摘 要:在我们日常生活中,水果是必不可少的一部分,菠萝就是其中的一种。所以无论是国内市场还是国外市场,它的前景都是相当广阔的。菠萝除了水果鲜食外,还可以作为美味的菜肴,设计一种安全卫生的削皮去刺工具,已越来越成为人们的迫切需求。本文设计一种机器,由皮带轮传动、齿轮传动、三角爪和丝杆传动实现菠萝的削皮去刺,代替目前人工削皮,操作方便,使用简单,提高了生活效率。

关键词:削皮去刺;皮带轮传动;齿轮传动;三角爪;丝杆传动

The Mini Pineapple Peeling Machine Design

Abstract:In our daily life,the fruit is an essential part of the pineapple,is one of a kind. So whether it is domestic or foreign market,its prospects are very broad.In addition to fresh pineapple fruit, can also be used as a tasty dish, design a safe and sanitary peeling deburring tools, has increasingly become the people's urgent needs. This paper designed a machine,composed of a belt pulley drive, gear drive, the triangular claw and a screw rod drive to achieve the pineapple peel to the thorn, replace the artificial skin, convenient operation, simple to use, improve the efficiency of life.

Key word: peeling deburring; pulley drive; gear drive; triangular claw; screw drive

目 录

摘要……………………………………………………………………………………1

关键词…………………………………………………………………………………1

1 前言………………………………………………………………………………2

1.1 菠萝削皮机的概述………………………………………………………2

2 菠萝削皮机的研究现状…………………………………………………………2

3 论文的主要任务和内容内容……………………………………………………2

4 菠萝削皮机的系统设计思路……………………………………………………3

