摘 要

本设计为焊接机械手的结构设计,主要研究内容:腰部回转机构的设计;大、小臂和腕部回转的结构设计。

本设计由整体布局入手,参考现有关节型机械臂的相关设计,初步确定腰部的转动惯量,从而确定电机的选型,安装等相关设计。在机械臂的灵活和精度的前提下完成总体结构的设计,然后根据总体结构,从而确定本设计的机械臂各个主要零部件的设计。

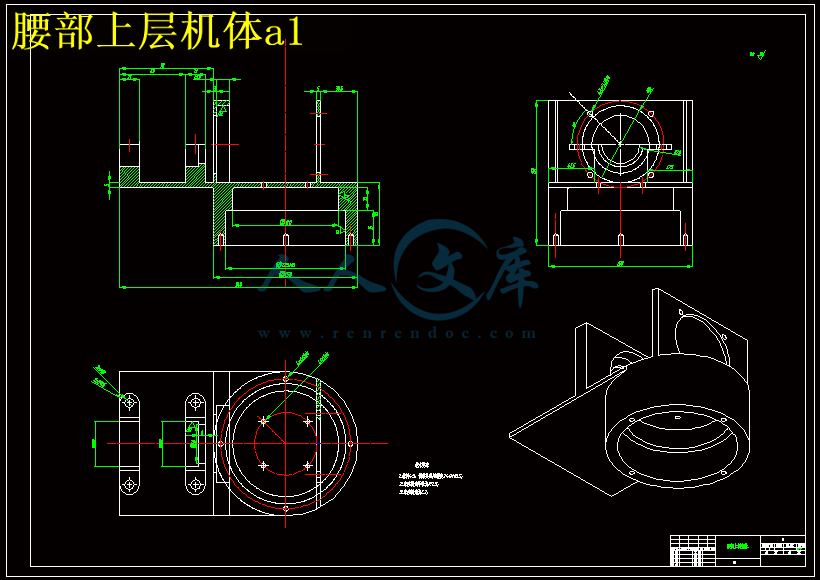

在主要零部件的设计中,主要包括腰部壳体的设计、轴的结构设计、轴承的选择、电机的设计计算、大小臂的结构和固定等。

本设计整体在现有关节型机械臂的结构上做了修改,使得它能够更好的满足本设计的设计要求。本设计结构简单、重量轻、外形尺寸小、设备费用低、运转安全、操作方便、便于维修和管理。

关键词:机械手;谐波减速器;结构设计

Structure design of robot arm

Abstract

The design for the design of welding structure of the manipulator, the main research contents: the design of the waist turning mechanism; structure design of large, small arm and wrist rotation.

This design by the overall layout with reference to the relevant design, the existing joint type manipulator, preliminary determine the moment of inertia of the waist, so as to determine the motor selection, installation and other related design. Complete the design of the overall structure of the flexible manipulator based on precision and the next, and then based on the overall structure, design of mechanical arm to determine the design of all the major components of the.

The design of the main components, including the housing design, structural design of shaft, bearing selection, design and calculation of the size of motor, arm structure and fixed.

The design of the whole made changes in the existing joint type manipulator structure, so that it can better meet the design requirement of this design. The design has simple structure, light weight, small size, low cost of equipment, operation safety, convenient operation, easy to repair and management.

KeyWords:robot arm;harmonic drive;structure design

目 录

1 绪论 1

1.1 机器人简介 1

1.1.1 机器人的发展及应用 2

1.1.2 点焊机器人介绍及其研究意义 4

1.1.3 机器人的组成 6

1.2 机械手的组成 8

1.3 本文主要研究工作 11

2 机械手的总体结构 12

2.1 机械手总体结构的类型 12

2.2 设计具体采用方案 13

3 机械手腰部机座 15

3.1 机械手腰部机座结构的设计 15

3.2 机械手腰部机座设计的具体采用方案 15

3.3 电动机的选择 16

3.4 减速器的选择 17

3.5 键的选择 18

4 机械手手臂的结构设计 20

4.1 设计具体采用方案 21

4.2 大臂电动机的选择 21

4.3 大臂减速器的相关计算 22

4.4 小臂电动机的选择 23

4.5 小臂减速器的相关计算 24

5 机械手腕部的结构方案设计 27

5.1 腕部电动机的选择 27

5.2 腕部减速器的选择 27

6 轴承的选用与校核 29

7 结论 39

参考文献 40

致谢 41

毕业设计(论文)知识产权声明 42

毕业设计(论文)独创性声明 43

1 绪论

1.1 机器人简介

工业机器人(英语:industrial robot。简称IR)是广泛适用的能够自主动作,且多轴联动的机械设备。它们在必要情况下配备有传感器,其动作步骤包括灵活的,转动都是可编程控制的(即在工作过程中,无需任何外力的干预)。它们通常配备有机械手、刀具或其他可装配的的加工工具,以及能够执行搬运操作与加工制造的任务。机器人是靠自身动力和控制能力来实现各种功能的一种机器。联合国标准化组织采纳了美国机器人协会给机器人下的定义:“一种可编程和多功能的,用来搬运材料、零件、工具的操作机;或是为了执行不同的任务而具有可改变和可编程动作的专门系统[1]。”

工业机器人在经历了长期发展后,已经成为制造业中不可缺少的核心设备。同时随着社会的发展和人们生活水平的提高,各种各样的机器人也被开发出来去适应制造领域意外的各个行业。这些机器人作为机器人家族的后起之秀,由于其用途广泛而大有后来居上之势,仿形机器人、农业机器人、服务机器人、水下机器人、医疗机器人、军用机器人、娱乐机器人等各种用途的特种机器人纷纷面世,而且正以飞快的速度向实用化迈进。

工业机器人由操作机(机械本体)、控制器、伺服驱动系统和检测传感装置构成,是一种仿人操作、自动控制、可重复编程、能在三维空间完成各种作业的机电一体化自动化生产设备。特别适合于多品种、变批量的柔性生产。它对稳定、提高产品质量,提高生产效率,改善劳动条件和产品的快速更新换代起着十分重要的作用。

机器人并不是在简单意义上代替人工的劳动,而是综合了人的特长和机器特长的一种拟人的电子机械装置,既有人对环境状态的快速反应和分析判断能力,又有机器可长时间持续工作、精确度高、抗恶劣环境的能力,从某种意义上说它也是机器的进化过程产物,它是工业以及非产业界的重要生产和服务性设备,也是先进制造技术领域不可缺少的自动化设备。

1.1.1 机器人的发展及应用

1920年 捷克斯洛伐克作家卡雷尔·恰佩克在他的科幻小说《罗萨姆的机器人万能公司》中,根据Robota(捷克文,原意为“劳役、苦工”)和Robotnik(波兰文,原意为“工人”),创造出“机器人”这个词。

1939年 美国纽约世博会上展出了西屋电气公司制造的家用机器人Elektro。它由电缆控制,可以行走,会说77个字,甚至可以抽烟,不过离真正干家务活还差得远。但它让人们对家用机器人的憧憬变得更加具体。

1942年 美国科幻巨匠阿西莫夫提出“机器人三定律”。虽然这只是科幻小说里的创造,但后来成为学术界默认的研发原则。

1954年 美国人乔治·德沃尔制造出世界上第一台可编程的机器人,并注册了专利。这种机械手能按照不同的程序从事不同的工作,因此具有通用性和灵活性。

川公网安备: 51019002004831号

川公网安备: 51019002004831号