摘 要

旋转超声磨削是在传统机械磨削的基础上,将超声振动加入到磨削工具上的一种新型的复合加工方法。该方法不仅保留了传统机械磨削的一些优良特性,又因加入超声振动后,能较大地提高加工效率,有效地改善工程陶瓷、复合材料等难加工材料磨削表面质量。本文旨在研制出旋转超声磨削装置,并利用该装置进行了一些实验研究。全文主要内容概括如下:

1. 讨论分析了旋转超声磨削的材料去除机理。旋转超声磨削中材料去除机理同时具有冲击(磨具上的磨粒对工件表面的高频高速冲击)和磨蚀(磨削工具的旋转和进给运动可模型化为磨削过程)两种作用。

2. 研制了一种新型旋转超声磨削装置。该装置能以附件的形式安装在数控机床上或普通机床上,进行常见表面、甚至一些较复杂型面的旋转超声磨削加工。

关键词:超声加工意义,旋转超声磨削,结构设计与校核,

Abstract

Rotary ultrasonic grinding (RUG) is a new machining method which integrates rotary movement of traditional grinding with ultrasonic oscillation. This method can keep down some excellent grinding characters of Mechanical grinding, greatly enhance process rate and effectively improve the effect of grinding surface of difficult-to-cut materials (stainless steel and composite material and the like). The aim of this paper is that we design and manufacture the grinding device of rotary ultrasonic machining, and carry out some research by using developed develop. The main content of this paper can be sum up as follows:

1. We have analysis the material remove mechanism of RUG, and material

remove of rotary ultrasonic grinding conclude on high frequency impact of abrasive particles on grinding tool against work piece and ablation that rotary and in-feed movement of grinding tool can form grinding process.

2. A new grinding device of rotary ultrasonic machining have been designed and manufactured. This device can be installed on numerical control machine or common machine tool as an accessory and can carry out rotary ultrasonic grinding for usual surface and even some complicated surface.

Key words: ultrasound processing significance ; Rotate ultrasound grind ;

