资源目录

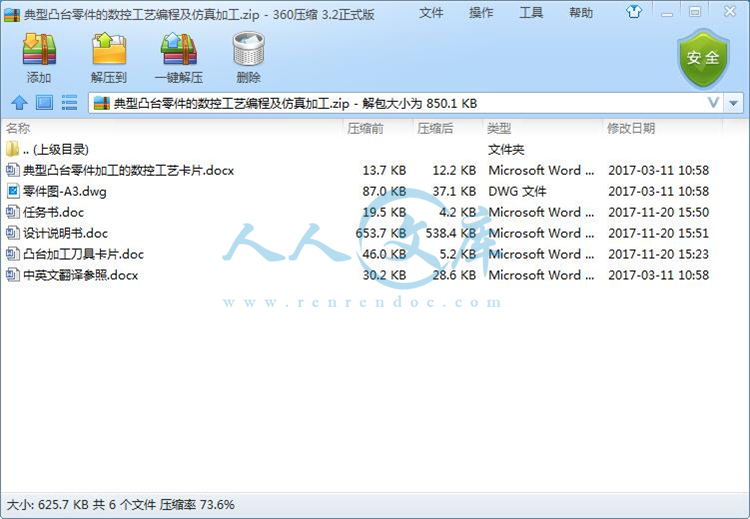

压缩包内文档预览:

编号:6377818

类型:共享资源

大小:626.55KB

格式:ZIP

上传时间:2017-12-12

上传人:小***

认证信息

个人认证

林**(实名认证)

福建

IP属地:福建

50

积分

- 关 键 词:

-

典型

零件

数控

工艺

编程

仿真

加工

- 资源描述:

-

!【包含文件如下】【工艺设计类】CAD图纸+word设计说明书.doc【需要咨询购买全套设计请企鹅97666224】.bat

中英文翻译参照.docx

任务书.doc

典型凸台零件加工的数控工艺卡片.docx

典型凸台零件的数控工艺编程及仿真加工.zip

凸台加工刀具卡片.doc

设计说明书.doc

零件图-A3.dwg

摘??要?

在零件的数控加工过程中,零件的数控加工工艺分析和工艺设计至关重要。本毕业设计选取典型的铣削零件,针对其数控加工工艺展开分析,制定加工方案,选择加工设备、夹具、刀具、量具、确定切削用量、安排加工顺序、制定走刀路线等。依据分析的结果,对该零件进行了数控加工工艺设计,并编制了零件的数控加工工序卡片。最后,采用手工编程与自动编程相结合编制了该零件的数控加工程序,在编程过程中,还要对一些工艺问题(如工件的装夹、对刀、换刀、刀具补偿等)做相应处理。???

关键词:数控加工??工艺设计??加工工序??切削用量

目 录

1 前言 3

2 零件的数控工艺分析 4

2.1 零件图的分析 4

2.2 确定数控加工工艺 5

2.3 刀具和切削用量的选择 6

2.4 零件的装夹及夹具的选择 6

3 数控加工程序的编制 7

3.1 程序原点的设置 7

3.2 对刀方法和设置 7

3.3 数值计算 12

3.4 编制程序 12

4 仿真过程和结果 18

4.1 数控加工仿真系统软件简介 18

4.2 仿真过程 19

4.3 仿真结果 22

5 总结 23

6 致谢 24

参考文献 25

- 内容简介:

