3.0吨调度绞车的设计【汽车车辆类优秀机械毕业设计@word+7张CAD全套图纸@任务书】.bat

任务书.doc

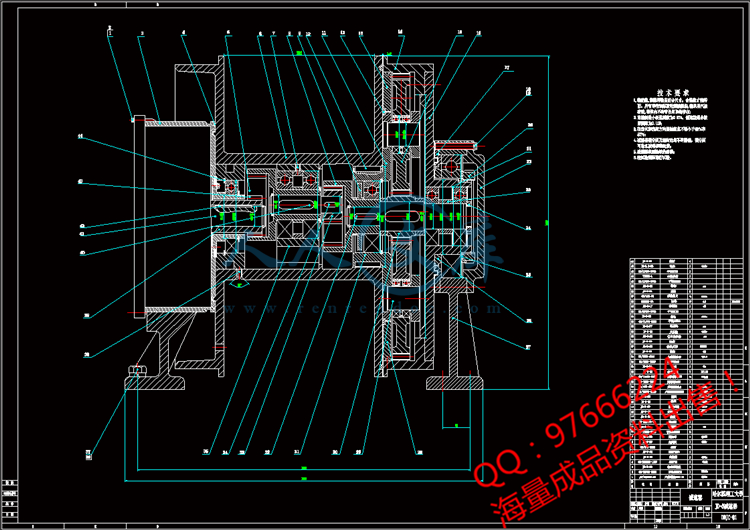

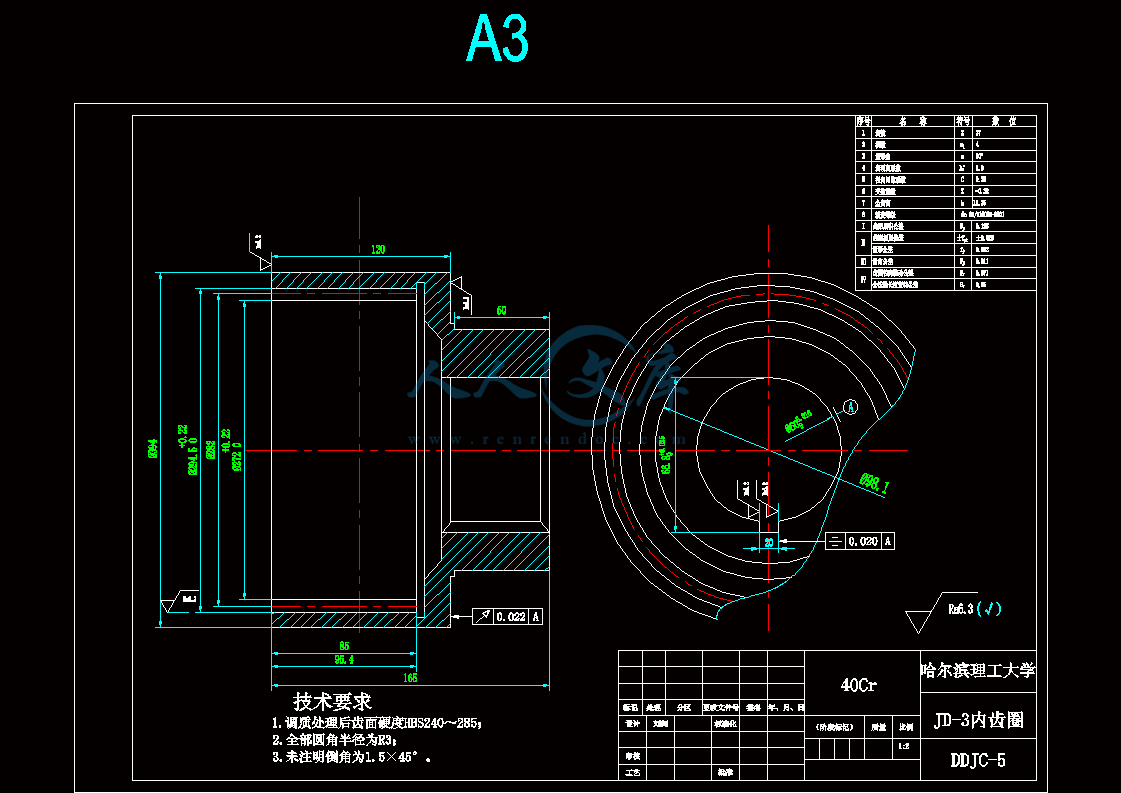

内齿圈-A3.dwg

减速器-A0.dwg

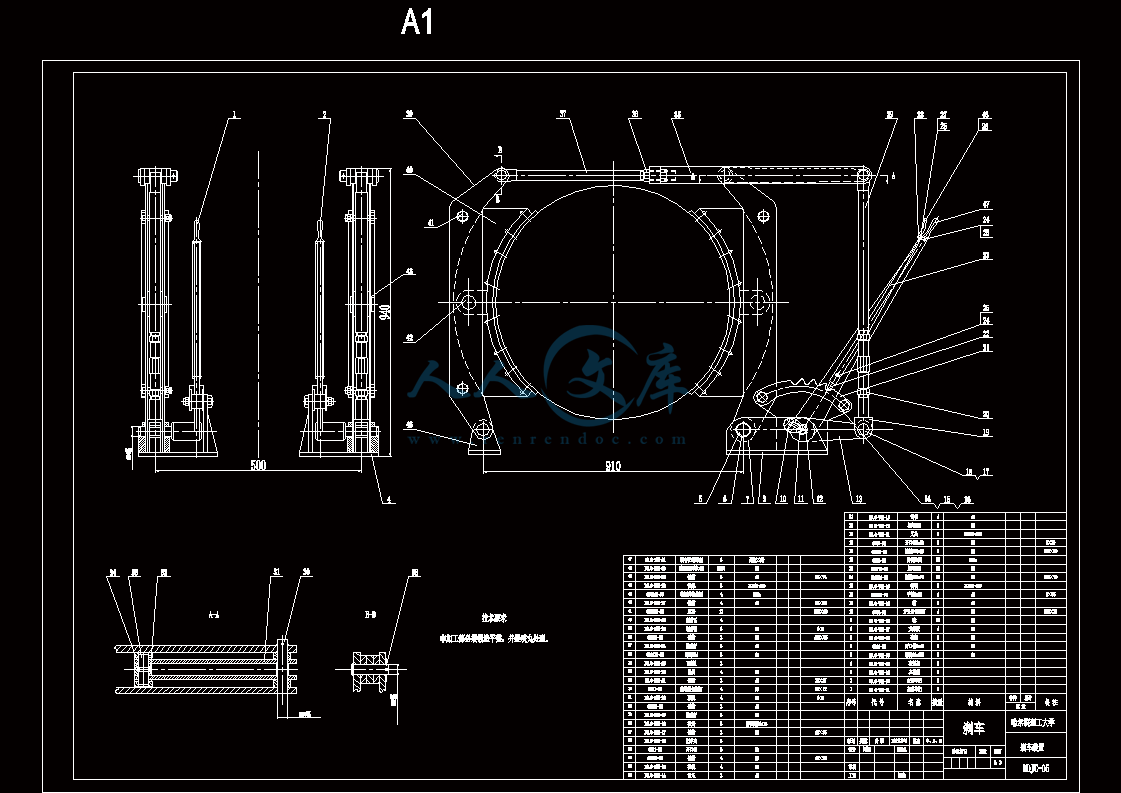

刹车装置-A1.dwg

卷筒-A1.dwg

外文翻译.doc

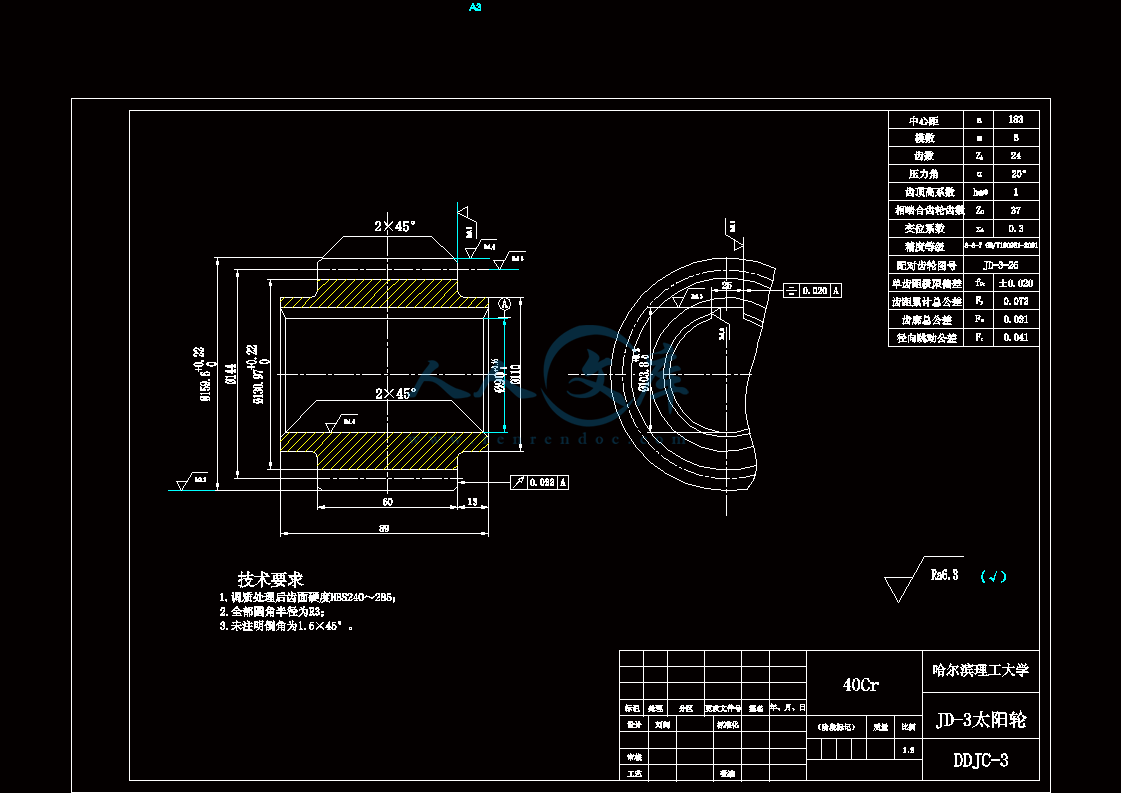

太阳轮-A3.dwg

正文.doc

目录.doc

