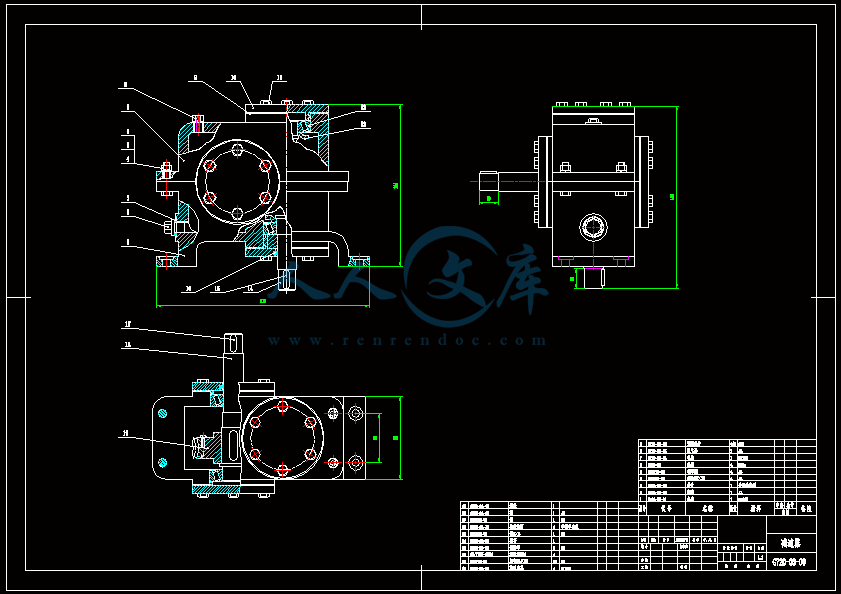

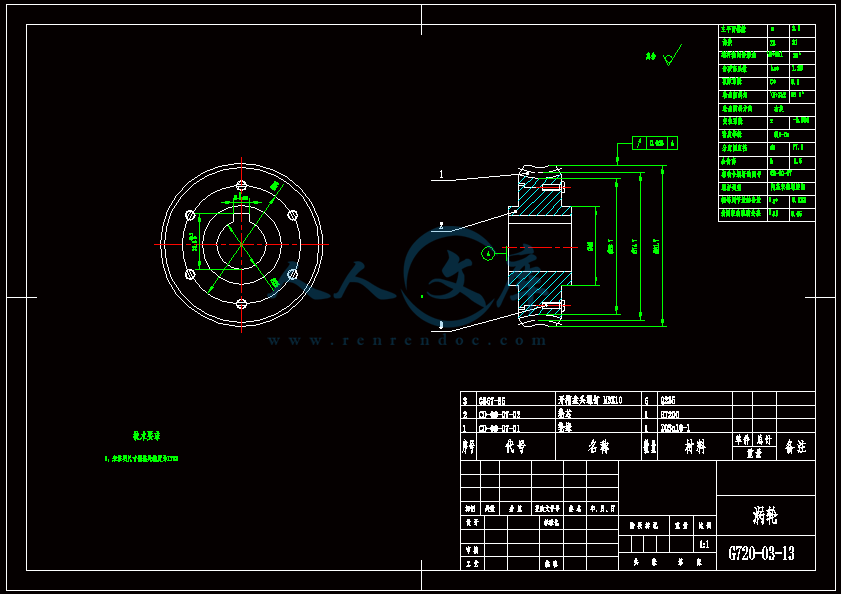

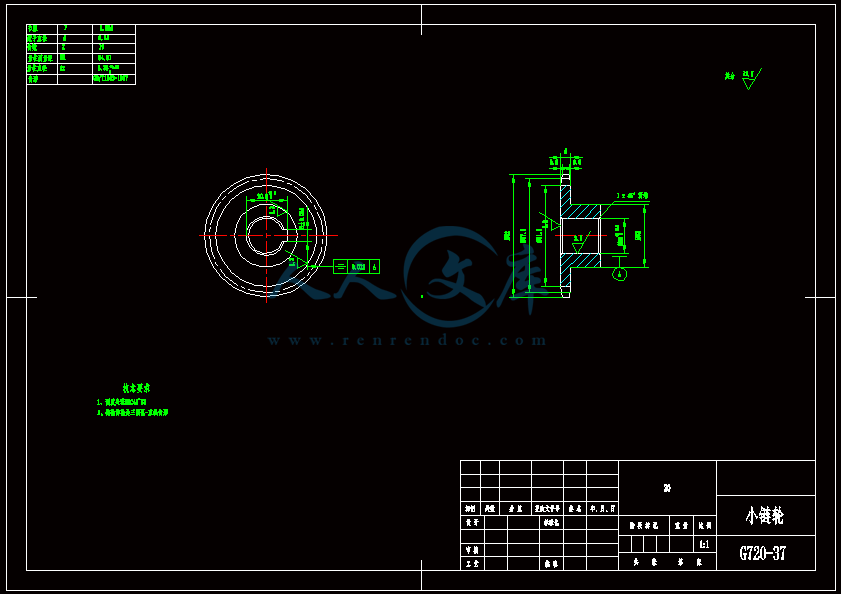

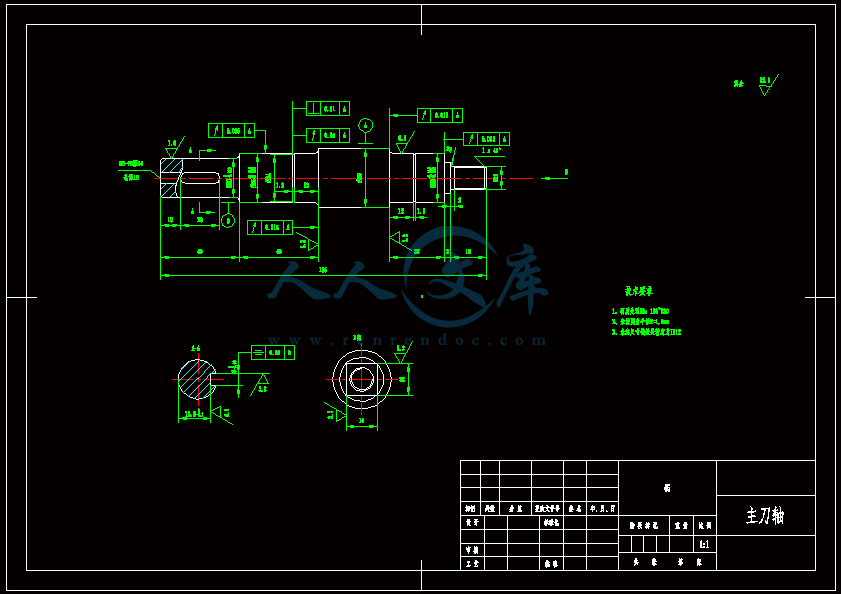

自行式割草机的设计传动部件、罩壳部件设计(含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:9694098

类型:共享资源

大小:1.96MB

格式:ZIP

上传时间:2018-03-21

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

自行

割草机

设计

传动

部件

罩壳

cad

图纸

- 资源描述:

-

- 内容简介:

-

COMPUTERSANDELECTRONICSINAGRICULTURE362002215223COMPUTERVISIONBASEDSYSTEMFORAPPLESURFACEDEFECTDETECTIONQINGZHONGLIA,MAOHUAWANGB,WEIKANGGUA11DEPARTMENTOFINFORMATIONANDELECTRONICENGINEERING,ZHEJIANGUNIVERSITY,HANGZHOU,PEOPLESREPUBLICOFCHINABRESEARCHCENTREFORPRECISIONAGRICULTURE,CHINAAGRICULTURALUNIVERSITY,BEIJING,PEOPLESREPUBLICOFCHINAABSTRACTANOVELAUTOMATEDAPPLESURFACEDEFECTSORTINGEXPERIMENTALSYSTEMBASEDONCOMPUTERIMAGETECHNOLOGYHASBEENDEVELOPEDTHEHARDWARESYSTEMHASTHEADVANTAGEOFBEINGABLETOINSPECTSIMULTANEOUSLYFOURSIDESOFEACHAPPLEONTHESORTINGLINETHEMETHODS,INCLUDINGIMAGEBACKGROUNDREMOVAL,DEFECTSSEGMENTATIONANDIDENTIFICATIONFORSTEMENDANDCALYXAREAS,WEREDEVELOPEDTHERESULTSSHOWTHATTHEEXPERIMENTALHARDWARESYSTEMISPRACTICALANDFEASIBLE,ANDTHATTHEPROPOSEDALGORITHMOFDEFECTDETECTIONISEFFECTIVE2002ELSEVIERSCIENCEBVALLRIGHTSRESERVEDKEYWORDSMACHINEVISIONAPPLESURFACEDEFECT1INTRODUCTIONCHINAISALARGEAGRICULTURALCOUNTRYITSANNUALAPPLEPRODUCTIONISOVER17MILLIONTONSMUCHOFTHESORTINGANDGRADINGPROCESS,HOWEVER,ISSTILLNOTAUTOMATEDHANDINSPECTIONOFFRUITISTEDIOUSANDCANCAUSEEYEFATIGUEITISALSOSUBJECTTOSORTINGERRORSDUETODIFFERENTJUDGMENTBYDIFFERENTPERSONSALTHOUGHSOMEQUALITYINSPECTIONPROCEDURESSUCHASCOLOR,SIZE,ANDSHAPEAREPERFORMEDBYAUTOMATEDSYSTEMSINWESTERNCOUNTRIES,THEAUTOMATIONOFTHEDEFECTSORTINGPROCESSISSTILLACHALLENGINGSUBJECTDUETOTHECOMPLEXITYOFTHEPROBLEMCURRENTLYTHEREARETWOMAINPROBLEMSBLOCKINGTHEIMPLEMENTATIONOFAUTOMATICAPPLEGRADINGONEISHOWTOACQUIRETHEWHOLESURFACEIMAGEOFANAPPLEBYCAMERASATANONLINESPEEDTHEOTHERISHOWTOQUICKLYIDENTIFYTHESTEMANDCORRESPONDINGAUTHOREMAILADDRESSMHWPUBLICBTANETCNMWANG01681699/02/SEEFRONTMATTER2002ELSEVIERSCIENCEBVALLRIGHTSRESERVEDPIIS0168169902000935216QLIETAH/COMPUTERSCMDELECTRONICSINAGRICULTURE362002215223CALYXTOSOLVETHEFIRSTPROBLEM,GROWEANDDELWICHE1996,TAO1996USEDAROLLERCONVEYERSYSTEMTHEDRAWBACKOFTHISMETHODWASTHATTHECAMERAABOVETHECONVEYORCANNOTINSPECTTHETWOENDSIDESOFTHEHORIZONTALAXESOFTHEROLLINGFRUITSFORTHESECONDPROBLEM,THROOPETAL1997DEVELOPEDTWOKINDSOFORIENTINGDEVICESTHESEDEVICESWEREUSEDTOROTATEAPPLESOFDIFFERENTVARIETIESALONGTHESTEMCALYXAXESBUTTHERESULTSSHOWEDTHATTHEVARIETIESTHATWERESUCCESSFULLYORIENTEDWITHONESYSTEMWOULDNOTORIENTUSINGTHEOTHERDEVICEYANG1993USEDSTRUCTUREDLIGHTINGTOIDENTIFYTHESTEMANDCALYXOFAPPLESTHEMAJORPROBLEMWITHTHESTRUCTUREDLIGHTINGISTHEMISCLASSIFICATIONOFLASERLINESONTHEIMAGEWENAADTAO1998SUCCESSFULLYDEVELOPEDADUALCAMERANIR/MIRIMAGINGMETHODFORAPPLEDEFECTRECOGNITIONANDSTEMCALYXIDENTIFICATIONBUTTHEMIRCAMERAISTOOEXPENSIVETOUSEINCHINATHEOBJECTIVEOFTHEWORKDESCRIBEDINTHISPAPERWASTODEVELOPANEXPERIMENTALSYSTEMTHATCANINSPECTFOURSIDESOFEACHAPPLE,SIMULTANEOUSLY,ATONLINETHROUGHPUTOVERTHREETOFOURFRUITSPERSANDTHECORRESPONDINGMETHODSFOREFFECTIVEDEFECTSSEGMENTATIONANDRECOGNITION2SYSTEMSETUPOVERVIEWASYSTEMCAPABLEOFINSPECTINGFOURDIRECTIONSOFEACHAPPLEATONLINETHROUGHPUTWASDEVELOPEDTHESETUPOFTHESYSTEMISSHOWNINFIG1ITCONSISTEDOFAFEEDINGUNIT,ANAPPLEUNIFORMSPACINGUNIT,AMACHINEVISIONSYSTEM,ANDASORTINGCONVEYORTHEBASICFEEDINGCONVEYORTRANSPORTEDTHEAPPLESTOTHEUNIFORMSPACINGCONVEYORTHEN,THEAPPLESWEREFEDTOTHEMACHINEVISIONSYSTEMFORTHEDEFECTQLIETAL/COMPUTERSANDELECTRONICSINAGRICULTURE362002215223217INSPECTIONFINALLY,THEAUTOMATICSORTINGUNITACCOMPLISHEDTHEAPPLEGRADINGOPERATIONTHEMACHINEVISIONSYSTEMINCLUDEDACUPTYPECONVEYOR,ALIGHTINGCHAMBERFORTHEDESIREDSPECTRUMANDLIGHTDISTRIBUTIONFORFRUITILLUMINATION,TWOCAMERAS,ANDANIMAGEGRABBINGCARDWITHFOURINPUTCHANNELSINSERTEDINAMICROCOMPUTERPROCESSORSPEED500MHZASANEXPERIMENTALSYSTEM,THEFRUITFEEDINGSYSTEMANDTHEAUTOMATICSORTINGSYSTEMWERENOTCONSTRUCTEDINTHEFIRSTSTAGEOFTHERESEARCHTOACHIEVEABASICALLYCOMPLETEINSPECTIONOFAPPLESONTHEFRUITSORTINGLINE,TWOIDENTICALMONOCHROMATICCAMERASWEREMOUNTEDABOVEANDBELOWTHECONVEYOR,RESPECTIVELYTHESETUPOFTHEVISIONSYSTEMISSHOWNINFIG2THEIMAGESENSORSINTHECAMERASHADANACTUALRESOLUTIONOF580HORIZONTALAND350VERTICALTVLINESEACHCAMERAWASSYNCHRONIZEDTOANOTHERTIMINGSOURCEANDHADAVARIABLEELECTRONICSHUTTERIDENTICAL85MMFOCALLENGTHCMOUNTLENSESWEREATTACHEDTOTHECAMERAS,WITHINTERFERENCEBANDPASSOPTICALFILTERS840NMATTACHEDTOTHEOUTSIDEOFEACHLENSTHECONVEYORWASCOMPOSEDOFFRUITCUPSWITHOUTBOTTOMSASSHOWNINFIG2TWOMIRRORSWEREFIXEDONBOTHSIDESOFTHECONVEYORTHUSTHECAMERAABOVETHECONVEYORTOOKTHREESIDEVIEWSOFANAPPLE,IETOPANDTWOSIDESTHECAMERABELOWTHECONVEYORTOOKABOTTOMVIEWOFTHEFRUITMOREOVER,THISIMAGINGSYSTEMWASABLETOINSPECTSEVERALAPPLESONTHECONVEYORSIMULTANEOUSLYTHISSCHEMEHADTHEADVANTAGEOFBEINGABLETOINSPECTSIMULTANEOUSLYFOURSIDESOFEACHAPPLEWHILEITWASTRAVELINGONTHECONVEYOR3ALGORITHMDESCRIPTIONTHEALGORITHMDEVELOPEDFORTHESURFACEDEFECTDETECTIONMAINLYINCLUDEDMODULESOFIMAGEPREPROCESSING,DEFECTSEGMENTATION,STEMCALYXRECOGNITION,ANDDEFECTAREACALCULATIONANDGRADINGTHEALGORITHMISSHOWNSCHEMATICALLYINFIG331IMAGEBACKGROUNDREMOVALTHROUGHAMETHODOFSUBTRACTIONTHEIMAGEBACKGROUNDSINTHEMIRRORANDONTHECONVEYORWEREDIFFERENT,SOITWASIMPOSSIBLETOSEGMENTTHEPARTSOFFRUITBYASIMPLETHRESHOLDPROCESSTHEREFORE,ASUBTRACTINGMETHODWASUSED,ASDEPICTEDBELOW218QLIETAL/COMPUTERSANDELECTRONICSINAGRICULTURE362002215223WHEREGX,YISTHEIMAGEAFTERITSBACKGROUNDHASBEENREMOVED,FX,Y)ISTHEORIGINALIMAGE,BX,YISTHEBACKGROUNDIMAGE,ANDTISTHETHRESHOLD32DEFECTSSEGMENTATIONBYUSINGREFERENCEAPPLEIMAGESAPPLESUNDERINSPECTIONHADSUBSTANTIALLYSPHERICALSHAPES,RESULTINGINCURVEDDISTRIBUTEDIMAGEINTENSITYTHISCURVEDDISTRIBUTIONCAUSEDTHEINTENSITYVALUESOFTHENORMALSURFACENEARTHEBOUNDARYTOBELOWERTHANTHEINTENSITYOFTHEDEFECTPATCHESONTHESURFACEOFTHEFRUITITISDIFFICULTTOUSEANYSIMPLEGLOBALTHRESHOLDSEGMENTATIONALGORITHMFORDEFECTEXTRACTIONLOCALADAPTIVEMETHODSCOULDBEUSEDFORDEFECTSEGMENTEXTRACTIONHOWEVER,THEPROCESSINGTIMEPREVENTSTHEIRPRACTICALUSEINREALTIMEFRUITSORTINGOPERATIONSBASEDONTHEREFERENCEIMAGEOFANAPPLE,LIANDWANG1999DEVELOPEDAMETHODTOACCOMPLISHDEFECTSEGMENTATIONFORACURVEDFRUITIMAGEINTHISMETHOD,AREFERENCEFRUITIMAGERFIWASGENERATEDFIRSTANDTHEORIGINALFRUITIMAGEFORINSPECTIONWASTHENNORMALIZEDQLIETAL/COMPUTERSANDELECTRONICSINAGRICULTURE362002215223219TOACHIEVETHENORMALIZEDREFERENCEFRUITIMAGENRFIFINALLYBYSUBTRACTINGNORMALIZEDORIGINALFRUITIMAGENOFIFROMTHENRFIANDTHENBYSIMPLETHRESHOLDPROCESSING,THEDEFECTSCOULDBEEXTRACTEDEASILY33STEMCALYXIDENTIFICATIONBASEDONFRACTALFEATURESANDARTIFICIALNEURALNETWORKDURINGTHEDEFECTINSPECTIONPROCESS,ITISDIFFICULTTODISTINGUISHTHESTEMANDCALYXFROMTRUEDEFECTS,BECAUSETHEYARESIMILARTODEFECTIVESPOTSINTHEIMAGEBASEDONFRACTALDIMENSIONSANDNEURALNETWORKSNN,THEAUTHORSOFTHISPAPERDEVELOPEDANOVELMETHODTODISTINGUISHTHESTEMCALYXCONCAVEAREAFROMTRUEDEFECTS220QLIETAL/COMPUTERSANDELECTRONICSINAGRICULTURE362002215223FRACTALISATERMUSEDTODESCRIBETHESHAPEANDAPPEARANCEOFTHEOBJECTS,WHICHHAVETHEPROPERTIESOFSELFSIMILARITYANDSCALEINVARIANCEFRACTALDIMENSIONISASCALEINDEPENDENTMEASUREOFTHEDEGREEOFSURFACEROUGHNESSORBOUNDARYIRREGULARITYALTHOUGHTHEINTENSITYOFSTEMCALYXANDTRUEDEFECTSARESIMILAR,THEIRFRACTALFEATURESMAYBEDIFFERENTMOREOVER,FRACTALANALYSISINTHEFREQUENCYDOMAINONLYDEPENDSONTHEFREQUENCYDISTRIBUTIONOFTHEIMAGESURFACETHESEFRACTALTEXTURALFEATURESWOULDBEINDEPENDENTOFTHEVARIATIONOFAMBIENTLIGHTINTENSITYANDORIENTATIONOFTHEAPPLESBEINGSORTEDSOTHISMETHODISSUITABLEFORAPPLESORTINGOPERATIONSWHEREAPPLESAREINRANDOMORIENTATIONSTHEIMAGEDISTRIBUTIONCANBEREGARDEDASATHREEDIMENSIONALCURVEDSURFACEBASEDONTHEABOVECONSIDERATION,FIVEFRACTALDIMENSIONSINCLUDINGONETRADITIONALFRACTALDIMENSIONANDFOURORIENTEDFRACTALDIMENSIONSWERESELECTEDASTHEFEATURESOFTHEIMAGESPOTSPRODUCEDBYSTEMCALYXCONCAVEAREAORTRUEDEFECTSTHEFOURORIENTEDFRACTALDIMENSIONSD1,D12,D3,D4ARESHOWNINFIG4INFACT,THEORIENTEDFRACTALDIMENSIONSWERETHEFRACTALDIMENSIONSOFTHECURVESINTHECORRESPONDINGDIRECTIONSFIG5THEFIVEFRACTALDIMENSIONSARECALCULATEDBYTHEMETHODDERIVEDBYLIANDWANG2000THEDIGITALIMAGECANBEDEPICTEDASZFX,Y,WHEREX,YISTHECOORDINATESOFAPIXELZISTHEGRAYVALUEASSUMINGTHEAREAOFTHEIMAGEISMXMTHEXYPLANEOFTHEIMAGEISDIVIDEDINTOGRIDSWITHAREATHEMAXIMUMANDTHEMINIMUMOFGRAYVALUESINTHEGRIDAREEXPRESSEDASUI,JANDBI,J,RESPECTIVELYANDTHEIRDIFFERENCEISDUI,JBI,JTHENTHETOTALNONEMPTYBOXNUMBERNFORALLTHEGRIDSISCALCULATEDASFORALLTHEGIVENADATASETFROMASERIESOFPOINTSLOG,LOGNCANBEOBTAINEDTHROUGHLINEARREGRESSIONOFTHEPOINTSLOG,LOGN,THEMINUSSLOPEOFTHEREGRESSIONLINEGIVESTHEESTIMATEDFRACTALDIMENSIONTHEFOURORIENTEDDIMENSIONSCANBEESTIMATEDBYUSINGASIMILARMETHODAFEEDFORWARDBACKPROPAGATIONBPNNALGORITHMWASUSEDTOCLASSIFYSTEMCALYXFROMTRUEDEFECTAREASTHEFEEDFORWARDNETWORKSTRUCTUREWASSUITABLEFORHANDLINGNONLINEARRELATIONSHIPSBETWEENINPUTANDOUTPUTVARIABLESOFPREDICTIOND4D3D2QLIETAL/COMPUTERSANDELECTRONICSINAGRICULTURE362002215223221222QLIETAL/COMPUTERSANDELECTRONICSINAGRICULTURE362002215223FIG5ORIENTEDFRACTALCURVEHIDDENLAYERRELATEDPROBLEMSTHEDESIGNEDBPNETWORKISSHOWNINFIG6THENNMODELHADFIVEINPUTNODES,ONEHIDDENLAYERWITHFOURHIDDENNODES,ANDONEOUTPUTNODEDURINGTHETRAININGPROCESS,THEWEIGHTSOFTHENETWORKWEREUPDATEDAFTEREACHPASSTHROUGHALLTHETRAININGSAMPLESTHECONVERGENCEOFTHELEARNINGWASJUDGEDBYTWOCONDITIONSWHETHERTHEMEANSQUAREDERRORFORALLTRAININGSAMPLESWERESMALLERTHANATOLERANCEVALUE,ANDWHETHERTHEOUTPUTERRORSFOREACHTRAININGSAMPLEWERESMALLERTHANANOTHERPREDEFINEDTOLERANCEVALUE34REALTIMEIMPLEMENTATIONOFAPPLESURFACEDEFECTDETECTIONTHEREALTIMEIMPLEMENTATIONOFAPPLESURFACEDEFECTDETECTIONISDIVIDEDINTOTWOSTAGESTHEFIRSTISTHESEGMENTATIONOFDOUBTFULSPOTAREAS,INCLUDINGDEFECTSANDSTEMCALYXAREAS,BYTHEMETHODDESCRIBEDINSECTION32THESEGMENTATIONRESULTSSHOWTHATTHESTEMCALYXAREASAREOFTENWITHBIGGERAREASSOINTHESECONDSTAGE,THESEGMENTEDSPOTSWITHAREASBIGGERTHANAGIVENVALUEAREFURTHERPROCESSEDFORDISTINGUISHINGSTEMCALYXCONCAVEAREASFROMDEFECTSBYTHEMETHODPRESENTEDINSECTION334TESTSANDRESULTSTHEALGORITHMWASUSEDTODETECTDEFECTSANDSTEMCALYXAREASINFORTYSAMPLESOFFUJIAPPLESSOMERESULTSARESHOWNINFIG7,WHEREA,C,E,ANDGARETHEQLIETAL/COMPUTERSANDELECTRONICSINAGRICULTURE362002215223223ORIGINALIMAGEOFTHEAPPLESTOBEINSPECTED,ANDB,D,(F,ANDHARETHEDEFECTSEGMENTATIONRESULTSTHESERESULTSSHOWTHATTHEDEFECTSANDSTEMCALYXAREASWEREBASICALLYEXTRACTEDTHESEGMENTEDSPOTSWITHAREABIGGERTHANAGIVENVALUEWEREFURTHERPROCESSEDFORDISTINGUISHINGSTEMCALYXCONCAVEAREAFROMDEFECTSBYTHEMETHODINSECTION33TABLE1LISTSSOMERESULTSOFTHESTEMCALYXRECOGNITIONBYTHEBPNETWORKIFTHEOUTPUTVALUEOFTHENETWORKISNEAR1,THEDETECTEDPATCHISTHESTEMCALYXAREASIMILARLY,IFTHEOUTPUTVALUEISNEAR0,THEDETECTEDPATCHISATRUEDEFECTAREATHETESTRESULTSSHOWTHATTHEACCURACYOFTHENETWORKCLASSIFIERWASOVER93THENUMBER16AND23DEFECTPATCHESINTABLE1WEREROTTENAREASANDTHEDEGREEOFROTWASSOHIGHTHATTHEIRSURFACESWERECONCAVETHERESULTSSHOWTHATTHEINPUTFRACTALFEATURESAREEFFECTIVEFORCLASSIFYINGCONCAVESURFACESFROMNORMALFRUITSURFACESBECAUSETHESTEMCALYXPATCHESAREUSUALLYCONCAVEINSHAPE,THEPROPOSEDMETHODFORSTEMCALYXRECOGNITIONISFEASIBLETHEPROCESSINGTIMEFORTHEDEFECTDETECTIONANDGRADINGFORONEAPPLEWAS320MSWITHMICROCOMPUTERPROCESSORSPEED500MHZABCDEFGHFIG7DEFECTSSEGMENTATIONRESULTSAC,E,GORIGINALIMAGEB,C,F,HSEGMENTEDDEFECTS224QLIETAL/COMPUTERSANDELECTRONICSINAGRICULTURE3620022152235CONCLUSIONSTHERESULTSSHOWTHATTHEINPUTFRACTALFEATURESAREEFFECTIVEFORCLASSIFYINGCONCAVESURFACESFROMTHENORMALFRUITSURFACESBECAUSETHESTEMCALYXPARTICLESAREUSUALLYCONCAVEINSHAPETHEPROPOSEDMETHODFORSTEMCALYXRECOGNITIONISFEASIBLETHESYSTEMHASTHEADVANTAGEOFBEINGABLETOINSPECT,SIMULTANEOUSLY,FOURASPECTSOFEACHAPPLEONASORTINGLINEFURTHERMORE,BASEDONTHEREFERENCEIMAGEOFANAPPLE,THEDEVELOPEDMETHODOFDEFECTSEGMENTATIONCANEXTRACTMOSTOFTHESURFACEDEFECTSONAPPLESATASPEEDCOMMENSURATEWITHTHEREQUIREMENTSOFAPRACTICALGRADINGSYSTEM,WHICHISTHEOBJECTIVEOFFURTHERRESEARCHQLIETAL/COMPUTERSANDELECTRONICSINAGRICULTURE362002215223225ACKNOWLEDGEMENTSITISGRATEFULLYACKNOWLEDGEDTHATTHISWORKISSUPPORTEDUNDERUNIVERSITYDOCTORALCOURSESPECIALFUNDPROJECTNO950801REFERENCESGROWE,TG,DELWICHE,MJ,1996REALTIMEDEFECTDETECTIONINFRUITPARTIDESIGNCONCEPTSANDDEVELOPMENTOFPROTOTYPEHARDWARETRANSASAE396,22992308LI,Q,WANG,M,1999STUDYONHIGHSPEEDAPPLESURFACEDEFECTSEGMENTALGORITHMBASEDONCOMPUTERVISIONPROCEEDINGSOFINTERNATIONALCONFERENCEONAGRICULTURALENGINEERING99ICAE,BEIJING,PEOPLESREPUBLICOFCHINA,1417DECEMBER1999,PPV2731LI,Q,WANG,M,2000AFASTIDENTIFICATIONMETHODFORFRUITSURFACEDEFECTBASEDONFRACTALCHARACTERSJIMAGEGRAPHICSCHINA52,144148TAO,Y,1996SPHERICALTRANSFORMOFFRUITIMAGESFORONLINEDEFECTEXTRACTIONOFMASSOBJECTSOPTENG352,344350THROOP,JA,ANESHANSLEY,DJ,UPCHURCH,BL,1997APPLEORIENTATIONONAUTOMATICSORTINGEQUIPMENTPROCEEDINGSOFTHESENSORSFORNONDESTRUCTIVETESTINGINTERNATIONALCONFERENCE,NRAES,ITHACA,NY,PP328342YANG,Q,1993FINDINGSTALKANDCALYXOFAPPLESUSINGSTRUCTUREDLIGHTINGCOMPUTELECTRONAGRIC8,3142WEN,Z,TAO,Y,1998METHODOFDUALCAMERANIR/MIRIMAGEFORFRUITSORTINGASAEPAPER983043STJOSEPH,MI图1实验装置示意图基于计算机视觉系统对苹果表面的缺陷探测QINGZHONGLIA,MAOHUAWANGB,2,WEIKANGGUADEPARTMENTOFINFORMATIONANDELECTRONICENGINEERING,ZHEJIANGUNIVERSITY,HANGZHOU,PEOPLESREPUBLICOFCHINARESEARCHCENTREFORPRECISIONAGRICULTURE,CHINAAGRICULTURALUNIVERSITY,BEIJING,PEOPLESREPUBLICOFCHINA摘要一种基于计算机图像处理,对苹果表面缺陷进行探测的视觉技术得到发展。硬件系统能同时检查分类线上每个苹果的四边。其方法包括图像的背景移除,缺陷的分类,茎和花萼的辨别。实验结果表示其系统是实际可行的,探测表面缺陷的运算法则也被证明是有效的。2002ELSEVIERSCIENCEBV版权所有。关键词计算机视觉系统,苹果,表面探测1绪论中国是一个农业大国,其一季的苹果产量达到1700万吨,但是其等级分类并没有实现自动化。人工检查是非常乏味的,而且会引起视觉疲劳。另外,每个人判别标准各不相同。尽管,在一些西方国家可以通过计算机自动检查水果的质量,如颜色,尺寸和外形,但由于环境的复杂性其自动控制方法还是具有一定的挑战性。一般苹果的自动分级有两个主要问题一是怎样通过照相机及时获得苹果的完整图像,二是如何快速辨别茎和花萼。为解决第一个问题,GROWEANDDELWICHE1996,TAO1996使用了一种滚轴运输系统。这种方法的缺点是运送装置上方的照相机不能同时检查旋转中苹果的两个边缘。为解决第二个问题,THROOPETAL1997发明了两种相应的装置。这些装置使苹果沿着垄干旋转不同的角度。但是结果显示其中一个装置的分级方法不能在另外的装置上实行。YANG1993发明了一种照明装置来辨别苹果的茎干和花萼。其照明装置的主要问题是图像处理中光线的误分类。