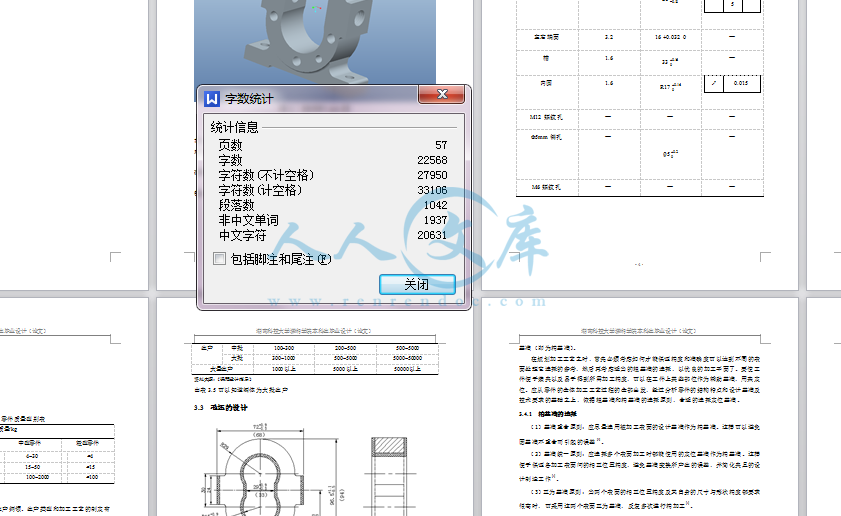

【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

经过几十年改革开放的快速发展,我国的装备制造产业在国际水平上有了质的飞跃,使我国进入了制造业大国的行列,正朝向装备制造强国迈进。在当今装备制造产业不断的向前发展中,对机械制造装备各个环节也提出了更高的要求。

本设计为“阀体加工工艺及夹具设计”。阀体是构成阀门压力腔的主要零件,与阀盖或管道(或机器设备)直接连接,与阀芯以及阀座密封圈一起形成密封后能够有效承受介质压力,用来控制流体的方向、压力和流量。

设计的主要内容包括:阀体的工艺分析与加工工艺规划,计算编写加工工艺卡片与工序卡片;夹具结构的总体方案设计;定位分析与夹具定位误差计算;装配图及零件工作图的设计。在工艺设计中首先对零件进行分析,了解零件的工艺和加工要求,确定毛坯制造形式和尺寸,并选择好零件的加工基准,规划零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是确定各个工序的工艺装备、切削用量和基本工时;然后进行专用夹具的设计,确定定位与夹紧方案,设计选择夹具的各组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件;计算夹具定位误差,分析夹具结构的合理性与不足之处,并进行改进。