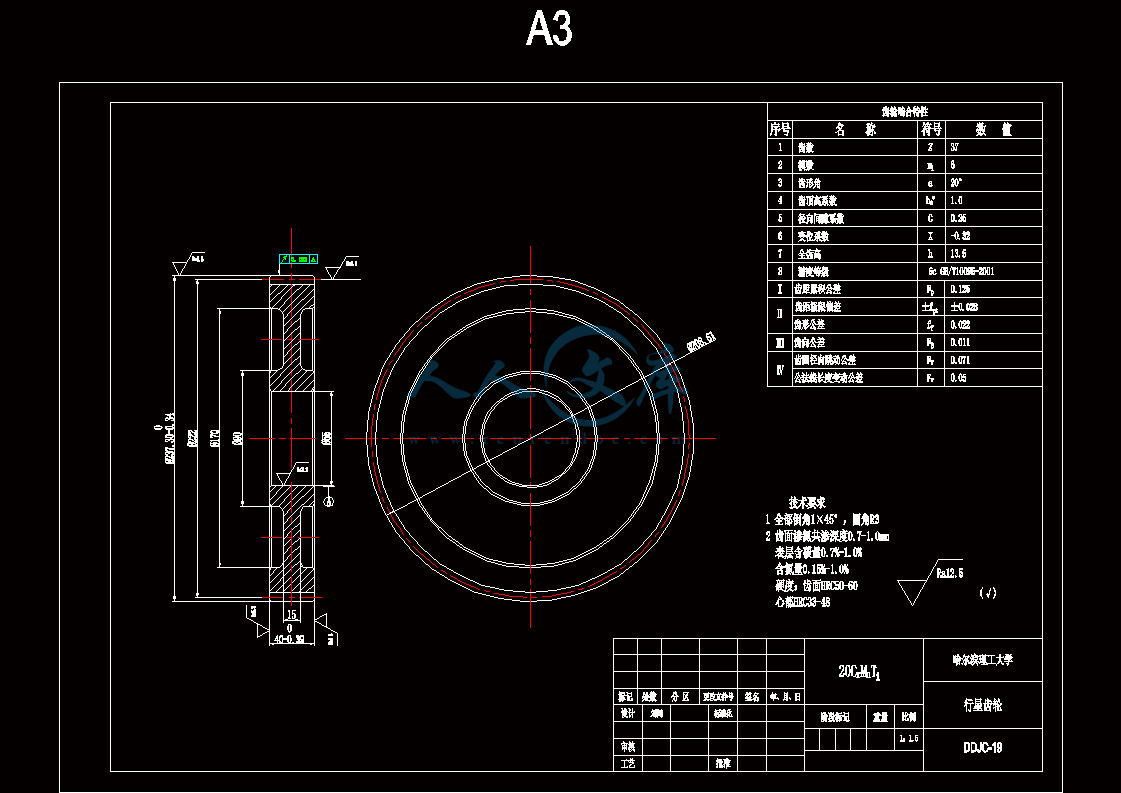

行星齿轮-A3.dwg

装配图-A0.dwg

任务书

毕业设计题目: 3.0吨调度绞车的设计

设计3吨调度绞车,

主要设计参数

牵引力:≈30

速绳: ≈1.2

容绳量:≈500 m

摘 要

本次设计的题目是3吨调度绞车的设计。调度绞车由于结构简单、重量不大、移动方便,而被广泛应用于矿山地面、冶金矿场或建筑工地等进行调度和其它运输工作。

绞车的主要特点为:结构尺寸和重量较小、钢丝绳速度不高,安装及撤除操作方便、启动平衡(稳)、故障率低、常见故障易处理、维护方便。

