摘 要

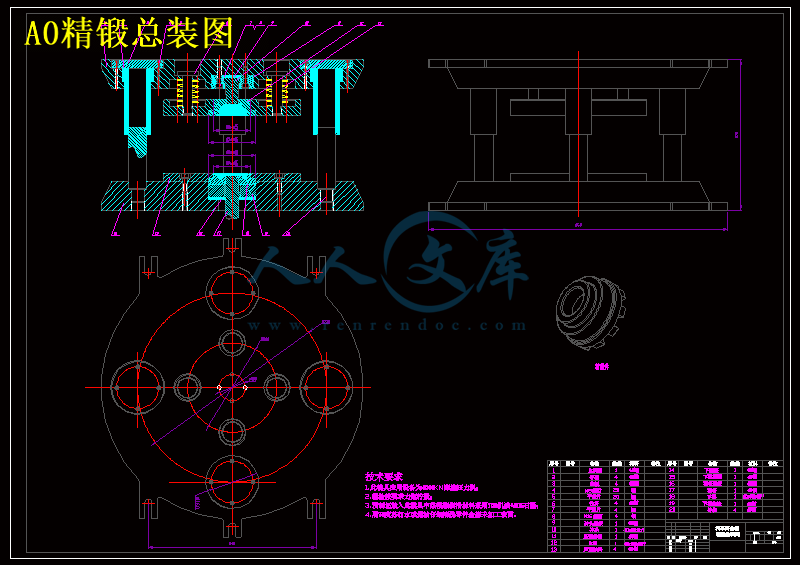

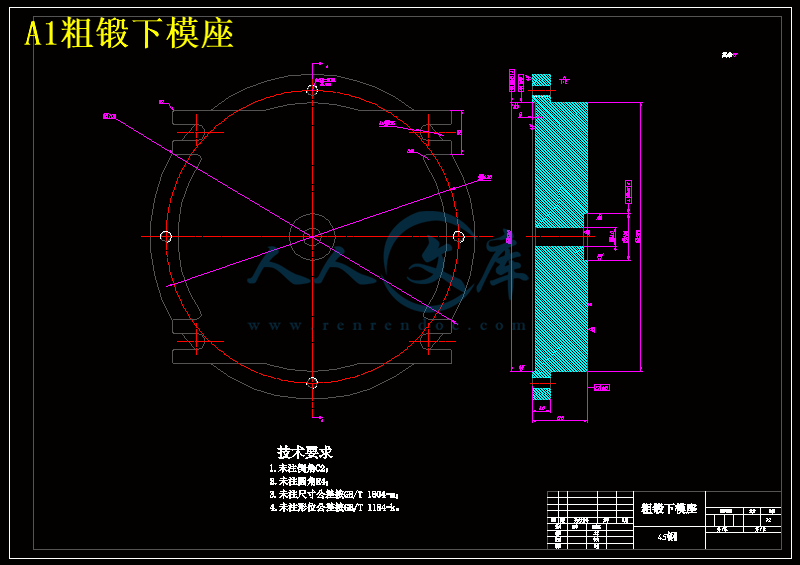

随着经济的发展,汽车已逐步成为人们日常生活中必不可缺少的工具。汽车的需求量在不断增长。在没有找到更好的替代品之前,对汽车而言汽车离合器一直将发挥着不可或缺的作用。汽车的性能与汽车离合器质量有着密切相关。因此怎样找到一种加工方法使离合器加工精度高,加工质量好,生产成本低是目前最重要的。而精密模锻是一种相对而言比较有优势的加工方法。针对啮合套结构特点,提出了模膛设计加工的要素及制造锻模齿形模的工艺,确定了其精锻成形工艺。在模具设计过程中,利用三维设计软件Solid Works完成了啮合套模具和零件的几何形状造型和二维工程图,通过AutoCAD对其二维工程图进行修改完善。

关键词:啮合套;加工方法;精密模锻;Solid Works

Abstract

As the economy develops, cars have gradually become an indispensable tool in daily life. The demand for automobiles is ever-increasing. Before an alternative could be found, the clutch will always play an essential role in cars—since the performance of a car is directly related to the quality of its clutch. Therefore, at this point, the most important task is to find a way in which clutches can be produced in high precision, superior quality, but at the same time, at a lower cost. Relatively speaking, the precision die forging process is a better method. Considering the structural characteristics of the meshing bush—the core structure of a clutch, this paper explains the constituent elements of designing mold chambers and the process of making bevel gear mold, which together decide both the design and making of the meshing bush’s precision die forging mold. The solid modeling software Solid Works was used to produce the geometric designs and 2-D engineering drawings of the mold and its product, facilitated by AutoCAD in revising and improving the 2-D drawings.

