!【包含文件如下】【机械类设计类】CAD图纸+word设计说明书.doc【需要咨询购买全套设计请企鹅97666224】.bat

01任务书(带参考文献).docx

02开题报告.docx

03中英文翻译.doc

04说明书大纲.doc

05设计说明书.doc

1.txt

A型支撑板.dwg

传动箱壳体.dwg

加工中心夹具.dwg

圆柱定位销.dwg

夹具体.dwg

机械加工工艺卡片.doc

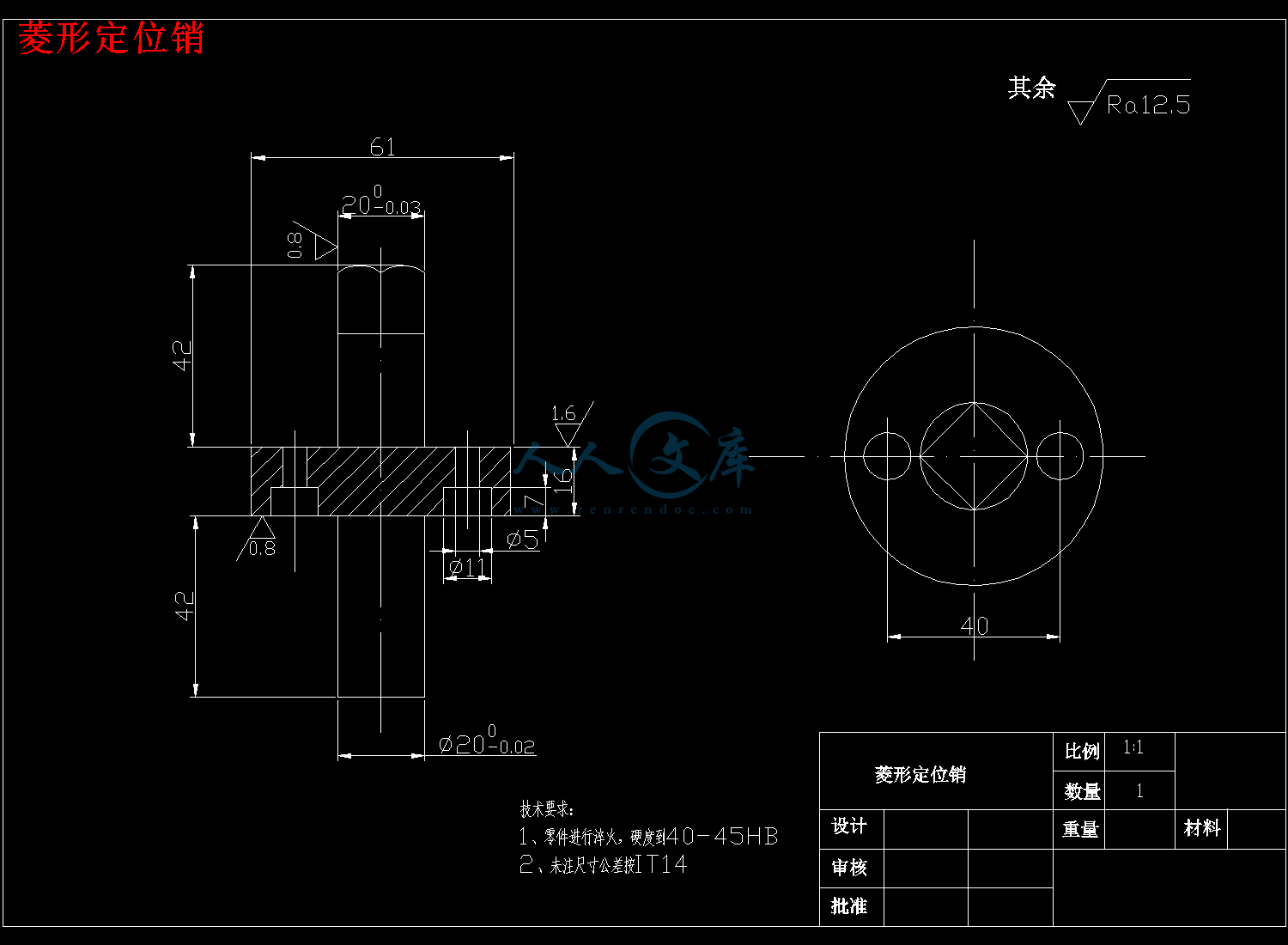

菱形定位销.dwg

表二工艺过程.docx

装配图.dwg

目 录

摘要...............................................................II

Abstract.......................................................... III

第一章 零件的分析..................................................1

1.1 零件的分析...................................................1

1.2 零件的功用...................................................2

1.3 零件的工艺分析...............................................2

第二章 制定工艺规程................................................3

2.1 零件定位基准的选择...........................................3

2.2 加工阶段的划分...............................................3

2.3 传动箱加工顺序...............................................3

2.4 工序的集中与分散.............................................4

第三章 制定加工工艺路线及机床刀具选择..............................5

3.1 制定加工工艺路线.............................................10

3.2 加工工艺的选择...............................................10

3.3 机床、刀具的选择.............................................11

3.4 加工余量及切削用量的确定.....................................12

第四章夹具体的设计.................................................13

4.1 加工中心的夹具设计...........................................14

结论...............................................................16

参考文献...........................................................17

LF804拖拉机传动箱体加工工艺及加工中心夹具的设计

摘 要

该LF804拖拉机传动箱箱体的加工工艺及加工中心的夹具的设计主要是箱体上一些平面的加工以及各平面上一些孔系的加工。在箱体类零件的加工过程中,主要是平面与一些孔系的相对位置的公差要求,以及表面粗糙度的要求,直接影响箱体上各个运动零件之间的安装精度等等。在本设计中,我们采用一面两销的固定方法,本次设计拖拉机箱体有关于加工工艺的安排和加工中心夹具的设计。随着机械行业的迅速发展,基本上都采用自动化生产技术,实现加工工艺过程的优化控制。

【关键词】工艺、工序、夹具

川公网安备: 51019002004831号

川公网安备: 51019002004831号