我国许多调度绞车的设计是引进前苏联的技术,并在其基础上作了一些改进,本设计方案的主要特点:?该型绞车采用两级内啮合传动和一级行星轮传动。Z1/Z2和Z3/Z4为两级内啮合传动,Z5、Z6、Z7组成行星传动机构。在电动机轴头上安装着加长套的齿轮Z1,通过内齿轮Z2、齿轮Z3和内齿轮Z4,把运动传到齿轮Z5上,齿轮Z5是行星轮系的中央轮(或称太阳轮),再带动两个行星齿轮Z6和大内齿轮Z7。行星齿轮自由地装在2根与带动固定连接的轴上,大内齿轮Z7齿圈外部装有工作闸,用于控制绞车滚筒运转。

为了达到良好的均载效果,在设计的均载机构中采取无多余约束的浮动方式。另外,变位齿轮的使用也可以获得准确的传动比,提高啮合传动质量和承载能力。

本次设计主要对两级内啮合传动和一级行星轮传动、滚筒结构、制动器等进行了详细的设计。

关键词: 调度绞车;行星齿轮;行星传动;内啮合传动

Abstract

The design is the subject of three tons scheduling winch design. Scheduling winch as simple structure, less weight, mobile convenience, and the ground was widely used in mining, metallurgical mines or construction sites, such as dispatching and other transportation work.

