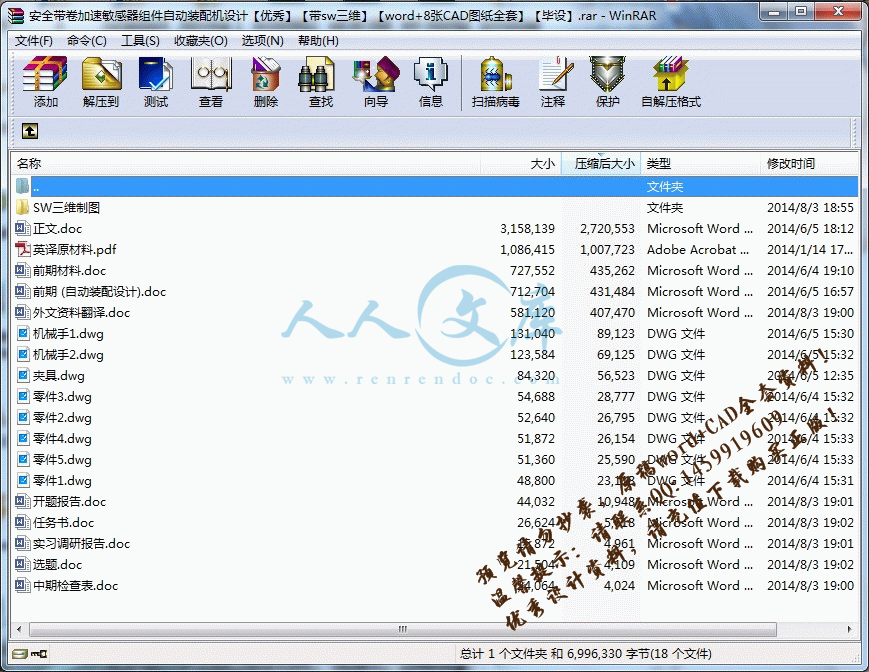

安全带卷加速敏感器组件自动装配机设计【优秀】【带sw三维】【word+8张CAD图纸全套】【毕业设计】

【带任务书+开题报告+中期检查表+外文翻译+实习报告】【38页@正文16600字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

