一种基于电加热的导热油系统及其关键零部件的加工工艺设计.doc

一种基于电加热的导热油系统及其关键零部件的加工工艺设计【8张CAD图纸和说明书】

收藏

资源目录

压缩包内文档预览:(预览前20页/共47页)

编号:6044284

类型:共享资源

大小:2.26MB

格式:ZIP

上传时间:2017-10-30

上传人:俊****计

认证信息

个人认证

束**(实名认证)

江苏

IP属地:江苏

40

积分

- 关 键 词:

-

一种

基于

加热

导热油

系统

及其

关键

症结

枢纽

零部件

加工

工艺

设计

cad

图纸

以及

说明书

仿单

- 资源描述:

-

- 内容简介:

-

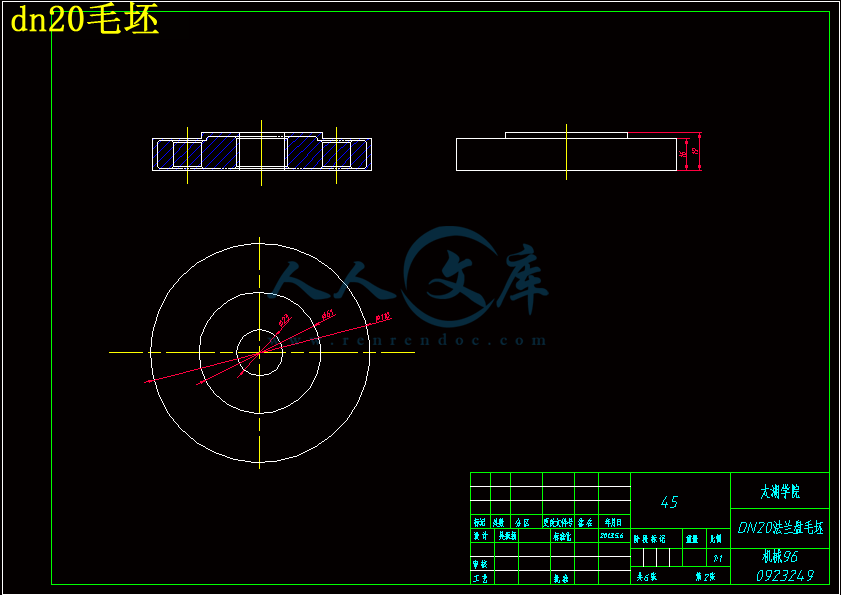

编 号无锡太湖学院毕 业 设 计 ( 论 文 )相 关 资 料题目: 一种基于电加热的导热油系统设计及其关键零部件的加工工艺设计信 机 系 机 械 工 程 及 自 动 化 专 业学 号: 0923249 学生姓名: 吴 振 扬 指导教师: 薛庆红 (职称:副教授 ) (职称: ) 2013 年 5 月 25 日目 录一、毕业设计(论文)开题报告二、毕业设计(论文)外文资料翻译及原文三、学生“毕业论文(论文)计划、进度、检查及落实表”四、实习鉴定表无锡太湖学院毕 业 设 计 ( 论 文 )开 题 报 告题目:一种基于电加热的导热油系统设计及其关键零部件的加工工艺设计信 机 系 机 械 工 程 及 自 动 化 专 业学 号: 0923249 学生姓名: 吴 振 扬 指导教师: 薛庆红 (职称:副教授)(职称: )2012 年 11 月 20 日课题来源来源于企业,为企业正在生产系统,要求学生熟悉流体传动的基本原理,液压管路的设计和接头设计,同时运用机械专业知识,设计该系统中关键零部件的机械加工工艺设计。科学依据(1)课题科学意义随 着 科 学 技 术 的 进 步 和 工 业 生 产 的 发 展 , 有 机 热 载 体 炉 得 到 了 不 断 的 发 展 和应 用 。 虽 然 有 机 热 载 体 炉 的 工 作 压 力 比 较 低 , 但 是 炉 内 热 传 导 液 温 度 高 , 且 大 多热 传 导 液 具 有 易 燃 易 爆 的 特 性 , 一 旦 在 运 行 中 发 生 泄 漏 , 将 会 引 起 火 灾 、 爆 炸 等事 故 , 这 样 不 仅 有 很 重 大 的 财 产 损 失 , 严 重 的 甚 至 会 造 成 人 员 伤 亡 。因 此 , 对 有 机 热 载 体 炉 的 安 全 运 行 和 管 理 , 必 须 高 度 重 视 , 防 患 于 未 然 。 电热 油 炉 作为一种直接的热能供给方式,已成为一种基础且关键的工业及民用设施。随着全球经济的快速增长,工业发展及城市建设步伐的不断加快,为电热产业带来了无限商机。(2)研究状况及其发展前景导热油系统是企业正在用的设备,可在较低的运行压力下,获得较高的工作温度,有效降低管线和锅炉的工作压力。导热油系统热传导效率高、热损失小,升温快、降温慢。温度控制精确,受热相对均匀。成倍延长设备使用寿命。闭式循环和开式操作均安全可靠。节约能耗约50%左右,对大气烟尘排放减少一半。节油节水节电,对于沙漠缺水、高寒地区、缺电地区推广价值高。研究内容电热式油加热器(电热油炉)是一种新型、节能、能提供高温热能的工业设备。供热原理:以电热升温,采用导热油作传热介质;在闭路循环系统中通过泵使热载体强制循环,在低压、高温状态下运行,直接释放热量,从而达到了提供热源的目的。经 用 热 设 备 卸 载 后 , 重 新 通 过 循 环 泵 , 回 到 加 热 器 , 再 吸 收 热 量 , 传 递 给 用 热 设 备 ,如 此 周 而 复 始 , 实 现 热 量 的 连 续 传 递 , 使 被 加 热 物 体 温 度 升 高 , 达 到 加 热 的 工 艺 要求 。 将热能输送给用热设备后,继加热循环再加热再循环的特种工业油炉拟采取的研究方法、技术路线、实验方案及可行性分析1、到图书馆或网上查阅相关资料,查找相关书籍。对导热油系统深入了解2、工艺性分析,选用合理的零部件。3、工艺方案确定,包括工序性质、顺序及其种类组合,编写法兰的工艺三卡。4、总装图的绘制,编制技术文件。课题完全由生产数据决定整个系统装配图及其零件图,通过对实际情况的了解,以数据为依据进行设计分析,具体的设计计算也完全可以通过查表或者书籍获得,加上对于整套设计有完整的设计思路,完全有可行性。研究计划及预期成果研究计划:2012 年 11 月 12 日-2012 年 12 月 2 日:按照任务书要求查阅论文相关参考资料,填写毕业设计开题报告书。2012 年 12 月 3 日-2013 年 1 月 20 日:机械制造实训2013 年 1 月 21 日-2013 年 3 月 1 日:到企业实习,了解本专业实践知识2013 年 3 月 4 日-2013 年 3 月 8 日:查阅与设计相关的资料不少于 10 篇,其中外文不少于 5 篇。2013 年 3 月 11 日-2013 年 3 月 15 日:翻译外文资料(8000-10000 字符)。2013 年 3 月 18 日-2013 年 3 月 22 日:分析导热油系统的工作原理,熟知导热油系统在生产中的应用。2013 年 3 月 25 日-3 月 29 日:确定导热油系统的结构2013 年 4 月 1 日-4 月 5 日:选用合理的零部件2013 年 4 月 8 日-4 月 12 日:主要零件设计及制造工艺的确定2013 年 4 月 15 日-4 月 19 日:初步绘制导热油系统装配图2013 年 4 月 22 日-4 月 26 日:修改导热油系统装配图2013 年 4 月 29 日-5 月 3 日:绘制导热油系统非标零件图2013 年 5 月 6 日-5 月 10 日:填写法兰盘工艺三卡2013 年 5 月 13 日-5 月 17 日:完成设计说明书(论文)、摘要和小结2013 年 5 月 20 日-5 月 25 日:整理所有资料,打印后上交指导教师,准备答辩预期成果:1完成系统装配图:1 张(A0 或 A1);2零件图:主要非标准件零件图(不少于 5 张);3工艺三卡:3 份;4设计说明书:1 份;5翻译 8000 以上外文印刷字符或译出约 5000 左右汉字的有关技术资料或专业文献,内容要尽量结合课题。特色或创新之处1、使用 CAD,绘图方便快捷,方便改变参量,能够直观表现加工的零件。2、在设计时通过对系统的深入了解,真实地知道设计里存在的不足。3、电加热的导热油系统比一般加热设施更高效,节能环保。已具备的条件和尚需解决的问题已具备的条件: 设计方案思路已经非常明确,已初步具备设计基础,工程制图与 AutoCAD,机械制造工艺学,工程材料及热处理等知识,完全含盖了设计所涉及的各个方面。 能够使用相关制图软件绘制装配图及其零件图。尚需解决的问题:对设计的每个环节考虑不是很周全。在法兰盘的设计时,要准确掌握加工余量、切削用量、进给量、切削速度等各种要素。对系统里的标准件使用需也要相当注意。指导教师意见指导教师签名:年 月 日教研室(学科组、研究所)意见教研室主任签名:年 月 日系意见主管领导签名:年 月 日英文原文Machine from the early egyptians pedal cars and John Wilkinson boring machine development. They provide rigid support for the workpiece and cutting tool and can precisely control their relative position and relative velocity. Basically speaking, the metal cutting refers to the woven form a sharpen tools from ductile workpiece surface to remove a narrow metal. Chip is abandoned product, compared with other artifacts chip is shorter, but not for the thickness of the cutting part have some increase. Geometry on the surface of the workpiece depends on the shape of the tool