【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

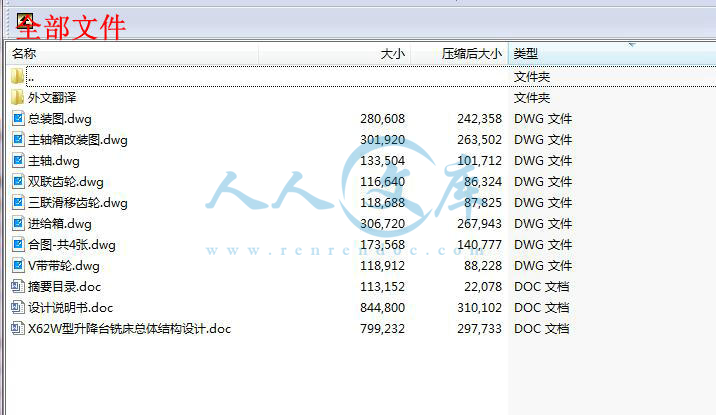

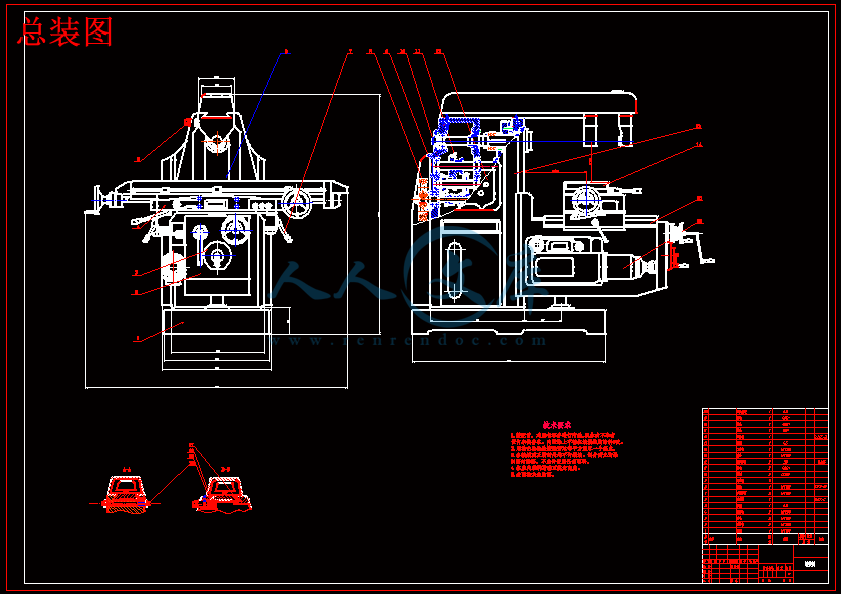

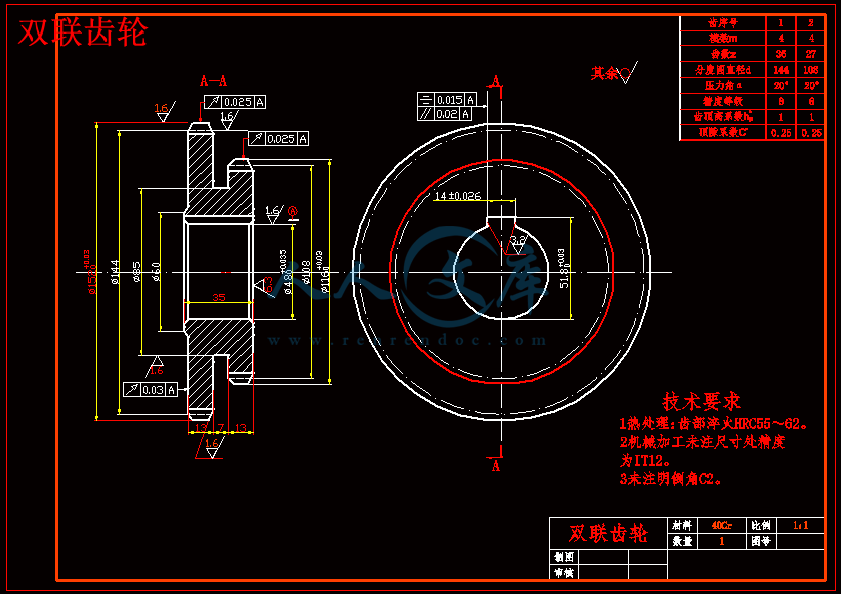

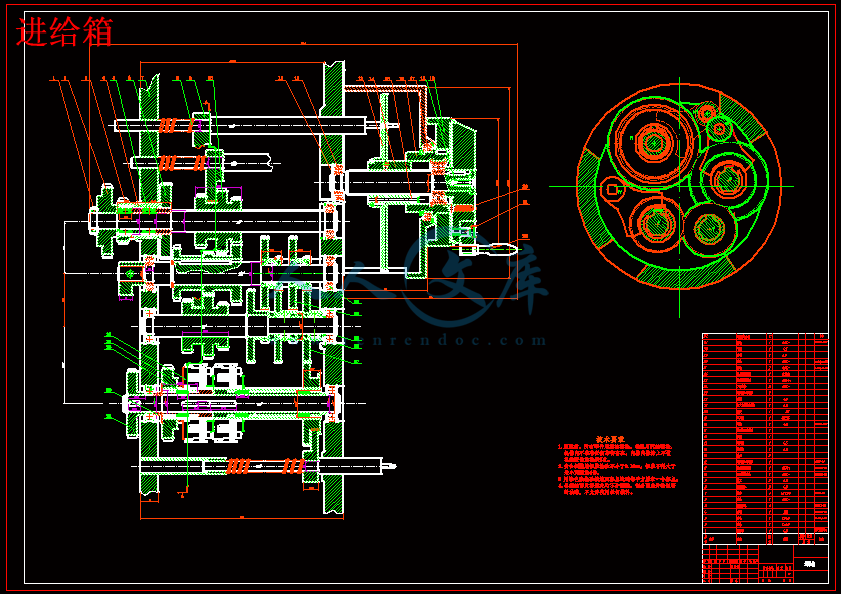

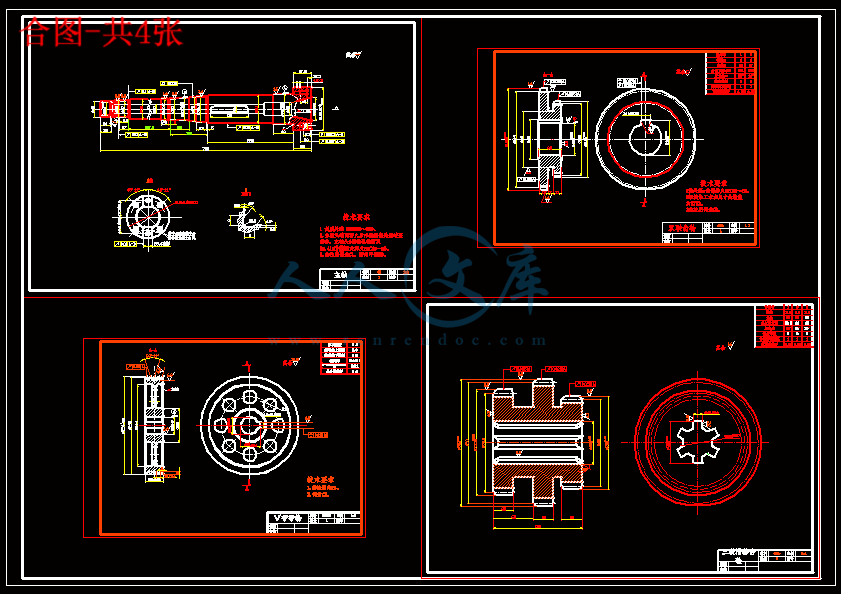

本题主要是X62W型升降台铣床的总体结构及各部件的设计,主轴箱及进给箱是由异步电动机进行驱动,通过齿轮传动,分别使主轴获得18级转速,进给系统实现21级变速。通过对主轴箱和进给箱中零部件的分析和校核,合理的选择零部件包括齿轮,轴等,满足工作时的加工要求,确保加工时铣削零件尺寸、形状的精度要求。该铣床适用于对平面、斜面、螺旋面及成型表面加工,机床具有足够的刚度和强度,能进行高速度切削和承受一定强度的切削工作。通过对主轴箱和进给箱进行了简要的设计和较核,设计的总体布局满足工艺要求,传动系统满足加工要求。X62W铣床具有主轴转速高、调速范围宽、操作方便、工作台进给速度宽等特点,大大提高了加工范围。

