【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

在汽车行驶时的动力传递过程中,变速器是其中的重要环节。汽车变速器是汽车传动系统的主要组成部分,主要作用是将发动机的转矩经过改变后传递给主减速器,最终将动力有效而经济地传至驱动车轮,以满足汽车的使用要求。设置空档用来中断动力传递,设置倒档,使汽车能够倒退行驶。

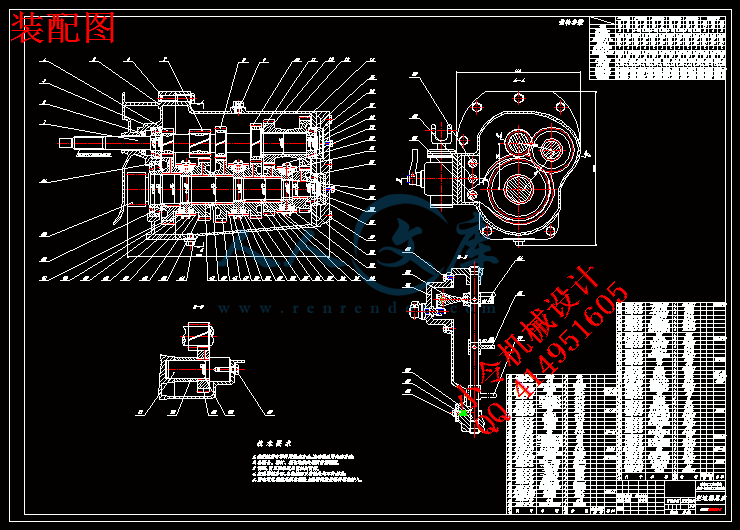

本设计以现有企业正在生产的远舰汽车变速器为基础,在给定发动机输出转矩、转速及最高车速、总质量、车轮滚动半径等条件下,着重对变速器齿轮的结构参数、轴的结构尺寸等进行设计计算;并对变速器的传动方案和结构形式进行设计;同时对操纵机构和同步器的结构进行设计;从而提高汽车的整体性能。

文中对变速器的主要参数进行验证,包括齿轮强度的校核、变速器轴强度和刚度的校核、轴承寿命的验算等,计算结果表明整体性能满足要求。

关键词:两轴式;变速器;齿轮;同步器;设计;校核

ABSTRACT

In the process of power delivery of the auto movement, transmission is the necessary link. Auto transmission is the main component of the drive train, the main effect is to transfer torque from engine to final drive through by changing gear ratio is to expand the scope and speed to adapt to the driving conditions effectively and economically. Setting neutral is to interrupt power transmission; Setting up to reverse, the vehicle can drive back.

The design based on the existing enterprises production Yuanjian Transmission, In conditions that knowing the engine output torque speed of engine and maximum speed of vehicles, maximum degree, focus on the designing of transmission gear structural parameters, axis geometry design computation; as well as the transmission and drive program structure design; Meanwhile on the structure of components to manipulation and synchronous design; thereby enhancing the overall performance of cars.

The main parameters for transmission have been checked, including the strength of gear, the transmission shaft strength and stiffness of the coupling, Bearing life, results show overall performance meet the requirement.