Winch the main features are: small size and weight of the structure, the rope speed is not high, installation and removal easy to operate, start balance (stability), the failure rate is low and easy to deal with common fault, and easy maintenance. Many of our scheduling winches are designed to introduce the former Soviet Union, and on the basis of their made some improvements, the design of the main features: the use of two-winch internal drive and a planetary gear transmission. Z1/Z2 and Z3/Z4 for two Internal Drive, Z5, Z6, Z7 composition of planetary transmission mechanism. Installation of the motor shaft head of the extended sets of gear Z1, through the gears Z2, with gear Z3 and Z4, the movement spread to gear Z5, the Z5 is the planetary gear wheel of a central round (or round the sun), Further promote the two planetary gear Z6, and the gear Z7. Planetary gear freely installed in the two driven and connected to a fixed axis, the largest in the gear Z7 Gear work with the external gateway, used to control winch drum operation.

In order to achieve good results, are contained in the design of the bodies contained no extra bound to take the floating manner. In addition, the use of variable gear can also get accurate than the drive to improve the quality and meshing transmission capacity.

The design of the two main transmissions and meshing with a planetary gear transmission, the drum structure, such as brake carried out a detailed design.

Key words: scheduling winch; planetary gear; planetary transmission; Internal Drive

目 录

一、整体方案设计1

1.1产品的名称、用途及主要设计参数1

1.2整体设计方案的确定1

1.3 设计方案的改进2

二、 牵引钢丝绳直径及卷筒直径的确定3

2.1钢丝绳的选择3

2.1.1 计算钢丝绳直径3

2.1.2钢丝绳强度校核:3

2.2卷筒3

2.2.1 卷筒的名义直径3

2.2.2 确定卷筒的宽度B4

2.2.3 初选钢丝绳的缠绕层数为:4

2.2.5 确定卷筒直径4

2.2.6 卷筒厚度:4

三、 电机的选取:6

3.1系统的总效率6

3.2绳速的确定6

3.3电机的选型6

四、总传动比的计算及传动比的分配7

4.1总传动比的计算:7

4.2 传动比的分配7

五、 两级内齿圈传动设计9

5.1齿轮材料处理工艺及制造工艺的选定9

5.2确定各主要参数9

5.2.1传动比9

5.2.2 第一级传动齿轮模数m9

5.2.3 内啮合标准圆柱齿轮传动几何尺寸的计算10

