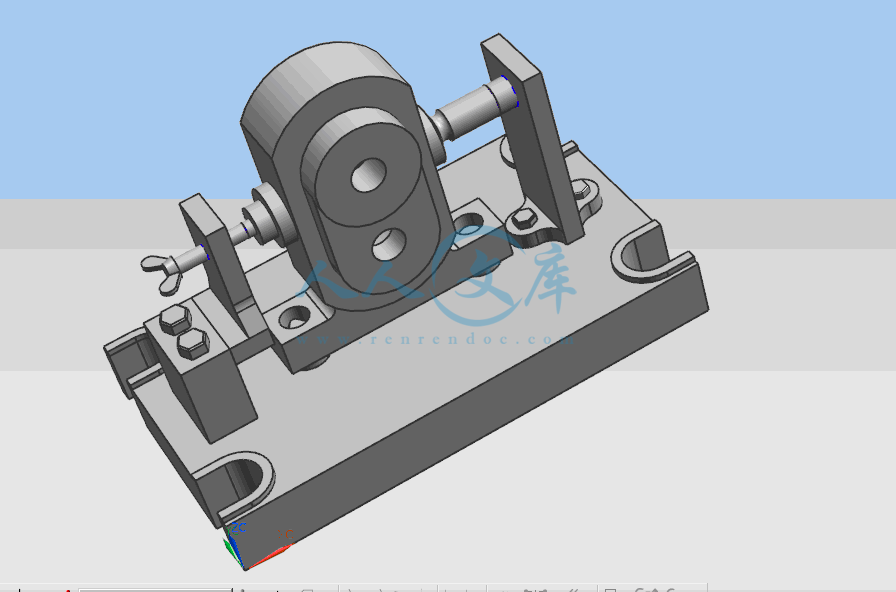

UG图两套。

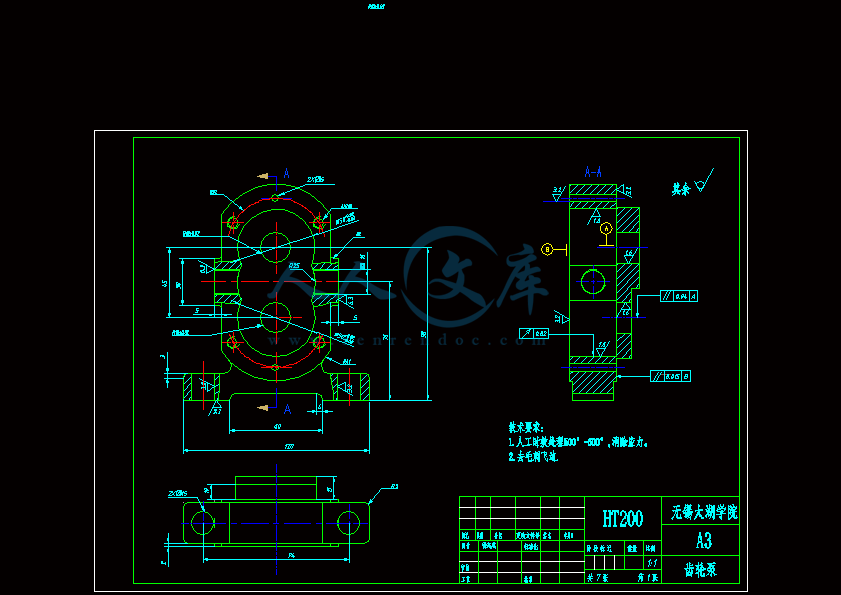

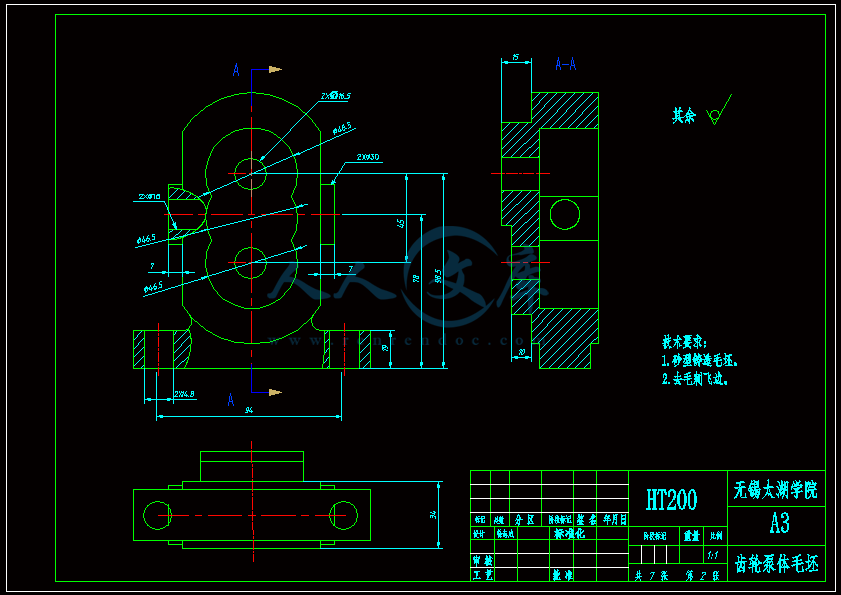

图纸共7张,如下所示

A1-夹具1装配图.dwg

A1-夹具2装配图.dwg

A2-支撑板 .dwg

A3-齿轮泵毛坯.dwg

A3-齿轮泵零件图.dwg

A4-支架1.dwg

A4-支架2.dwg

- 内容简介:

-

1 英文原文 s to of to in a a of of a in of a is is in of a is a is it a in of of on of of If a a to of a of is is If a is on on in a is an of is If in a of a of be if is is a be by a to of or be or be by or in to of In it is to it is of a is is on a it is to it as in is at be by be a up 0 or is In a a of to or be on of of or of be of be in of to of a by a in a of a of to of is to a of of or of of of is of by be as in or as in or of a A 1. it or 2. it 3. it a of in 2 pf of of of be in of be by to of a V) is by of to in at is by of or is in of is of or of on he on an in 11 on a on by a be as or of a is to of as as as a of on to on a to a of on to be by on or in of of of to is by a be by a or in a of be in a or in a to to by to be if is to in be by A is to by on of is be in to to in as as as to of to in or in or in a be at by a a at a of in be it is to it is by by be of or on an to be as or on at by to to be as a on a a he of a in a 3 1、 To 2、 To to 、 To of 4、 To a in he of is to of is in of to a it be of of of be by in so is to be of of is in of is to be is in a is by of on to be if be of be be to of is or be is to of is in of is to of is to of of is by of be or be to to of a on of on be of is by a of to be it is be of in to be of a is to is to to be a on a is on of to in a to of on is is on a be in in to in to of it to a in is in a to be on of is to s of be on a to is a by a a In is is it a In 4 in to in to is at a of or to a at a in a a of is of in of on be to or in a of be by of or is of in of of of by of of if of be to in a of of of or On by or in of is in a to in of to or of or of on be on on an is at of of or at of be if be if be is on of on of is at to is no to of is to a be in a at of to a is by as in of of is by of of or by of in of so it on It is by of of is or in of a of or on is by on of is as In it is to a a to of if to be in to be if at of in a to or to or be is to A of to of or of :3. 5 中文译文 基本的加工工序 切削,镗削和铣削 机床是从早期的埃及人的脚踏动力车床和约翰 们用于为工件和刀具两者提供刚性支撑并且可以精确控制它们的相对位置和相对速度。一般来说,在金属切削中用一个磨尖的楔形工具以紧凑螺纹形的切屑形式从有韧性工件表面上去除一条很窄的金属。切屑是废弃的产品,与其工件相比,它相当短但是比未切削的部分厚度有相对的增加。机器表面的几何形状取决于刀具的形状以及加工过程中刀具的路径 。 不同的加工工序生产出不同几何形状的部件。如果一个粗糙的柱形工件绕中心轴旋转而且刀具穿透工件表面并沿与旋转中心平行的方向前进,就会产生一个旋转面,这道工序叫车削。如果以类似的方式加工一根空心管的内部,则这道工序就叫镗削。制造一个直径均匀变化的锥形外表面叫做锥体车削。如果刀具尖端以一条半径可变的路径前进,就可以制造出象保龄球杆那种仿形表面;如果工件足够短而且支撑具有足够的刚性,仿形表面可以通过用一个垂直于旋转轴的仿形刀具来制造。短的锥面或柱面也可以仿形切削。 常常需要的是平坦的或平的表面。它们可以通过径向车 削或端面车削来完成,其中刀具尖端沿垂直于旋转轴的方向运动。在其他情况下,更方便的是固定工件不动,以一系列直线方式往复运动刀具横过工件,在每次切削行程前具有一定横向进给量。这种龙门刨削和牛头刨削是在刨床上进行的。大一些的工件很容易保持刀具固定不动,而像龙门刨削那样在其下面拉动工件,再每次往复进给刀具。仿形面可以通过使用仿形刀具来制造。 也可以使用多刃刀具。钻削使用两刃刀具,深度可达钻头直径的 5。不管是钻头转动还是工件转动,切削刃与工件之间的相对运动都是一个重要因素。在铣削作业中,有许多切削刃的旋转铣刀 与工件相接合,这种工件相对铣刀运动缓慢。根据铣刀的几何形状和进给的方式,可以加工出平面和仿形面。可以使用水平或垂直旋转轴,工件可以沿三个坐标方向中的任意一个进给。 基本的机床 机床用于以切屑的形式从韧性材料上去除金属来加工特殊几何形状和精密尺寸的部件。切屑是废品,其变化形状从像钢这样的韧性材料的长的连续带状屑到铸铁形成的易于处理、彻底断掉的切屑,从处理的观点来讲,不想要长的连续带状屑。机床完成 5 种基本的金属切削工艺:车削、刨削、钻削、铣削和磨削。其他所有金属切削工艺都是这 5 种基本工艺的变形。例如:镗削是内部 车削;铰削、锥体车削和平底锪孔则修改钻孔,与钻削有关;滚齿与切齿是基本铣削作业;弓锯削和拉削是铣削和磨削的一种形式;而研磨、超精加工、抛光和磨光是磨削和研磨切削作业的各种变化形式。因此,仅有 4 种使用专用可控几何形状的刀具基本机床: 1、车床, 2、刨床, 3、钻床, 4、铣床。磨削工艺形成碎屑,但是磨粒的几何形状不可控制。 不同加工工艺切削的材料的数量和速度却不相同。可能极大,如大型车削作业;或者极小,如磨削和超精加工作业,只有表面高出的点被去除。 机床完成 3 种主要功能: 1、刚性支撑工件或工件夹具以及切削刀具; 2、 提供工件与切削刀具之间的相对运动; 3、提供了一定范围的速度进给,通常每种有 4选择。 切削速度和进给 切削速度、进给量和切削深度是切削加工的 3 个主要变量,其他变量还有工件和工具材料、冷却剂以及切削刀具的几何形状。金属切削的速率和加工所需的功率就决定于这些变量。 切削深度、进给量和切削速度是任何金属切削作业中必须都建立的变量。它们都影响切削力、功率和对金属切

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号