and the machining tool path in the process of operation. Most of the manufacturing process to produce different geometric shapes of parts. If a rough workpiece on the center shaft rotation and tool cutting surface parallel to the center of rotation, a rotating surface is created, this operation is called turning. If a hollow pipe in the same way, surface processing, this operation is called boring. When changing diameter evenly and produced a conical surface, this is known as a taper turning. If the radius of cutter contact point to change the movement way, then an outline like a ball of artifacts produced; Or if the workpiece is enough short and support is very rigid, so forming tool relative to the axis of rotation normal feed can generate an outer surface, short conical or cylindrical surface can also be formed. Flat surfaces are often needed, they can by the cutting tool relative to the axis of rotation of the radial cutting contact point. When planing for larger artifacts easier to fix knives positioned below the cutting tool and workpiece. Tool can reciprocating feed. Forming surface can be generated through the molding tooling. Using double groove drill to drill deep is the hole diameter hole of 5 to 10 times. Bit rotation and workpiece rotating cutting blade and the relative motion between the workpiece is an important factor. When milling a rotary tool with lots of cutting edges in contact with the workpiece, workpiece relative tool movement slowly. Flat or forming surface according to the shape of the geometry of the cutting tool and the way of feed may be produced. Can produce horizontal or vertical shaft rotate and can progress to in any of the three coordinate directions. Through a variety of machining operations remove the number and speed of the materials is huge, as in the large turning processing, or tiny, such as grinding and super precision machining only the highs were removed. One machine tools to perform three major function: 1. It supports workpiece or jig and tool (2) it provides relative motion for the workpiece and tool 3. In each case provide a range of feeding and in the speed of up to 4-32 kinds of choices. Speed, feed and cutting depth is the processing of the three variables. Other measure is tapping and cutting tool materials, coolant and geometry, of tools to remove metal speed and the power needed to rely on these variables. Cutting depth, feed and the cutting speed is a metal processing working procedure must be established in the mechanical parameter. Both impact force to remove the metal, power and speed. Cutting speed can be defined as the rotating speed when the week record surface relative to any instant radiating the spread of the needle, or the distance of two adjacent grooves. Cutting depth is into the depth and the depth of the groove. All processing operations including turning, boring can be categorized as rough machining, finish machining or semi finishing. Is processed as quickly as possible and effective to remove a large number of materials, and left a small part of the workpiece material used in finish machining. Finishing for artifacts for the size, shape and surface accuracy. Sometimes, semi-finishing leave schedule for finishing a certain amount of material, it is prior to finish machining. Generally speaking, the longer the workpiece at the same time by one or two lathe center support. Taper hole, the so-called central hole, on both ends of the artifacts of the drill is suitable for lathe center - usually along the axis of the cylindrical workpiece. Artifacts near for side frame is usually supported by the tailstock center, near the main bearing that comprised