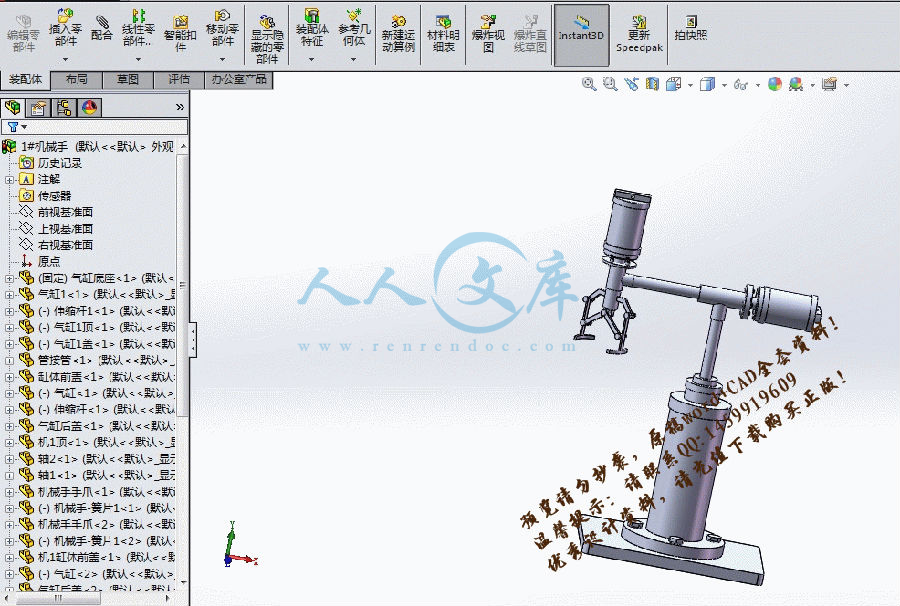

SW三维制图

中期检查表.doc

任务书.doc

前期 (自动装配设计).doc

前期材料.doc

外文资料翻译.doc

夹具.dwg

实习调研报告.doc

开题报告.doc

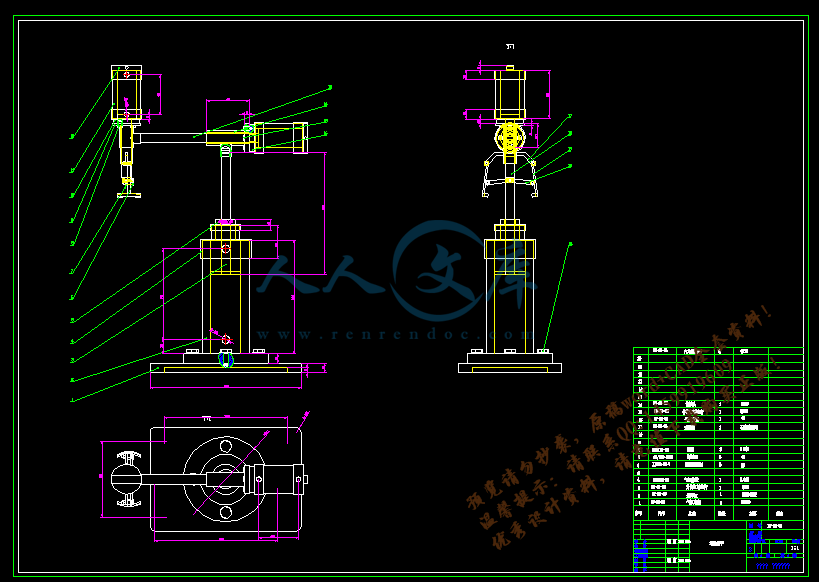

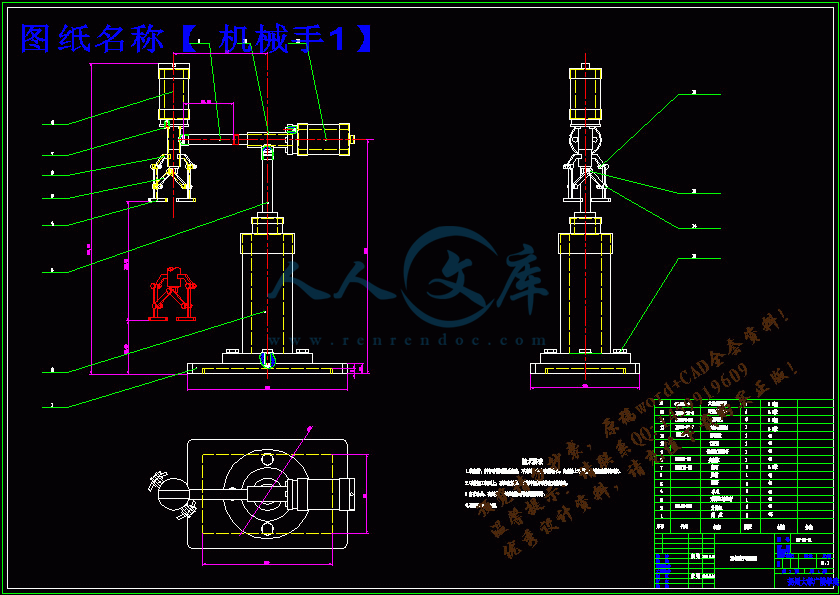

机械手1.dwg

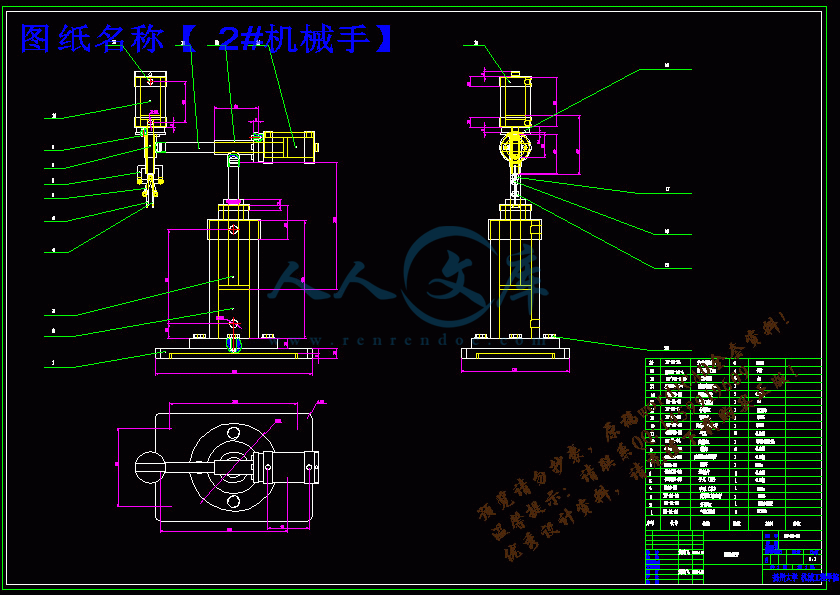

机械手2.dwg

正文.doc

英译原材料.pdf

选题.doc

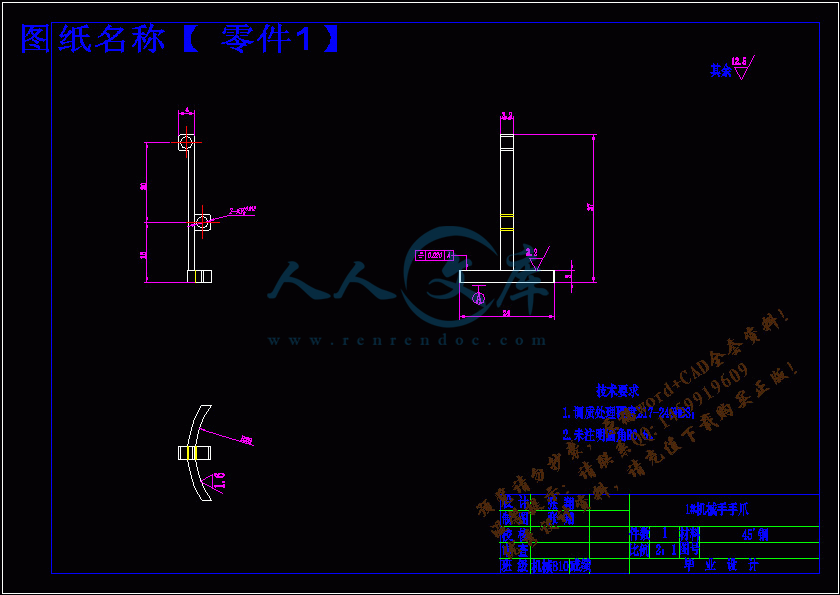

零件1.dwg

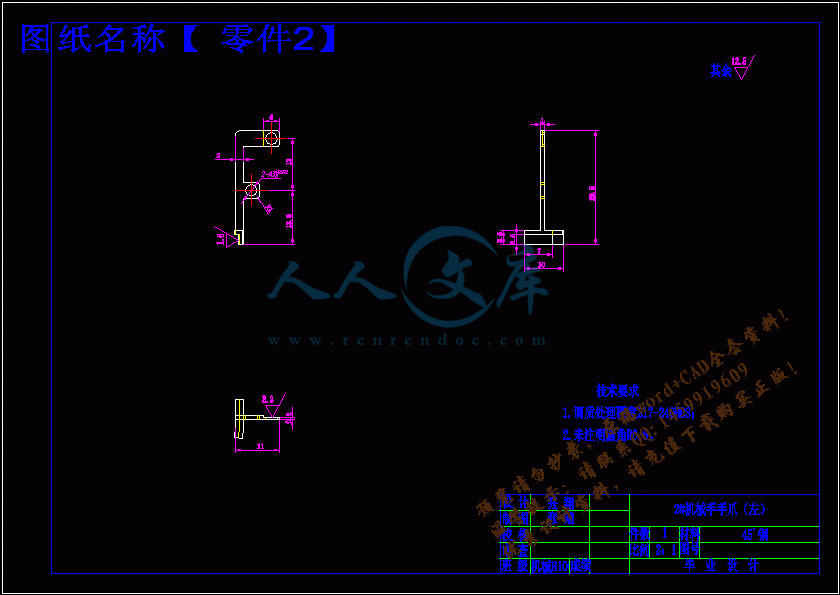

零件2.dwg

零件3.dwg

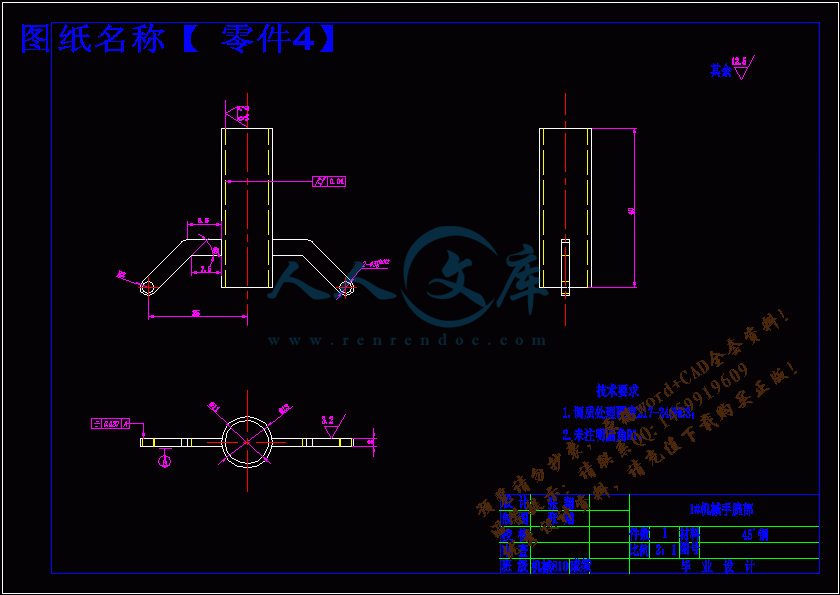

零件4.dwg

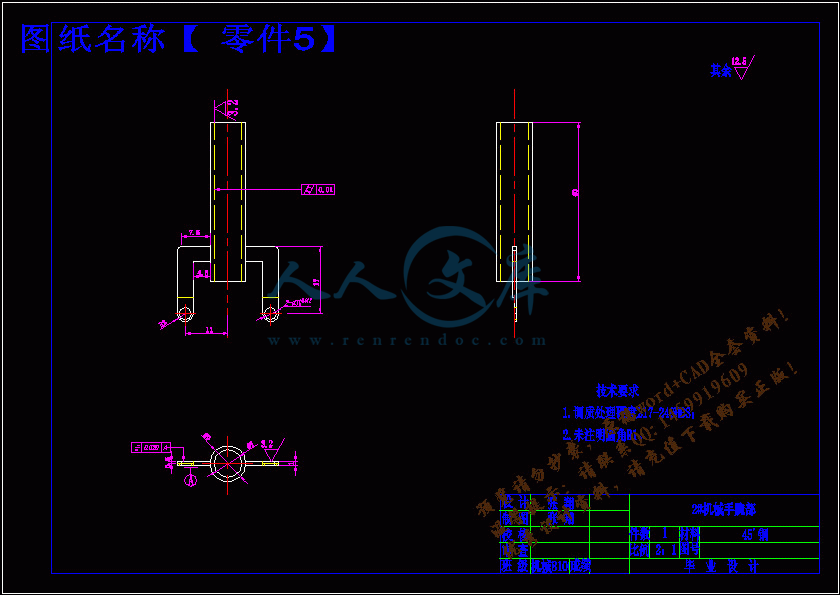

零件5.dwg

任务书

1、本毕业设计(论文)课题应达到的目的:

通过课题研究,使学生掌握机械制造装备设计、分析的方法,并且熟悉使用一种CAD软件,着重培养学生综合应用专业知识和自动装配机器人设计技术知识的能力,以及独立解决和分析实际问题的能力。

2、本毕业设计(论文)课题任务的内容和要求(包括原始数据、技术要求、工作要求等):

