【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

随着社会的不断发展,人们对能源资源的需求不断增长促成风电产业的飞速繁荣,作为风电机组的核心部件,风电齿轮箱的研发倍受国内外风电相关行业和研究机构的关注。然而国内风电齿轮箱研究起步晚,生产工艺落后,尤其在兆瓦级风电齿轮箱方面,主要依靠引进国外技术。因此,兆瓦级风电齿轮箱的开发研究势在必行,完全掌握风电齿轮箱设计及制造技术,实现风机国产化目标。

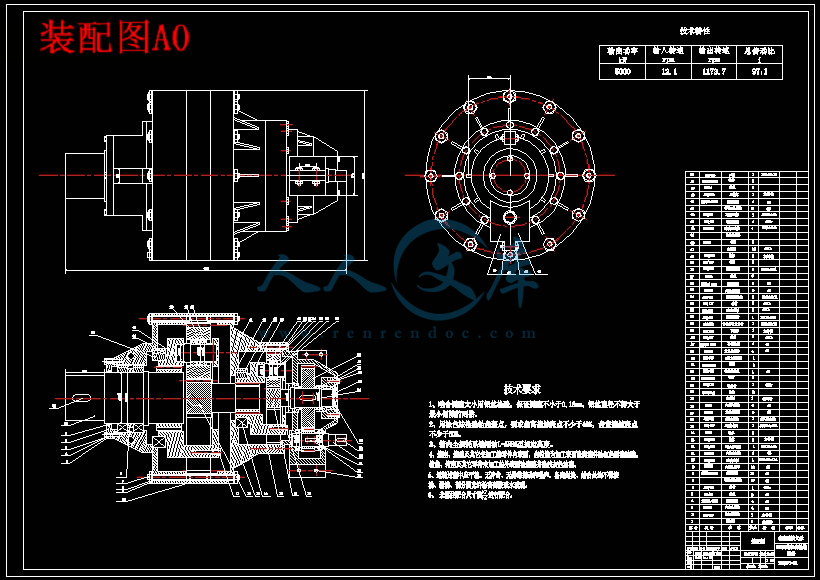

本毕业设计的是五兆瓦风力发电机组的齿轮箱,通过方案的选取,齿轮参数计算,轴的参数计算、轴承的选取以及对其配套的齿轮箱进行自主设计。

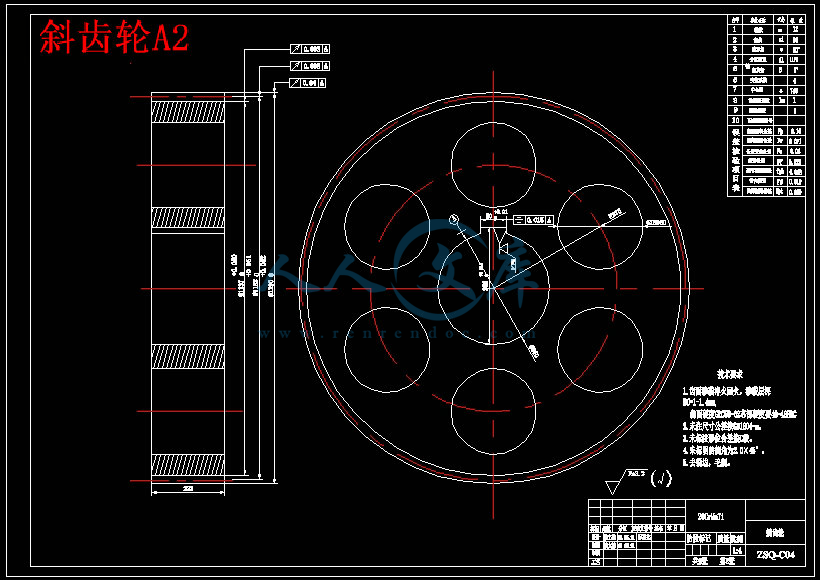

1)选取两级行星派生型传动方案,在此基础上进行传动比分配与各级传动参数如模数,齿数,螺旋角,压力角,变位系数等参数的确定;通过计算,确定各级传动的齿轮参数;选择适当的齿轮。