本次设计的是X62W型升降台铣床的总体结构、主轴箱和进给箱的设计,铣床主传动变速箱,主要由滑移齿轮的变速使主轴获得多级转速,以满足不同铣削加工的要求其中,电磁离合器按装在轴上,有制动主轴的作用;铣床进给变速部分中, 不同的电磁离合器分别控制工作进给和快速进给由,运动经过变速箱变速后,工作台在3个进给方向上都得到不同的多个进给速度,在工作进给时,由滚珠式安全离合器实现过载保护,变速操纵采用了孔盘集中变速。孔盘的轴向移动由一套螺旋差动机构实现。

关键词:总体设计;传动系统;主轴箱;进给箱;升降台

Abstract

This thesis is mainly about the design of whole structure and all parts of elevating table miller X62W. Head stock and feeding box are driven by asynchronous motors. By gear’s transmission main shaft gains 18 stages turning speed, and feeding system realizes 21 stages speed-changing. Based on analysis and checks on parts of headstock and feeding box, work elements are properly chosen, including gears and shaft and so on, in order to satisfy processing requirements guarantee and milling machine have high precision on sizes and shapes. This miller is applied to machining of planes, bevel faces, helicoids and forming faces. It has enough rigidness and strength, which makes it mill with high speed and bearing strength to some extense. Through simple checks on headstock and feeding box, general layout satisfies the processing requirement, and transmission system also satisfies the machining requirement. X62W miller has the characteristics of high headstock turning speed, wide speed-change ranges, easy to manipulate, and wide ranges of feeding speed. All of these enlarge the processing scope.