Structure design and checking

目 录

前言 1

1.绪论 2

1.1 超声的发展史 2

1.2超声加工的原理及特点 2

1.3 工程陶瓷材料的使用价值及加工技术 3

1.4超声加工陶瓷的意义及前景 7

2. 设计说明书 8

2.1超声磨削装置的结构设计 8

2.1.1超声加工设备及其组成部分 8

2.1.2初步结构设计 8

2.1.3 结构的比较 10

2.1.4 最后结构的确定 11

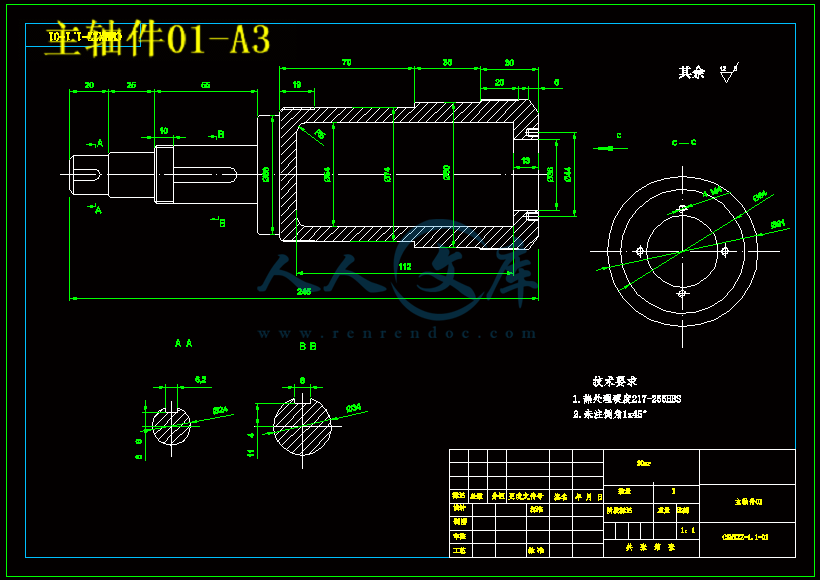

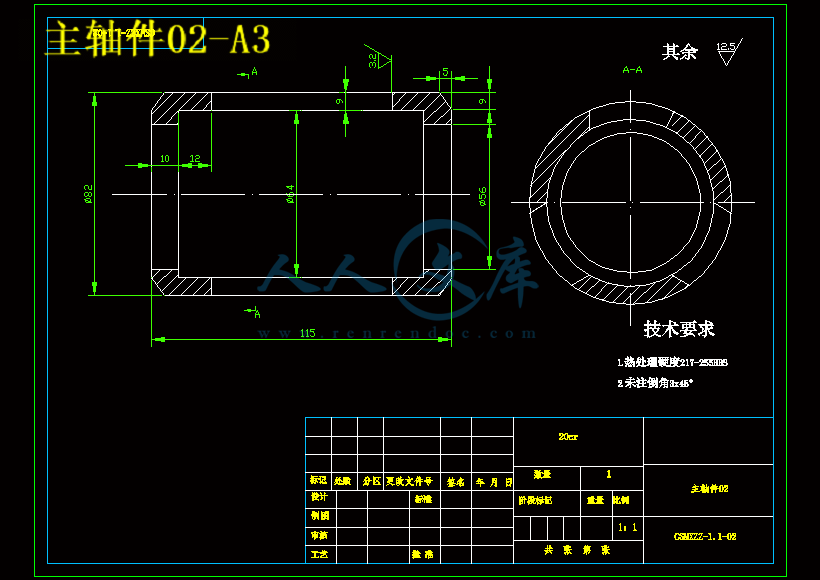

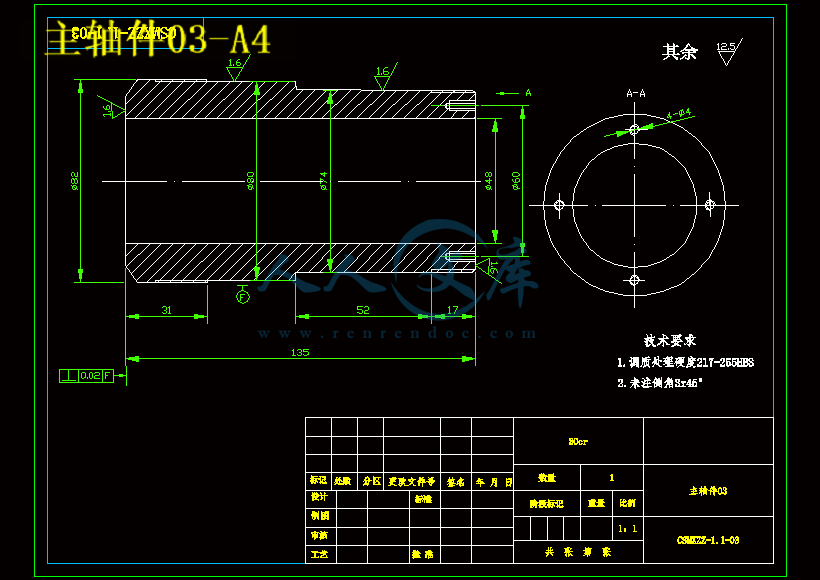

2.2 装置中的各部件的设计及校核 13

2.2.1 电机的计算与选择 13

2.2.2 变幅杆的设计与计算 15

2.2.3 压电陶瓷的选择 17

2.2.4 轴强度的较核 18

2.2.5 键的校核 19

3.总结与展望 21

3.1总结 21

3.2展望 21

参考资料 23

致谢 24

前言

随着科学技术的发展及航空航天等领域的需求,不锈钢、复合材料、工程陶瓷等难加工材料应用日趋广泛,而此类材料的特殊性能使其加工制造非常困难。例如,海洋结构件普遍采用耐腐蚀的不锈钢,而不锈钢加工起来切削力大、切削温度高、粘刀现象严重、加工硬化趋势强等特点,使得不锈钢切削过程中切削功率消耗大,切削温度高,而且加工工件表面质量较低。又如航空发动机重要零件如机匣、压气机风扇叶片等广泛采用钛、镍基合金等先进结构材料,而钛、镍基合金材料切削加工性较差,主要表现在材料热硬度和热强度很高,所需切削力很大,工件、刀具容易产生较大变形。航天飞机机顶首部广泛采用工程陶瓷,但工程陶瓷具有高强度、高硬度、高脆性等特点,使得陶瓷材料的加工十分困难,加工成本很高。此类材料的出现及广泛应用,对机械制造业提出了一系列迫切需要解决的新问题。对此,采用传统加工方法十分困难,甚至无法加工,而特种加工很适合对这些材料进行经济加工。而在众多特种加工方法中,超声加工有其独特的优点,因而迅速得以发展和推广。

1 绪 论

1.1超声的发展史

超声波是指频率高于人耳听觉上限的声波。一般来讲,人耳可以听到的声波的频率范围约为16~20KHz。因此,人们常把高于20KHz的声波称为超声波。而在实际应用种,有些超声技术使用的频率可能在16KHz以下。早在1830年,为了探讨人耳究竟能够听到多高的频率,F.Savart曾用一个多齿的轮首次产生了频率为2x104HZ的超声,但人们一般却认为,首次有效产生高频声的,应是1876年F.Galton的气哨实验。第一次世界大战期间,P.Langevin发明了石英晶体换能器,用来在水中发射和接收频率较低的超声波,开始了人类真正科学的开展超声技术的研究。

超声具有许多独特的性质和优点,如频率高、波长短、在一定距离内沿直线传播具有良好的束射性和方向性、并在液体介质中传播时可在界面上产生强烈的冲击和空化现象。因此,近年来,随着科学技术的发展,超声技术发展极为迅速,应用领域非常广泛。目前,其应用遍及航空、航海、国防、生物工程以及电子等领域,在我国国民经济建设中发挥越来越大的作用。

1.2超声加工的原理及特点

旋转超声磨削的加工原理如图1-1所示,其中,压电陶瓷换能器用于将从外部接入的高频电振荡信号(由220V或380V的交流电经超声波发生器转换而成)转换为超声频机械振动;由于压电陶瓷换能器产生的振幅较小(大约有5μm),一般不能满足需求,需用变幅杆将换能器的振动振幅放大后(振幅为20~30μm)再传至磨削工具,磨削工具在由电机驱动做旋转运动的同时也做纵向超声振动,其振动方向如下图中的箭头所示。

川公网安备: 51019002004831号

川公网安备: 51019002004831号