of main bearing center support or by jaw clamping. This approach can be strong to artifacts and can be smoothly will force to the workpiece; Auxiliary support provided by the chuck of the workpiece to reduce cutting chatter of the trend, if we can carefully and accurately with the method of chuck supporting artifacts, you can obtain accurate results. Between the two centers supporting artifacts can be very accurate results. One end of the workpiece has been processing, then the workpiece can be turned. On a lathe processing at the other end, center hole as accurate positioning and carry the workpiece weight and resist the bearing surface of cutting force. When the workpiece is removed from the lathe for any reason, center hole will be accurately to make back to work on the lathe or another lathe or a cylindrical grinding machine. Is not permitted to chuck and workpiece clamp on the main bearing lathe center. The first thought is, however, a quick method of adjust the chuck on the workpiece, but because it is not allowed in the chuck clamping is also supported by the lathe center is not possible. Provided by the lathe center adjustment will not be able to continue and claw plate can be damaged by pressure center hole and lathe center, even the lathe main spindle. Floating claw discs for the above statement provides an exception, it almost completely used in high production, the chuck is the real work driver and not for the same purposes such as three jaw, common used four jaw chuck. As produced in the shape of a kind of method, all machining is the most commonly used in the process of manufacturing and is one of the most important method. Machining process is a process generated shape, in this process, drivers device on the parts of some material in the form of a chip has been removed. Although in some occasions, the workpiece without support, use of mobile equipment to machining, but most of the mechanical processing is through the supporting artifacts and supporting tools and equipment to complete. Small volume, low cost. Machining in manufacturing, there are two applications. Is casting, forging and working pressure, each special shape, even a part, is almost always have higher mould cost. The shape of the weld depends largely on the raw materials. By using the total cost high but no special tooling equipment, processing is possible; Starting from almost any form of raw materials, as long as the external dimensions large enough, the arbitrary shape of material design. So when production processing is the preferred method, one or several parts during mass production, even design logically lead to the casting parts, forging or stamping products. High precision and surface accuracy. Mechanical processing of the second application is based on the possible high precision and surface accuracy. If mass production on the rest of the process, a lot of low volume parts will produce low but acceptable tolerance. Many, on the other hand, the shape of the parts is produced by some of the large deformation process in general, and only in selected with very high precision surface processing. The paint process, for example, is seldom produce any way other than mechanical processing and followed by a small hole on the pressure after the operation can be processed. Basic tool when cutting the work fully description method has four factors: cutting tool geometry, cutting speed and cutting depth. Cutting tools must be made of proper material; It must have a certain strength, roughness, hardness and resistance to fatigue. Cutting tool geometry described by the surface and Angle of each cutting operation is correct. Cutting speed