4.1 菠萝削皮机的性能要求…………………………………………………3

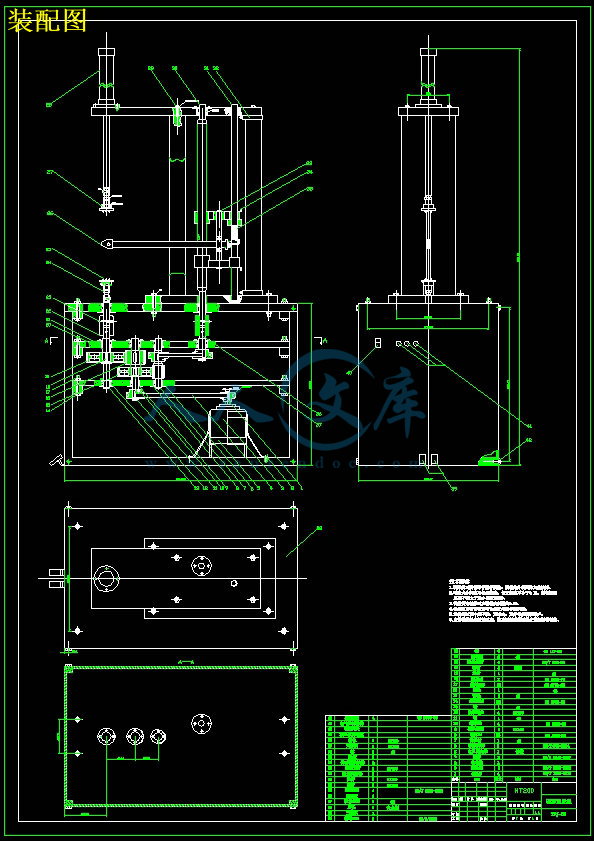

5 菠萝削皮机的基本结构及工作原理……………………………………………3

5.1 整机机构…………………………………………………………………3

5.2 液压控制系统……………………………………………………………4

5.3 电气控制系统……………………………………………………………4

5.4 传感器与检测系统………………………………………………………5

5.5 传动机构…………………………………………………………………5

6 工作机构的设计与计算…………………………………………………………6

6.1 运行阻力的计算…………………………………………………………6

6.2 电动机功率的计算………………………………………………………6

7 传动机构的设计与计算…………………………………………………………6

7.1 丝杆的设计与计算………………………………………………………6

7.1.1 设计选择丝杆传动的原因………………………………………6

7.1.2 丝杆的运动形式及其载荷分析…………………………………7

7.1.3 丝杆设计的基本尺寸等参数计算………………………………8

7.1.4 丝杆的材料与许用应力…………………………………………10

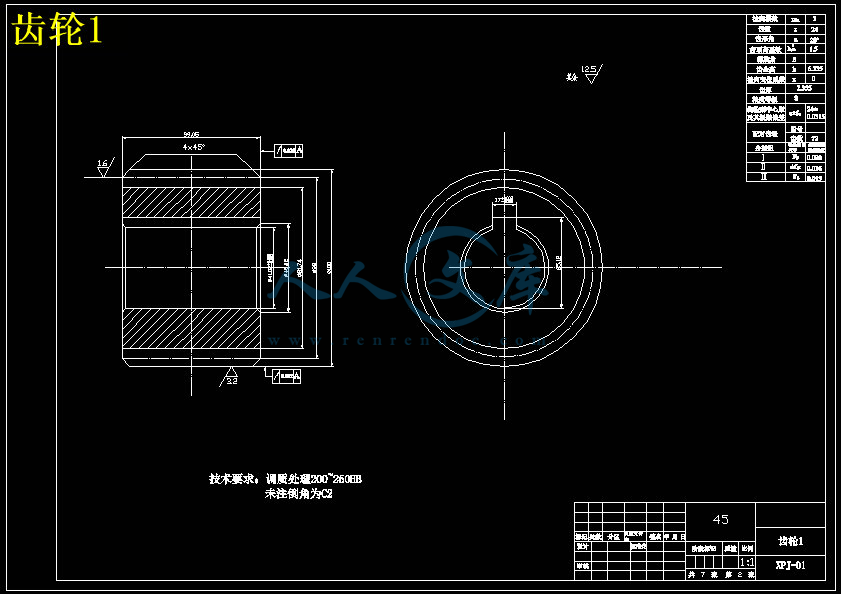

7.2 齿轮机构的设计与计算…………………………………………………11

7.2.1 设计选择齿轮传动的原因………………………………………11

7.2.2 齿轮的设计及其参数的计算……………………………………11

7.2.3 主轴齿轮的设计…………………………………………………12

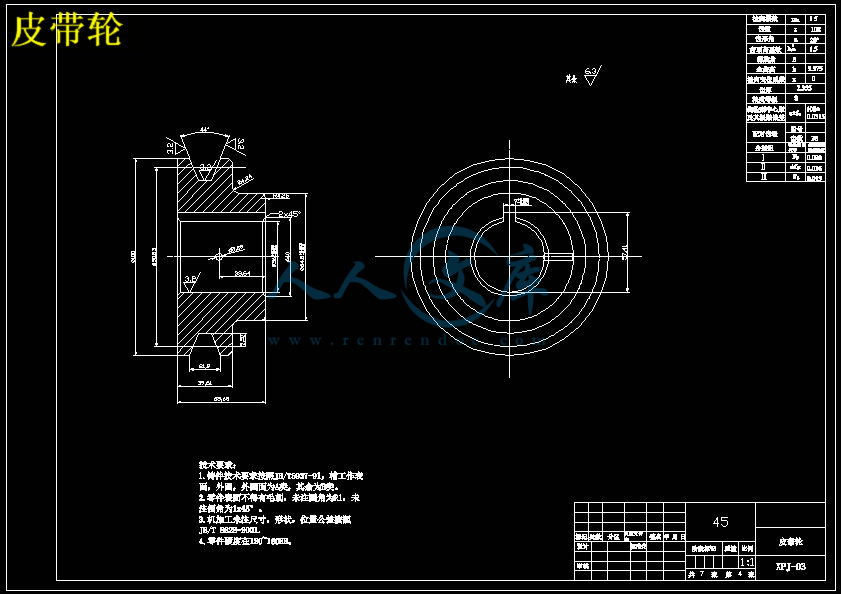

7.3 皮带轮的设计与计算……………………………………………………17

7.4 联轴器的选择……………………………………………………………19

7.4.1 联轴器的分类……………………………………………………19

7.4.2 联轴器的选用……………………………………………………20

7.4.3 确定联轴器的型号………………………………………………21

8 结论………………………………………………………………………………22

参考文献………………………………………………………………………………23

致谢……………………………………………………………………………………24

1 前言

1.1 菠萝削皮机的概述

