!【详情如下】CAD图纸+word设计说明书.doc[16000字,34页]【需要咨询购买全套设计请加QQ97666224】.bat

中文翻译.doc

开题报告.doc

摘要.doc

模具总装图8张.dwg

读书笔记.doc

课题任务书.doc

设计说明书.doc[16000字,34页]

附录.doc

摘 要

介绍了轴承盖冷冲压成形过程,经过对轴承盖的批量生产、零件质量、零件结构以及使用要求的分析、研究,按照不降低使用性能为前提,将其确定为冲压件,用冲压方法完成零件的加工,冲压基本工序为:落料、拉深、冲孔,然后根据对工序的初步计算,确定工序数目,如冲压次数,拉深次数,对工序顺序的安排,一般根据各工序的变形特点,质量要求来确定,由于本工件为带孔的落料、拉深件,因此先落料,再拉深,最后冲孔,根据生产批量和条件(冲压加工条件和模具制造条件)确定工序组合,因为生产批量大,所以将各个工序组合在一起,并用复合模冲压,这样就提高了产品的生产率。通过充分利用现代模具制造技术对传统机械零件进行结构改进、优化设计、优化工艺方法能大幅度提高生产效率,这种方法对类似产品具有一定的借鉴作用。

关键字:轴承盖;冲压;工序;生产批量;生产效率

ABSTRACT

Introduced to carry the bearing cover cold hurtle to press to take shape the process, pass by to the batch quantity production, spare parts quantity, the spare parts structure and usage request of carry the bearing cover of analysis, study, according to not lower to use the function as premise, is certain in order to hurtle to press the piece, it uses to hurtle to press the method to complete the spare parts to process, hurtling to press basic work preface is: Fall to anticipate, pull deep, hurtle the bore, then according to the initial calculation of the work preface, make sure the work ordinal number eyes, if hurtle to press the number of times, pulling the deep number of times, to the in proper order arrangement of the work preface, general transform the characteristics according to each work preface, the quantity request to certain, because of in order to take the bore to fall to anticipate, pull the deep piece, this work piece so fall to anticipate first, then pull deeply, blunt bore of end, according to produce the batch quantity and condition( hurtle to press to process the condition and molding tools to make the condition)s to make sure the work that the preface combine, because of produce the batch quantity big, so combine each work preface together, counteract compound the mold hurtles to press, raising the rate of production of the product thus. Pass to make use of the modern molding tool manufacturing technique to carry on the structure improvement to the traditional machine spare parts well, excellent turn the design, the excellent chemical engineering skill method ability the significant exaltation produces the efficiency, this kind of method to similar the product has to certainly draw lessons from the function.

Key words: bearing cover; stamping; process; Production batch; Production efficiency

目 录

1 分析零件的工艺性2

1.1 冲裁工艺性2

1.2 拉深工艺性2

2 分析计算确定工艺方案4

2.1 计算毛坯尺寸4

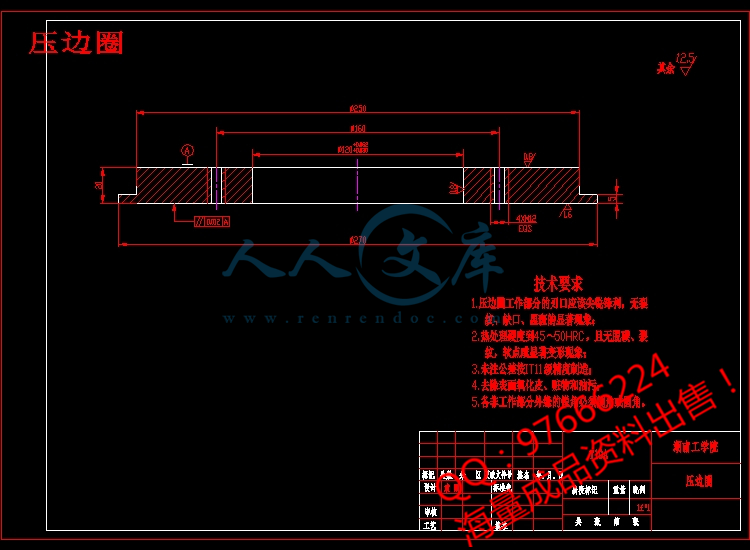

2.2 确定是否需要压边圈4

2.3 计算拉深次数5

2.4 确定工艺方案6

3 主要工艺参数的计算7

3.1 确定排样、裁板方案7

3.2 计算工艺力、初选压力机8

3.2.1 计算工艺力8

3.2.2 初选压力机11

3.3 计算压力中心11

3.4 计算凸、凹模刃口尺寸及公差12

4 模具的整体结构设计14

4.1 模具结构形式的选择14

4.2 模具总体设计14

4.3 模具工作部分尺寸计算15

4.3.1 落料凹模15

4.3.2 冲孔凸模16

4.3.3 拉深凸模16

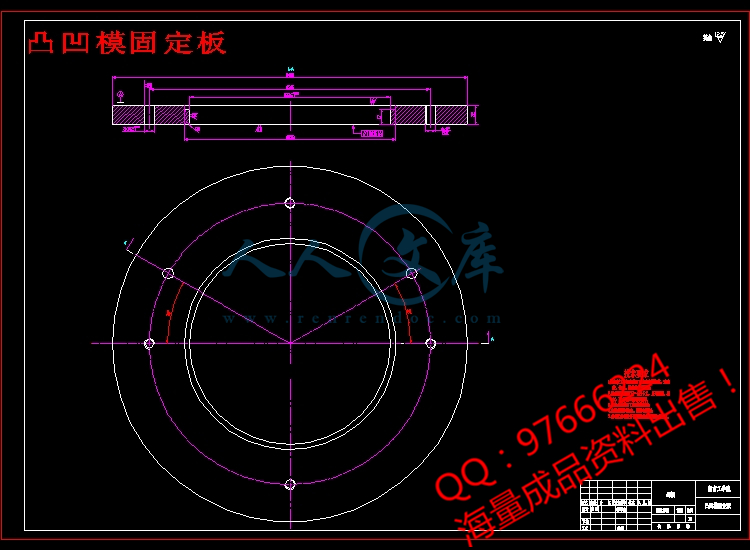

4.3.4 凸凹模16

5 模具的主要零部件结构设计18

5.1 模架18

5.2 模座18

5.3 模柄18

5.4 定位零件19

5.4.1 挡料销19

5.4.2 导料销19

5.4.3 导料板19

5.5 卸料装置20

5.5.1 固定卸料板20

5.5.2 橡胶21

5.6 其他支撑与固定零件21

5.6.1 凸模固定板21

5.6.2 导向零件22

5.6.3 垫板22

5.7 紧固件22

6 确定冲压设备24

7 模具的装配25

7.1 复合模的装配25

7.2 凸、凹模间隙的调整25

8 重要零件的加工工艺过程编制26

结 论28

致 谢29

参考文献30

川公网安备: 51019002004831号

川公网安备: 51019002004831号