Key words: Twin-shaft; Transmission; Gears; Synchronizer; Design; Parameters

目 录

摘要 I

ABSTRACT II

第1章 绪论 1

1.1 概述 1

1.1.1 汽车变速器的设计要求 1

1.1.2 国内外汽车变速器的发展现状 2

1.2 设计的内容及方法 2

第2章 变速器传动机构与操纵机构方案选择 4

2.1 变速器传动机构布置方案 4

2.1.1 变速器传动方案分析与选择 4

2.1.2 倒档布置方案 4

2.1.3 零部件结构方案分析 5

2.2 变速器操纵机构布置方案 7

2.2.1 概述 7

2.2.2 典型的操纵机构及其锁定装置 8

2.3 本章小结 10

第3章 变速器传动机构的设计与计算 11

3.1 变速器主要参数的选择 11

3.1.1 档数 11

3.1.2 传动比范围 11

3.1.3 变速器各档传动比的确定 11

3.1.4 中心距的选择 14

3.1.5 变速器的外形尺寸 15

3.1.6 齿轮参数的选择 15

3.1.7 各档齿轮齿数的分配及传动比的计算 16

3.1.8 变速器齿轮的变位 19

3.2 变速器齿轮强度校核 23

3.2.1 齿轮材料的选择原则 23

3.2.2 变速器齿轮弯曲强度校核 23

3.2.3 轮齿接触应力校核 27

3.2.4 倒档齿轮的校核 31

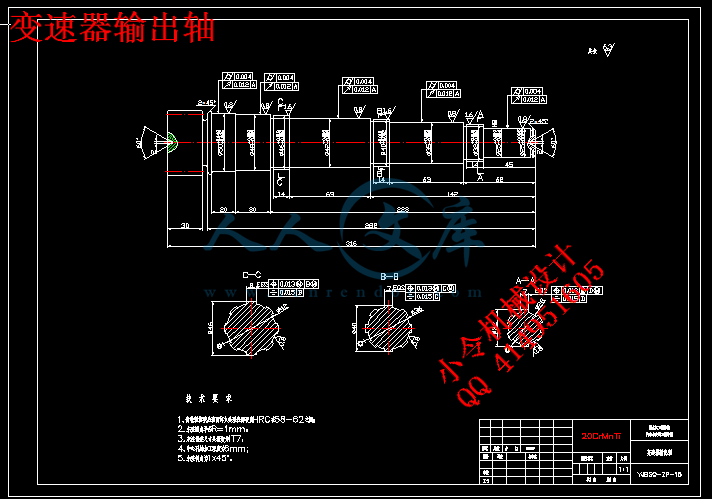

3.3 轴的结构和尺寸设计 32

3.3.1 轴的工艺要求 33

3.3.2 初选轴的直径 33

3.3.3 轴最小直径的确定 34

3.4 轴的强度验算 35

3.4.1 轴的刚度计算 35

3.4.2 轴的强度计算 42

3.5 轴承选择与寿命计算 48

3.5.1 输入轴轴承的选择与寿命计算 49

3.5.2 输出轴轴承的选择与寿命计算 52

3.6 本章小结 53

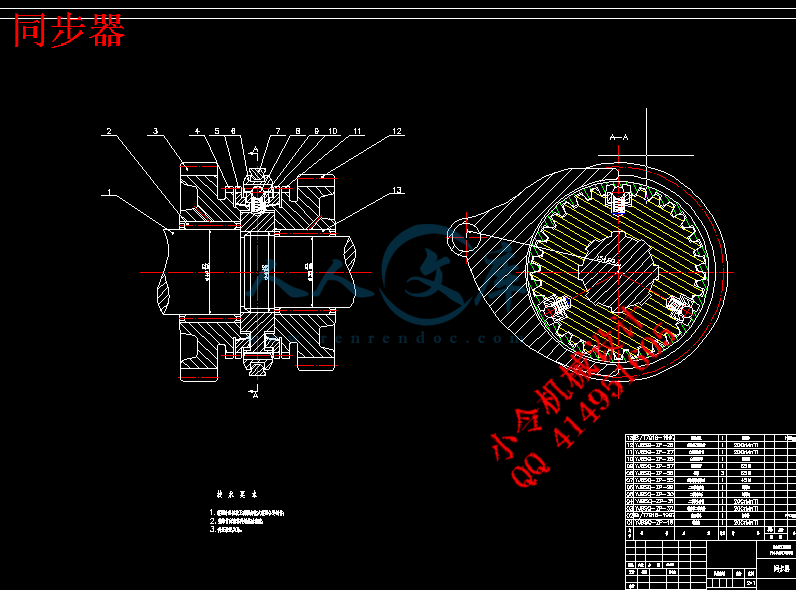

第4章 变速器同步器及操纵机构的设计 54

4.1 同步器 54

4.1.1 同步器工作原理 54

4.1.2 惯性式同步器 54

4.1.3 锁环式同步器主要尺寸的确定 56

4.1.4 主要参数的确定 56

4.2 操纵机构 59

4.2.1 概述 59

4.2.2 典型操纵换档机构 59

4.3 变速器壳体 60

4.4 本章小结 60

结论 61

参考文献 62

致谢 63

附录A1 64

附录A2 67

第1章 绪 论

1.1概述

随着汽车工业的迅猛发展,车型的多样化、个性化已经成为汽车发展的趋势。而变速器设计是汽车设计中重要的环节之一。它是用来改变发动机传到驱动轮上的转矩和转速,目的是适应汽车在起步、加速以及克服各种道路障碍等不同行驶条件下对驱动车轮的不同要求的需要,使汽车获得不同的牵引力和速度,同时使发动机在最有利的工况范围内工作。因此它的性能影响到汽车的动力性和经济性指标,对乘用车而言,其设计意义更为明显。在对汽车性能要求越来越高的今天,车辆的舒适性也是评价汽车的一个重要指标,而变速器的设计不合理,将会使汽车的舒适性下降,使汽车的运行噪声增大,影响汽车的整体性。

1.1.1汽车变速器的设计要求

汽车传动系是汽车的核心组成部分。其任务是调节、变换发动机的性能,将动力有效而经济地传至驱动车轮,以满足汽车的使用要求。变速器是完成传动系任务的重要部件,也是决定整车性能的主要部件之一。变速器的结构要求对汽车的动力性、燃料经济性、换档操纵的可靠性与轻便性、传动平稳性与效率等都有直接的影响。随着汽车工业的发展,轿车变速器的设计趋势是增大其传递功率与重量之比,并要求其具有更小的尺寸和良好的性能。在汽车变速器的设计工作开始之前,首先要根据变速器运用的实际场合来对一些主要参数做出选择。主要参数包括中心距、变速器轴向尺寸、轴的直径、齿轮参数、各档齿轮的齿数等。

川公网安备: 51019002004831号

川公网安备: 51019002004831号