is refers to the cutting edge through the speed of working face, it has been said by number of feet per minute. For machining efficiency, cutting speed relative to the combination of special work must have the appropriate size. In general, harder the workpiece, the less speed. Feed is the rate of tool into the workpiece. When the workpiece or tool rotation and feeding unit is inch per revolution. As it moves, a tool or workpiece reciprocating feed unit is inch time, overall, in other similar cases, feed and the cutting speed is inversely proportional to. Ins in cutting speed, cutting tool into the workpiece distance said, when it refers to cutting the width of the chip or the linear cutting chip thickness. When rough machining cutting depth is greater than finishing cutting depth. Heat generated during the metal cutting operations in the main and second deformation area and the results led to the complex temperature in the cutting tool, workpiece and chip. A typical isothermal first as shown, it can be seen that, as predicted, when the workpiece material through the main deformation, cut less, has a very large temperature gradient across the whole width of the chip. When the second chip deformation area and a short distance to reach maximum temperature. Because almost all the work is completed in metal cutting is converted into heat, can be predicted to increase removal per unit volume of metal cutting temperature will increase energy consumption. So before all the other parameters constant, Angle greaten, remove less energy per unit volume of metal and the cutting temperature. When considering the increasing lack of chip thickness and speed, the situation is more complicated. Cutting thickness tends to increase greatly influence the heat to the workpiece, tool, and can make the chip to stay in a fixed amount, at the same time, the change of cutting temperature will be small, but increase the cutting speed can reduce the heat is passed to the workpiece, at the same time, this will increase the main deformation of the chip temperature rise. In addition, the second deformation zone is relatively small, will raise the temperature in the deformation zone. Cutting parameters of other changes almost does not affect the removal of energy consumption per unit volume and the cutting temperature. So has shown that even small changes in cutting temperature has significant influence on tool wear rate, from cutting data to estimate the cutting temperature is appropriate. The most direct the most accurate method to detect high speed steel tools, trent gave details of the temperature distribution in the high speed steel tools. The technology is data detection based on high speed steel cutting tools and related to the microscopic changes of thermal history. Trent has describes the measurement of the temperature of cutting and processing a wide range of temperature distribution of workpiece when high speed steel tools. Using scanning electron microscope (sem) to study the fine scale microstructure change, the technology has been further developed. This technology is also used to study the high speed steel single point cutting tool and the temperature distribution of twist drill, Brittle fracture has been handled, tool wear there are basically three types. After the blade wear, boundary wear and the surface of the knife before wear. Blade wear occurred in the main cutting edge and the cutting edge. Main cutting edges is responsible for removing a lot of metal, which adds to the cutting force and temperature, if left unchecked will lead to the vibration of the cutting tool and workpiece, it can not efficiently cutting again. Cutting