Keywords:clutch;mold;Processing method;Precision forging;Solid Works

目 录

摘要

Abstract

引言··························1

第一章 模具的概述 ··························· 2

1.1 模具的概念、作用和优点·························· 2

1.2 模具的分类和成形特点························ 3

1.3 模具的加工方法和发展趋势 ··························7

1.4模具的材料选择 ····················· 8

第二章 模锻生产工艺 ·························· 11

2.1 模锻成形方法 ····························· 11

2.1.1模锻成形过程 ····························11

2.1.2模锻时金属的流动方向判别······················· 13

2.1.3模锻的分类 ························· 13

2.1.4锻造工艺的基本工序和工步 ··············· 14

2.2 模锻变形的力学与金属学基础 ····························· 18

2.2.1基本物理量 ························ 18

2.2.2 塑性变形 ························ 18

2.2.3塑性条件(屈服准则) ·············· 19

2.2.4塑性变形体积不变条件 ·················· 20

2.2.5 塑变图····························· 20

2.2.6金属的塑性和塑性指标·················· 21

2.3锻模的基本失效形式及外观检查··················· 22

2.4模锻工艺制定的主要内容 ······················ 24

2. 4. 1 制定与模锻变形相关的工艺 ······················ 24

2. 4. 2 制定模锻变形前和变形后的工艺 ················· 25

2.5 模锻件图设计 ···························· 26

2.5.1 分模面设计··························· 26

2. 5. 2 加工余量、锻件公差和锻造余块 ·················· 26

2. 5. 3 模锻斜度 ······················ 29

2. 5. 4 圆角半径 ························· 30

2. 5. 5 冲孔连皮 ······················· 31

2. 5. 6飞边槽的设计 ····················· 31

2. 5. 7 技术条件 ···························33

第三章 啮合套的精密锻压模具设计 ·······················34

3.1 课题主要设计内容 ····························34

3.2主要设计步骤 ····························34

3.3具体设计分析计算·······························35

3.4预锻模膛设计································44

3.4.1 预锻模膛作用····························44

3.4.2 预锻模膛设计····························45

3.5 终锻模膛设计 ·····························45

3.6 原毛坯尺寸的确定·······························47

3.7 模锻变形前的热处理工序························48

3.7.1加热的目的 ····························48

3.7.2加热的方法 ····························48

3.7.3锻件温度的选择 ··························49

3.7.4锻件的冷却 ···························50

3.7.5钢在加热过程中的物理、化学变化··················50

3.8模具材料的选择 ····························51

第四章 模具的三维实体造型···································53

4.1 Solid Works功能简介························53

4.2 SolidWorks三维造型····················53

第五章 总结 ·········56

致谢 ········57

附录:参考文献 ······················57

引言

锻造是金属加工方法之一,在现代制造业中占有重要地位。锻造一般属于体积成形,是通过金属体积的转移和分配,来获得机械零件或接近于零件尺寸的毛坯,锻造的产品称为锻件。模锻是适合于大批量生产锻件的锻造方法。模锻时,使用特制、开设有与锻件形状一致或相近的型腔(模膛)的锻模,将锻模安装在锻造设备上,金属毛坯置于锻模的模膛中,锻造设备通过锻模对毛坯施加载荷,是毛坯产生塑性变形,同时变形流动又受到模膛空间的限制。

金属材料通过模锻塑性成形,可以获得形状尺寸精确、表面光洁程度较高的锻件,同时其内组织能够得到显著改善,使用性能得到提高。并且,模锻具有很高的生产率,模锻件机械加工余量较小,材料利用率较高;锻件流线分布合理,零件使用寿命高;生产操作简单方便。在工程应用中承受较大或复杂载荷的零件,常采用模锻方法进行大批量生产。

模锻成形在国民经济各个领域中得到广泛应用。例如汽车、拖拉机、机械、航空、航天、军工等领域,某些需要考虑形状尺寸和内部质量的稳定性,以及有某些特殊性能要求的零件,也经常采用模锻方法生产。由于社会需求和生产技术的进步,各种先进的、特殊的模锻方法不断产生和发展。例如精密模锻、液态模锻、粉末锻造、摆动辗压、自动辗环、高速模锻、超塑模锻等,所加工的材料,也从普通钢和一般的有色金属,发展到特殊钢、高温合金、铝镁合金、复合材料等。

锻造是历史久远的生产行业,也是飞速发展的学科领域,从依靠简单机械装置驱锤的古老锻造模式,发展到以高压蒸汽、压缩空气、液体等多种介质驱动多种锻造机器,使用多样化模具体系进行的近现代化模锻生产,进而到采用计算机控制的、全自动的、集成化模锻生产线或柔性化锻造加工系统,传统的成产方式正在被先进生产方式改造、取代。因此锻造工作者需要不断“充电”来适应学科、行业的发展。

本次设计的主要是锻模,是对于汽车离合器的精密锻压模具设计。由于能力和时间有限,又是初次设计与分析,没有什么经验,仅凭的是别人总结出来的经验,还有许多不恰当的地方,错误和不妥之处肯定在所难免,敬请各位老师批评指正。

第一章 模具的概述

1.1模具的概念、作用和优点

模具的概念

在工业生产中,用各种压力机和装在压力机上的专用工具,通过压力机的压力,使金属或非金属材料在专用工具内变形、流动获得所需形状和尺寸的制件,这种专用工具统称为模具。

模具的作用

模具是工业生产中使用极为广泛的重要工艺装备。采用模具生产制品及零件,具有生产效率高,节约原材料成本低廉,保证质量等一系列优点,是现代工业生产的重要手段和主要发展方向。

模具是成型金属、塑料、橡胶、玻璃、陶瓷等制件的基础工艺装备,是工业生产中发展和实现少无切削加工技术不可缺少的工具。如汽车、拖拉机、电器、电机、仪器仪表、电子等行业有60%~80%的零件需要用模具加工,轻工业日用品的生产需要用模具更多,螺母、螺钉、垫圈等标准零件,没有模具就无法大量生产。由此看来,模具是工业生产中使用极为广泛的主要工艺装备之一。

模具是一种高效率的工艺装备,用模具进行各种材料的成形可实现高速度的大批量生产,并能在大批量生产条件下稳定的保证制件的质量、节约原材料。因此,在现代工业生产中,模具的应用日益广泛,是当代工业生产的重要手段和工艺发展方向。许多现代工业的发展和技术水平的提高,在很大程度上取决于模具工业的发展水平。模具工业的水平和发展状况已被认为是衡量一个国家工业水平的重要标志之一。

川公网安备: 51019002004831号

川公网安备: 51019002004831号