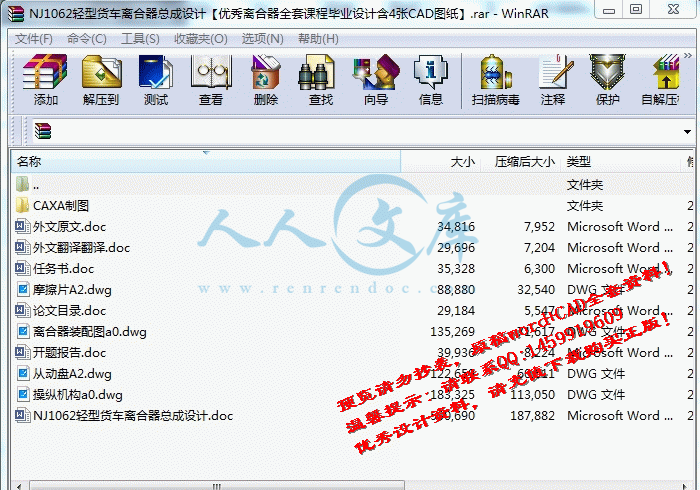

NJ1062轻型货车离合器总成设计【优秀离合器全套课程毕业设计含4张CAD图纸】

【带任务书+开题报告+外文翻译】【37页@正文14500字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

NJ1062轻型货车离合器总成设计.doc

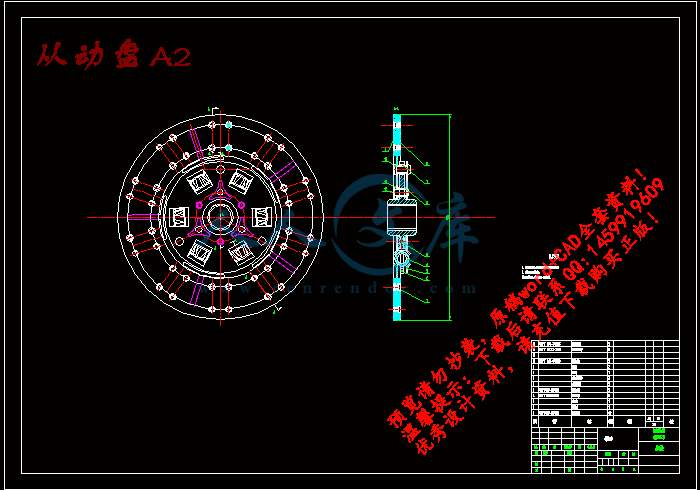

从动盘A2.dwg

任务书.doc

外文原文.doc

外文翻译翻译.doc

开题报告.doc

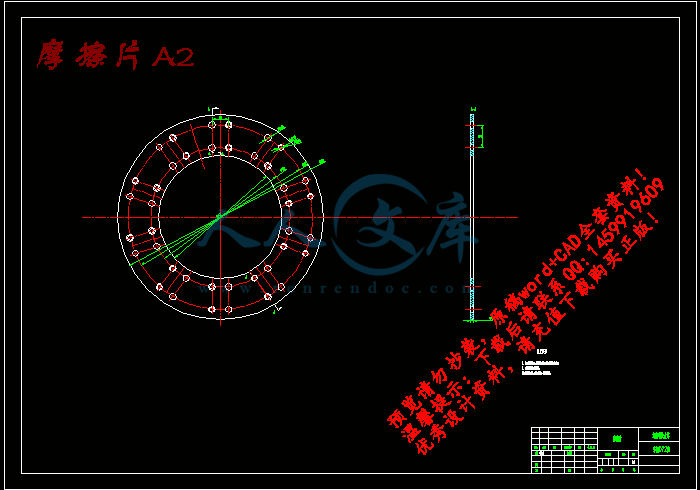

摩擦片A2.dwg

操纵机构a0.dwg

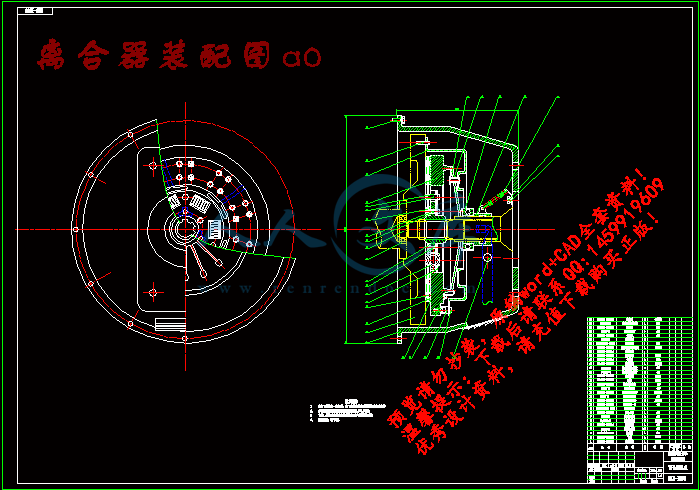

离合器装配图a0.dwg

论文目录.doc

任务书

题目NJ1062轻型货车设计(离合器总成设计)