菠萝成为了人们在生活中很好的一种水果之一,菠萝的去皮不仅仅是必须的,更重要的是防止皮中残留的农药的等有害物质伤害人体的一种最有效办法。然而,传统的人工一刀一刀削皮的方式不仅浪费时间,费力伤神还不卫生。于是本课题设计的菠萝削皮机就应运而生了。

本设计的菠萝削皮机是由人工控制刀头的夹持与松开,刀头的向上运动与向下运动,电动机的正反转,汽缸控制的上爪的上升与下降,从而来完成菠萝的削皮动作。在菠萝的削皮生产中,应用本设计生产的菠萝削皮机可以提高生产的质量和生产效率,从而可以实现减轻人工的工作强度,保证产品质量,实现快速生产,在各个方面的意义都很重大,因此本设计的菠萝削皮机可以在餐饮行业中广泛应用。

2 菠萝削皮机的研究现状

近年来,我国的水果蔬菜的加工业取得了巨大的成就,水果蔬菜速冻食品在我国农产品贸易中占据了重要地位。目前,我国的果蔬加工业已具备了一定的技术水平和较大的生产规模,外向型果蔬加工产业布局已基本形成。

先进的设计理念和全新的控制方式,是菠萝削皮的使用灵活性更高,性能更稳定,效率更高。对于食品加工等行业来讲,生产用的菠萝削皮机给行业的就是效率和效益,所以,人们对菠萝削皮机的各项功能要求越来越多,削皮机的发展完善速度也是比较快速的。

随着食品加工工业的发展,食品深入加工已越来越受到各种餐饮行业的重视,特别是高级的餐饮行业酒店,这更要求原材料的深入加工。其中菠萝的原料的削皮加工就收到了人们的高度重视。

但是目前国内还没有这样的大型去皮设备,所以值得我们去研究,设计开发和生产。

3 论文的主要任务和研究内容

本课题研究主要是对菠萝的削皮机的整个装置设计和计算进行分析探讨,然后对液压控制系统,电气控制系统,传感器与检测系统,传动机构和工作机构等部分组成部分进行设计和计算。

该课题设计要就的主要流程如下所示:

设计背景分析总体方案分析结构与案例分析系统适用性分析

4 菠萝削皮机的系统设计思路

目前菠萝的加工行业中还是广泛的使用人工削皮,费时费力,劳动强度大,为解决上述不足而提供一种降低劳动强度,提高劳动效率的半自动菠萝削皮机装置。

4.1 菠萝削皮机的性能要求

菠萝削皮机应满足半自动化程度高,去皮效率高,系统稳定,安全性能高等为前提,做到技术先进,结构巧妙合理,经济合理等。

本课题设计的菠萝削皮机应该具备以下性能:

方便操作的使用性能

(1)系统的稳定性及运动的平稳性准确,能保证规定的运动精度和运动位移等;

(2)工作的可靠性即能根据功能要求完成既定的动作,而且各个动作必需稳定协调;

(3)结构简单,制造容易,成本低;

(4)生产效率高,能耗少;

(5)减轻劳动强度,不污染环境,创造文明生产条件;

(6)留有发展余地,需要改进时而不至于造成全机废弃。

川公网安备: 51019002004831号

川公网安备: 51019002004831号