自动装配是当前应广泛的一种制造工艺,在生产生活中日益受到重视。本课题针对企业实际零件的制造需求和自动装配技术的应用现状,设计满足企业专门零件加工需要的自动装配机。主要针对专门零件,结合其装配工艺特点,设计满足企业实际工艺要求的专用自动装配机器人,为企业生产提供有效的手段和方法。

主要任务:

1)查阅相关文献资料15篇以上,并完成指定的不少于五千印刷符的英文资料翻译,掌握自动装配系统设计的一般方法,学会使用相关手册完成设计任务;

2)明确本题目的设计参数,技术条件,根据设计任务完成自动装配系统方案的拟定,绘制全套自动装配夹具和机器人的机械零件图、装配图;

3)完成毕业设计说明书。

毕业设计(论文)任务书

1、对本毕业设计(论文)课题成果的要求(包括毕业设计论文、

图表、实物样品等):

1)机器人零件图一套;

2)自动装配夹具和机器人装配图一份;

3)毕业设计论文一份。

4、主要参考文献:

[1] 李陆山. 安全带卷收预紧装置[J]. 汽车运用. 2000,07:28-43

[2] 尚久浩主编.自动机械设计[M]. 中国轻工业出版社, 2003 ,02:18-25

[3] 融亦鸣等著.计算机辅助夹具设计[M]. 机械工业出版社, 2002,06:34-56

[4] Walter Frick. 需要定制的自动化系统[J]. 现代制造. 2008,28):

[5] 岁丰. 新型自动装配线[J]. 管理科学文摘. 1996,08:27-37

[6] 赵锡芳. 智能装配机器人机构的研究和发展[J]. 机器人. 1990,04:17-27

[7] 丛明,钱文瀚,张坚志. 自动装配线故障分析与研究[J]. 组合机床与自动化加工技术. 1994,10:39-45

[8] 王镛. 自动化装配技术的研究与发展[J]. 组合机床与自动化加工技术. 1990,11:47-51

[9] 李瑾,李婕,陈涛. 随夹的自动定位夹紧装置的设计[J]. 制造技术与机床. 2010,12:50-55

[10] 孙铭启. 机器人在装配作业中的应用[J]. 组合机床与自动化加工技术. 1994,09:33-35

[11] 姜中威. 自动化装配技术与柔性装配系统探索[J]. 黑龙江科技信息. 2004,10:11-17

[12] 平雪良,陶宇,叶晶,董宁. 基于坐标系的自动装配方法的研究与实现[J]. 机械设计. 2011,11:23-26

[13] 张肇富. 自动装配零件的检测装置[J]. 上海计量测试. 1997,06:13-17

[14] 张萍,廖文和,刘长毅. 基于装配特征的零件自动装配[J]. 机械制造与自动化. 2004,05:21-24

[15] 林绳宗. 国外制造业自动化现状及其发展趋向[J]. 世界产品与技术. 1996,02:47-50

毕业设计(论文)任务书

5、本毕业设计(论文)课题工作进度计划

起止日期工 作 内 容

1.20~3.1

3.1~4.5

4.5~4.25

4.25~5.15

5.15~5.24

查阅资料,完成外文资料的翻译;

明确本题目的设计参数,技术条件,根据设计任务完成自动装配系统方案确定,绘自动装配夹具和机器人装配图;

完成自动装配夹具和机器人零件图的绘制;

撰写论文,指导老师审阅;

准备毕业论文答辩;

所在专业审核意见:

摘 要

随着现代科技的迅速发展,装配自动化正在逐步发展成为当今世界装配的发展主流,逐步取代人工的手工装配。它已成为衡量一个国家机械发展水平的主要标志之一。自动装配技术的重要性还在于促进产品制造系统的整体优化,生产率得以全面提高,用少量调整工人服务于一定数量的自动装配设备,在一定程度上提高均衡生产水平。自动装配不会因为工人疲劳,疏忽,情绪,技术不熟练等因素影响而造成产品质量缺陷或不稳定。时间表明,当达到一定批量的与手工装配保持同一水平的自动化装配将会使成本下降。同时,在许多情况下,装配自动化所占用的生产面积比手工装配完成同样生产任务的工作面积要小的多。

本课题设计一种应用于工业生产装配线中的专用自动装配机械手,能通过自动控制操作工业机械手,实现多自由度的抓持与运动,代替人完成安全带卷加速敏感器组件的装配。

关键词:自动装配,机械手,气动,结构设计

ABSTRACT

With the rapid development of modern science and technology, assembly automation is gradually developed into the mainstream of development in the world and gradually replace the manual assembly .It has become one of the main signs to measure the level of development of a national machinery. The importance of Automatic assembly technology is to promote products manufacturing system overall optimization .productivity can be overall improved. Minor adjustment workers are used for a certain number of automatic assembly equipment, in certain extent, It improves the balance in the level of production. Automatic assembly can not affect product quality resulting from errors or instability because of the factors of worker’s fatigue, neglect, emotional, unskilled. It has shown that when a certain amount of automated assembly will decline costs than manual assembly. At the same time, in many cases, the production assembly automation occupies a smaller area than manual assembly in completing the same task.

This?subject?is?about?a?manipulator?used?in?production?assembly?line?to?complete?assembly?work.?It?is?automatic?controlled?with?mufti-function,?mufti-degree?of?freedom?.Its?entire?structure?consists?of?the?implementing?agencies,?drive?system,?control?system?and?other?components.

Key words: Automatic assembly ,Manipulator ,Air pressure drive ,Structural design

目 录

摘 要II

ABSTRACTIII

第一章 绪论1

1.1 自动装配机的概况1

1.1.1 自动装配机的定义1

1.1.2 自动装配机的组成1

1.1.3 自动装配机的传动结构1

1.1.4 自动装配机的控制系统2

1.1.5 自动装配机的适用性2

1.2. 机械手的发展趋势2

1.3 课题研究的目的及要求4

1.4 课题背景4

第二章 总体方案设计与论证6

2.1 机械手的概况6

2.1.1 机械手的概述及分类6

2.1.2 机械手的组成结构7

2.2设计背景9

2.3机械手的坐标型式与自由度10

2.4机械手的主要参数10

2.5驱动方式和传动方式的选择11

2.5.1驱动方式的选择11

2.5.2传动方式的选择11

2.6各个自由度的实现12

2.6.1腕部纵向运动12

2.6.2手臂伸缩运动12

2.6.3底座升降运动12

第三章 装配夹具的结构设计13

3.1 定位原理13

3.2 确定定位方式14

3.3 夹紧机构14

3.4 确定总体结构和尺寸15

第四章 1#机械手的结构设计18

4.1 路径规划18

4.2 手部结构设计18

4.2.1 手指的形状和分类18

4.2.2设计时考虑的几个问题19

4.2.3 手部夹紧气缸的设计20

4.3 手臂结构设计23

4.3.1 手臂伸缩结构设计23

4.3.2 手臂伸缩驱动力的计算23

4.3.3 手臂伸缩气缸的设计25

4.4 升降缸结构设计27

4.4.1 升降缸结构设计27

4.4.2 升降缸驱动力的计算27

4.4.3 升降气缸的设计28

第5章 2#机械手的结构设计30

5.1 路径规划30

5.2 手部结构设计31

5.2.1 手指的形状31

5.2.2 手部夹紧气缸的设计31

5.3各气缸的设计32

第六章 总结33

致 谢34

参 考 文 献35

第一章 绪论

1.1 自动装配机的概况

1.1.1 自动装配机的定义

装配是指将产品的若干个零部件通过紧配、卡扣、螺纹连接、粘合、铆合、焊接等方式组合到一起得到符合预定的尺寸精度及功能的成品(半成品)。由人工处理(接触、整理、抓取、移动、放置、施力等)每一个零部件而实现的装配,严格的讲,只能称为人工装配。不需要由人工处理(接触、整理、抓取、移动、放置等)零部件而完成的装配,可称为自动装配。介于两者之间的为半自动装配。