2)对行星齿轮传动、轴承进行受力分析,得出各级齿轮载荷结果。依据标准进行静强度校核,结果符合安全要求。

3)绘制三维图、CAD装配图,并确定恰当合理参数。

关键词:风电齿轮箱;结构设计;两级行星

ABSTRACT

With the continuous development of society, people's demand for energy resources growing promoting the rapid prosperity of the wind power industry, as the core component of the wind turbine, the development of wind power gear box has attracted more and more wind power at home and abroad attention of related industries and research institutes.However the domestic wind power gear box research started late, backward production technology, especially in terms of MW wind power gear box, mainly rely on the introduction of foreign technology.Therefore, MW wind power gear box of the development, it is imperative to study, to fully grasp the wind power gear box design and manufacturing technology, wind machine to achieve the goal of domestic.

This graduation design is 5 MW wind turbine gear box, through scheme selection, calculation of gear parameter, the shaft parameter calculation, bearing selection and the matching of gear box for independent design.

1) two-stage planetary derived type transmission scheme selection, on the basis of transmission ratio distribution and levels of transmission parameters such as modulus, number of teeth, spiral angle and pressure angle, coefficient etc. parameters determined by calculation, to determine the levels of transmission gear parameters; choose the proper gear.

2)stress analysis of planetary gear transmission, bearing, gear loadresults obtained. According to the standard of static strength check, the results meet the safety requirements.

3) rendering 3D graph, CAD assembly, and to determine the appropriateparameters.

KEYWORDS:Gearbox for Wind Turbine;Structure Design;Two-stage Planetary

目录

第一章 前 言 1

1.1 国内外发展现状与趋势 1

1.1.1 风力发电国内外发展现状 1

1.1.2风电齿轮箱市场前景 4

1.1.3我国风电齿轮箱设计制造技术的现状 5

1.1.4存在问题及展望 6

1.2论文的主要内容 6

第二章 齿轮的设计及强度校核 7

2.1 增速箱齿轮的设计参数 7

2.2 增速箱齿轮设计方案 8

2.3齿轮参数计算 9

2.3.1低速级参数计算: 9

2.3.1中速级参数计算: 11

2.3.1高速级参数计算: 13

2.3齿轮强度的校核 14

第三章 行星架的设计与校核 27

第四章 传动轴的设计与校核 29

4.1.1低速级传动轴尺寸参数计算 29

4.1.2低速级传动轴的强度校核 29

4.2中间级传动轴的设计计算与校核 31

4.2.1中间级传动轴尺寸参数计算 31

4.2.2中间级传动轴的强度校核 32

4.3 高速级传动轴的设计计算 32

4.4输出传动轴的设计计算 32

第五章 齿轮箱其他部件的设计 34

5.1轴系部件的结构设计 34

5.2 行星架的结构设计 34

5.3 传动齿轮箱箱体设计 35

5.4齿轮箱的密封、润滑、冷却 35

5.4.1 齿轮箱的密封 35

5.4.2 齿轮箱的润滑、冷却 36

5.5齿轮箱的使用安装 37

第六章 结论 38

参考文献 39

致 谢 40

第一章 前 言

1.1 国内外发展现状与趋势

1.1.1风力发电国内外发展现状

当今社会随着经济日益发展,人们对能源的需求越来越大,而石油等不可再生能源也面临枯竭,人们急需寻找替代能源。自然界中具有非常大的风能储存量,由于太阳的辐射作用,地球每年大约可获得的 地球每年大约可获得 KW·h 的风能。其中,边界层占整个大气层的 35%,因而边界层大气中可利用的风能功率约为 KW,如果人类在近地面层能利用其中的十分之一,则全球可开发风能的功率为KW。这个值相当于 2005 年全球发电能力的 74.7 倍[1]。通过上述数据可知,风能是地球上最重要的能源之一,合理的开发利用风能可以解决越来越严重的能源短缺问题。风能作为一种清洁的、储量极为丰富的可再生能源,在未来的能源市场很有开发潜力,各国政府相继投入大量的人力及资金研究生产风力发电机,力图设计出安全可靠高效的风力发电机。风力发电机中很重要的一部分就是齿轮传动增速箱,如何把齿轮传动系统设计好便成了关键问题

川公网安备: 51019002004831号

川公网安备: 51019002004831号