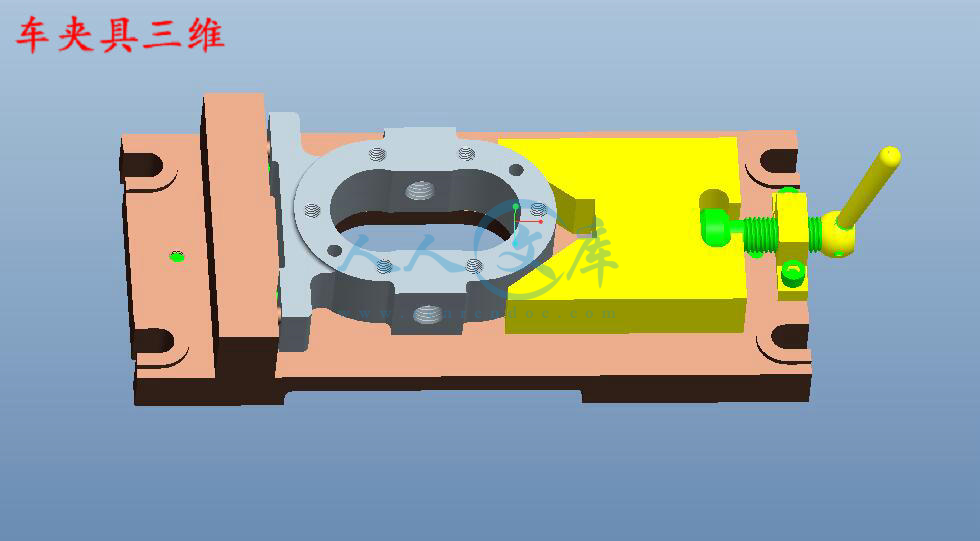

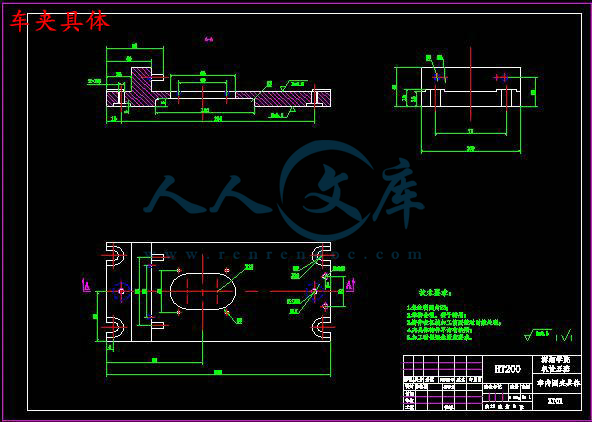

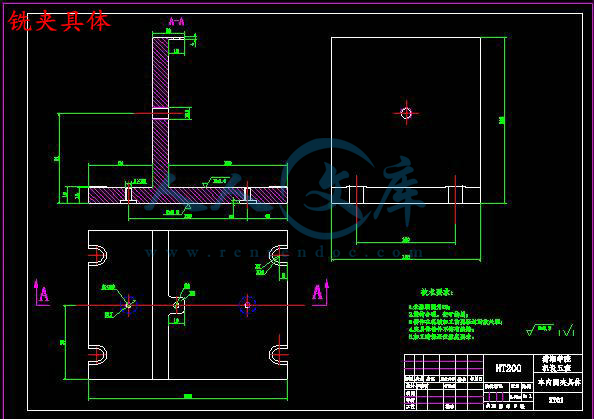

文中采用PRO/E进行夹具三维结构设计,利用AutoCAD绘制二维工程图。分别针对铣端面、车内孔、钻销孔等工序设计了三套专用夹具,能够保证加工工艺的要求、提高生产效率,减轻劳动强度和扩大机床的工艺范围,其特点是结构紧凑,操作迅速、方便、省力,可以保证较高的加工精度和生产效率。

关键词:定位,工艺规划,工艺,误差分析量

Abstract

After decades of rapid development of reform and opening up, China's equipment manufacturing industry at the international level has been a qualitative leap that China has entered the ranks of the big manufacturing country, is facing equipment manufacturing power forward. In today's equipment manufacturing industry continued to move forward in all aspects of machinery and equipment also put forward higher requirements.

The design for the "body and fixture design process." The valve body constitutes the main part of the pressure chamber is directly connected to the valve cover or pipe (or equipment), the valve body and the valve seat and the sealing ring is formed together with the medium to effectively withstand the pressure used to control the direction of fluid pressure and flow.

The main content of the design include: process analysis and process planning body, the calculation processing cards and writing processes card; overall program structure is designed fixtures; positioning jig positioning error analysis and calculation; assembly drawing and parts working drawings design. First of all parts for analysis in process design, process and understand the parts of the processing requirements, determine the form and dimensions of blank manufacturing and processing benchmark select routings good part of the planning of parts; then on the part of each process step size calculation performed The key is to identify the various processes of technology and equipment, and cutting the amount of basic work; then special fixture designed to determine the positioning and clamping solutions, design options for each fixture component parts, such as positioning elements, clamping elements, guiding elements, clip Specific connection with the machine parts and other components; computing fixture positioning error analysis of the reasonableness of the fixture structure and shortcomings, and make improvements.

This paper uses PRO / E conducted fixture design three-dimensional structure, the use of AutoCAD drawing two-dimensional drawings. Respectively, for face milling, interior holes drilled pin holes and other processes designed three special fixture, to ensure processing requirements, improve production efficiency, reduce labor intensity and scope of the expansion process of the machine, which features a compact, fast operation , convenient, energy, can ensure high precision and productivity.

