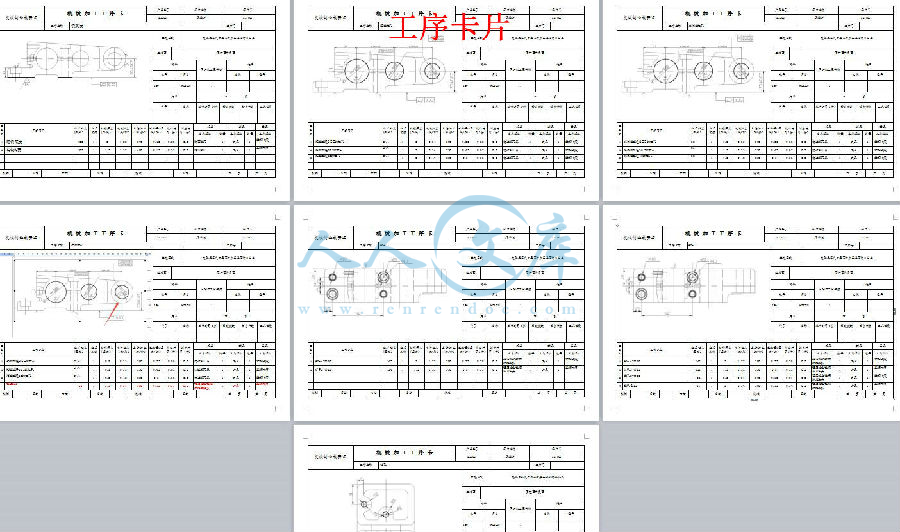

车床后托架[831001]加工工艺及铣底面夹具设计【版本3】【5张CAD图纸 说明书 工序卡片】

收藏

资源目录

压缩包内文档预览:

编号:7403739

类型:共享资源

大小:1.65MB

格式:RAR

上传时间:2018-01-15

上传人:好资料QQ****51605

认证信息

个人认证

孙**(实名认证)

江苏

IP属地:江苏

20

积分

- 关 键 词:

-

托架

加工

工艺

底面

夹具

设计

版本

- 资源描述:

-

【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件 更清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

- 内容简介:

-

SINGLESCREWMACHINETOOLLAYOUTANDSTRUCTUREABSTRACTMACHINEISANATIONALSYMBOLOFHIGHANDLOWLEVELOFMANUFACTURINGINDUSTRY,THECOREISACNCSYSTEMWEARECURRENTLYNOTSAYTHATTHESYSTEMISTHEQUALITYOFDOMESTICMADECNCMACHINETOOLSALITTLEBETTER,THEUSEOFHIGHPRECISIONBALLSCREWS,BEARINGSAREIMPORTED,MAINLYTOBUYINJAPAN,OURHOMEGROWNBALLSCREW,BEARINGSINPRECISION,THEREAREPROBLEMSINLIFETHISPAPERDESCRIBESFOURAREASFROMTHEEXISTINGSINGLESCREWMACHINELAYOUTANDSTRUCTURE,ANDPUTOUTTHEADVANTAGESANDDISADVANTAGESOFTHELIST,BECAUSEOFTHECOMPRESSORPLANTSINGLESCREWMACHINETOOLSANDMACHINETOOLEXTERNALSECURITYINFORMATION,THEABOVEINTRODUCTIONTHEREISINEVITABLYONESIDEDANDWRONG,ANDARETHEREFORESINGLESCREWCOMPRESSORFORTHEPRODUCTIONOFREFERENCEWORKSKEYWORDSMACHINESPINDLEBEARINGTOOLMACHINEISANATIONALSYMBOLOFHIGHANDLOWLEVELOFMANUFACTURINGINDUSTRY,THECOREISACNCSYSTEMWEARECURRENTLYNOTSAYTHATTHESYSTEMISTHEQUALITYOFDOMESTICMADECNCMACHINETOOLSALITTLEBETTER,THEUSEOFHIGHPRECISIONBALLSCREWS,BEARINGSAREIMPORTED,MAINLYTOBUYINJAPAN,OURHOMEGROWNBALLSCREW,BEARINGSINPRECISION,THEREAREPROBLEMSINLIFECURRENTLYTHEMAJORMACHINETOOLPLANT,PURCHASED100OFNCSYSTEM,THEMANUFACTURERSGENERALLYBUYAJAPANESEFANUC,MITSUBISHISYSTEMS,ACCOUNTINGFORMORETHAN80,BUTALSOGERMANYSSIEMENSSYSTEM,BUTRELATIVELYSMALLWHYISGERMANYSSIEMENSSYSTEMUSEDBYSMALLEARLY,THEGERMANSYSTEMISNOTABLETOFITOURPOWERGRIDOURPOWERGRIDSTABILITYISNOTENOUGH,SIEMENSELECTRONICSERVOSYSTEM,THEMODULEEASYTOBURNOUTJAPANISDIFFERENT,ANDTHEIRSYSTEMISNOTABADBURNRECENTLY,ANUMBEROFSIEMENSSYSTEMIMPROVEMENTS,PRICEISSTILLSLIGHTLYHIGHERGERMANYISVERYGREATIMPORTANCETOCHINA,SOCHINESEOFTHEIRSYSTEMONLYRECENTLY,UNLIKEJAPAN,THEREARECHINESEBASEDVERSIONOFTHELONGAGOTHEYAREINTRODUCEDINTHELATE90SJAPANESETECHNOLOGYDEVELOPMENTSOUTHKOREASHOULDBEALITTLEBETTERITHASITSOWNMANUFACTURING,HASCOMMERCIALIZEDTHENCSYSTEM,BUTIMPORTSOFMACHINETOOLSINCHINAINRESPONSETOOURREQUIREMENTS,BUTALSOREPLACEDTHEJAPANESESYSTEMWETRUSTEDTHEIRSYSTEMSSOUTHKOREANCNCMACHINETOOLSAREMAINLYTWODAEWOOANDHYUNDAIDAEWOOCURRENTLYHASAJOINTVENTUREINCHINAHOWEVER,THEIRPOORQUALITYMACHINETOOLS,LIFEISSHORT,THECURRENTBADINFLUENCEINTHEMAINLANDINFACT,THEYWEREBETTERTHANWEMADEALITTLEHOWEVER,OUROWNPOOR,WECANTOLERATE,TAIWANSMACHINEISPURCHASEDWITHUSDOLLARS,WITHTHEBAD,ANDTHATTHEFIRELARGERTAIWANSMAINPLANT,SEVERALTOOLSHAVEBEENINTENDEDTOMOVETHEIRFACTORIESTOTHEMAINLAND,MOSTOFTHEMINSHANGHAITHESEPLANTSCURRENTLYINTHEDOMESTICCOMPETITION,BUTALSOTHENAMEOFTHEBANNERMADEONTHEDOMESTICADVANCEDNUMERICALCONTROLMACHINETOOLS,ITSMAINPROFITISTAKENAWAYBYFOREIGNERSRECENTLY,ASCHINASECONOMICDEVELOPMENT,ALSOCAUSEDSOMEOFTHEMAJORMACHINETOOLMANUFACTURERSINTHEWORLDSATTENTIONIN2000,CHINASETUPAJOINTVENTUREOFNCMACHINETOOLPLANT,SAIDPRODUCTIONLEVELISVERYHIGH,KNOWNAS“INTELLIGENT,NETWORKBASED“FACTORY,ANDTHEWORLDSIMULTANEOUSLYALSOTHISYEAR,AMAJORJAPANESEOKUMAMACHINETOOLPLANTINBEIJING,SETUPANANNUALOUTPUTOF1000SETSCNCMACHINETOOLSCANBEAHOLDINGCOMPANYOFAWELLKNOWNGERMANCOMPANIESARESETTINGUPASHANGHAIFACTORYATPRESENT,THECOUNTRIESHAVEDEVELOPEDANUMBEROFPOLICIESTOENCOURAGEPEOPLETOUSEDOMESTICCNCMACHINETOOL,EACHMANUFACTURERISTRYINGTOCATCHUPTHE80AREIMPORTED,DOMESTICMACHINETOOLSTOMEETNEEDSWITHINTHENEXTFIVEYEARS,THISTRENDWILLNOTCHANGEHOWEVER,INTERMSOFTHEPRESENTDOMESTICNEEDS,CHINASCNCMACHINETOOLSNOWAREABLETOMEETTHEMEDIUMANDLOWPRODUCTORDERSFIRST,INTRODUCETHELAYOUTOFMACHINETOOLSTHEFIRSTISMACHINETOOLROTARYTOOLSPINDLECENTERANDTHECENTERDISTANCEFORTHEFIXEDMACHINETOOLROTARYTOOLSPINDLECENTERANDTHECENTERDISTANCEFORTHEFIXED,CANNOTADJUSTTHECENTERDISTANCEPROCESSINGOFSEVERALOFTHESCREWDIAMETERONTHECENTERDISTANCEREQUIREDSEVERALDIFFERENTSPECIFICATIONSOFTHEMACHINEADVANTAGESSIMPLESTRUCTUREOFTHEMACHINEDISADVANTAGEEACHMACHINECANONLYPROCESSASPECIFICATIONOFTHESCREW,WHENTHEMARKETONACERTAINSPECIFICATIONREQUIREMENTSWHENTHESCREWCOMPRESSOR,RESULTINGINAMACHINE,OTHERMACHINEIDLETHESECONDTHEMACHINETOOLSPINDLEBOXFORROTARYSPINDLEBOXTHATTHEMACHINECANTURNONAMACHINEATTHEABOVEMENTIONEDARTICLEONTHEUSEOFTHEIMPROVEMENTS,WITHTHEFIRSTSTRUCTUREOFAMACHINETOOLISBASICALLYTHESAMEADVANTAGESTHESTRUCTUREOFMACHINETOOLEASYTOADAPTTOAVARIETYOFSPECIFICATIONSOFTHEPROCESSINGSCREWONEDISADVANTAGEAFTERTHEROTATINGSPINDLEBOXANDTHETOOLSPINDLETURNINGCENTERLINEDISTANCEBETWEENTHECENTERLINEOFACCURATEMEASUREMENTDIFFICULTTHETHIRDTHEMACHINETOOLSPINDLEBOXFORHORIZONTALMOBILEBOXATTHEBOTTOMOFTHESPINDLEANDTHEBASETHEREISARRANGEDBETWEENTHERECTANGULARSLIDINGRAIL,SPINDLEBOXPERPENDICULARTOTHEDIRECTIONOFMOVEMENTOFSPINDLECENTERLINEANDPERPENDICULARTOTHECENTERLINEOFTHETOOLROTATIONTHROUGHTHEPOWEROFTHESPINDLEBOXSHAFTTOTHEBASEOFTHETOOLFEEDMECHANISMSCREWDIAMETER,ACCORDINGTOTHESIZEOFTHEPROCESSINGINTHEPROCESSINGOFTHEPREVIOUSROUNDBYHANDTOTHEBODYPUTINTOTHESCREWSPINDLEBOXMOVEDTOTHEAPPROPRIATELOCATION,ANDTHENSCREWTHESPINDLEBOXONAFIXEDBASEHORIZONTALSPINDLEBOXCANBEUSEDASAMOBILEMACHINECANPROCESSDIAMETER95385MMANYKINDBETWEENTHESCREWSPECIFICATIONS95385MMPROCESSINGBECAUSEOFTHEDIAMETEROFTHESCREW,CAUSINGTHEFRONTSURFACEANDTHETOOLSPINDLEROTATIONTHEDISTANCEBETWEENTHECENTERLINEOFTHEMARGINISTOOLARGE,THEACTUALAPPLICATIONINTHEDESIGNSPECIFICATIONSOFTHEMACHINEINTOTWO,A95205MMMACHINESCREWDIAMETERANOTHER180385MMMACHINESCREWDIAMETERADVANTAGESAVARIETYOFTOOLSTOADAPTTOTHESPECIFICATIONSOFTHEPROCESSINGSCREW,EACHSCREWSPECIFICATIONSNEEDNOTBEPROVIDEDWITHTHEAPPROPRIATEMACHINETOOLSDISADVANTAGETHESTRUCTUREOFMACHINETOOLSANDMACHINETOOLASSEMBLYOFTHETWOKINDSOFMORECOMPLEXMACHINETOOLS,MACHINETOOLSTHANTHECOSTOFTWOKINDSOFMACHINETOOLSBEFORETHEHIGHSECOND,INTRODUCETHESTRUCTUREOFMACHINETOOLSPINDLETHELEVELOFMACHINETOOLSPINDLEBOXONTHEMAINAXISANDTHEBASEOFTHEVERTICALAXISDETERMINESTHEDEGREEOFPRECISIONWASTHEPRECISIONSCREWMACHINING,ATTHESAMETIMESCREWCOMPRESSORATASPEEDOFTHOUSANDSOFHIGHSPEEDROTARYSWITCH,THEACCURACYOFTHESCREWWILLBELESSSOTHATTHECOMPRESSORHAVEAFEVER,VIBRATION,LOWEFFICIENCY,SUCHASWEARANDTEARSITUATIONQUICKLYCURRENTLYAVAILABLESINGLESCREWMACHINESPINDLESTRUCTUREOFTHEPROGRAMHASTHEFOLLOWINGTWOTHEFIRSTISBEARINGRADIALCLEARANCEISNOTADJUSTABLESPINDLESTRUCTUREBEFORESPINDLEBEARINGOUTTHEUSEOFONEPAIRSOFCYLINDRICALROLLERBEARINGSANDTHRUSTBALLBEARINGCOMBINATIONOFBOTH,THEMAINUSEOFDOUBLEROWCYLINDRICALROLLERBEARINGSUNDERRADIALCUTTINGFORCE,THEUSEOFTWOBALLBEARINGSTOBEARAXIALTHRUSTCUTTINGFORCEMAINADVANTAGESOFTHISSTRUCTURETHEMAINAXISOFTHEPROCESSINGANDASSEMBLYOFSIMPLE,LOWCOSTONEDISADVANTAGEBECAUSETHEMAINAXISOFTHERADIALBEARINGCLEARANCECANNOTBEADJUSTEDSOPOORPRECISIONSPINDLEALTHOUGHTHEUSEOFBEARINGSANDSHAFTDIAMETERFITTOELIMINATETHERADIALBEARINGCLEARANCE,BUTEACHBEARINGDIAMETERANDRADIALCLEARANCEISNOTAFIXEDVALUE,SOITISDIFFICULTTODESIGNANDPROCESSINGTOTHEQUASIAXIALRADIALANDBEARINGSWITHBORETOLERANCES2DISADVANTAGEITISVERYDIFFICULTTOBUYINTHEMARKETOFDOMESTICALLYPRODUCEDORIMPORTED,C,DORP4,P5CLASSTHRUSTBALLBEARINGS,MACHINETOOLMANUFACTURINGPLANTCOMMONLYUSEDALTERNATIVETOTHEUSEOFORDINARYCLASSBEARINGS,WHICHALSOAFFECTEDTHEACCURACYOFTHEENHANCESPINDLEBEARINGRADIALCLEARANCEADJUSTABLESPINDLESTRUCTUREDONOTAPPLYTOTHEGENERALACCURACYOFTHEGENERALMACHINETOOLS,DOESNOTAPPLYTOREQUIREAHIGHERACCURACYOFTHESPINDLEOFMACHINETOOLSTHESECONDTHERADIALBEARINGCLEARANCEADJUSTABLESPINDLESTRUCTUREBEFORETHEADOPTIONOFASPINDLEBEARINGP4CLASSOFDOUBLEROWTAPEREDHOLECYLINDRICALROLLERBEARINGSANDAP4CLASSDOUBLEROWBALLBEARINGTHRUSTTOTHECOMBINATIONOFHEARTTHEUSEOFTHESPINDLEHOLEOFTHEDOUBLEROWTAPEREDCYLINDRICALROLLERBEARINGSUNDERRADIALCUTTINGFORCE,THEUSEOFDOUBLEROWBALLBEARINGTHRUSTTOTHEHEARTTOBEARPARTOFTHEAXIALANDRADIALCUTTINGFORCECUTTINGFORCESPINDLEBEARINGSGENERALLYUSEDAFTERAP5CLASSOFDOUBLEROWTAPEREDHOLECYLINDRICALROLLERBEARINGSDOUBLEROWTAPEREDHOLECYLINDRICALROLLERBEARINGSWITHINNERRINGANDSHAFTARETAPERED112,BEARINGLOCKNUTWITHAROUNDLEDABEARINGINTHEAXIALDISPLACEMENTOFTHEINNERRINGBEARINGSANDEXPANSION,TOREDUCEORELIMINATEBEARINGRADIALCLEARANCEPURPOSESMAINDISADVANTAGEOFTHISSTRUCTURETHEPRINCIPALAXISOFTHEMORECOMPLICATEDPROCESS,THESPINDLEASSEMBLYALSOHASTHEEXPERIENCENECESSARYTOMAKETHEWORKERSTOOPERATETHESPINDLEACHIEVETHEDESIREDNUMERICALACCURACYTHIRD,THEDEPTHOFTHETOOLFEEDCONTROLREQUIREDDIFFERENTPROCESSINGSCREWDIAMETERSPIRALGROOVEDEPTHISALSODIFFERENTFROMTHEDEPTHOFTHESPIRALGROOVEMMFROMDOZENSTOMORETHAN100MILLIMETERSRANGEAROUNDTHETOOLINTOTHEINSTITUTIONSREQUIREDTOFEEDTHETHOUSANDSOFRINGROTATIONINORDERTOACHIEVEASCREWMACHINEFEEDBECAUSEOFTHETOOLINTHETOOLROTATINGATTHESAMETIMEACHIEVEMOTIONFEED,SOONANUMBEROFGENERALMACHINETOOLSUSEDINMECHANICAL