-

中英文翻译参照自动化技术已经成为当下社会各个领域普及的技术,随着机械工程建设的 发展趋势,机械自动化技术在机械工程建设中的应用与发展,不仅可以促进生产水平的提高,还可以推动经济的高速增长,符合现代化生产的发展规律,也符合我国的实际基本国情。本文通过对自动化技术在机工程建设中的重要意义、表现方式及应用问题等进行分析探讨,旨在为我国机械工程建设中的自动化技术应用提供一些有价值的参考。机械工程概述机械设备是生产事业中的必备工具,可以分为动力机械、搬运机械、交通运输机械、粉碎机械等。当前机械设备在工作的过程中需要依照不同原理及方法制造,可以产生不同机械工程内容,系节能工程相互配合及相互衔接的分支系统,如机械设计系统、机械制造系统、机械运用及维修系统等。机械工程系统之间的相互交叉及重叠提升了技术融合效果,提升了我国国民经济发展效益,是确保生产逐渐迈向高层次的关键。机械工程中的自动化技术,主要指在实施机械生产的过程中依照程序和预设指令完成机械操作和控制的操作技术。通过机械工程 自动化控制可以明显提升设备生产、运行效益,提升系统之间的管理控制质量。将自动化技术贯彻于机械工程,在今后的机械发展过程中势在必行。自动化技术在机械工程建设中的重要意义自动化技术本身是一种高新技术,融入到机械工程当中能够使企业的生产工艺发生很大的变化,可提高企业生产的整体运行效率。在机械工程建设中,生产加工是重要的操作环节,而自动化技术主要就是给生产加工提供便捷,给企业带来更多的经济效益。增强企业的市场竞争力。在机械工程建设中,应用自动化技术调控整个生产流程,能够很好地保证 生产成本和质量,从而在很大程度上缩短 生产周期。目前,自动化技术在机械工程建设中的应用已经取得了明显的效果,随着社会的不断进步,其必然会普及到各行各业当中。自动化技术在机械工程中的表现形式随着自动化技术的逐渐提升,机械工程建设得到了飞速发展。自动化技术在机械工程中的表现主要体现在对信息流的自动化控制、对物流供输系统的自动化控制、对加工中的自动化控制、对系统设备的自动化控制、对监测操作的自动化控制几方面。信息流自动化可控制是依照 产品数据管理需求实施的各项 计算机辅助控制或 计算机辅助制造。自动化技术通过对数据产品过程中的各项信息进行综合、集成,实现产品过程中的处理及控制,已经成为信息处理及控制的关键操作。上述信息处理完成后,自动化系统通过计算机设计,优化各项内容及设计理念,通过 计算机辅助绘图及设计,完成机械工程自动化构建,有效提升了信息控制的有效性和可靠性。对物流供输系统的自动化控制主要是通过物流运输系统设计及控制完成物料运输;对加工中的自动化控制主要是通过加工循环设计及辅助设备控制完成工件加工操作或设备加工操作;对系统设备的自动化控制主要是在系统生产过程中对参数调节,实现设备及零件控制,完成套件、组建;对监测操作的自动化控制主要是通过自动化监测提升监测的可控性,提升监测工作效益。基于自动化技术上的机械工程建设内容柔性自动化技术上的机械工程建设在柔性化自动化技术上的机械工程建设过程中,相关人员要将提升自动化技术性操作作为构建基础,提升操作的有效性。设计人员要明确机械设备加工目的,在常规机械工程操作基础上设计自动化过程,依托计算机技术及自动化操作设备,完成柔性自动化设计。构建的过程中,人员要将提升机械工程生产效益作为建设的主体,提升生产数量和生产效益,降低人工强度,要通过建设高端 计算机自动控制体系,提升产品的各项效益。柔性自动化机械工程要将数控技术为核心,对高端计算机内容进行明确,合理布线和设置设备,最大限度发挥柔性控制效益。集成自动化技术上的机械工程建设在集成自动化技术上的机械工程建设过程中,设计人员要首先定位设计方向,依托机械工程制造操作及内容,形成准确的设计框架。设计人员要对机械工程生产中的流程进行全面了解和认识,明确生产过程中的信息需求,合理设置信息收集途径,确保在集成自动化系统控制的过程中能够全方面收集有效信息,提升自动化控制的有效性。设计人员要将强化机械工程集成化效果作为设计的主体,对高精度、高集成性设备及操作进行运用,提升集成控制应用效果。例如在机械工程质量控制、数据库信息集成建设的过程中,设计人员可以合理选取自动化监测仪器、数据收集仪器,严格依照监控及收集原理,完成设备设置。除此之外,在集成自动化建设的过程中,人员还需对工业系统设计内容进行明确,依托机械工程 环境变化,不断改进及完善,最大限度发挥集成控制效益。智能自动化技术上的机械工程建设智能自动化技术上的机械工程建设主要是依托人工智能 网络及神经网络原理实现自动化控制的体系。在上述体系构建的过程中,设计人员要对数据收集及分析内容进行强化,提升智能化效果。人员要选取智能化设备,对智能机械及智能技术进行交叉应用,确保两者之间紧密结合在一起,形成统一的、集成化的机械核心。除此之外,在上述体系构建的过程中,设计人员还要对神经网络识别能力、机械制造中的适应能力进行强化,观察自动化控制效益及质量,对无法及时处理突发事件的系统要重新检查及分析,及时处理存在的问题。自动化技术在机械工程建设中的实际应用PLC 是机电一体化的重要组成部分。在安装设备时,由于 PLC 模块体积很小,而且很轻,所以特别容易安装,在连接器件时操作也十分方便。建立 PLC 控制系统所消耗的时间并不是很长,而且其操作界面上简单明了地给了用户指示,这为使用者的操作带来了很大方便。同时,在 PLC 系统中每个模块都安装了故障检测系统,通过监视器可以准确地判断故障的位置,当其中某个模块存在问题时,可以利用其他模块代替发生故障的模块继续工作,从而使系统快速地恢复正常,不影响系统的整体运行。所以通过 PLC 技术能够提高机械工程系统的运行效率。在机械工程建设中应用自动化技术可以使生产效率明显得到提升。首先,在工程建设和生产中应用自动化技术,能够提高建设和生产的安全可靠性,保证生产的正常稳定运行。其次,在实际操作中应用自动化技术能够缩短生产周期,提高产品质量和生产效率。最后,自动化技术在机械工程中的应用能够节约能源,减少原材料的浪费,对节能减排有着非常重要的作用,不仅可为环境保护做贡献,而且还能够降低企业的运营成本。所以自动化技术和机械工程的有机结合,在工业生产中发挥了巨大的作用。目前,我国机械自动化水平还处于初始阶段,所以要不断地加强对机械自动化技术的研究和创新。Automation technology has become the popular social fields of technology, with the development trend of mechanical engineering construction, mechanical automation technology in the application of the mechanical engineering construction and development, not only can promote the improvement of production, also can promote economic growth, in line with the law of development of the modern production, also accord with the actual basic national conditions of our country. Based on the significance of automation technology in machine construction, expression and application analysis, exploration aimed at the automation technology applications in mechanical engineering construction in China to provide some valuable reference.Summary of mechanical engineeringMechanical equipment is the essential tool in production enterprise, can be divided into power machinery, transportation machinery, transportation machinery, grinding machinery, etc. Current mechanical equipment in the process of work need to be in accordance with the principle and method for different manufacture, can produce different content in mechanical engineering, department of energy conservation project to cooperate with each other and join each branch system, such as mechanical design, mechanical manufacturing system, mechanical use and maintenance system, etc. Cross and overlap between mechanical engineering system improves the technology integration effect, improve the benefit of the national economy development of our country, is the key to ensure production gradually moving towards high level. Automation technology in mechanical engineering, mainly refers to in the process of the implementation of mechanical production in accordance with the procedures and the preset instruction to complete the mechanical operation and control the operation of the technology. Through mechanical engineering automation control can significantly improve equipment production and operation efficiency, improve the system between the management of quality control. To carry out the automation technology to the mechanical engineering, it is imperative to develop mechanical process in the future.The important value of automation technology in mechanical engineering constructionAutomation technology itself is a kind of high and new technology, integrated into the mechanical engineering can make the enterprise of a lot of changes in production technology, can improve the overall efficiency of enterprise production. In mechanical engineering construction, production and processing is an important operation link, the automation technology is mainly to production and processing to provide a convenient, bring more economic benefits. The enhancement enterprise market competitiveness. Application in mechanical engineering construction, control the whole production process automation technology, can effectively guarantee the production cost and quality, which to a great extent, shorten the production cycle. At present, the application of automation technology in mechanical engineering construction has achieved obvious effect, with the constant progress of the society, it will spread to all walks of life.The forms of automation technology in mechanical engineering With the rising of automation technology, mechanical engineering construction has been rapid development. Automation technology in mechanical engineering, the performance is mainly reflected in the automation control of the information flow, the automation control of the logistics for transport system, the processing of the automation control, the automation control of the system equipment, automatic control aspects of monitoring operation.Information flow automation is controlled in accordance with the product data management requirements of the computer aided control or computer aided manufacturing. Automation technology based on various information in the process of comprehensive, integrated data products, products in the process of processing and control, has become a key of information processing and control operation. After completion of the information processing, automation system design by computer, optimizing the content and design concept, through computer aided drawing and design, complete mechanical engineering, building automation, effectively improve the effectiveness of information control and reliability.The automation control of the logistics for transport system mainly through the logistics system design and control complete material handling; To automation control in the processing mainly through processing and auxiliary equipment control loop design complete workpiece machining operation or equipment operation; For system equipment automatic control system is mainly in the production process of parameter adjustment, realize the control equipment and spare parts, complete suite, forming; The automation control of monitoring operation mainly through automatic monitoring improve monitoring control, improve monitoring efficiency.Based on the automation technology in mechanical engineering construction contentConstruction of flexible automation technology in mechanical engineeringOn the flexible automation technology of mechanical engineering construction process, the relevant staff to improve technical operation as a foundation for building automation, improve the effectiveness of the operation. Design personnel should clear mechanical equipment processing purpose, on the basis of conventional mechanical engineering operation design automation process, relying on the computer technology and automation equipment, complete the flexible automation design. In the process of building, personnel to improve production efficiency as the main body of the construction of the mechanical engineering, improve the production quantity and production efficiency, reduce labor intensity, and through construction of high-end computer automatic control system, to promote the various benefits of the product. Flexible automation machinery engineering numerical control technology as the core, to clear the content of the high-end computers, reasonable wiring and setting up the equipment, the maximum play to the flexible control benefits.The mechanical engineering construction of intelligent automation technologyIntelligent automation technology in mechanical engineering construction mainly rely on artificial intelligence network and the neural network principle of automation control system. In the process of building the system, design staff to strengthen the content of the data collection and analysis, improve intelligence. Personnel to select intelligent equipment, to cross application of intelligent machine and intelligent technology, ensure between together, form a unified, integration of mechanical core. In addition, in the process of building the system, design personnel and the neural network recognition ability, strengthen the adaptability of machine manufacturing, observe the automation control efficiency and quality, to fail to deal with emergencies system to review and analysis of the problems existing in the timely processing.The actual application automation technology in mechanical engineering constructionPLC is an important part of the electromechanical integration. When the installation of the equipment, because of the very small PLC module, and is very light, so particularly easy to install, when connecting device operation is also very convenient. Establish a PLC control system of time is not long, and its operation interface simple and clear to the user instructions, this has brought great convenience for the operation of the user. At the same time, each module in a PLC system, fault detection systems have been installed by the monitor can accurately determine the location of the fault, when there is a problem when one module can use other modules instead of the failed module continue to work, so as to make the system quickly returned to normal, does not affect the overall operation of the system. S

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号