1.1.2 自动装配机的组成

1. 零部件定向排列、输送、擒纵系统

将杂乱无章的零部件按便于机器自动处理的空间方位自动定向排列,随后顺利输送到后续的擒纵机构,为后续的机械手的抓取做准备。

2. 抓取-移位-放置机构

将由擒纵机构定点定位好的零(部件)抓住或用真空吸住,随后移动至另一位置(通常为装配工作位置)。

3. 装配工作机构

指用来完成装配工作主动作的机构,如将工件压入、夹合、螺联、卡人、粘合、焊接、铆合、粘合、焊接于上一零部件。

4.检测机构

用来对上一步装配好的部件或机器上一步工作成果进行检测,如缺零件检测、尺寸检测、缺损检测、功能检测、清料检测。

5. 工件的取出机构

用来将装配好的合格部件、不合格部件从机器上分类取出的机构。

1.1.3 自动装配机的传动结构

1) 按被装配工件在机器中的流动时间连贯性来分,有间隙运动式装配机和连续运动式装配机。

2)按装配机中工作位置数量来分,有单工位装配机和多工位装配机。

3)按装配机中工件的传动轨迹来分,有圆形工作台式装配机和环形工作台式装配机。

1.1.4 自动装配机的控制系统

通常采用PLC控制,PLC要接收各种信号的输入,向各执行机构发出指令。机器中配备多种传感器等信号采集器来监视机器中每一执行机构的运行情况,经判断后发出下一步的执行指令。人机界面用来显示机器的运行情况、运行记录,以及用来由操作者向机器发指令。

1.1.5 自动装配机的适用性

近年来,随着中国经济的发展,更多的企业出现劳资纠纷及一线员工不好管理的问题频频发生,更多的企业都在选择自动化机械装配,如同富士康在近来三年内要增加100万台机器人来解决员工问题。当然根据行业的不同,自动装配机的应用也自然不同。自动装配机根据行业的不同可分为以下几种:

1 电子电气类 轻触开关装配机,继电器自动装配机,复位健装自动装配机,变压器自动装配机等

2 五金类 脚轮自动装配机,轴承自动装配机,玩具自动装配机,齿轮自动装配机,牙箱自动装配机等

自动装配机还应用到家电,汽车行业,总而言之,自动装配机将是工厂工业化的一种趋势。

1.2. 机械手的发展趋势

国外机械手领域发展近几年有如下几个趋势:

(1)工业机械手性能不断提高(高速度、高精度、高可靠性、便于操作和维修),而单机价格不断下降,平均单机价格从91年的10.3万美元降至97年的65万美元。

(2)机械结构向模块化、可重构化发展。例如关节模块中的伺服电机、减速机、检测系统三位一体化:由关节模块、连杆模块用重组方式构造机械手整机;国外已有模块化装配机械手产品问市。

(3)工业机械手控制系统向基于PC机的开放型控制器方向发展,便于标准化、网络化;器件集成度提高,控制柜日见小巧,且采用模块化结构:大大提高了系统的可靠性、易操作性和可维修性。

(4)机械手中的传感器作用日益重要,除采用传统的位置、速度、加速度等传感器外,装配、焊接机械手还应用了视觉、力觉等传感器,而遥控机械手则采用视觉、声觉、力觉、触觉等多传感器的融合技术来进行环境建模及决策控制;多传感器融合配置技术在产品化系统中已有成熟应用。

(5)虚拟现实技术在机械手中的作用已从仿真、预演发展到用于过程控制,如使遥控机械手操作者产生置身于远端作业环境中的感觉来操纵机械手。

(6)当代遥控机械手系统的发展特点不是追求全自治系统,而是致力于操作者与机械手的人机交互控制,即遥控加局部自主系统构成完整的监控遥控操作系统,使智能机械手走出实验室进入实用化阶段。美国发射到火星上的“索杰纳”机械手就是这种系统成功应用的最著名实例。

(7)机械手化机械开始兴起。从94年美国开发出“虚拟轴机床”以来,这种新型装置已成为国际研究的热点之一,纷纷探索开拓其实际应用的领域。

我国的工业机械手从80年代“七五”科技攻关开始起步,在国家的支持下,通过“七五”、“八五”科技攻关,目前己基本掌握了机械手操作机的设计制造技术、控制系统硬件和软件设计技术、运动学和轨迹规划技术,生产了部分机械手关键元器件,开发出喷漆、弧焊、点焊、装配、搬运等机械手;其中有130多台套喷漆机械手在二十余家企业的近30条自动喷漆生产线(站)上获得规模应用,弧焊机械手己应用在汽车制造厂的焊装线上。但总的来看,我国的工业机械手技术及其工程应用的水平和国外比还有一定的距离,如:可靠性低于国外产品;机械手应用工程起步较晚,应用领域窄,生产线系统技术与国外比有差距;在应用规模上,我国己安装的国产工业机械手约200台,约占全球已安装台数的万分之四。以上原因主要是没有形成机械手产业,当前我国的机械手生产都是应用户的要求,“一客户,一次重新设计”,品种规格多、批量小、零部件通用化程度低、供货周期长、成本也不低,而且质量、可靠性不稳定。因此迫切需要解决产业化前期的关键技术,对产品进行全面规划,搞好系列化、通用化、模块化设计,积极推进产业化进程.我国的智能机械手和特种机械手在“863”计划的支持下,也取得了不少成果。其中最为突出的是水下机械手,6000m水下无缆机械手的成果居世界领先水平,还开发出直接遥控机械手、双臂协调控制机械手、爬壁机械手、管道机械手等机种:在机械手视觉、力觉、触觉、声觉等基础技术的开发应用上开展了不少工作,有了一定的发展基础。但是在多传感器信息融合控制技术、遥控加局部自主系统遥控机械手、智能装配机械手、机械手化机械等的开发应用方面则刚刚起步,与国外先进水平差距较大,需要在原有成绩的基础上,有重点地系统攻关,才能形成系统配套可供实用的技术和产品,以期在“十五”后期立于世界先进行列之中。