Keywords : Layout Design;Driving System;Headstock;Feed Box;Knee Type

目 录

摘 要 I

Abstract 错误!未定义书签。

第1章 绪 论 1

1.1 课题背景和研究意义 1

1.2 铣床的概述及国内外发展概况 1

1.3 铣床的分类 1

1.4 研究设想 1

第2章 X62W型升降台铣床总体方案设计 2

2.1 X62W型铣床的结构特点主要参数和主要用途 2

2.1.1 X62W型铣床的结构 2

2.1.3 X62W型铣床的主要参数 3

2.1.4 X62W型铣床的主要用途 3

2.2 主要部分的总体设计 4

2.3 铣床的常用卡具 4

2.3.1 卡具的概念 4

2.3.2 卡具的作用 4

2.3.3 卡具的类型 5

2.3.4 卡具的组成 5

2.3.5 典型工件在铣床上的装夹方式 5

2.4 本章小结 5

第3章 X62W型升降台铣床的传动系统设计 6

3.1 主运动 6

3.1.1 主轴传动结构式 6

3.1.2 主轴转速图 6

3.2 进给运动 8

3.3 本章小结 9

第4章 主轴箱和进给箱的电动机的选择 10

4.1 主轴箱电机的选择 10

4.2 进给箱的电动机选择 11

4.3 本章小结 11

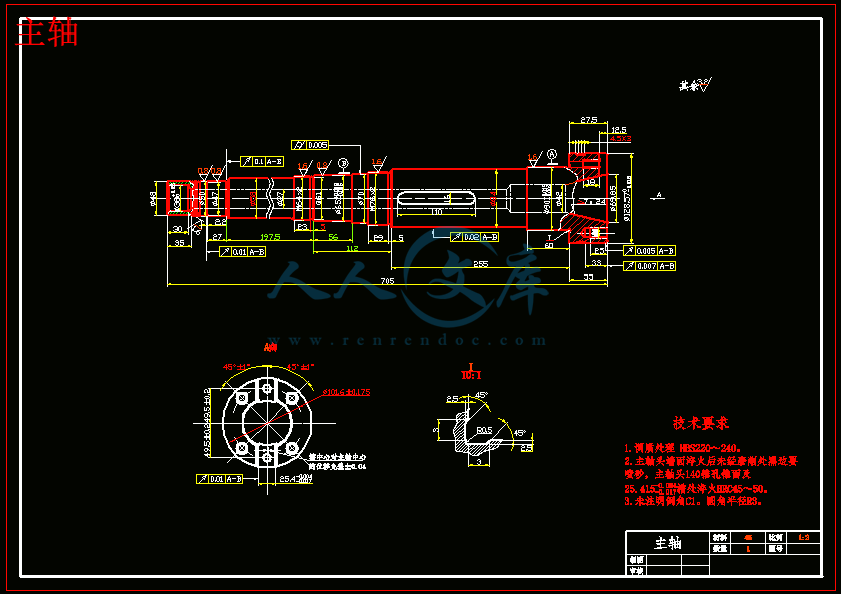

第5章 带传动的设计 12

5.1 概述 12

5.1.1 带传动的分类 12

5.1.2 带传动的失效形式 12

5.1.3 带传动的设计要求 12

5.2 带传动的计算及选定 13

5.2.1 计算带传动的条件 13

5.2.2 计算内容和步骤 13

5.3 带传动的张紧 15

5.3.1 V带的初张力的计算 15

5.3.2 V带常用的张紧方法 15

5.4 本章小结 15

第6章 主轴箱及进给箱的齿轮设计计算 16

6.1 齿轮的概述 16

6.1.1 齿轮的类型 16

6.1.2 齿轮传动的主要特点 16

6.1.3 齿轮传动的要求: 16

6.1.4 失效形式及设计准则 16

6.1.5 齿轮的材料及其选择原则 17

6.2 主轴箱齿轮的设计计算 17

6.3 本章小结 22

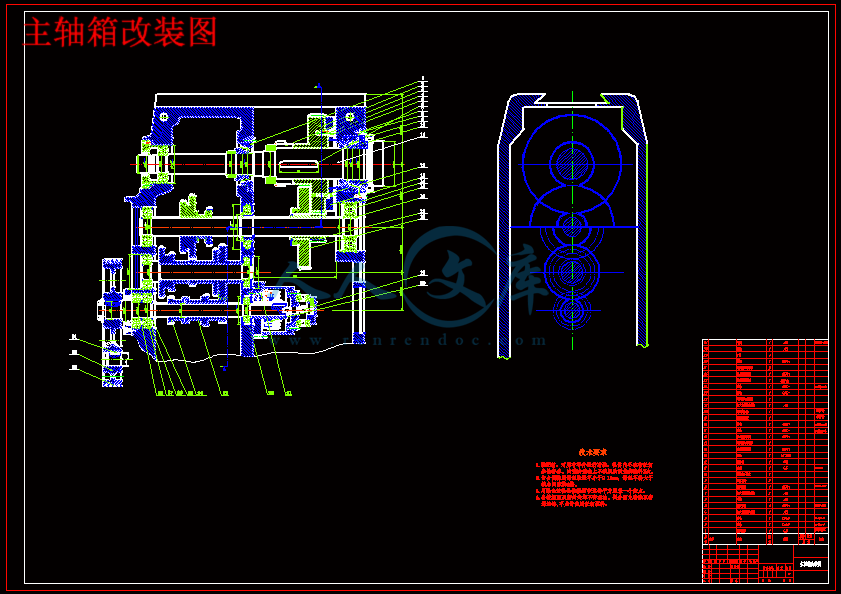

第7章 轴的设计计算 23

7.1 轴的概述 23

7.1.1 轴的功用及分类 23

7.1.2 轴的受力分析、失效形式和设计准则 23

7.1.3 轴上零件的固定 23

7.1.4 轴的加工和装配工艺性 24

7.2 轴的设计及计算 24

7.3 主轴的设计 26

7.4 本章小结 30

第8章 零部件的选择 31

8.1 键的选择 31

8.2 离合器选择 31

8.3 润滑系统设计 31

8.4 本章小结 31

结 论 32

致 谢 33

参考文献 错误!未定义书签。

第1章 绪 论

1.1课题背景和研究意义

铣床的加工是一种应用广泛的机床,在机械加工和机械修理中得到广泛应用。现代机床加工主要表现在自动化程度、技术水平和质量保证。而质量保证就是要保持机械加工的精度,现代大部分高精度的机床的性能还不能满足要求,精度保持性差。铣床的精度的提高不仅会使铣床的加工范围广,而且还会使其用于多种机械加工和机械修理的场所,因而提高铣床加工的精度成为日后的发展趋势。

1.2铣床的概述及国内外发展概况

最早的铣床是美国人惠特尼于1818年创制的卧式铣床;为了铣削麻花钻头的螺旋槽,美国人布朗于1862年创制了第一台万能铣床,这是升降台铣床的雏形;1884年前后又出现了龙门铣床;二十世纪20年代出现了半自动铣床,工作台利用挡块可完成“进给-决速”或“决速-进给”的自动转换。

1950年以后,铣床在控制系统方面发展很快,数字控制的应用大大提高了铣床的自动化程度。尤其是70年代以后,微处理机的数字控制系统和自动换刀系统在铣床上得到应用,扩大了铣床的加工范围,提高了加工精度与效率。

川公网安备: 51019002004831号

川公网安备: 51019002004831号