Keywords: positioning, process planning, process, analyze the amount of error

目 录

绪论····························································1

1.1 课题背景·························································1

1.2 夹具的发展历程···················································1

1.3 小结······························································2

第二章 零件的分析······················································3

2.1 零件的用途························································3

2.2 阀体的技术要求···················································4

2.3 阀体的工艺分析····················································5

第三章 工艺规程设计···················································6

3.1 确定毛坯的制造方法···············································6

3.2 零件生产类型的确定················································7

3.3 毛坯的设计·······················································8

3.4 选择定位基准·····················································8

3.4.1精基准的选择·················································9

3.4.2粗基准的选择·················································9

3.5 表面加工方法的选择···············································9

3.6 工艺路线的确定··················································10

3.7 工序装备的选用··················································12

3.7.1机床的选择···················································12

3.7.2刀具的选择··················································13

3.7.3量具的选择···················································14

3.8 工序基准的选择···················································14

第四章 切削用量的选择及时间额定的计算······························15

第五章 夹具设计·······················································30

5.1 铣床夹具的设计···················································31

5.1.1铣床夹具的定位方式··········································31

5.1.2定位误差分析与计算以及定位元件的选择·······················34

5.1.3以铣左右端面夹具设计为例····································35

5.1.4定位基准的选择··············································35

5.1.5切削力及夹紧力计算··········································36

5.1.6定位误差分析················································37

5.1.7夹具设计及操作简要说明······································37

4.2 钻床夹具的设计··················································38

4.3 车床夹具的设计··················································44

第六章 结论····························································46

参考文献·······························································47

致谢····································································48

第一章 绪 论

1.1 课题背景

如今时代的科学技术、各种新型材料、新工艺以及新技术不断涌现,机械制造技术正向着高质量、高效率和低成本的国际方向发展。各种新工艺的出现,已经突破传工艺加工的范围,能加工很多难加工材料、形状复杂的型面和一些具有特殊技术要求的零件。数控机床可提高加工效率和小零件的精度要求以及形状复杂的零件。在计算方法和计算机技术的飞速发展,加快了发展进程的步伐,从而使自动化技术提高一个新的阶段。

经过现代制造技术和机械制造工艺自动化的长期发展,夹具也在不断的创新中,发挥了十分重要的作用。夹具及固定装置可以提高零件的加工质量、加工速度和生产效率,大大降低生产成本。因此不管在传统制造或者现代制造系统内,夹具都是重要的加工工艺装备。

阀体加工工艺和夹具机械设计是在学完机械加工技术、机械制造技术、机械制图、机械工程材料和课程设计之后,才正确地解决一个零件在加工中的定位,夹紧以及工艺路线安排,工艺尺寸确定等问题,并设计出专用夹具,保证零件的加工质量。

本次设计也要培养自己的自学与创新能力。因此本次设计综合性和实践性强、涉及知识面广。所以在设计中既要注意基本概念、基本理论,又要注意生产实践的需要,只有将各种理论与生产实践相结合,才能很好的完成本次设计。

1.2 夹具的发展历程

夹具在其发展的200多年历史中,一共经历了3个阶段:第1阶段,夹具是工件加工、制造的各道工序中的重要夹紧装置,发挥着夹固工件及其重要的功用。第2阶段,军事生产以及内燃机发明,汽车行业的快速发展,夹具逐渐在规模生产中发挥出其高效率及稳定加工质量的优越性,夹紧装置的结构也逐渐提高,并逐步发展成为工艺设备,工艺系统就是这一阶段的重要组成部分,高效率是其主要特点。在前二个阶段,随着电子技术和数控技术,现代化的设备和高适应性,自动化的快速发展已经慢慢使夹具和工具整合,使得小批量的生产效率,循序渐进的方法,以专业级大规模生产。这个阶段,高精密夹具适应性强的主要特征。夹具可以预见,夹具在不一个阶段的主要发展趋势将是逐步提高智能化水平。

1.3 小结

一套优良的夹具设计一般情况下可大大加快生产,以提高零件的生产效率、加工质量和提高稳定性。尤其是那些外形轮廓结构较复杂的,不规则的阀体,几乎各道工序都离不开专门设计的高效率夹具。目前,中等生产规模的机械加工生产企业,其夹具的设计,制造工作量,占新产品工艺准备工作量的50%—80%。生产设计阶段,对夹具的选择和设计工作的重视程度,丝毫也不压于对机床设备及各类工艺参数的慎重选择。夹具的设计,制造和生产过程中对夹具的正确使用,维护和调整,对产品生产的优劣起着举足轻重的作用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号