某微型客车后驱动桥设计

摘 要

驱动桥是汽车行驶系统的重要组成部分。其基本功用是增大有传动轴或直接有变速器传来的转矩。并将动力分配给左、右两个驱动轮,使左、右驱动轮具有汽车形式运动学所要求的差速功能。所以其设计质量直接关系到整车性能的好坏。在设计过程中,需要严谨和认真的态度进行设计。

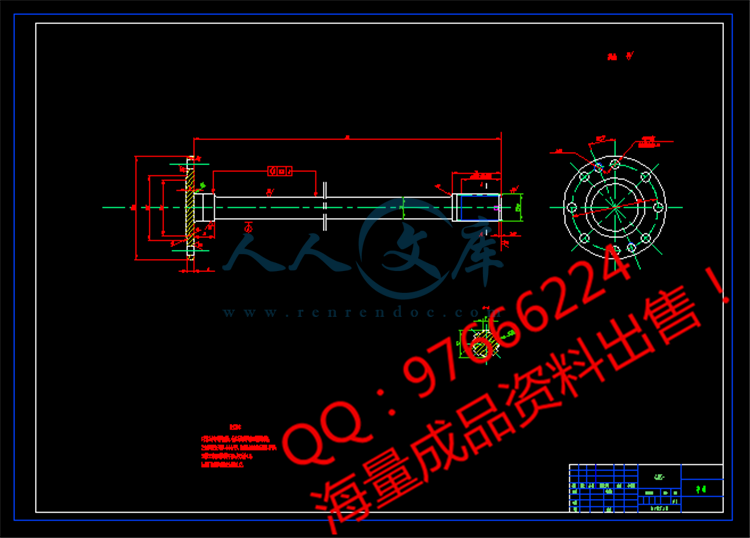

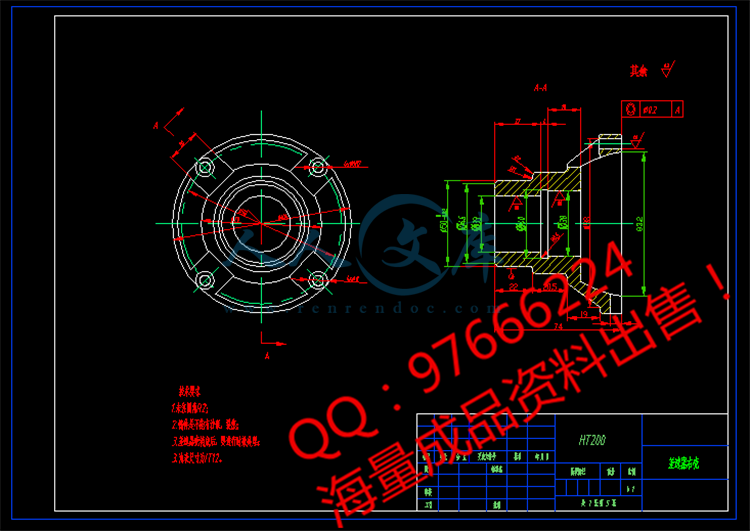

在绪论部分,对本课题的背景研究意义及国内外情况简明扼要的说明。在方案论证部分,对驱动桥及其总成结构形式的选择作了具体的说明。本设计选用了单级减速器,采用的是双曲面齿轮啮合传动,尽量的简化结构,缩减尺寸,有效的利用空间,充分减少材料浪费,减轻整体质量。由于是微型客车,主要行驶在路面较好的条件下,决定使用对称式圆锥行星齿轮差速器。半桥则选用全浮式半桥。在设计计算与强度校核部分,对主减速器、差速器、半轴和驱动桥壳等重要部件的参数作了选择。同时也对以上的几个部件进行了必要的校核计算。

结束语是对本次毕业设计的一些看法和心得体会,并对悉心帮助和指导过我的指导老师和同学表示衷心的感谢和深深的敬意。

关键词: 微型客车;驱动桥;主减速器;差速器

Design of drive axle minibus

Abstract

Drive axle is an important part of the car system. Its basic function is to increase the shaft or directly with the transmission of torque. And distributes power to the left and right two driving wheels, make the left and right driving wheels car form required by the kinematic differential function. So its design quality directly related to vehicle performance is good or bad. In the process of design, need strict and serious attitude to carry on the design.

In the introduction part, the background of this topic research significance and the situation at home and abroad and brief description.Part of the project demonstration, the choice of drive axle and assembly structure forms the specific instructions. This design chooses a single stage reducer, USES a hyperboloid gear meshing transmission, try to simplify the structure, reduced size, effective use of space, sufficient to reduce material waste, reduce the overall quality. Being minivans, main drive under the condition of the pavement better, decided to use the symmetric cone planetary gear differential. A half bridge is semi floating half bridge.In design calculation and intensity, the Lord reducer, differential and half shaft and drive axle housing, and other important components of the parameters has made the choice. And at the same time for more than a few parts for the necessary checking calculation.