edge decide the size and surface accuracy, the sword of the wear and tear can lead to a large number of products after the surface precision of poor. According to actual cutting condition, the main causes of the cutting tool is unavailable work ahead of time on the surface of the knife wear very big, this led to an unacceptable part. Because of the stress distribution of a tool, just started sliding, sliding region of the friction between the chip and achieve maximum, the friction force is zero. So abrasive wear occurred in this area, the chip with more wear in and adjacent to the area, it is more than adjacent to it. This led to the local pitting on the surface of the cutting tool and some distance to the surface, this surface is usually part of the circular arc form. In many ways, and based on the actual cutting condition, boundary wear compared with the knife after surface is a less serious wear and tear, thus grinding blunt knife surface wear is a relatively common standards. Then, because of the author suggests that along with the increase of cutting speed, the addition of surface temperature increase more than the knife surface, due to temperature change seriously affect the wear rate of any type, boundary wear usually occurs in the case of high cutting speed. Cutter and cutting face contact place, the work surface wear than along the residual wear at the end of the worn surface areas is more obvious. This is because the local effects such as is not cutting face by the previous cutting, oxidation scale, formed by high temperature caused by work hardening. This partial wear generally associated with boundary wear, sometimes very serious. Despite Nick will not seriously affect the tool cutting performance, notch is tend to be more deep, if continue to cutting tools are likely to rupture. If any form of gradual wear and tear to make dramatic continue to exist, the tool will face a catastrophic failure, such as cutting tools cannot be cut again, in a good situation, workpiece scrapped, the worst, may cause damage to the machine tools. For carbide cutting tools and various types of wear, in the event of a catastrophic failure before using the longest service life limit. But for high speed steel cutting tool wear is uneven, has found that when wear to continue and even catastrophic failure, the most meaningful and can copy can be got as a result, of course, in practice, cutting time is far less than the fault time. Catastrophic failure occurs few phenomenon, one of the most common is the cutting force increases suddenly, artifacts appear bright ring, significant increase in noise. Tolerance is the greatest change in component size, basic size is allowed to change the amount limited by the size of the derivative and the tolerance range. Sometimes deviation is only allowed in one direction, it allows the tolerance on the hole or shaft changes without serious impact to cooperate. When changes in tolerances in both directions, known as completely deviation (positive and negative). Deviations are completely separate, and in the basic size of each side will have. Compared with minimum size and maximum size limit of size. Thus, tolerance is defined as the difference between these two sizes. Products have been finished the shape and size, it is often necessary to some type of surface precision is that they can perform their functions as well. In some cases, in order to cut and abrasion resistance, improve the physical properties o

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

|

2:不支持迅雷下载,请使用浏览器下载

3:不支持QQ浏览器下载,请用其他浏览器

4:下载后的文档和图纸-无水印

5:文档经过压缩,下载后原文更清晰

|

川公网安备: 51019002004831号

川公网安备: 51019002004831号