!【详情如下】【注塑塑料模具类】CAD图纸+word设计说明书.doc[16000字,49页]【需要咨询购买全套设计请加QQ97666224】.bat

前言.doc

参考文献.doc

开题报告.doc

摘要.doc

目录.doc

结束语.doc

设计说明书.doc[16000字,49页]

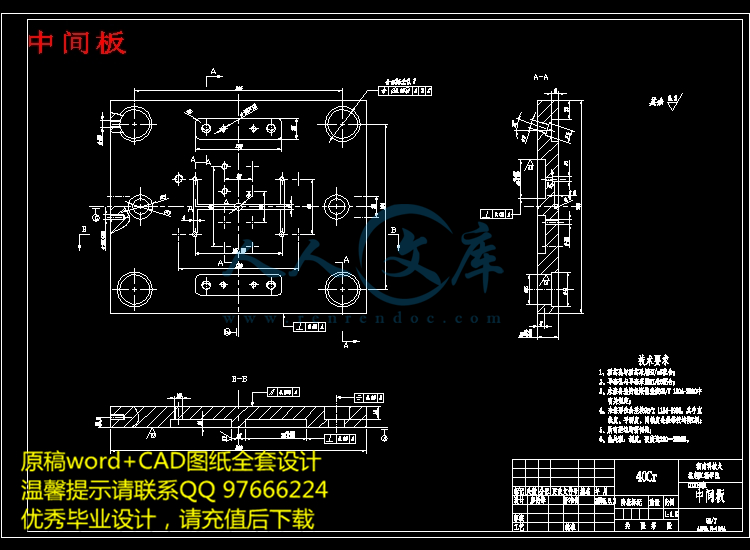

中间板.dwg

侧滑块.dwg

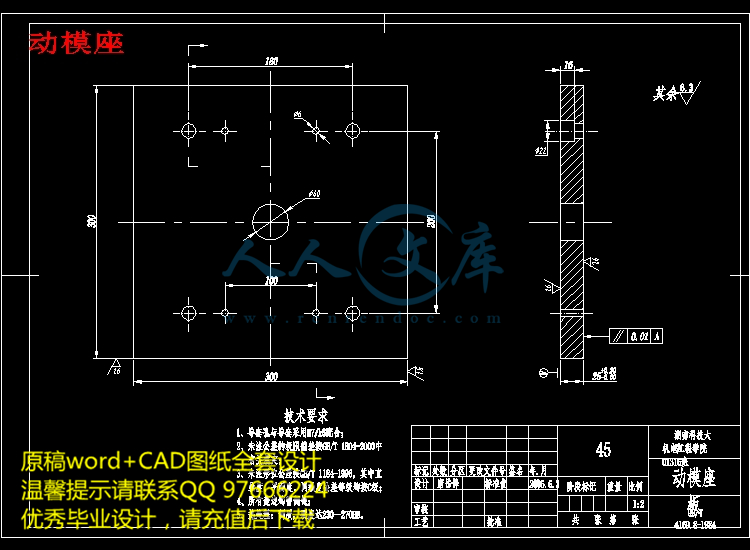

动模座.dwg

动模板.dwg

型腔.dwg

型芯.dwg

垫脚.dwg

定模座.dwg

推杆固定板.dwg

推杆布置.dwg

推板.dwg

支撑板.dwg

脱浇道板.dwg

装配图.dwg

说明书

零件图.dwg

目录

前言....................................................................................Ⅰ

设计说明书.............................................................................1

第一章 产品分析.......................................................................1

1.1 塑件分析.......................................................................1

1.2 塑件原材料分析.................................................................2

第二章 拟定型腔布局...................................................................4

2.1 型腔..........................................................................4

2.2 型腔数目的确定.................................................................4

2.3 型腔排布......................................................................5

第三章 塑件相关计算及注塑机的选择.....................................................6

3.1 塑件相关计算...................................................................6

3.2 注塑机选择及注射工艺参数确定...................................................7

第四章 分型面设计.....................................................................9

4.1 分型面设计原则.................................................................9

4.2 分型面设计.....................................................................9

第五章 浇注系统设计...................................................................10

5.1 总体设计.......................................................................10

5.2 主流道设计.....................................................................11

5.3 分流道设计.....................................................................11

5.4 进料口设计.....................................................................13

5.5 冷料穴的设计...................................................................14

5.6 浇口套及定位圈的设计...........................................................14

5.7 塑件模流分析...................................................................14

第六章 模架选用及注射参数校核.........................................................20

6.1 模架...........................................................................20

6.2 开模行程校核...................................................................21

第七章 成型零部件设计.................................................................22

7.1 成型零件的材料选择.............................................................22

7.2 成型零件结构设计...............................................................22

第八章 侧向分型抽芯机构设计...........................................................28

8.1 侧向分型抽芯机构类型选择.......................................................28

8.2 抽芯距确定与抽芯力计算.........................................................28

8.3 斜导柱分型与抽芯机构零部件设计.................................................29

第九章 合模导向机构设计...............................................................34

9.1 导向机构.......................................................................34

9.2 定位装置.......................................................................36

第十章 脱模机构设计...................................................................37

10.1 脱模装置......................................................................37

10.2 推出机构设计..................................................................38

10.3 拉料机构......................................................................40

第十一章 冷却及排气系统设计...........................................................42

11.1 冷却系统......................................................................42

11.2 排气机构......................................................................44

第十二章 模具总体结构.................................................................45

结束语..................................................................................48

致谢....................................................................................49

参考文献...............................................................................50

摘 要

注塑模在机械、电子、航天航空、生物领域及日用品的生产中得到广泛的应用。本次设计的是塑料挂钩座注射模具,设计内容主要包括模具总体结构和零部件设计,以及模具各部分的计算和校核,借助于软件PRO/ENGINEER对模具结构进行了合理性的分析,缩短了设计周期,以期设计出所要求的模具。

关键词:挂钩座;注塑模具;计算机辅助设计

Abstract

Injection mould is widely used in the field of machine, electronics, aviation, biology and commodity. What we designed in this present is an injection mould of a plastic pothook, which mainly including it’s holistic configuration and part design, calculation and check of every part of the mould. A software “PRO/ENGINEER” was used in the design process to analyze the rationality of the mould and decrease the design time for obtaining an ideal mould.

Key words: plastic pothook; injection mould; CAD

川公网安备: 51019002004831号

川公网安备: 51019002004831号