5.2.4 齿轮接触疲劳强度计算10

5.2.5齿轮强度校验12

5.3 第二级传动齿轮模数m16

5.3.1 内啮合标准圆柱齿轮传动几何尺寸的计算17

5.3.2 齿轮接触疲劳强度设计计算17

5.3.3 齿轮强度校验20

六、 行星轮传动设计24

6.1齿轮材料处理工艺及制造工艺的选定24

6.2确定各主要参数24

6.2.1传动比24

6.2.2行星轮数目24

6.2.3载荷不均衡系数24

6.2.4 配齿计算24

6.2.5 太阳轮分度圆直径25

6.2.6计算变位系数26

6.3几何尺寸计算29

6.4 啮合要素计算30

6.4.1 a—c传动端面重合度30

6.4.2 c—b传动端面重合度30

6.5 齿轮强度验算31

6.5.1 外啮合31

6.5.2 内啮合36

七、主轴的结构设计40

7.1轴的材料的选定40

7.2 轴直径的初步估算40

7.3轴的结构设计40

八、行星轴的结构设计和校核55

8.1行星轴55

8.1.1结构设计55

8.1.2行星轴材料55

8.1.3 轴的受力分析55

8.1.4按当量弯矩计算轴径56

8.1.5轴的疲劳强度安全因数校核计算56

8.1.6轴的表强度安全因数校核计算57

8.2行星轴校验58

8.2.1 轴径58

8.2.2行星轴材料58

8.2.3 轴的受力分析58

8.2.4按当量弯矩计算轴径59

8.2.5轴的疲劳强度安全因数校核计算60

8.2.6轴的表强度安全因数校核计算61

九、 行星架结构设计63

9.1行星架形式的确定和材料的选定63

9.2行星架的技术要求63

十、轴承及校核65

10.1调心滚子轴承65

10.2深汮球轴承66

十一、 联接(普通平键联接)69

11.1主轴上的平键联接69

11.1.1 键的选取69

11.1.2 键联接的强度校核69

11.2滚筒和行星架之间的联接70

11.2.1键的选取70

11.2.2键联接的强度校核70

十二、减速器铸造机体结构尺寸71

12.1铸造机体的壁厚71

12.2螺栓直径71

十三、 制动器的设计计算72

13.1制动器的作用与要求72

13.1.1制动器的作用72

13.1.2制动器的要求72

13.2制动器的类型比较与选择72

13.2.1制动器的类型72

13.2.2制动器的选择72

13.3外抱闸式制动器结构72

13.4外抱闸式制动器的几何参数计算73

十四、 主要零件的技术要求79

14.1对齿轮的要求79

14.1.1齿轮精度79

14.1.2对行星轮制造方面的几点要求79

14.1.3齿轮材料和热处理要求79

十五、维护及修理80

15.1润滑80

15.2维护80

15.3修理80

Abstract81

摘要88

毕业设计总结94

参考文献95

一、整体方案设计

1.1产品的名称、用途及主要设计参数

本次设计的产品名称是3吨调度绞车,调度绞车是一种小型绞车,通过緾绕在滚筒上的钢丝绳牵引车辆在轨道上运行,属于有极绳运输绞车。调度绞车适用于煤矿井下或地面装载站调度编组矿车,在中间巷道中拖运矿车,亦可在其它地方作辅助运输工具。

主要设计参数为:

牵引力 ≈30

绳速 ≈1.2

容绳 ≈500 m

1.2整体设计方案的确定

?该型绞车采用两级内啮合传动和一级行星轮传动。Z1/Z2和Z3/Z4为两级内啮合传动,Z5、Z6、Z7组成行星传动机构。

在电动机轴头上安装着加长套的齿轮Z1,通过内齿轮Z2、齿轮Z3和内齿轮Z4,把运动传到齿轮Z5上,齿轮Z5是行星轮系的中央轮(或称太阳轮),再带动两个行星齿轮Z6和大内齿轮Z7。行星齿轮自由地装在2根与带动固定连接的轴上,大内齿轮Z7齿圈外部装有工作闸,用于控制绞车滚筒运转。

?? 若将大内齿轮Z7上的工作闸闸住,而将滚筒上的制动闸松开,此时电动机转动由两级内啮轮传动到齿轮Z5、Z6和Z7。但由于Z7已被闸住,不能转动,所以齿轮Z6只能一方面绕自己的轴线自转,同时还要绕齿轮Z5的轴线(滚筒中心线)公转。从而带动与其相连的带动转动,此时Z6的运行方式很类似太阳系中的行星(如地球)的运动方式,齿轮Z6又称行星齿轮,其传动方式称为行星传动。

?? 反之,若将大内齿轮Z7上的工作闸松开,而将滚筒上的制动闸闸住,因Z6与滚筒直接相连,只作自转,没有公转,从Z1到Z7的传动系统变为定轴轮系,齿轮Z7做空转。倒替松开(或闸住)工作闸或制动闸,即可使调度绞车在不停电动机的情况下实现运行和停车。当需要作反向提升时,必须重新按动启动按钮,使电机反向运转。

