目录

第一章 绪论………………………………………………………………………………1

1.1造型设计的重要性……………………………………………………………1

1.2国外客车造型的现状与发展趋势………………………………………………2

1.2.1具有东方风格的日本式…………………………………………………3

1.2.2 欧式豪华大客车的几种典型风格………………………………………3

1.2.3美洲大客车………………………………………………………………4

1.3国内客车造型设计的现状及发展趋势…………………………………………4

1.3.1长途,旅游客车………………………………………………………4

1.3.2城市客车 ………………………………………………………………5

1.3.3高档豪华客车……………………………………………………………6

第二章 造型设计的特点,基本原则及要求……………………………………………7

2.1造型设计的特点…………………………………………………………………7

2.2造型设计的原则…………………………………………………………………7

2.3造型设计的要求和方法………………………………………………………9

2.3.1外型……………………………………………………………………9

2.3.2车内布局………………………………………………………………9

第三章 客车造型的特点以及形式的确定……………………………………………11

3.1客车造型的特点………………………………………………………………11

3.1.1中型客车,适用于城市之间的中短途运输…………………………11

3.1.2发动机前置……………………………………………………………11

3.1.3前悬短,乘客门中置…………………………………………………11

3.1.4兼容残疾人座椅………………………………………………………11

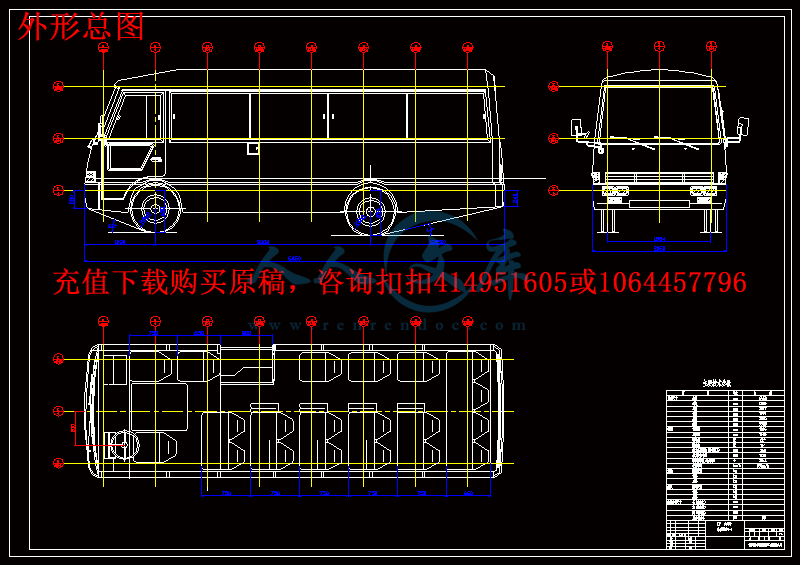

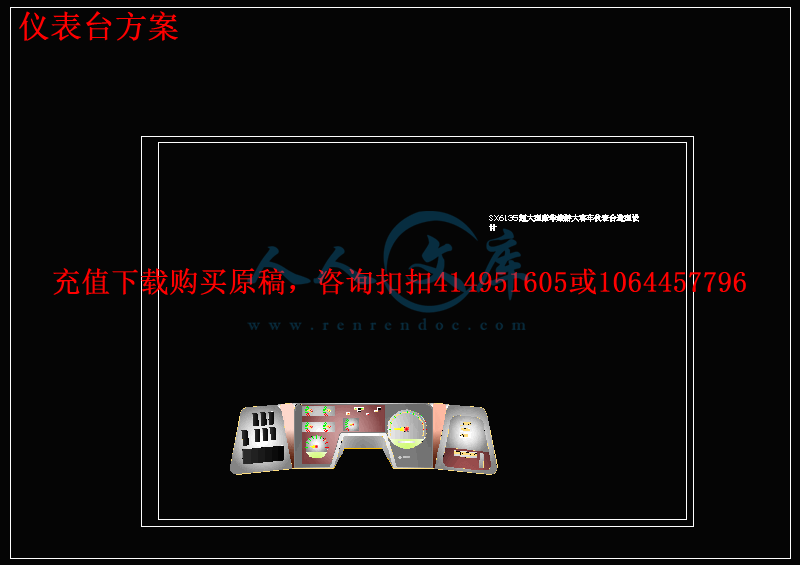

3.2整车造型设计方案以及CAD三维实体模型的建立…………………………12

3.2.1造型设计的重点部分……………………………………………………12

3.2.2本车造型特点……………………………………………………………14

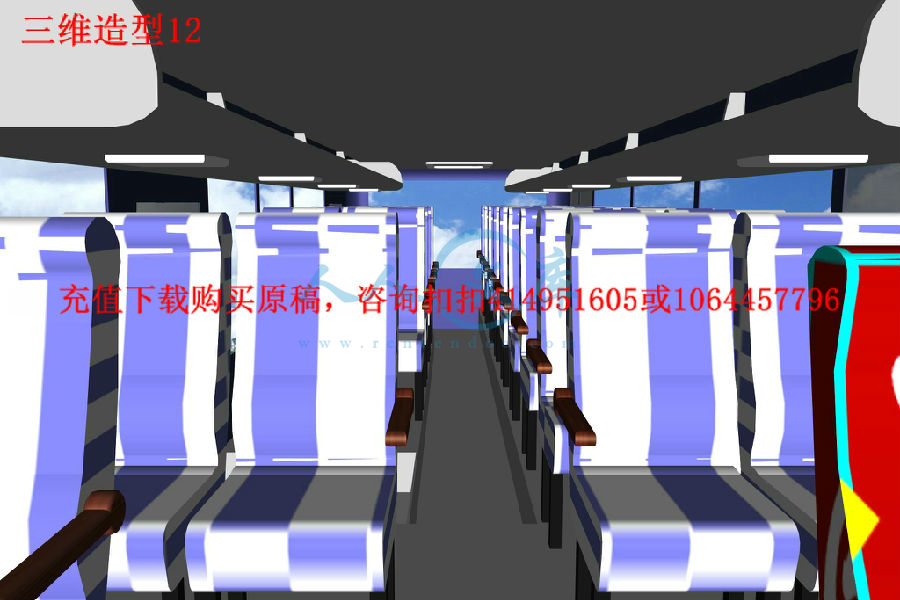

3.2.3 造型的表达以及CAD模型的建立………………………………15

第四章 内饰,保险杠及附件的设计……………………………………………………20

4.1内饰……………………………………………………………………………20

4.2保险杠…………………………………………………………………………20

4.2.1单一式保险杠……………………………………………………20

4.2.2 整体组合式保险杠……………………………………………20

4.2.3复合式保险杠………………………………………………21

4.3附件……………………………………………………………………………21

4.4安全装置………………………………………………………………………22

第五章 材料选用与工艺特点…………………………………………………………23

5.1材料选用………………………………………………………………………23

5.2工艺特点………………………………………………………………………23

第六章 存在的不足及改进的途径……………………………………………………24

6.1本车的造型设计存在的不足…………………………………………………24

6.2改进的途径……………………………………………………………………24

设计评价分析……………………………………………………………………………25

致谢………………………………………………………………………………………26

参考文献…………………………………………………………………………………27

摘 要

汽车造型相当重要,它不但直接影响整车的视觉效果,同时也在很大程度上影响到产品的市场表现。研究不同档次客车的造型风格和时代流行趋势,寻找其内在关系,对于企业新产品开发具有重要的指导意义。

文章简要介绍我国客车造型的发展和现状,较详细的说明了客车整体、局部造型及内饰技术和在造型中应注意的一些问题。介绍了客车造型设计的含义和评价标准。简述了构思草图、效果图、模型在客车造型设计过程中的作用。

在本车的造型设计过程中,结合兼容残疾人座椅的造型特点,在客车外观,内饰设计和一些细节问题上都有所创新,并通过CAD软件在三维设计过程中表现出来。通过对客车造型特点的研究,把握市场对客车造型的需求,提高产品的市场竞争力。

关键词:客车,造型,设计,CAD,残疾人

