矿井井口液压站设计

53页 20000字数+说明书+任务书+5张CAD图纸【详情如下】

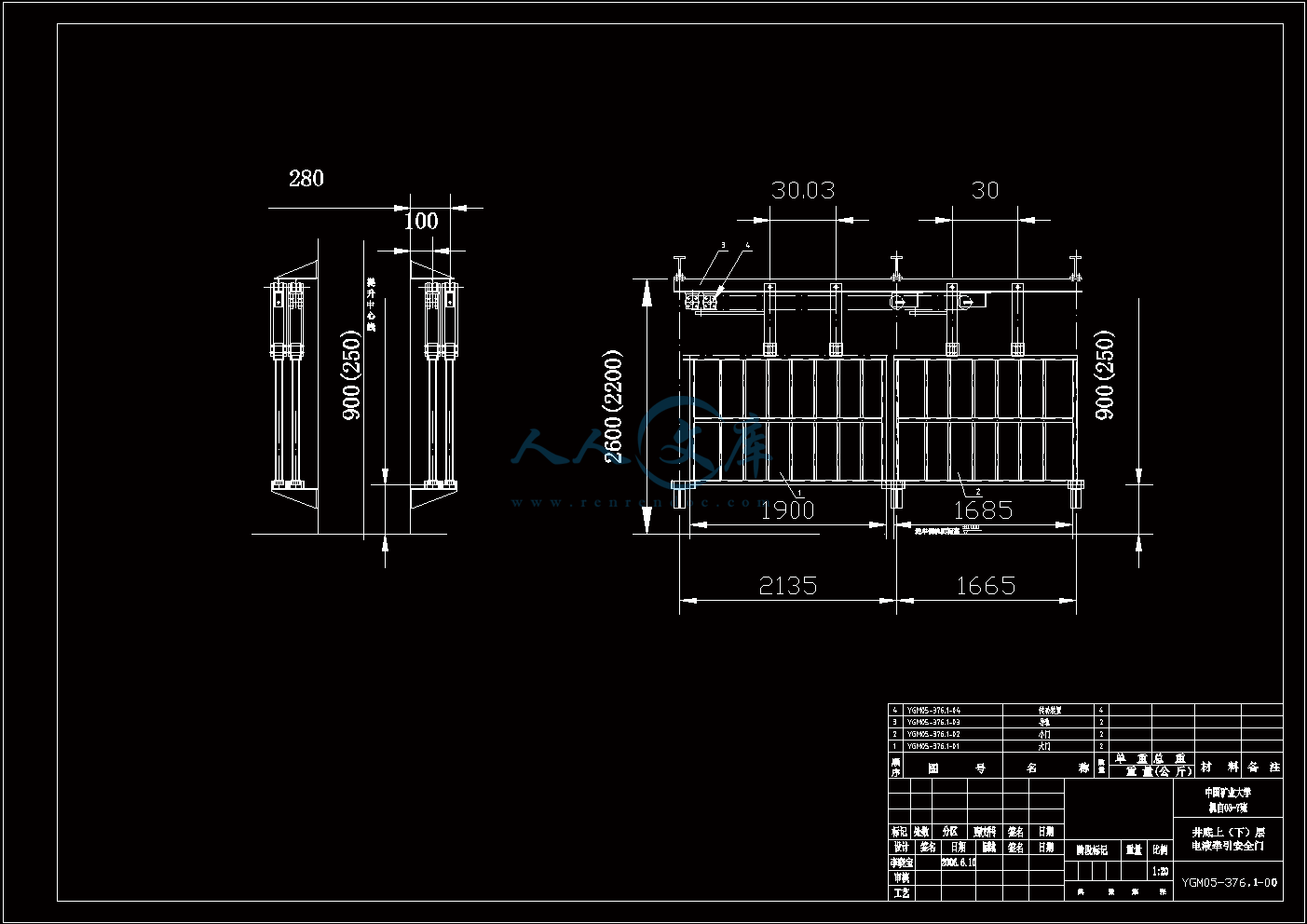

安全门.dwg

封皮、任务书,目录、摘要.doc

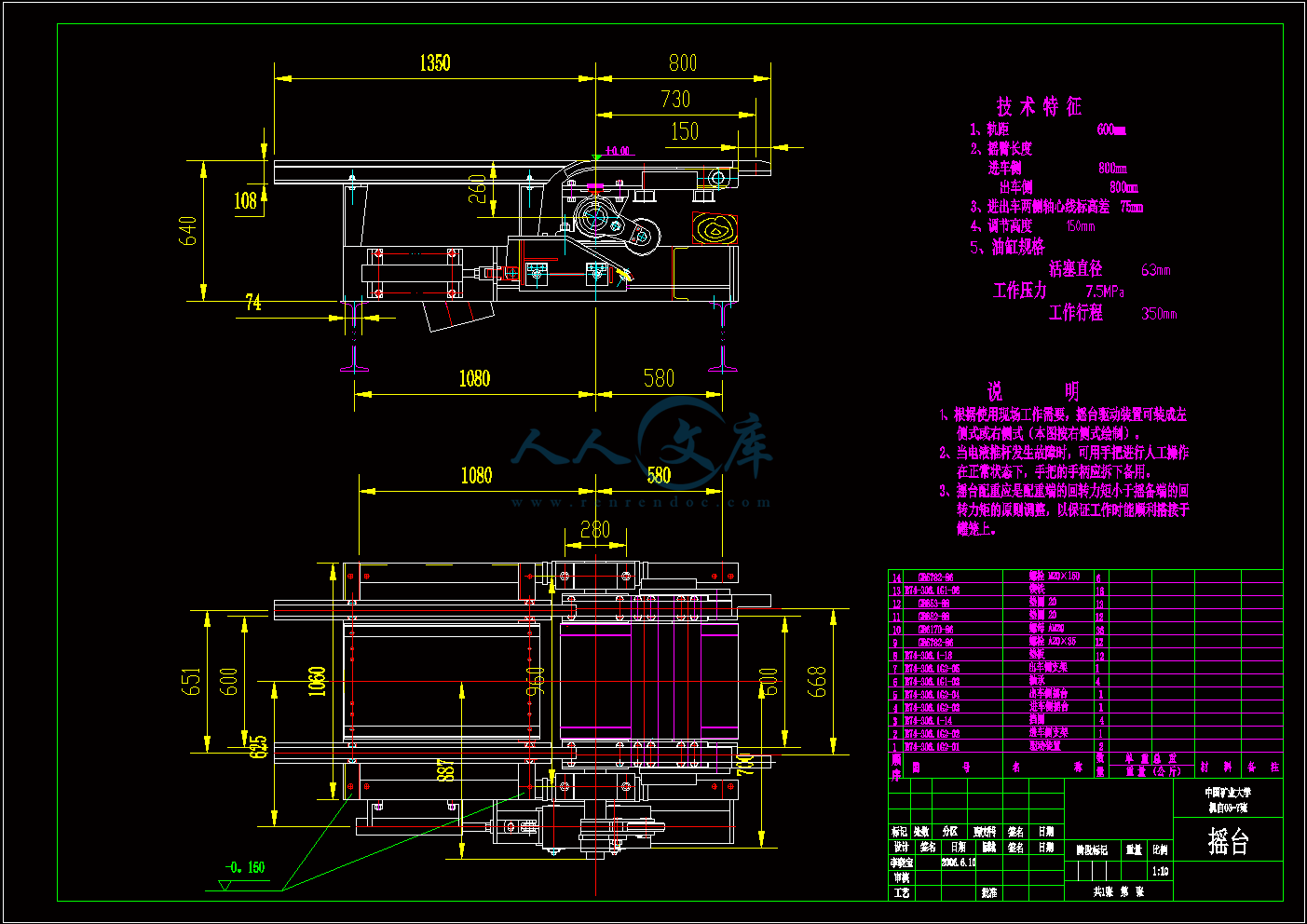

摇台装配图.dwg

液压系统原理图.dwg

矿井井口液压站设计说明书.doc

装配图.dwg

阻车器 .dwg

目 录

1绪论1

1.1论文研究的意义1

1.2目前可行的解决方案经过对国内其它单位使用的副井操车设备情况的调查,可知我国目前使用的操车情况如下:1

1.3液压技术的特点和应用情况3

1.4副井操车液压联动装置简介5

2液压系统原理图的拟定6

2.1液压系统原理图的拟定6

2.2液压元件的设计计算10

2.3摇台液压缸的设计计算14

2.4 液压泵的设计计算16

2.5电动机的选择20

2.6联轴器的选择21

2.7控制阀的选择23

2.8压力表以及压力表开关的选择31

3 液压辅助元件设计33

3.1液压管道的选择33

3.2管接头的选择35

3.3油箱的设计计算36

3.4系统的发热及散热计算39

3.5过滤器的选择41

3.6冷却器的选择42

4阀块设计44

4.1块简介44

4.2液压阀块有以下特点44

4.3阀块的设计及注意事项45

4.4阀块的尺寸的确定45

4.5阀块内的油道孔的设计45

4.6精度设计46

4.7材料设计46

5 液压站的设计46

5.1液压站外观设计的误区46

5.2液压站的设计47

参考文献48

致 谢49

摘 要

副井操车系统是煤矿生产中重要的一部分,它的含义是指井口、井底有关机械、电报设备在规定的闭锁条件下,按照设计的逻辑程序循环动作,辅助罐笼完成提升任务。

国内现役的煤矿副井操车系统暴露的缺点有:机构复杂、可靠性不高、维护维修不便等,往往带来巨大的损失。

副井操车系统要求控制系统具有技术先进、工作可靠、抗干扰能力强、自动化程度高等性能。在参考了三个系统的优缺点后,决定选择由液压作为动力源的第三套系统。

本系统要实现的流程从罐笼到们开始如下:

罐笼到位 安全门打开 前阻车器打开 摇台落下 推车机推车 罐笼内矿车出罐 罐内阻车器阻 矿车进罐头 推车机回车到位 前阻车器阻车 摇台择起,安全门关上,罐笼运行,后阻车器打开,矿车达到阻车器,下一循环。

本文主要的工作就是根据以上的工作流程进行液压原理的拟定,液压站的设计,以及各种器件的计算选型。

关键词:副井操车系统 前阻车器 推车机 罐笼 安全门 闭锁 摇台 矿车

本要实现的流程从罐笼到们开始如下:

罐笼到位 安全门打开 前阻车器打开 摇台落下 推车机推车 罐笼内矿车出罐 罐内阻车器阻 矿车进罐头 推车机回车到位 前阻车器阻车 摇台择起,安全门关上,罐笼运行,后阻车器打开,矿车达到阻车器,下一循环。

本文主要的工作就是根据以上的工作流程进行液压原理的拟定,液压站的设计,以及各种器件的计算选型。

关键词:副井操车系统; 前阻车器; 推车机; 罐笼; 安全门; 闭锁; 摇台; 矿车

ABSTRACT

Parade car belonging to coal production system is an important part, it refers to the meaning of the wellhead, the bottom of the machinery, telegraph equipment in the closed conditions, in accordance with the logic of the design cycle process moves auxiliary cage complete upgrade mandate.

China coal mine belonging to the service of the parade car system has exposed the shortcomings : institutional complexity, reliability is not high, maintaining maintenance inconvenience, often bring huge losses. Auxiliary System Requirements parade car control system with a more technologically advanced, reliable, anti-interference capability, high automation performance. In reference to the advantages and disadvantages of the three systems, choosing from hydraulic power source as the third set of system

Of the system to achieve the flow from cage to begin as follows : safety cage in place before the doors open car to open shake Taiwan fallen pusher carts cans cage tub out Tank Car resistance tub into resistance Enter canned pusher in place before the car stop car shake Taiwan optional, security doors, the cage operations, after the car to open. tub reached car for the next cycle. This paper is based on the work over the work process for the preparation of hydraulic principles, hydraulic design of the station, and the calculation of various device selection.

Keywords : parade car belonging to the former system for car pusher safety cage door locking shake Taiwan tub to be achieved in this process from the cage to begin the following : safety cage in place before the doors open car to open shake Taiwan fallen pusher carts cans cage tub out Tank Car resistance resistance Mine Progressive canned pusher round in place before the car stop car shake Taiwan optional, security doors, the cage operations, after the car stop fighting , tub reached car for the next cycle. This paper is based on the work over the work process for the preparation of hydraulic principles, hydraulic design of the station, and the calculation of various device selection. Keywords : parade car belonging to the former system for car pusher safety cage door locking shake Taiwan tub

川公网安备: 51019002004831号

川公网安备: 51019002004831号