,ELECTRICALCONTROLMETHODOFDEPTHOFCUTDOESNOTAPPLYTOSINGLESCREWMACHINESINGLESCREWMACHINETOOLSGIVEAGENCIESINTOTHEFOLLOWINGDIFFERENTWAYSCANBEFEEDTOCONTROLTHEDEPTHOFPURPOSETHEFIRSTISFRICTIONCLUTCHANDELECTRICALSWITCHESTOCONTROLTHEDEPTHOFTHETOOLFEEDITSPRINCIPLEISTOCONTROLDEPTHOFCUTINCREASESTHETOOLCUTTERFEEDMECHANISMINCREASESTHELOADTORQUESOTHATTHETOOLFEEDINGMECHANISMOFTHEFRICTIONTRANSMISSIONCHAINSLIPPINGCLUTCH,AMECHANICALLINKAGECONCURRENTSILENTTRIGGERELECTRICALSWITCHES,OPTICALSIGNALPROMPTEDOPERATOR,WHENMANUALOPERATORTODISCONNECTTHETOOLINTOTHEPOWERSECTORTHEADVANTAGESOFTHISCONTROLMETHODARETHECONTROLMETHODISSIMPLEANDSPAREPARTSPROCESSINGANDOPERATIONALPOWERFROMTHEIMPACTOFASUDDENPROCESSINGOFDIFFERENTDIAMETERSCREWTOADJUSTTHECLUTCHFRICTIONDISCSPRESSEDTHEPRELOADSPRINGMATERIALBECAUSEOFTHEDENSITYOFEACHSCREW,ANDTHEHARDNESSOFTHEEXISTENCEOFSUBTLEDIFFERENCESINTHEDEGREEOFCUTTINGTOOLSSHARPDIFFERENCESEXIST,THUSTHEACCURACYOFTHISCONTROLMETHODWASNOTTOOACCURATE,MAYLEADTOSCREWSPIRALGROOVEDEPTHTOLERANCEISTOOLARGETHESECONDUSEOFANELECTROMAGNETICCLUTCH,ENCODERCONTROLTOOLINTOTHEMIXTOTHEDEPTHOFTOOLFEEDSYSTEM,EQUIPPEDWITHELECTROMAGNETICCLUTCHANDATOOLFORDETECTINGTHENUMBEROFROTATINGRINGGEARANDAGUNENCODERITISATOOLOFCONTROLPRINCIPLEHANDSCREWSURFACEENCODERTOSTARTCOUNTINGSWITCH,THENSTARTCOUNTINGDEVICE,WHENTHEROTARYTOOLTOPRESETNUMBEROFLAPSWHENTHECUTTINGDEPTHISREACHED,THEELECTROMAGNETICCLUTCHAUTOMATICOFFOPENTOTHEPOWERTOOLINTOTHECONCURRENTSILENT,OPTICALSIGNALPARTSPROMPTEDTHEOPERATORHASFINISHEDPROCESSINGTHEDETECTIONDEVICETHROUGHTHEDIGITALDISPLAYSHOWSTHENUMBEROFFEEDCIRCLESORFEEDTORNOFFANDTHEELECTROMAGNETICCLUTCH,THETOOLDOESNOTONLYINTOTHEROTATIONWITHTHEVERTICALSHAFTTOTHESPORTTHEADVANTAGESOFTHISCONTROLMETHODARETHEDEPTHOFTHESPIRALGROOVESCREWTOLERANCECONTROLMOREACCURATE,BECAUSEOFSEVERALSIGNIFICANTTABLESHOWSTHEDEPTHOFPROCESSING,ORWANTAFEWLAPSANDTHEDEPTHOFPROCESSINGORCIRCLETHENUMBEROFOPERATIONSISALSOVERYINTUITIVEANDUSERFRIENDLYDISADVANTAGEAREELECTRICALCONTROLOFMACHINETOOLSATTHESAMETIMEMORECOMPLEXPARTSOFTHISCONTROLMETHODATTHEPROCESSINGPLANT,IFASUDDENPOWERFAILURE,THEPRIORDATASETWILLBELOSTIFYOUADDINTHEELECTRICALCONTROLOFTHEBATTERYTOPOWERATTHEEARLYDIMENSIONALDETECTIONDEVICESTOMAINTAINTHEJOB,THEPROBLEMCANBERESOLVEDDETECTDRIVEWAYTOOMUCHSPACEISAFIXEDPOWERINPUTSHAFTANDOUTPUTSHAFTROTATIONSHAKING,INTHECASEOFTHETRANSMISSIONSTRUCTUREOFCONVENTIONALDESIGNANDMANUFACTUREOFMACHINETOOLS,THETRANSMISSIONOUTPUTSHAFTANGLESPACEATMORETHANTENDEGREESTOTHEDOZENSOFDEGREESTRANSMISSIONGAPCAUSEDBYTOOLARGESPIRALSCREWGROOVESURFACETHENTHEREISOBVIOUSMARKS,THUSAFFECTINGTHEMACHININGACCURACYOFTHESCREWUPONCOMPLETIONOFTHEASSEMBLYMACHINETOOLAXISOFROTATIONOFTHEDRIVESPACEISTOOLARGE,INFACTARESUBJECTTOVARIOUSERRORSGEAR,CREATINGABACKLASHOFTHEGEARISTOOLARGEMACHINETOOLSINTHEMECHANICALTRANSMISSIONGEARAREUSEDREGARDLESSOFTHEACCURACYOFAFEWOFTHECLASS,THEDESIGNERSTAKEINTOACCOUNTTHEGEARMANUFACTURINGERROR,PROCESSINGERRORBOXCENTERDISTANCE,TEMPERATURE,LUBRICATINGOILFILMTHICKNESS,THEASSEMBLYERRORANDOTHERFACTORS,MACHINEDESIGNMUSTENSURETHATTRANSMISSIONGEARACERTAINAMOUNTOFBACKLASH,BACKLASHDECIDETHESIZEOFTHEGEARTOOTHTHICKNESSTOLERANCESIZESINGLESCREWMACHINEHASTHEMAINDRIVEFROMOTHERMACHINETOOLSTRUCTURESPECIFICITYTHEFIRSTISTHEINSTALLATIONATTHEOUTPUTSHAFTBRAKETOOLATTHEOUTPUTSHAFTROTATINGTHELOCATIONOFCYLINDRICALSYMMETRYWITHRADIALBRAKE,BRAKESTANDUPTOTHETOOLFRONTENDOFTHECYLINDRICALROTARYOUTPUTSHAFT,BRAKEFORSPRINGPRELOADTHEWORKINGPRINCIPLEOFTHEBRAKEISGENERATEDBYTHEFRICTIONBRAKETOINCREASETHEOUTPUTSHAFTDAMPING,REDUCINGTHESENSITIVITYOFTHEROTATIONAXISAREBRAKEANDEASYDOESNOTCHANGETHESTRUCTUREOFTHEORIGINALMACHINETOOLSTRUCTURE,THEMETHODOFINDIRECTREDUCTIONTOACHIEVETHEPURPOSEOFDRIVESPACE,INPRACTICALAPPLICATIONSTHEREISACERTAINEFFECTTHEPRESPRINGBRAKETOOLBECAUSEOFTHECYLINDRICALOUTPUTSHAFTTOEXERTAGREATERRADIALFORCE,INFACTINCREASESTHELOADMACHINETORQUE,RESULTINGININCREASEDMOTORPOWERATTHESAMETIMEGEARS,BEARINGSTOACCELERATEWEARANDTEARCONCLUSIONTHISARTICLEDESCRIBESFOURAREASFROMEXISTINGSINGLESCREWMACHINELAYOUTANDSTRUCTURE,ANDPUTOUTTHEADVANTAGESANDDISADVANTAGESOFTHELIST,BECAUSEOFTHECOMPRESSORPLANTSINGLESCREWMACHINETOOLSANDMACHINETOOLEXTERNALSECURITYINFORMATION,THEABOVEINTRODUCTIONTHEREISINEVITABLYONESIDEDANDWRONG,ANDARETHEREFORESINGLESCREWCOMPRESSORFORTHEPRODUCTIONOFREFERENCEWORKS附件1外文资料翻译译文单螺杆加工机床的布局和结构摘要机床是一个国家制造业水平高低的象征,其核心就是数控系统。