Is the conclusion of this graduation design of some of the views and comments, and carefully to help and guidance of my instructor and classmates express my heartfelt thanks and deep respect.

Key words: minivans;drive axle;The main reducer;differential

主 要 符 号 表

大齿轮节锥距

从动锥齿轮中点锥距

轴承的额定动载荷

、分别为主、从动双曲面齿轮的外圆直径

、分别为主、从动双曲面齿轮的节圆直径

双曲面齿轮偏移距

双曲面齿轮的从动齿轮齿面宽

汽车正常使用时的平均爬坡能力系数

汽车或汽车系列的性能系数

道路滚动阻力系数

后轴对水平地面的荷重

汽车满载总重量

、分别为主、从动齿轮的齿顶高

、分别为主、从动齿轮的齿根高

齿工作高

齿工作高系数

齿全高系数

驱动桥主减速比

分动器高档传动比

变速器1档传动比

轮边减速器传动比

传动系低档传动比

双曲面齿轮轮齿弯曲计算用综合系数

双曲面齿轮的从动齿轮齿顶高系数

双曲面齿轮强度计算用表面质量系数

双曲面齿轮强度计算用载荷分配系数

双曲面齿轮强度计算用超载系数

双曲面齿轮强度计算用尺寸系数

双曲面齿轮强度计算用质量系数

轴承的额定寿命

齿轮模数、端面模数

发动机最大功率下的转速

发动机最大功率

单位齿长上的圆周力

刀盘的名义半径

车轮的滚动半径

发动机转矩

发动机最大转矩

计算转矩

发动机最大转矩配以传动系最低挡传动比时作用在主减速器从动齿轮上的计算转矩

驱动车轮滑转时作用在主减速器从动齿轮上的计算转矩

主减速器从动齿轮的平均计算转矩

齿轮齿数

齿轮压力角

中点螺旋角或名义螺旋角

、分别为双曲面齿轮主、从动齿轮的节锥角

、分别为主、从动齿轮的面锥角

、分别为主、从动齿轮的根锥角

轮胎与路面的附着系数

汽车传动系效率

轮边减速器的传递效率

接触应力

弯曲应力

扭转应力

剪切应力

目 录

1 绪论1

1.1题目背景1

1.2研究意义1

1.3国内外相关研究情况1

1.4本设计研究的主要内容3

2 驱动桥总成结构形式及布置4

2.1总体方案论证4

2.2驱动桥的分类4

2.2.1非断开式驱动桥4

3 主减速器设计6

3.1主减速器结构方案的分析6

3.2主减速器主、从动锥齿轮的支承方案8

3.3主减速器锥齿轮设计9

3.3.1主减速比i0的确定9

3.3.2主减速器齿轮计算载荷的确定10

3.4主减速器齿轮基本参数的选择11

3.4.1齿数的选择11

3.4.2从动锥齿轮节圆直径的选择11

3.4.3从动锥齿轮端面模数的选择12

3.4.4螺旋锥齿轮齿宽F的选择12

3.4.5螺旋锥齿轮的螺旋方向12

3.4.6螺旋角的选择12

3.4.7齿轮法向压力角的选择13

3.5主减速器圆弧齿螺旋锥齿轮的几何尺寸计算13

3.6主减速器螺旋锥齿轮的强度计算15

3.6.1单位齿长上的圆周力15

3.6.2轮齿的弯曲强度计算16

3.6.3轮齿的齿面接触强度计算17

3.7主减速器齿轮的材料及热处理17

3.8主减速器轴承的计算18

3.8.1作用在主减速器主动齿轮上的力18

3.8.2主减速器轴承载荷的计算20

3.8.3主减速器轴承额定寿命的计算21

3.9主减速器的润滑22

4 差速器设计24

4.1差速器结构形式的选择24

4.2对称式圆锥行星齿轮差速器的设计25

4.2.1差速器齿轮的基本参数选择25

4.2.2差速器齿轮的几何尺寸计算27

4.3差速器齿轮的材料选择28

4.4差速器齿轮的强度计算28

5 半轴设计30

5.1半轴的型式30

5.2半轴的设计与计算31

5.2.1全浮式半轴计算载荷的确定31

5.2.2全浮式半轴杆部直径的初选31

5.2.3半轴的结构设计、材料与热处理31

5.2.4半轴的强度计算32

6 驱动桥壳体设计34

6.1驱动桥壳的分类34

6.1.1可分式桥壳34

6.1.2整体式桥壳35

6.1.3组合式桥壳36

6.2驱动桥壳的选择36

7 结 论37

参考文献38

致 谢39

毕业设计(论文)知识产权声明40

毕业设计(论文)独创性声明41

川公网安备: 51019002004831号

川公网安备: 51019002004831号