主要研

究内容1. 设计内容:参考NJ1062DB轻型货车,完成所要求条件的轻型货车离合器及操纵机构设计;绘制离合器与操纵机构总成图;装配图及主要零部件工作图不少于3张零号图纸,其中应包含一张以上用计算机绘制的具有中等难度的1号图纸,同时至少有折合1号图幅以上的图纸用手工绘制。

2. 计算内容:完成离合器及操纵机构方案分析,完成离合器的设计计算。

3. 设计说明书内容:不少于12000字,其中的曲线及插图全部用计算机绘制;阅读参考文献不少于15篇;撰写中英文摘要,中文摘要400-500字,英文摘要300-450个实词,关键词一般为4-6个;设计说明书全部用计算机打印。

4. 外文翻译:完成不少于10000印刷符的外文翻译(并附原文)。

主要技

术指标(或研究目标)驱动型式:4╳2(后驱);驾驶室:平头;整车外形尺寸:5995╳2076╳2285;整车整备质量:2625kg;额定最大装载质量:2750 kg;轴距:3308 mm;轮距(前/后):1675/1485 mm;最小离地间隙:213 mm;最高车速:95 km/h;最小转弯半径:76 00mm;

发动机型号:YZ4102Q1-1,最大功率 70.6KW/3200rpm,最大扭矩245Nm/2000~2200rpm;

该离合器及操纵机构设计应满足它们各自系统的基本要求,以及该参考车型的设计要求。

进度计划(5周): 调研、收集、分析资料;

(6周): 全组集体讨论,制定、确定总体方案;

(7~9周): 完成主要总图设计;

(10~12周): 完成零件图、部件图、设计说明书等;

(13周): 整理图纸及全部设计资料,上交所有设计资料;

(14周): 审核、互审评阅设计;

(14周): 答辩,评定成绩;

NJ1062轻型货车设计(离合器总成设计)

摘要

在这三个月的时间里,我的最重要的任务之一就是设计汽车离合器、其操纵机构,以及传动轴的设计。

众所周知汽车底盘包括传动系、行驶系和转向系,传动系部件包括离合器、变速器、传动轴、驱动桥、半轴及驱动轮。在传动系的这些部件中,离合器和变速器无疑是两个最为重要的部件。驾驶员通过操纵离合器既可以在变速器换档时使发动机与离合器暂时分离,也可以在汽车起步时使发动机与离合器平稳接合。离合器的设计采用膜片弹簧压紧机构,液压式操纵机构。在国外,常采用液压操纵机构的离合器以减轻驾驶员的疲劳,

通过对传动轴的传动类型分析,对传动方式和传动轴进行了选型;通过对传动轴的类型与结构分析,选择了传动轴的十字轴滚针轴承的密封形式——盖板式密封。通过对万向节的十字轴、滚针轴承、万向节叉的设计计算,确定了所设计车辆使用的这些部件的具体尺寸。

综合各部分的设计及校核结果,所设计的离合器、传动轴能满足所设计的轻型货车的传动要求。

关键词:离合器,传动轴,十字轴,操纵机构

THE DESING OF A LIGHT TRUCK

(THE CLUTCKAND THE MANIPULATION

OF INSTITUTIONS AND SHAFT DESIGN)

ABSTRACT

In these two month-long time, one of my most vital duties is designs the automobile clutch ,Its control mechanism, as well as drive shaft design. The well known motor car chassis including the power transmission, the travel is and the steering system, the power transmission part including the meeting and parting Transmission gearbox, drive shaft, driving axle, rear axle and driving gear. In power transmission these parts, to Gathering and the transmission gearbox are two most important parts without doubt. The pilot through operates the coupling already to be possible in The transmission gearbox shifts gears when causes the engine and the coupling separates temporarily, also may starts when the automobile cause the engine and Coupling steady joint. The coupling design used the disk spring to contract the organization, hydraulic control organization. In overseas, often uses the hydraulic control organization the coupling by to reduce pilot's weariness.

Through to the drive shaft transmission type analysis, has carried on the shaping to the type of drive and the drive shaft; Through to the drive shaft type and the structure analysis, chose the drive shaft cross axle needle bearing seal form to cover the board style seal. Through to the universal joint cross axle, the needle bearing, the universal joint sliding yoke design calculation, had determined designs these parts concrete sizes which the vehicles uses.

Synthesizes each part of designs and the check result, designs the coupling, the drive shaft can satisfy skin truck which designs to use the transport vehicle the transmission request.