1.3 课题研究的目的及要求

自动装配是当前应广泛的一种制造工艺,在生产生活中日益受到重视。本课题针对企业实际零件的制造需求和自动装配技术的应用现状,设计满足企业专门零件加工需要的自动装配机。主要针对专门零件,结合其装配工艺特点,设计满足企业实际工艺要求的专用自动装配机器人,为企业生产提供有效的手段和方法。

通过课题研究,使学生掌握机械制造装备设计、分析的方法,并且熟悉使用一种CAD软件,着重培养学生综合应用专业知识和自动装配机器人设计技术知识的能力,以及独立解决和分析实际问题的能力。

主要任务:

1)查阅相关文献资料15篇以上,并完成指定的不少于五千印刷符的英文资料翻译,掌握自动装配系统设计的一般方法,学会使用相关手册完成设计任务;

2)明确本题目的设计参数,技术条件,根据设计任务完成自动装配系统方案的拟定,绘制全套自动装配夹具和机器人的机械零件图、装配图;

3)完成毕业设计说明书。

1.4 课题背景

装配过程是机械制造过程中必不可少的环节。人工操作的装配是一个劳动密集型的过程,生产率是工人执行某一具体操作所花费时间的函数,其劳动量在产品制造总劳动量中占有相当高的比例。随着先进制造技术的应用,制造零件劳动量的下降速度比装配劳动量下降速度快得多,如果仍旧采用人工装配的方式,该比值还会提高。据有关资料统计分析,一些典型产品的装配时间占总生产时间的53%左右,是花费最多的生产过程,因此提高装配效率是制造工业中急需解决的关键问题之一。

自动化装配具备如下优点。

1. 装配效率高,产品生产成本下降。尤其是在当前机械加工自动化程度不断得到提高的情况下,装配效率的提高对产品生产效率的提高具有更加重要的意义。

2 .自动装配过程一般在流水线上进行,采用各种机械化装置来完成劳动量最大和最繁重的工作,大大降低了工人的劳动强度。

3. 不会因工人疲劳、疏忽、情绪、技术不熟练等因素的影响而造成产品质量缺陷或不稳定。

4 .自动化装配所占用的生产面积比手工装配完成同样生产任务的工作面积要小得多。

5 .在电子、化学、宇航、国防等行业中,许多装配操作需要特殊环境,人类难以进人或非常危险,只有自动化装配才能保障生产安全。

随着科学技术的发展和进步,在机械制造业,CNC、FMC,FMS的出现逐步取代了传统的制造技术,它们不仅具备高度自动化的加工能力,而且具有对加工对象的灵活性。如果只有加工技术的现代化,没有装配技术的自动化,FMS就成了自动化孤岛。装配自动化的意义还在于它是CIMS的重要组成部分。

第二章 总体方案设计与论证

在科学技术突飞猛进的今天,装配线机械手的设计思想主要是通过对以前及现有的最具有代表性的装配线机械手进行分析研究,吸收它们的优点,将各个优点结合起来,将不同结构进行组合变化,使之达到较理想的方案。从而达到较好的运动精度和工作稳定性,进而使之在市场上更具有竞争力。本次设计就是在分析、研究以往优秀的装配线机械手的基础上加以改进而成的。

2.1 机械手的概况

2.1.1 机械手的概述及分类

机械手是模仿着人手的部分动作,按给定程序、轨迹和要求实现自动抓取、搬运或操作的自动机械装置。在工业生产中应用的机械手被称为“工业机械手”。生产中应用机械手可以提高生产的自动化水平和劳动生产率:可以减轻劳动强度、保证产品质量、实现安全生产;尤其在高温、高压、低温、低压、粉尘、易爆、有毒气体和放射性等恶劣的环境中,它代替人进行正常的工作,意义更为重大。因此,在机械加工、冲压、铸、锻、焊接、热处理、电镀、喷漆、装配以及轻工业、交通运输业等方面得到越来越广泛的引用.

机械手的结构形式开始比较简单,专用性较强,仅为某台机床的上下料装置,是附属于该机床的专用机械手。随着工业技术的发展,制成了能够独立的按程序控制实现重复操作,适用范围比较广的“程序控制通用机械手”,简称通用机械手。由于通用机械手能很快的改变工作程序,适应性较强,所以它在不断变换生产品种的中小批量生产中获得广泛的引用。机械手一般分为三类。第一类是不需要人工操作的通用机械手,它是一种独立的不附属于某一主机的装置。它可以根据任务的需要编制程序,以完成各项规定工作。它的特点是除具备普通机械的物理性能外,还具备通用机械、记忆智能的三元机械。第二类是需要人工操作的,称为操作机。它起源于原子、军事工业,先是通过操作机来完成特定的作业,后来发展到用无线电信号操作机械手来进行探测月球、火星等。第三类是专用机械手,主要附属于自动机床或自动线上,用于解决机床上下料和工件传送。这种机械手在国外称为“Mechanical Hand”,它是为主机服务的,由主机驱动,除少数外,工作程序一般是固定的,因此是专用的。本项目要求设计的机械手模型可归为第一类,即通用机械手。