我们目前不要说系统,就是国内造的质量稍微好一点的数控机床,所用的高精度滚珠丝杠,轴承都是进口的,主要是买日本的,我们自产的滚珠丝杠、轴承在精度、寿命方面都有问题。本文从四个方面介绍了国内现有单螺杆加工机床的布局和结构,并把优缺点一一列举出来,由于压缩机生产厂的单螺杆加工机床和机床资料对外保密,以上介绍难免有片面、不妥之处,因此仅供单螺杆压缩机生产厂参考。关键词机床主轴轴承刀具机床是一个国家制造业水平高低的象征,其核心就是数控系统。我们目前不要说系统,就是国内造的质量稍微好一点的数控机床,所用的高精度滚珠丝杠,轴承都是进口的,主要是买日本的,我们自产的滚珠丝杠、轴承在精度、寿命方面都有问题。目前国内的各大机床厂,数控系统100外购,各厂家一般都买日本发那科、三菱的系统,占80以上,也有德国西门子的系统,但比较少。德国西门子系统为什么用的少呢早期,德国系统不太能适合我们的电网,我们的电网稳定性不够,西门子系统的电子伺服模块容易烧坏。日本就不同了,他们的系统就烧不坏。近来西门子系统改进了不少,价格方面还是略高。德国人很不重视中国,所以他们的系统汉语化最近才有,不像日本,老早就有汉语化版的。韩国、台湾的数控机床制造能力比大陆地区略强,不过水平差不多。他们也是在上世纪90年代引进日本技术发展的。韩国应该好一点,它有自己制造的、已经商业化了的数控系统,但进口到中国的机床,应我们的要求,也换成了日本系统。我们对他们的系统信不过。韩国数控机床主要有两家大宇和现代。大宇目前在我国设有合资企业。台湾机床和我们大体一样,自己造机械部分,系统采购日本的。但他们的机床质量差,寿命短,目前在大陆影响很坏。其实他们比我们国产的要好一点。但我们自己的差,我们还能容忍,台湾的机床是用美金买来的,用的不好,那火就大了。台湾最主要的几家机床厂已打算把工厂迁往大陆,大部分都在上海。这些厂目前在国内的竞争中,也打着国产的旗号。就国产高级数控机床而言,其利润的主体是被外国人拿走了,中国只是挣了一个辛苦钱。近来随着中国的经济发展,也引起了世界一些主要机床厂商的注意,2000年,日本最大的机床制造商“马扎克”在中国银川设立了一家数控机床合资厂,据说制造水平相当高,号称“智能化、网络化”工厂,和世界同步。今年日本另外一家大机床厂大隈公司在北京设立了一家能年产1000台数控机床的控股公司,德国的一家很有名的企业也在上海设立了工厂。目前,国家制定了一些政策,鼓励国民使用国产数控机床,各厂家也在努力追赶。国内买机床最多的是军工企业,一个购买计划里,80是进口,国产机床满足不了需要。今后五年内,这个趋势不会改变。不过就目前国内的需要来讲,我国的数控机床目前能满足中低档产品的订货。一、介绍机床的布局压缩机排气量的大小决定了星轮、螺杆直径的大小和啮合中心距的大小,因此螺杆直径的不同,机床的主轴与刀具的回转中心也不同。为满足加工不同直径的螺杆,目前国内单螺杆加工机床的布局大致有以下几种方案。第一种机床的主轴与刀具回转中心的中心距为固定式机床的主轴与刀具回转中心的中心距为固定式,中心距不可调整。加工几种直径的螺杆就需要几种中心距规格不同的机床。优点机床的结构简单。缺点每种机床只能加工一种规格的螺杆,当市场上某种规格的压缩机螺杆需要量大时,造成一台机床加工,其他机床闲置。第二种机床的主轴箱为可回转式机床可根据加工螺杆直径的大小在加工前把主轴箱旋转一个角度。这种主轴箱能够回转的机床是对上述第一种机床在使用方法上的改进,与第一种机床的结构基本相同。优点机床的结构简单,能适应多种规格螺杆的加工。缺点1主轴箱旋转后主轴回转中心线与刀具回转中心线间的距离不易精确测量。缺点2主轴箱旋转后主轴前端面与刀具的回转中心线间的距离减少,因此加工较大直径的螺杆受到限制。第三种机床的主轴箱为横向移动式主轴箱底部与底座之间布置有矩形滑动导轨,主轴箱移动的方向垂直于主轴回转中心线并垂直于刀具回转中心线。主轴箱的动力通过花键轴传给底座内的刀具进给机构。根据加工螺杆直径的大小,在加工前用手轮丝杠进给机构把主轴箱移动到适当位置,然后用螺钉将主轴箱固定在底座上。主轴箱的移动距离可用光栅尺检测,位置误差0005MM。采用主轴箱可横向移动的一个机床就可以加工直径95385MM之间任何一种规格的螺杆。由于加工95385MM直径的螺杆,造成主轴前端面与刀具回转中心线间的

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号