WENANDTAO1998成功发明了一种双重照相NIR/MIR成像法来识别苹果的茎和花萼。但是在中国使用MIR照相机花费太昂贵了。本论文的目的是介绍一种实验装置和实验方法,使其在生产线上(每秒3至4个苹果)能检查苹果的四侧,并有效的进行识别和分级。2关于系统装置的总体看法一种在生产线上能同时检查苹果四侧的装置被发明,其机构形式如图1。它由输送装置,形似于苹果的空间间隔,机械视觉系统和信息传输装置组成。输送装置将苹果分到每一小格,再反馈给视觉系统以检查苹果表面。最终,分类系统将苹果分成各个等级。机械视觉系统包括一个杯状的运送装置,一个能发出不同光谱和对水果表面色泽进行分类的装置,两个照相机,一个连接于微型电子计(处理速度500MHZ带有四个输入通道的图像抓取装置。作为一个实验系统,水果输送装置和自动分类系统在第一阶段没有被建立。为完成苹果的初步检查,两个相同的单色照相机被分别安置在输送装置的下方。其视觉系统的机构如图2。照相机里的摄像传感器的分辨率为580X350。每个照相机和另一个是同步的,并有多个电子快门。同样的85MM焦距的透镜被安装在照相机内,光学带通滤波器840NM安装在每个透镜外。传送装置由多个无底的杯状物体组成(如图2,两边固定有两面镜子,因此,其上方的照相机可以拍摄到苹果的三面(顶部和两边,而底部的照相机可以拍摄到苹果的仰视图。此外,这个系统可以同时检查运送机上的数个苹果。其好处就是可以同时检查运送机上苹果的四面。3运算法则的描述苹果表面检测的运算法则主要包括图像预处理、缺点分割、茎和花萼的识别、缺陷区域的计算和分类。运算法则示意图如图3。图3缺陷识别运算法则流程图31图像背景的移除运送机两边镜子里的图像背景是不同的,所以不能通过简单的处理将水果的图像进行分割。因此,一种减法法则被运用,如下所述。GX,Y是移除背景图像后的图像,FX,Y是原始图像,BX,Y是背景图像,T是初始值。32参考苹果图像进行区域分割在检验时,由于苹果形状,造成了图像强度的曲线分布。这导致边界附近的表面亮度比有缺陷的表面亮度更低,因此难以使用简单的运算法则辨别出真正的缺陷表面。参考苹果的图像,LIANDWANG1999发明了一种方法完成水果曲线图像缺陷区域的分割。在这个方法中,首先产生一个水果的参考图像,经过检验后,使其变成规格化后的水果参考图像。经过初始阶段处理后,表面的缺点会被更容易地识别。33基于几何学和人工神经网络辨别茎和萼在缺陷识别过程中,因为茎和萼的图像与缺陷类似,导致系统难以对它们进行识别。基于几何学和人工神经网络,本文作者发明了一种方法来区分茎和萼的凹面区域与真正的表面缺陷。不规则碎片形一种几何形状,被以越来越小的比例反复折叠而产生不能被标准几何所定义的不标准的形状和表面。虽然茎和花萼与真实的缺点表面很相似,但它们不规则碎片形状还是不同的。而且,在频域中,不规则碎片形状分析只依赖于表面的频率分布。组织上的这些不规则碎片形状特征与周围光强和苹果的方位无关。因此,此方法可以对任意方位的苹果进行分类。图像的分布形状可看作是三位曲线表面。基于上述考虑,包括传统的不规则碎片形状和四导向的不规则碎片形状的五维不规则碎片被用来描述茎花萼弯曲区域和真实缺陷区域图像的特征。四导向的不规则碎片形尺寸(DL,D2,D3,D4如图4所示。事实上,导向的不规则碎片形尺寸是对应方向(图5的曲线不规则碎片形尺寸。五个不规则碎片形尺寸被LIANDWANG2000的方法计算出来。其数字式可写为ZFX,Y,(X,Y是象素的坐标,Z是灰度值。假定图像的分辨率为MM,在XY平面内,图像被分成数个的区域。栅格灰度的最大值和最小值分别表达为U(I,J)和B(I,J),它们的差值为DU(I,J)B(I,J),非空的栅格总数为对于所有给定的S取其对数得到一系列的点,可获得LOGN。通过点(LOG,LOGN的线,其斜率为负,由此估算出不规则碎片形的尺寸。用近似法求出另外四个不规则碎片形的尺寸。NN神经网络)运算法则用来前馈来自真实缺陷区域的花萼。前馈网络结构可适当预测输入和输出间的非线性关系的相关问题。被设计的BP网络结构如图6所示。NN模型有五个输入点,一个含有四个隐藏输入点的层和一个输出点。在程序学习过程中,网络结构的权重不断被刷新。其收敛性有两个条件是否每个区域误差比允许误差值更小,是否每个样品的输出误差比预先确定的允许误差值小。图6关于茎萼缺陷分类的神经网络34苹果表面缺陷的即时检查苹果表面缺陷的即时检查分为两个阶段。第一阶段是32中描述的方法对可疑缺陷区域的分割(包括茎、萼和缺陷表面),其结果显示莲萼区域时常为较大的区域。在第二阶段中,对较大的分割区域进一步处理以区别真正的表面缺陷。4实验和结果运算法则被用于探测四个富士苹果的表面缺陷和茎萼区域。结果如图7,A、C、E和(G是苹果的原始探测图像。(B、(D、(F和(H是缺陷区域分割后的结果。这些结果显示缺陷区域和茎萼区域基本上被提取出来,大于指定值的分割区域被进一步分割。表1为BP对茎萼区域的识别结果。如果神经网络的输出值接近1,则为茎萼区域。如果神经网络的输出值接近0,则为真实的缺陷区域。实验结果显示不规则碎片形状对正常的水果凹入

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号