ABSTRACT

Automobile styling is important, it will not only directly affect the vehicle's visual effects, they have also greatly affected the product's market performance. Study of different grades and 380 modeling style and the era fashion trends, finding its intrinsic relationship For enterprise new product development is of great significance.

The article briefly introduced China Bus modeling development and the status quo, a more detailed explanation of the whole bus, Interior and Local modeling and modeling technology should pay attention to the issue. Passenger train on the meaning of Design and evaluation criteria. Plan outlines the concept, the effect map, model passenger cars in the design process modeling role.

In the shape of the car design process, compatible with the disabled seating modeling features, the Bus appearance, Interior design and some of the details on both innovation and the adoption of 3D CAD software in the design process demonstrated. By modeling features of the bus, the bus market grasp the shape of demand, improve product competitiveness on the market.

Key word: automobile, styling, design, CAD, disabled

绪论 国内外客车造型的现状及发展趋势分析

1.1造型设计的重要性

爱美之心,人皆有之。美的事物总会给人以视觉上的冲击,让人难忘。(见图1-1)

图1-1 宇通客车

造型是为了满足人们的特定需要、并受其制约而创造设计并加工出来的特定形式,主要包括形态、质地与色彩、人机关系等内涵。造型款式不仅本身是评价汽车产品好坏的重要指标之一,还和汽车性能、质量、价格等方面的指标有密切的相关性,因此车身的造型设计在汽车产品设计中占有十分突出的地位。

汽车造型设计是汽车设计过程中的一个重要的组成部分。汽车造型设计是指汽车总布置和车身总布置基本确立之后进一步使汽车获得具体形状和艺术面貌的过程,它包括外型设计和室内造型设计。汽车造型设计师的工作是:参与汽车总布置设计和车身总布置设计,绘制效果图,塑制模型,将外形形体上的曲线表达在主图版上,制定室内造型和覆饰,最后协同结构设计师将造型形象的体现在具体的车身结构上。

在汽车造型设计中要考虑多方面的要求,包括空气动力学、机械工程学、人机工程学、安全法规、美学等要素。其中机械工程学和人机工程学要素已达到相当成熟的发展阶段,对车身内、外造型的要求与约束形成了较为固定的规范。从这个意义上讲,现代汽车车身造型(尤其是外部造型)的演变与发展,很大程度上受汽车空气动力学和造型美学两大变数的影响甚至支配。

汽车造型设计不是那种附属的简单的美化工作,而是独特的综合创作。因为汽车不仅是现代化的工业产品和交通工具,而且是一件精致的艺术品,是科学技术与艺术技巧的高度融会交织的结晶。汽车的造型既包含结构、性能、工艺等科学技术因素的作用和影响。为了承担这项工作,汽车造型设计师应具备广泛的知识和较高的艺术素质。

在国外,各厂商还把汽车造型设计视为占领市场、打开销路的竞争手段,对造型工作倍加重视。为了与瞬息万变的市场相适应,各厂商都制定较多的车型方案,以便从中选择适合市场销售形势的方案投产,因而需要大量的技术储备和庞大的技术班子。由于对造型人才的要求较高,需要精心培养和训练,他们有时甚至不惜重金聘请外国名师带行造型设计。

川公网安备: 51019002004831号

川公网安备: 51019002004831号