参 考 文 献

[1] 李陆山. 安全带卷收预紧装置[J]. 汽车运用. 2000,07:28-43

[2] 尚久浩主编.自动机械设计[M]. 中国轻工业出版社, 2003 ,02:18-25

[3] 融亦鸣等著.计算机辅助夹具设计[M]. 机械工业出版社, 2002,06:34-56

[4] Walter Frick. 需要定制的自动化系统[J]. 现代制造. 2008,28):

[5] 岁丰. 新型自动装配线[J]. 管理科学文摘. 1996,08:27-37

[6] 赵锡芳. 智能装配机器人机构的研究和发展[J]. 机器人. 1990,04:17-27

[7] 丛明,钱文瀚,张坚志. 自动装配线故障分析与研究[J]. 组合机床与自动化加工技术. 1994,10:39-45

[8] 王镛. 自动化装配技术的研究与发展[J]. 组合机床与自动化加工技术. 1990,11:47-51

[9] 李瑾,李婕,陈涛. 随夹的自动定位夹紧装置的设计[J]. 制造技术与机床. 2010,12:50-55

[10] 孙铭启. 机器人在装配作业中的应用[J]. 组合机床与自动化加工技术. 1994,09:33-35

[11] 姜中威. 自动化装配技术与柔性装配系统探索[J]. 黑龙江科技信息. 2004,10:11-17

[12] 平雪良,陶宇,叶晶,董宁. 基于坐标系的自动装配方法的研究与实现[J]. 机械设计. 2011,11:23-26

[13] 张肇富. 自动装配零件的检测装置[J]. 上海计量测试. 1997,06:13-17

[14] 张萍,廖文和,刘长毅. 基于装配特征的零件自动装配[J]. 机械制造与自动化. 2004,05:21-24

[15] 林绳宗. 国外制造业自动化现状及其发展趋向[J]. 世界产品与技术. 1996,02:47-50

[16] 张桂香.机电类专业毕业设计指南[J].北京:机械工业出版社,2005.29-30

[17] 王孙.关节式机械手本体及控制系统设计[M].西安交大机械电子工程研究所,CN 44-1259/TH.

[18]机电一体化技术手册编委会.机电一体化技术手册[J].北京:1999,7.49-52

[19]徐小龙. 机床夹具设计方案的分析与研究[D].太原科技大学,2013.53-56

[20]曹海燕. 上下料机械手柔性手腕的运动分析及优化设计[D].江南大 学,2012.45-48

[21]王志明. 基准定位的自动装配技术[J]. 工具技术,2008,02:49-52.

[22]谢存禧,温继圆,郑时雄,李杞仪. 机器人自动装配线的规划设计[J]. 华南理工大学学报(自然科学版),2004,04:1-7.

[23]谢存禧,郭炽盛,陈星海. 机器人自动装配线上提高装配精度的方法[J]. 华南理工大学学报(自然科学版),2004,04:41-45.

[24]陶湘厅,袁锐波,罗璟. 气动机械手的应用现状及发展前景[J]. 机床与液压,2007,08:226-228.

[25]袁玉比. 气动机械手夹持力控制系统的研究[D].昆明理工大学,2012.

[26]李庭贵. 气动机械手搬运物料精确定位控制系统设计[J]. 液压与气动,2012,01:54-56.

[27]侯兰香,李凤刚,赵钟波. 气动机械手关节结构设计[J]. 枣庄学院学报,2012,05:73-81.

[28]蔡瑾,段国林,李翠玉,李德红. 夹具设计技术发展综述[J]. 河北工业大学学报,2002,05:35-40.

[29]周太平,康志成,夏翔. 数控铣床与加工中心夹具设计[J]. 现代制造工程,2011,02:91-95.

[30]王海叶. 轻型气动平动搬运机械手设计[J]. 机械制造与自动化,2010,04:167-168+178.

[31]周虹. 气动与PLC技术相结合在机械手设计中的应用[J]. 液压与气动,2004,03:38-39.

[32]杨玲玲,胡树根,王耘,林小哲,来明. 基准定位的自动装配技术[J]. 轻工机械,2008,01:59-62.

[33] 徐炳辉.气动手册[M].上海科学技术出版社,2005.26-28.

[34] 周骥平,林岗.机械制造自动化技术[M].北京:机械工业出版社,2007.32-35

[35]Tbndu B,Lopez.P Modeling and control of mckibben artificial muscle robot aetuatom[J].IEEE Control systems Magazine 2000,5:15-38.

[36] 陆鑫盛,周洪.气动自动化系统的优化设计[M].上海科学技术文献出版社,1999.86-89.

[37] 路甬祥. 液压气动技术手册[M].机械工业出版社,2003.10-12.

川公网安备: 51019002004831号

川公网安备: 51019002004831号