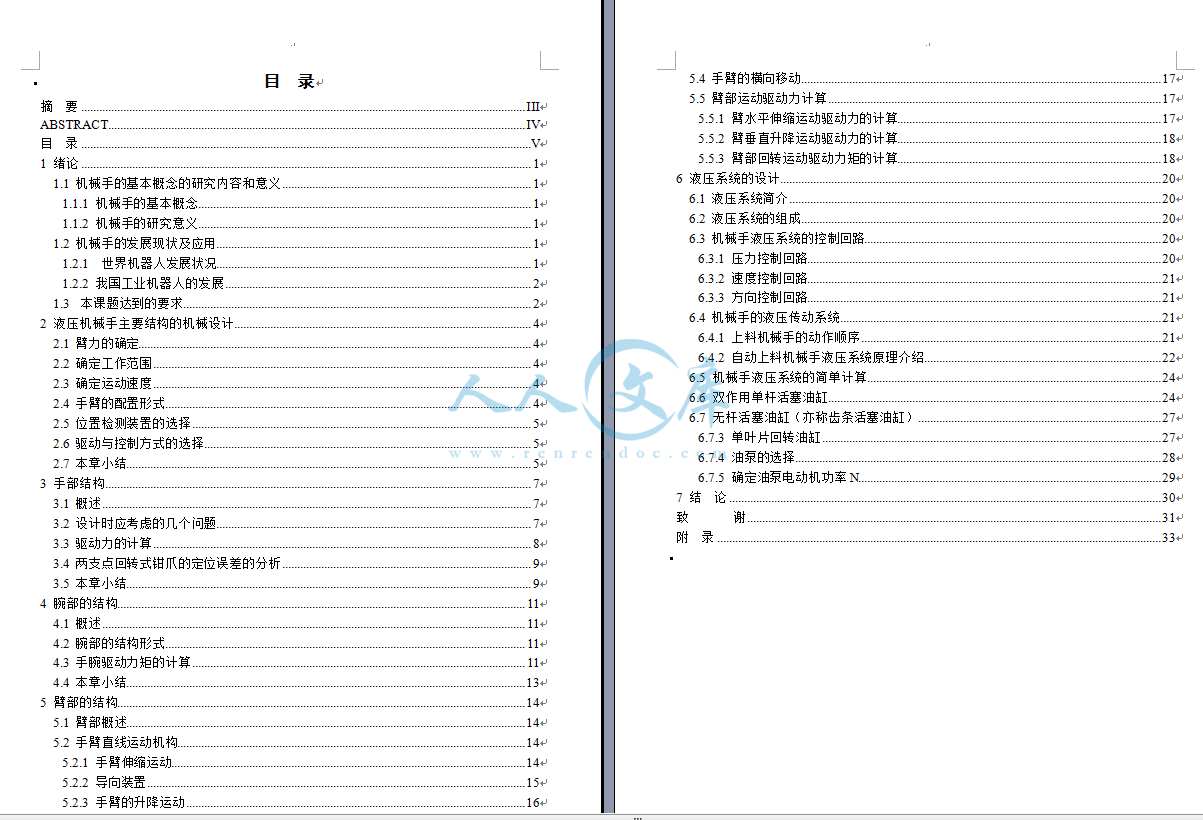

五自由度液压搬运机械手设计(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:9796564

类型:共享资源

大小:2.38MB

格式:ZIP

上传时间:2018-03-27

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

自由度

液压

搬运

机械手

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

COMBINATIONOFROBOTCONTROLANDASSEMBLYPLANNINGFORAPRECISIONMANIPULATOORABSTRACTTHISPAPERRESEARCHESHOWTOREALIZETHEAUTOMATICASSEMBLYOPERATIONONATWOFINGERPRECISIONMANIPULATORAMULTILAYERASSEMBLYSUPPORTSYSTEMISPROPOSEDATTHETASKPLANNINGLAYER,BASEDONTHECOMPUTERAIDEDDESIGNCADMODEL,THEASSEMBLYSEQUENCEISFIRSTGENERATED,ANDTHEINFORMATIONNECESSARYFORSKILLDECOMPOSITIONISALSODERIVEDTHEN,THEASSEMBLYSEQUENCEISDECOMPOSEDINTOROBOTSKILLSATTHESKILLDECOMPOSITIONLAYERTHESEGENERATEDSKILLSAREMANAGEDANDEXECUTEDATTHEROBOTCONTROLLAYEREXPERIMENTALRESULTESHOWTHEFEASIBILITYANDEFFICIENCYOFTHEPROPOSEDSYSTEMKEYWORDSMANIPULATORASSEMBLYPLANNINGSKILLDECOMPOSITIONAUTOMATEDASSEMBLY1INTRODUCTIONOWINGTOTHEMICROELECTROMECHANICALSYSTEMSMEMSTECHNIQUES,MANYPRODUCTSAREBECOMINGVERYSMALLANDCOMPLEX,SUCHASMICROPHONES,MICROOPTICALCOMPONENTS,ANDMICROFLUIDICBIOMEDICALDEVICES,WHICHCREATESINCREASINGNEEDSFORTECHNOLOGIESANDSYSTEMSFORTHEAUTOMATEDASSEMBLYHAVEBEENFOCUSEDONMICROASSEMBLYTECHNOLOGIESHOWEVER,MICROASSEMBLYTECHNIQUESOFHIGHFLEXIBILITY,EFFICIENCY,ANDRELIABILITYSKILLOPENTOFURTHERRESEARCHTHISPAPERRESEARCHESTOHOWTOREALIZETHEAUTOMATICASSEMBLYOPERATIONONATWOFINGERMICROMANIPULATORAMULILAYERASSEMBLYSUPPORTSYSTEMISPROPOSEDAUTOMATICASSEMBLYISACOMPLEXPROBLEMWHICHMAYINVOLVEMANYDIFFERENTISSUES,SUCHASTASKPLANNING,ASSEMBLYSEQUENCESGENERATION,EXECUTION,ANDCONTROL,ETCITCANBESIMPLYDIVIDEDINTOTWOPHASES,THEASSEMBLYPLANNINGANDTHEROBOTCONTROLATTHEASSEMBLYPLANNINGPHASE,THEINFORMATIONNECESSARYFORASSEMBLYOPERATION,SUCHASTHEASSEMBLYSEQUENCE,ISGENERATEDATTHEROBOTCONTROLPHASE,THEROBOTISDRIVENBASEDONTHEINFORMATIONGENERATEDATTHEASSEMBLYPLANNINGPHASE,ANDTHEASSEMBLYOPERATIONSARECONDUCTEDSKILLPRIMITIVESCANWORKASTHEINTERFACEOFASSEMBLYPLANNINGTOROBOTCONTROLSEVERALROBOTSYSTEMSBASEDONSKILLPRIMITIVESHAVEBEENREPORTEDTHEBASICIDEABEHINDTHESESYSTEMSISTHEROBOTPROGRAMMINGROBOTMOVEMENTSARESPECIFIEDASSKILLPRIMITIVES,BASEDONWHICHTHEASSEMBLYTASKISMANUALLYCODEDINTOPROGRAMSWITHTHEPROGRAMS,THEROBOTISCONTROLTOASSEMBLYTASKSAUTOMATICALLYASKILLBASEDMICROMANIPULATIONSYSTEMHASBEENDEVELOPEDINTHEAUTHORSLAB,ANDITCANREALIZEMANYMICROMANIPULATIONOPERATIONSINTHESYSTEM,THEASSEMBLYTASKISMANUALLYDISCOMPOSEDINTOSKILLSEQUENCESANDCOMPLIEDINTOAFILEAFTERIMPORTINGTHEFILEINTOTHESYSTEM,THESYSTEMCANAUTOMATICALLYEXECUTETHEASSEMBLYTASKTHISPAPERATTEMPTSTOEXPLOREAUSERFRIENDLY,ANDATTHESAMETIMEEASY,SEQUENCEGENERATIONMETHOD,TORELIEVETHEBURDENOFMANUALLYPROGRAMMINGTHESKILLSEQUENCEITISANEFFECTIVEMETHODTODETERMINETHEASSEMBLYSEQUENCEFROMGEOMETRICCOMPUTERAIDEDDESIGNCADMODELSMANYAPPROACHESHAVEBEENPROPOSEDTHISPAPERAPPLIESASIMPLEAPPROACHTOGENERATETHEASSEMBLYSEQUENCEITISNOTINVOLVEDWITHTHELOWLEVELDATASTRUCTUREOFTHECADMODEL,ANDCANBEREALIZEDWITHTHEAPPLICATIONPROGRAMMINGINTERFACEAPIFUNCTIONSGRAPHAMONGDIFFERENTCOMPONENTSISFIRSTCONSTRUCTEDBYANALYZINGTHEASSEMBLYMODEL,ANDTHEN,POSSIBLESEQUENCESARESEARCHED,BASEDONTHEGRAPHACCORDINGTOCERTAINCRITERION,THEOPTIMALSEQUENCEISFINALLYOBTAINEDTODECOMPOSETHEASSEMBLYSEQUENCEINTOROBOTSKILLSEQUENCES,SOMEWORKSHAVEBEENREPORTEDINNNAJIETALWORK,THEASSEMBLYTASKCOMMANDSAREEXPANDEDTOMOREDETAILEDCOMMANDS,WHICHCANBEASROBOTSKILLS,ACCORDINGTOAPREDEFINEDFORMATTHEDECOMPOSITIONAPPROACHOFMOSEMANNANDWAHLISBASEDONTHEANALYSISOFHYPERARCSOFAND/ORGRAPHSREPRESENTINGTHEAUTOMATICALLYGENERATEDASSEMBLYPLANSTHISPAPERPROPOSESAMETHODTOGUIDETHESKILLDECOMPOSITIONTHEASSEMBLYPROCESSESOFPARTSAREGROUPEDINTODIFFERENTSTARTATATEANDTARGETOFTHEWORKFLOW,THESKILLGENERATORCREATESASERIESOFSKILLSTHATCANPROMOTETHEPARTTOITSTARGETSTATETHEHIERARCHYOFTHESYSTEMPROPOSEDHERE,THEASSEMBLYINFORMATIONONHOWTOASSEMBLEAPRODUCTISTRANSFERREDTOTHEROBOTTHROUGHMULTIPLELAYERSTETOPLAYERISFORTHEASSEMBLYTASKPLANNINGTHEINFORMATIONNEEDEDFORTHETASKPLANNINGANDSKILLGENERATIONAREEXTRACTEDFROMTHECADMODELANDARESAVEDINTHEDATABASEBASEONTHECADMODEL,THEASSEMBLYTASKSQUENCESAREGENERATEDATTHESKILLDECOMPOSITIONLAYER,TASKSAREDECOMPOSEDINTOSKILLSEQUENCESTHEGENERATEDSKILLSAREMANAGEDANDEXECUTEDATTHEROBOTCONTROLLAYER2TASKPLANNINGSKILLSARENOTUSEDDIRECTLYATTHEASSEMBLYPLANNINGPHASE,THECONCEPTOFATASKISUSEDATASKCANFULFILLASERIESOFASSEMBLYOPERATIONS,FOREXAMPLE,FROMLOCATINGAPART,THROUGHMOVINGTHEPART,TOFIXINGITWITHANOTHERPARTINOTHERWORDS,ONETASKINCLUDESMANYFUNCTIONSTHATMAYBEFULFILLEDBYSEVERALDIFFERENTSKILLSATASKISDEFINEDASTBASEPARTASSEMBLYPARTOPERATIONBASEDPARTANDASSEMBLYPARTARETWOPARTSTHATAREASSEMBLEDTOGETHERBASEPARTISFIXEDONTHEWORKTABLE,WHILEASSEMBLYPARTISHANDLEDBYROBOTSENDEFFECTORANDASSEMBLEDONTOTHEBASEPARTOPERATIONDESCRIBESHOWTHEASSEMBLYPARTISASSEMBLEDWITHTHEBASEPARTOPERATIONINTERTIONT,SEREWT,ALIGNT,THESTRUCTUREOFMICROPARTSISUSUALLYUNCOMPLICATED,ANDTHEYCANBEMODELEDBYTHECONSTRUCTIVESOLIDGEOMETRYCAGMETHODCURRENTLY,MANYCOMMERCIALCADSOFTWAREPACKAGESCANSUPPORT3DCSGMODELINGTHEASSEMBLYMODELISREPRESENTEDASANOBJECTTHATCONSISTSOFTWOPARTSWITHCERTAINASSEMBLYRELATIONSTHATDEFINEHOWTHEPARTSARETOBEASSEMBLEDINTHECADMODEL,THERELATIONSAREDEFINEDBYGEOMETRICCONSTRAINTSTHEGEOMETRICINFORMATIONCANNOTBEUSEDDIRECTLYTOGUIDETHEASSEMBLYOPERATIONWEHAVETODERIVETHEINFORMATIONNECESSARYFORASSEMBLYOPERATIONSFROMTHECADMODELTHROUGHSEARCHINGTHEASSEMBLYTREEANDGEOMETRICRELATIONSMATESRELATIONSDEFINEDINTHEASSEMBLYSCADMODEL,WECANGENERATEARELATIONGRAPHAMONGPARTS,FOREXAMPLE,INTHEGRAPH,THENODESREPRESENTTHEPARTSIFNODESARECONNECTED,ITMEANSTHATTHEREAREASSEMBLYRELATIONSAMONGTHESECONNECTEDNODESPARTS21MATINGDIRECTIONINCSG,THERELATIONSOFTWOPARTS,GEOMETRICCONSTRAINTS,AREFINALLYREPRESENTEDASRELATIONSBETWEENPLANESANDLINES,SUCHASCOLLINEAR,COPLANAR,TANGENTIAL,PERPENDICULAR,ETCFOREXAMPLE,ASHAFTISASSEMBLEDINAHOLETHEASSEMBLYRELATIONSBETWEENTHETWOPARTSMAYCONSISTOFSUCHTWOCONSTRAINTSASCOLLINEARBETWEENTHECENTERLINEOFSHAFTLCSHAFTANDTHECENTERLINEOFHOLELCHOLEANDCOPLANARBETWEENTHEPSHAFTANDTHEPLANEPHOLETHEMATINGDIRECTIONISAKEYISSUE,FORANASSEMBLYOPERATIONTHISPAPERAPPLIESTHEFOLLOWINGAPPROACHTOCOMPUTETHEPOSSIBLEMATINGDIRECTIONBASEDONTHEGEOMETRICCONSTRAINTSTHESHAFTINHOLEOPERATIONOFFIG3ISTAKENASANEXAMPLEFORAPARTINTHERELATIONGRAPH,CALCULATEITSREMAININGDEGREESOFFREEDOM,ALSOCALLEDDEGREESOFSEPARATION,OFEACHGEOMETRICCONSTRAINTFORTHECONPLANARCONSTRAINT,THEREMAININGDEGREESOFFREEDOMARER1X,Y,ROTZFORTHECOLLINEARCONSTRAINT,THEREMAININGDEGREESOFFREEDOMARER2Z,ROTZR1ANDR2CANALSOBEREPRESENTEDASR11,1,0,0,0,1ANDR20,0,1,0,0,1HERE,1MEANSTHATTHEREISADEGREEOFSEPARATIONBETWEENTHETWOPARTSR1R20,0,0,0,1,ANDSO,THEDEGREEOFFREEDOMAROUNDTHEZAXISWILLBEIGNOREDINTHEFOLLOWINGSTEPSINTHEEASETHATTHEREISLOOPINTHERELATIONGRAPH,SUCHASPARTSPART5,PART6,ANDPART7INFIG2,THELOOPHASTOBEBROKENBEFORETHEMATINGDIRECTIONISCALCULATEDUNDERTHEASSUMPTIONTHATALLPARTSINTHECADMODELAREFULLYCONSTRAINEDANDNOTOVERCONSTRAINED,THEFOLLOWINGSIMPLEAPPROACHISADOPTEDFORTHEPARTTINTHELOOP,CALCULATETHENUMBEROFISINNINRI1RI2RINWHERERISTHEREMAININGDEGREESOFFREEDOMOFCONSTRAINTKBYPARTIFOREXAMPLE,INFIG2,GIVENTHATTHENUMBEROF1SINUISLARGERTHANU,THENITCANBEREGARDEDTHATTHEPOSITIONOFPART7ISDETERMINEDBYCONSTRAINTSBETWEENPART5ANDPART6,WHILEPART5ANDPART6CANBEFULLYCONSTRAINEDBYCONSTRAINTSBETWEENPART5ANDPART6WECANUNITEPART5ANDPART6ASONENODEWILLBEREGARDEDASASINGLE,BUTITISOBVIOUSTHATTHECOMPOSITENODEIMPLIESANASSEMBLYSEQUENCECALCULATEMATINGDIRECTIONSFORALLNODESINTHERELATIONGRAPHAGAIN,BEGINNINGATTHESTATETHATTHESHAFTANDTHEHOLEAREASSEMBLED,SEPARATETHEPARTINONEDEGREEOFSEPARATIONBYACERTAINDISTANCELARGERTHANTHEMAXIMUMTOLERANCE,ANDTHANCHECKIFINTERFERENCEOCCURSSEPARATIONINBOTHXAXISANDYAXISOFR1CAUSESTHEINTERFERENCEBETWEENTHESHAFTANDTHEHOLESEPARATIONINTHEZDIRECTIONRAISESONINTERFERENCETHEN,SELECTTHEZDIRECTIONASTHEMATINGDIRECTION,WHICHISREPRESENTEDASAVECTORMMEASUREDINTHECOORDINATESYSTEMOFTHEASSEMBLYITSHOULDBENOTEDTHAT,INSOMECASE,THEREMAYBESEVERALPOSSIBLEMATINGDIRECTIONSFORAPARTTHECONDITIONFORASSEMBLYOPERATIONINTHEMATINGDIRECTIONATTHEASSEMBLEDSTATE,WHICHCANBECHECKEDSIMPLYWITHGEOMETRICCONSTRAINTS,THEENDCONDITIONISMEASUREDBYFORCESENSORYINFORMATION,WHEREASPOSITIONINFORMATIONISUSEDASANENDCONDITIONCALCULATETHEGRASPINGPOSITIONINTHISPAPER,PARTSAREHANDLEDANDMANIPULATEDWITHTWOSEPARATEPROBES,WHICHWILLBEDISCUSSEDINTHESECT4,ANDPLANESOREDGESARECONSIDEREDFORGRASPINGINTHECASETHATTHEREARESEVERALMATINGDIRECTIONS,THEGRASPINGPLANSARESELECTEDASG1G2GI,WHEREGIISPOSSIBLEGRASPINGPLANE/EDGESETFORTHEITHMATINGDIRECTIONWHENTHEPARTISATITSFREESTATEFOREXAMPLE,INFIG4,THEPAIRPLANESP1/P1,P2/P2,ANDP3/P3CANSERVEASPOSSIBLEGRASPINGPLANES,ANDTHENTHEGRASPINGPLANESAREP1/P1,P2/P2,P3/P3/P1/P1,P3/P3/P1/P1,P2/P2P1/P1THEAPPROACHINGDIRECTIONOFTHEENDEFFECTORISSELECTEDASTHENORMALVECTOROFTHEGRASPINGPLANESITISOBVIOUSTHATNOTALLPOINTSONTHEGRASPINGPLANECANBEGRSPEDTHEFOLLOWINGMETHODISUSEDTODETERMINETHEGRASPINGAREATHEENDEFFECTOR,WHICHISMODELEDASACUBOID,ISFIRSTADDEDINTHECADMODEL,WITHTHECONSTRAINTOFCOPLANARORTANGENTIALWITHTHEGRASPINGPLANEBEGINNINGATTHEEDGETHATISFARAWAYFROMTHEBAEPARTINTHEMATINGDIRECTION,MOVETHEENDEFFECTORINTHEMATINGDIRECTIONALONGTHEGRASPINGPLANEUNTILTHEENDEFFECTORISFULLYINCONTACTWITHTHEPART,THEGRASPINGPLANEISFULLYINCONTACTWITHTHEENDEFFECTOR,ORACOLLISIONOCCURSRECORDTHEEDGEANDTHEDISTANCE,BOTHOFWHICHAREMEASUREDINTHEPARTSCOORDINATESYSTEMSEPARATEGRADUALLYTHETWOPARTSALONGTHEMATINGDIRECTION,WHICHCHECKINGINTERFERENCEINTHEOTHERDEGREESOFSEPARATION,UNTILNOINTERFERENCEOCCURSINALLOFTHEOTHERDEGREESOFSEPARATIONTHEREISOBVIOUSLYASEPARATIONDISTANCETHATASSURESINTERFERENCENOTTOOCCURINEVERYDEGREEOFSEPARATIONITISCALLEDTHESAFELENGTHINTHATDIRECTIONTHISLENGTHISUSEDFORTHECOLLISIONFREEPATHCALCULATION,WHICHWILLBEDISCUSSEDINTHEFOLLOWINGSECTION22ASSEMBLYSEQUENCESOMECRITERIACANBEUSEDTOSEARCHTHEOPTIMALASSEMBLYSEQUENCE,SUCHASTHEMECHANICALSTABILITYOFSUBASSEMBLIES,THEDEGREEOFPARALLELEXECUTION,TYPESOFFIXTURES,ETCBUTFORMICROASSEMBLY,WESHOULDPAYMOREATTENTIONTOONEOFITSMOSTIMPORTANTFEATURES,THELIMITEDWORKSPACE,WHENSELECTINGTHEASSEMBLYSEQUENCEMICROASSEMBLYOPERATIONSAREUSUALLYCONDUCTEDANDMONITOREDUNDERMICROSCOPY,ANDTHEWORKSPACEFORMICROASSEMBLYISVERYSMALLTHEASSEMBLYSEQUENCEBRINGSMUCHINFLUENCEONTHEASSEMBLYEFFICIENCYFOREXAMPLE,ASIMPLEASSEMBLYWITHTHREEPARTSINSEQUENCEA,PARTAISFIRSTFIXEDONTOPARTBINTHECASETHATPARTCCANNOTBEMOUNTEDINTHEWORKSPACEATTHESAMETIMEWITHCOMPONENTABBECAUSEOFTHESMALLWORKSPACE,INORDERTOASSEMBLEPARTCWITHAB,COMPONENTABHASTOUNMOUNTEDFROMTHEWORKSPACETHEN,COMPONENTCISTRANSPORTEDANDFIXEDINTOTHEWORKSPACEAFTERTHAT,COMPONENTABISTRANSPORTEDBACKINTOTHEWORKSPACEAGAININSEQUENCEB,THEREISNONEEDTOUNMOUNTPAYPARTSEQUENCEAISOBVIOUSLYINEFFICIENTANDMAYCAUSEMUCHUNCERTAINTYBYANASSEMBLYSEQUENCE,THEMOREINEFFICIENTTHEASSEMBLYSEQUENCEINTHISPAPER,DUETOTHESMALLWORKSPACEFEATUREOFMICROASSEMBLY,THENUMBEROFTIMESNECESSARYFORMOUNTINGOFPARTSISSELECTEDASTHESEARCHCRITERIATOFINDTHEASSEMBLYSEQUENCETHATHASAFEWANUMBEROFTIMESFORTHEMOUNTINGOFPARTSASPOSSIBLETHISPAPERPROPOSESTHEFOLLOWINGAPPROACHTOSEARCHTHEASSEMBLYSEQUENCETHERELATIONGRAPHOFTHEASSEMBLYISUSEDTOSEARCHTHEOPTIMALASSEMBLYSEQUENCEHEURISTICAPPROACHESAREADOPTEDINORDERTOREDUCETHESEARCHTIMESCHECKNODESCONNECTEDWITHMORETHANTWONODESIFTHEMATINGDIRECTIONSOFITSCONNECTEDNODESAREDIFFERENT,MARKTHEMASINACTIVENODES,WHEREASMARKTHESAMEMATINGDIRECTIONSASACTIVEMATINGDIRECTIONSELECTANODETHATISNOTANINACTIVENODEMARKTHECURRENTNODEASTHEBASENODEPARTTHEFIRSTBASEPARTISFIXEDONTHEWORKSPACEWITHTHEMATINGDIRECTIONUPSIDETHISISDONEINTHECADMODELCOMPARETHESIZEEG,WEIGHTORVOLUMEOFTHEBASEPARTWITHITSCONNECTEDPARTS,WHICHCANBEDONEEASILYBYREADINGTHEBILLOFMATERIALSBOMOFTHEASSEMBLYIFTHEBASEPARTISMUCHSMALLER,THENMARKITASANINACTIVENODESELECTANODECONNECTEDWITHTHEBASENODEASANASSEMBLYNODEPARTCHECKTHEMATINGDIRECTIONIFTHEBASENODENEEDSTOBEUNMOUNTEDFROMTHEWORKSPACEIFNEEDED,UPDATEAVARIABLEINTHECADMODEL,MOVETHEASSEMBLYPARTTOTHEBASEPARTINTHEPOSSIBLEMTINGDIRECTION,WHICHCHECKINGIFINTERFERENCECOLLISIONOCCURSIFINTERFERENCEOCCURS,MARKTHEBASENODEASANINACTIVENODEANDGOTOSTEP2,WHEREASSELECTTHEOPERATIONTYPEACCORDINGTOPARTSGEOMETRICFEATURESINTHISSTEP,ANOBSTACLEBOXISALSOCOMPUTEDTHEBOX,WHICHISMODELEDASACUBOID,INCLUDESALLPARTSINTHEWORKSPACEITISUSEDTOCALCULATETHECOLLICIONFREEPATHTOMOVETHEASSEMBLYPART,WHICHWILLBEINTRODUCEDINTHEFOLLOWINGSECTIONTHEOBSTACLEBOXISDESCRIBEDBYAPOSITIONVECTORANDITSWIDTH,HEIGHT,ANDLENGTHRECORDTHEASSEMBLYSEQUENCEWITHOPERATIONTYPE,THEMATINGDIRECTION,ANDTHEGRASPINGPOSITIONIFALLNODESHAVEBEENSEARCHED,THENMARKTHEFIRSTBASENODEASANINACTIVENODEANDGOTOSTEP2IFNOT,SELECTANODECONNECTEDWITHTHEASSEMBLYNODEMARKITASANASSEMBLYNODE,ANDTHEASSEMBLYNODETHATISSAMEASTHEMATINGDIRECTIONOFTHEFORMERASSEMBLYNODEIFTHEREIS,USETHEFORMERMATINGDIRECTIONINTHEFOLLOWINGSTEPSGOTOSTEP3AFTERSEARCHINGTHEENTIREGRAPH,WEMAYHAVESEARCHASSEMBLYSEQUENCESCOMPARINGTHEVALUESOFMOUNT,THEMOREEFFICIENTONECANBESELECTEDIFTHEREARENNODESINTHERELATIONGRAPHOFFIG2B,ALLOFWHICHARENOTCLASSEDASINACTIVENODE,ANDEACHNODEMAYHAVEMMATINGDIRECTIONS,THENITNEEDSMCOMPUTATIONSTOFINDALLASSEMBLYSEQUENCESBUTBECAUSE,USUALLY,ONEPARTONLYHASONEMATINGDIRECTION,ANDTHEREARESOMEINACTIVENODES,THECOMPUTATIONSHOULDBELESSTHANMNITSHOULDBENOTEDTHAT,INTHEABOVECOMPUTATION,SEVERALCOORDINATESYSTEMSAREINVOLVED,SUCHASTHECOORDINATESOFTHEASSEMBLYSEQUENCES,THECOORDINATESOFTHEBASEPART,ANDTHECOORDINATES,OFTHEASSEMBLYTHERELATIONSAMONGTHECOORDINATESAREREPRESENTEDBYA44TRANSFORMATIONMATRIX,WHICHISCALCULATEDBASEDONTHEASSEMBLYCADMODELWHENCREATINGTHERELATIONSGRAPHTHESEMATRIXESARESTOREDWITHALLOTHERELATEDPARTSINTHEDATABASETHEYAREALSOUSEDINSKILLDECOMPOSITION3SKILLDECOMPOSITIONANDEXECUTION31DEFINITIONOFSKILLPRIMITIVESKILLPRIMITIVESARETHEINTERFACEBETWEENTHEASSEMBLYPLANNINGANDROBOTCONTROLTHEREHAVEBEENSOMEDEFINITIONSONSKILLPRIMITIVESTHEBASICDIFFERENCEAMONGTHESEDEFINITIONSISTHESKILLSCOMPLEXITYANDFUNCTIONSTHATONESKILLCANFULFILLFROMTHEPOINTOFVIEWOFASSEMBLYPLANNING,ITISOBVIOUSLYBETTERTHATONESKILLCANFULFILLMOREFUNCTIONSHOWEVER,THECONTROLOFASKILLWITHMANYFUNCTIONSMAYBECOMECOMPLICATEDINTHEPAPER,TWOSEPARATEPROBES,RATHERTHANASINGLEPROBEORPROCESSISNOTEASYINADDITION,FOREXAMPLE,MOVINGAPARTMAYINVOLVENOTONLYTHEMANIPULATORBUTALSOTHEWORKTABLETHEREFORE,TOSIMPLIFYTHECONTROLPROCESS,SILLSDEFINEDINTHEPAPERDONOTINCLUDEMANYFUNCTIONSMOREIMPORTANTLY,THESKILLSSHOULDBEEASILYAPPLIEDTOVARIOUSASSEMBLYTASKS,THATIS,THESETOFSKILLSHOULDHAVEGENERALITYTOEXPRESSSPECIFICTASKSTHERESHOULDNOTBEOVERLAPAMONGSKILLINTHEPAPER,ASKILLPRIMITIVEFORROBOTCONTROLISDEFINEDASATTRIBUTEI,ACTIONIATTRIBUTEI,SISTARTIATTRIBUTEI,ENDIATTRIBUTEICONDITIONIATTRIBUTEIATTRIBUTEIINFORMATIONNECESSARYFORSITOBEEXECUTEDTHEYCANBECLASSIFIEDASREQUIREDATTRIBUTESANDOPTIONATTRIBUTES,ORSENSORYATTRIBUTESANDCADMODELDRIVENATTRIBUTESTHEATTRIBUTESAREREPRESENTEDBYGLOBALVARIABLESUSEDINDIFFERENTLAYERSACTION_IROBOTSACTION,WHICHISTHEBASICSENSORMOTIONMANYACTIONSAREDEFINEDINTHESYSTEM,SUCHASMOVE_WORKTABLE,MOVE_PROBES,ROTATION_WORKTABLE,ROTATION_PROBES,TOUCH,INSERT,SCREW,GRASP,ECTFORONESKILL,THEREISONLYONEACTIONDUETOTHELIMITEDSPACE,THEDETAILSOFACTIONSWILLNOTBEDISCUSSEDINTHEPAPERSTART_ITHESTARTSTATEOFACTION_I,WHICHISMEASUREDBYSENSORVALUESEND_ITHEENDSTATEOFACTION_I,WHICHISMEASUREDBYSENSORVALUESCONDITION_ITHECONDITIONUNDERWHICHACTION_IISEXECUTEDFROMTHEABOVEDEFINITIONS,WEMAYFINDTHATSKILLPRIMITIVESINTHEPAPERBOBOTMOTIONSWITHSTARTSTATEANDENDSTATE,ANDTHATTHEYAREEXECUTEDUNDERSPECIFICCONDITIONSASSEMBLYPLANNINGINTHEPAPERISTOGENERATEASEQUENCEOFROBOTACTIONSANDTOASSIGNVALUESTOATTRIBUTESPFTHEDEACTIONS32SKILLDECOMPOSITIONSOMEAPPROACHESHAVEBEENPROPOSEDFORSKILLDECOMPOSITIONTHISPAPERPRESENTSANOVELAPPROACHTOGUIDETHESKILLDECOMPOSITIONASDISCUSSEDABOVE,INTHEPRESENTPAPER,ATASKISTOASSEMBLETHEASSEMBLY_PARTWITHTHEBASE_PARTWEDEFINETHEPROCESSFROMTHESTATETHATASSEMBLY_PARTISATAFREESTATETOTHESTATEITISFIXEDWITHBESE_PARTASTHEASSEMBLYLIFESTYLEOFTHEASSEMBLY_PARTINITSASSEMBLYLIFECYCLE,THEASSEMBLY_PARTMAYBEATDIFFERENTASSEMBLYSTATESHERESHOWSASHAFTSSATESSHOWASBLOCKSANDASSOCIATEDWORKFLOWSOFANINSERTIONTASKAWORKFLOWCONSISTINGOFGROUPOFSKILLSPUSHESFORWARDTHEASSEMBLY_PARTFROMONESTATETOANOTHERSTATEAWORKFLOWISASSOCIATEDWITHASPECIFICSKILLGENERATORTHATISINCHARGEOFGENERATINGSKILLSFORDIFFERENTASSEMBLYTASKS,THESAMEWORKFLOWSMAYBEUDED,THOUGHSPECIFICSKILLSGENERATEDFORDIFFERENTTASKSMAYBEDIFFERENTTHESYSTEMPROVIDESDEFAULTTASKTEMPLATES,INWHICHDEFAULTSTATESAREDEFINEDTHESETEMPLATESAREIMPORTEDINTOTHESYSTEMANDINSTANTIATEDAFTERTHEYAREASSOCIATEDWITHTHECORRESPONDINGASSEMBLY_PARTINSOMECASES,SOMESTATESDEFINEDBYTHEDEFAULTTEMPLATEMAYBENOTNEEDEDFOREXAMPLE,DETERMINEDBYTHEFIXTURE,THENTHEFREEANDIN_WSSTATESCANBEREMOVEDFROMTHESHAFTSASSEMBLYLIFECYCLETHESYSTEMPROVIDESATOOLFORUSERSTOMODIFYTHEDETEMPLATESORGENERATETHEIROWNTEMPLATESTHETOOLSUSERINTERFACEISDISPLAYEDINFORAWORKFLOW,THESTARTSTATEISMEASUREDBYSENSORYVALUES,WHICHTHETARGETSTATEISCALCULATEDBASEDONTHECADMODELANDSENSORYATTRIBUTESACCORDINGTOTHESTARTSTATEANDTARGETSTATE,THEGENERATORGENERATESASERIESOFSKILLSHERE,WEUSETHEMOVEWORKFLOWINASANEXAMPLETOSHOWHOWSKILLSAREGENERATEDAFTERTHEASSEMBLYTASKASSEMBLYLIFECYCLEISINITIATED,THETEMPLATEISREADINTOTHECOORDINATORFORTHEWORKFLOWMOVE,ITSSTARTISGRASPED,WHICHIMPLIESTHATTHEASSEMBLY_PARTISGRASPEDBYTHEROBOTSENDEFFECTORAND,OBVIOUSLY,THEPOSITIONOFTHEASSEMBLY_PARTISALSOOBTAINEDITSTARGETSTATEISADJUSTED,WHICHISTHESTATEIMMEDICTELYBEFOREITISTOBEFIXEDWITHTHEBASE_PARTATTHEADJUSTEDATATE,THEORIENTATIONOFTHEASSEMBLY_PARTISDETERMINEDBYTHEMATINGDIRECTION,WHICHTHEPOSITIONISDETERMINEDBYTHESAFELENGTHTHESEVALUESHAVEBEENCALUATEDINTHETASKPLANNINGLAYERANDARESTOREDINADATABASEWHENTHETASKTEMPLATEISIMPORTED,THESEVALUEDAREREADINTOTHEMEMORYATCOORDINATEANDTRANSFORMEDINTOTHECOORDINATEDOFTHEWORKSPACETHEREISANIMPORTANTANDNECESSARYSTEPTHATHASTOBEPERFORMEDINTHESKILLDECOMPOSITIONPHASETHEGENERATIONOFACOLLISIONFREEPATHHERE,WEUSEASTRAIGHTLINEPATH,WHICHISSIMPLEANDEASYCALCULATEDASSUMETHATP3ISTHEPOSITIONOFTHEASSEMBLYPARTATTHEADJUSTEDSTATEANDP0ISTHEPOSITIONATTHEGRASPEDSTATETHEFOLLOWINGAPPROACHISAPPLIEDTOGENERATETHEPATHBASEDONTHEORIENTATIONOFTHEASSEMBLYPARTANDMATINGDIRECTION,SELECTSKILLSROTATETABLEORROTATEPROBESTOADJUSTTHEORIENTATIONOFTHEPARTANDASSIGNVALUESTOTHEATTRIBUTESOFTHESESKILLSBASEDONTHEOBSTACLEBOX,MATINGDIRECTION,REALPOSITION/ORIENTATIONOFTHEASSEMBLYPART,THEINTERMEDIATEPOSITIONSP1ANDP2NEEDTOBECALCULATEDFOREACHSEGMENTPATH,VERIFYWHETHERTHEMOVETABLESKILLFORALARGERANGEORTHEMOVEPROBESKILLFORASMALLRANGESHOULDBEUSEDGENERATESKILLLISTSFOREACHSEGMENTANDASSIGNVALUESTOTHESESKILLS33EXECUTIONOFSKILLSAFTERAGROUPOFSKILLSWHICHCANPROMOTETHEPARTASPECIFICSTATEAREGENERATED,THESESKILLSARETRANSFERREDTOTHESKILLMANAGEMENTMODELTHESYSTEMPROMOTESONEORSEVERALSKILLSI

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号