为了调节起升和下放速度或停止,两刹车装置可交替刹紧和松开。

1.3 设计方案的改进

为了达到良好的均载效果,在设计的均载机构中采取无多余约束的浮动,既在行星轮中安装一个球面调心轴承。高速级行星架无支承并与低速级太阳轮固定联接。此法的优点是机构中无多余约束,结构简单,浮动效果好,沿齿长方向的载荷分布均匀。由于行星轮内只装一个轴承,当传动比较小时,轴承尺寸小,寿命较长。

设计中还采用了合理的变位齿轮,在渐开线行星齿轮传动中,可以获得如下的效果:获得准确的传动比,提高啮合传动质量和承载能力,在传动比得到保证的前提下得到理想的中心距,在保证装配及同心等条件下,使齿数的选择有较大的灵活性。

二、 牵引钢丝绳直径及卷筒直径的确定

2.1钢丝绳的选择

2.1.1 根据GB/T8918-1996知,钢丝绳直径可由钢丝绳最大工作静拉力,按下式确定:

d = (2-1)

式中d-钢丝绳最小直径

C-选择系数 ,取C =0.1

S-钢丝绳最大静拉力N

则由公式(2-1)可得:

d =17.32

所以选择钢丝绳直径d =19.5

初选钢丝绳直径 =19.5

型号为:6×19(a)-19.5-155

2.1.2钢丝绳强度校核:

由钢丝绳型号知:

钢丝绳公称抗拉强度为1550

所以最小钢丝破断拉力总和

整条钢丝绳的破断拉力为

式中:—拉力影响系数,取=0.85

安全系数

所以=5

故所选钢丝绳满足要求。

2.2卷筒

2.2.1 卷筒的名义直径

(2-3)

式中:—按钢丝绳中心计算的卷筒最小直径

d—钢丝绳直径

h—与机构工作级别和钢丝绳的结构有关的系数,因为机构的工作级别为M5级,所以取h =18

参考文献:

[1]马从谦,陈自诊等,渐开线行星齿轮传动设计。北京:机械工业出版社,1987

[2]《现代机械传动手册》编辑委员会。现代机械传动手册。北京:机械工业出版社,1995

[3]单丽云,强颖怀,张亚非。工程材料。徐州:中国矿业大学,2000

[4]张国端,张展等,行星传动技术。上海:上海交通大学出版社,1989

[5]胡来,何金国等,行星传动设计与计算。北京:煤炭工业出版社,1983

[6]朱龙根,简明机械零件设计手册。北京:机械工业出版社,1997

[7]周明衡,离合器、制动器选用手册。北京:化学工业出版社,2003

[8]成大先,机械设计手册(单行本)机械传动。北京:化学工业出版社,2004

[9]王洪欣等,机械设计工程学Ⅰ,徐州:中国矿业大学,2001

[10]唐大放等,机械设计工程学Ⅱ,徐州:中国矿业大学,2001

[11]单丽云,强颖怀,张亚非。工程材料。徐州:中国矿业大学,2000

[12]尤瑞琳,行星减速器行星架的改造设计。起重运输机械,2002

[13]张树森,机械制造工程学。沈阳:东北大学出版社,2001

[14]甘永立,几何量公差与检测。上海科学技术出版社,2003

[15]刘鸿文,简明材料力学,北京:高等教育出版社,1997

[16]F .T .thwaites,S. M. G allager. A Winch and C able for the Autonmous Vertacally Profiling Plankton Observatory. Woods Hole Oceanographic Institutino, 1998

[17]Davis, C. S, S. M Ggllager, and M. S Berman. The Video Planlton Recorder (VPR) Design and initial results Arch Hydrobiol Beih, 36,pp 67-81,1992

[18]Wang Yixing etc, Aatudy on jumping-over-teeth phenol menon in Roller china drive .New Youk :ASME journal of Mechnical Desingn, 1990

川公网安备: 51019002004831号

川公网安备: 51019002004831号