KEY WORDS: Coupling drive shaft cross axle control mechanism

目 录

前 言 ………………………………………………………1

第一章 离合器设计分析与方案选择………………………3

§1.1 概述…………………………………………………3

§1.2 离合器结构方案分析………………………………4

§1.2.1 从动盘数的选择 ………………………5

§1.2.2 压紧弹簧和布置形式的选择 …………6

§1.2.3 膜片弹簧支承形式 ……………………7

§1.2.4 压盘驱动方式的选择 …………………8

第二章 离合器基本参数和主要尺寸选择…………………9

§2.1 离合器基本参数计算………………………………10

§2.2 膜片弹簧主要参数的选择…………………………12

§2.3 扭转减震器的设计…………………………………13

§2.4 离合器压盘的设计…………………………………17

§2.5 离合器从动盘毂花键的强度校核…………………19

§2.6 离合器操纵机构的设计计算………………………19

第三章 传动轴的设计与计算………………………………23

§3.1 概 述………………………………………………23

§3.2 万向节结构方案分析………………………………24

§3.3 万向节的设计计算…………………………………24

§3.3.1 万向节设计 ……………………………24

§3.3.2 传动轴的设计 …………………………26

第四章 结 论 ………………………………………………29

参考文献 ……………………………………………………30

致 谢 ……………………………………………………31

前 言

自从十九世纪末期诞生第一辆汽车以来,汽车工业经历了100年的发展过程。由于社会需求的不断增长和科学技术发展的推动,汽车设计日臻精巧,其运输生产率和各项性能都有很大提高。因此,现在汽车已成为世界各国国民经济和社会生活中不可缺少的的一种运输工具。汽车工业规模和其产品的质量也成为衡量一个国家技术水平的重要标志之一。

50年代以来,由于高速公路的发展,促使汽车的运输能力和载货量逐渐加大。目前,国外公路用牵引半挂式汽车的总质量可达40吨,车速可达100km/h以上,每年平均行驶里程约15万km。一些工业发达国家的汽车货运量在总货运量的比例高达80%之多。60年代以来,载货汽车向大型化发展,是汽车在矿山、钢铁、建筑、石油开发等部门运输量的比重也逐渐上升,各国还采用变型和集装箱运输方式来扩大汽车的用途和降低汽车运输成本。在农业部门生产过程中,汽车运输也占有很重要的地位。由此可见,汽车已渗透到国民经济的各个部门中了。除载货汽车外,不少国家每年还要生产数量众多的供私人用的各种形式的轿车(在有些国家中轿车产量占整个汽车产量的80%),车主用以上下班、采购、旅游和出差时代步。在这里汽车起到了节省时间、加快生活节奏和使生活现代化的作用。因此在有些国家中,轿车就成为人们生活中十分需要的工具,非常普及。正是由于汽车的用途日益广阔,所以近20年来汽车的产量不断增加。据80年代初统计,全世界汽车年产量已达4000万辆,保有量达4亿辆以上。汽车作为路上运输工具在社会中发挥的作用已经接近甚至超过了铁路车辆。但它也给社会带来了许多新问题。在车辆多的国家中造成车流密度大,交通拥挤和频繁的交通事故;废气和噪声对环境造成了污染,这些已形成了社会公害。这些都严重影响了社会的治安和人民的生活。所以许多国家制定了各种法规来加以防治,并对汽车设计提出了很严格的要求。综上所述,今天的汽车,其作用不仅深入到国民经济的各个部门,还与社会和人民生活息息相关,因此在汽车设计时,必须考虑到这些因素而形成自己的特点。

参考文献

[1] 陈家瑞主编. 汽车构造(第3版). 北京:机械工业出版社2001

[2] 刘惟信编著. 汽车制动系的结构分析与设计计算. 北京:机械工业版社,2004

[3] 刘惟信主编. 汽车设计(第3版). 北京: 清华大学出版社, 2001

[4] 余志生主编. 汽车理论(第3版). 北京: 清华大学出版社, 2002

[5] 王望予主编. 汽车设计(第3版). 北京: 机械工业出版社, 2002

[6] 张则曹主编. 汽车构造图册(底盘) . 北京: 人民交通出版社,1998

[7] 张洪欣主编. 汽车设计(第2版) . 北京: 机械工业出版社,1995

[8] 邓楚南主编. 轿车构造 . 北京: 人民交通出版社, 2001

[9] 王巍,钱可强主编. 机械工程图册 . 北京: 机械工业出版社, 2000

[10]李传禹主编.汽车设计标准资料手册 . 长春: 吉林科学技术出版社,1992

[11]甘永立主编.几何量公差与检测 . 上海: 上海科学技术出版社,2001

[12]汪卸建主编.汽车底盘简明教学图解 . 北京: 电子工业出版社,1993

[13]刘世桤主编.汽车的传动系 . 北京: 人民交通出版社,1978

[14]羊拯民主编.传动轴于万向节 . 北京: 人民交通出版社,1986

[15]藏新群主编.汽车滚动轴承应用手册 . 北京: 机械工业出版社,1997

川公网安备: 51019002004831号

川公网安备: 51019002004831号