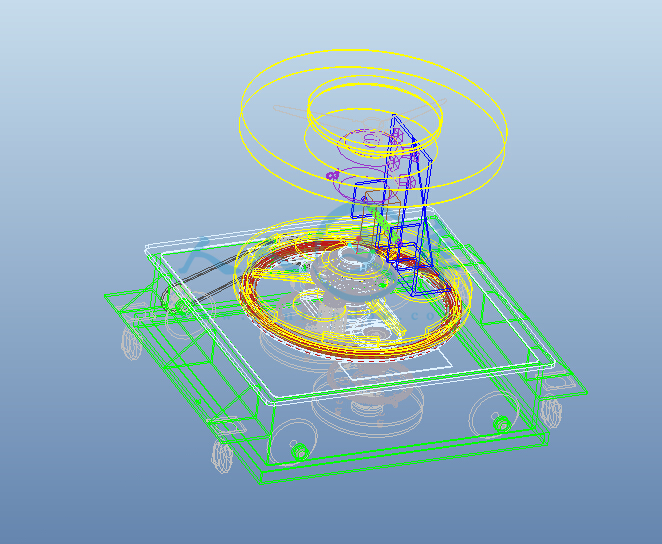

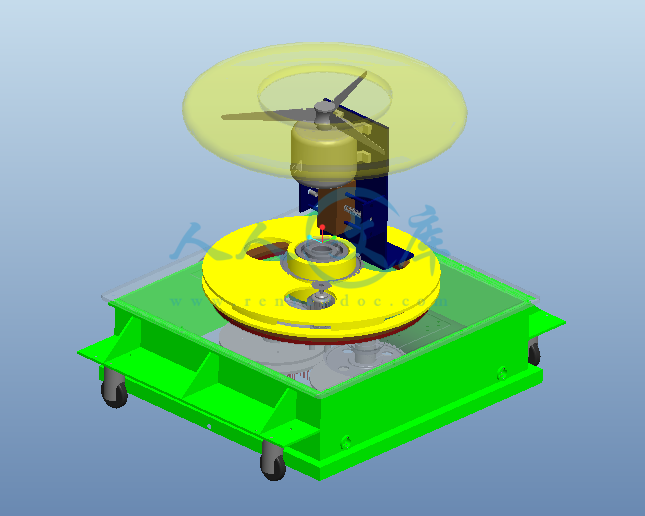

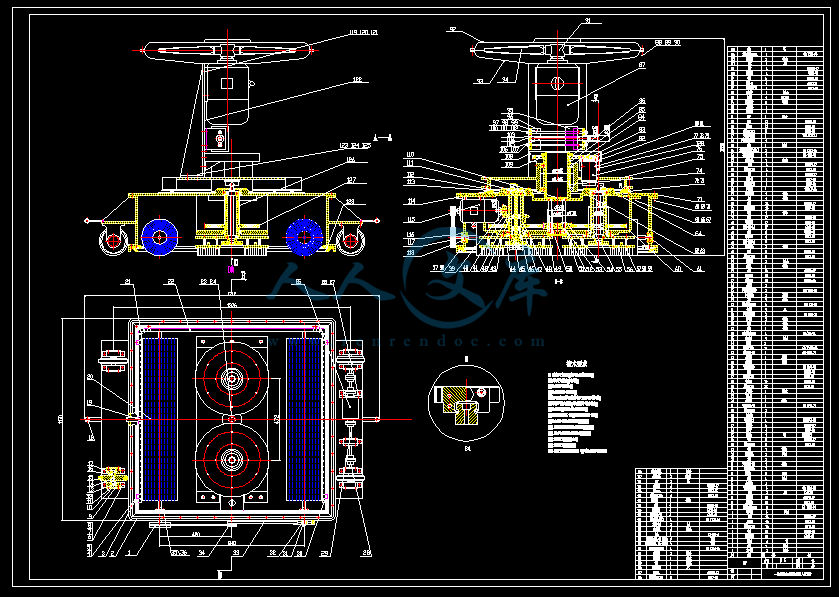

一种新型玻璃清洁机器人的设计【全套含有CAD图纸三维建模】

收藏

资源目录

压缩包内文档预览:

编号:10073112

类型:共享资源

大小:15.73MB

格式:ZIP

上传时间:2018-05-04

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

100

积分

- 关 键 词:

-

一种

新型

玻璃

清洁

机器人

设计

全套

含有

cad

图纸

三维

建模

- 资源描述:

-

- 内容简介:

-

ANEXPERIMENTALSTUDYOFTHEWATERASSISTEDINJECTIONMOLDINGOFGLASSBERLLEDPOLYBUTYLENETEREPHTHALATEPBTCOMPOSITESABSTRACTTHEPURPOSEOFTHISREPORTWASTOEXPERIMENTALLYSTUDYTHEWATERASSISTEDINJECTIONMOLDINGPROCESSOFPOLYBUTYLENETEREPHTHALATEPBTCOMPOSITESEXPERIMENTSWERECARRIEDOUTONAN80TONINJECTIONMOLDINGMACHINEEQUIPPEDWITHALABSCALEWATERINJECTIONSYSTEM,WHICHINCLUDEDAWATERPUMP,APRESSUREACCUMULATOR,AWATERINJECTIONPIN,AWATERTANKEQUIPPEDWITHATEMPERATUREREGULATOR,ANDACONTROLCIRCUITTHEMATERIALSINCLUDEDVIRGINPBTANDA15GLASSBERLLEDPBTCOMPOSITE,ANDAPLATECAVITYWITHARIBACROSSCENTERWASUSEDVARIOUSPROCESSINGVARIABLESWEREEXAMINEDINTERMSOFTHEIRINUENCEONTHELENGTHOFWATERPENETRATIONINMOLDEDPARTS,ANDMECHANICALPROPERTYTESTSWEREPERFORMEDONTHESEPARTSXRAYDIRACTIONXRDWASALSOUSEDTOIDENTIFYTHEMATERIALANDSTRUCTURALPARAMETERSFINALLY,ACOMPARISONWASMADEBETWEENWATERASSISTEDANDGASASSISTEDINJECTIONMOLDEDPARTSITWASFOUNDTHATTHEMELTLLPRESSURE,MELTTEMPERATURE,ANDSHORTSHOTSIZEWERETHEDOMINANTPARAMETERSAECTINGWATERPENETRATIONBEHAVIORMATERIALATTHEMOLDSIDEEXHIBITEDAHIGHERDEGREEOFCRYSTALLINITYTHANTHATATTHEWATERSIDEPARTSMOLDEDBYGASALSOSHOWEDAHIGHERDEGREEOFCRYSTALLINITYTHANTHOSEMOLDEDBYWATERFURTHERMORE,THEGLASSBERSNEARTHESURFACEOFMOLDEDPARTSWEREFOUNDTOBEORIENTEDMOSTLYINTHEOWDIRECTION,BUTORIENTEDSUBSTANTIALLYMOREPERPENDICULARTOTHEOWDIRECTIONWITHINCREASINGDISTANCEFROMTHESKINSURFACE2006ELSEVIERLTDALLRIGHTSRESERVEDKEYWORDSWATERASSISTEDINJECTIONMOLDINGGLASSBERREINFORCEDPOLYBUTYLENETEREPHTHALATEPBTCOMPOSITESPROCESSINGPARAMETERSBMECHANICALPROPERTIESCRYSTALLINITYAPOLYMERMATRIXCOMPOSITESPROCESSING1INTRODUCTIONWATERASSISTEDINJECTIONMOLDINGTECHNOLOGY1HASPROVEDITSELFABREAKTHROUGHINTHEMANUFACTUREOFPLASTICPARTSDUETOITSLIGHTWEIGHT,FASTERCYCLETIME,ANDRELATIVELYLOWERRESINCOSTPERPARTINTHEWATERASSISTEDINJECTIONMOLDINGPROCESS,THEMOLDCAVITYISPARTIALLYLLEDWITHTHEPOLYMERMELTFOLLOWEDBYTHEINJECTIONOFWATERINTOTHECOREOFTHEPOLYMERMELTASCHEMATICDIAGRAMOFTHEWATERASSISTEDINJECTIONMOLDINGPROCESSISILLUSTRATEDINFIG1WATERASSISTEDINJECTIONMOLDINGCANPRODUCEPARTSINCORPORATINGBOTHTHICKANDTHINSECTIONSWITHLESSSHRINKAGEANDWARPAGEANDWITHABETTERSURFACENISH,BUTWITHASHORTERCYCLETIMETHEWATERASSISTEDINJECTIONMOLDINGPROCESSCANALSOENABLEGREATERFREEDOMOFDESIGN,MATERIALSAVINGS,WEIGHTREDUCTION,ANDCOSTSAVINGSINTERMSOFTOOLINGANDPRESSCAPACITYREQUIREMENTS24TYPICALAPPLICATIONSINCLUDERODSANDTUBES,ANDLARGESHEETLIKESTRUCTURALPARTSWITHABUILTINWATERCHANNELNETWORKONTHEOTHERHAND,DESPITETHEADVANTAGESASSOCIATEDWITHTHEPROCESS,THEMOLDINGWINDOWANDPROCESSCONTROLAREMORECRITICALANDDICULTSINCEADDITIONALPROCESSINGPARAMETERSAREINVOLVEDWATERMAYALSOCORRODETHESTEELMOLD,ANDSOMEMATERIALSINCLUDINGTHERMOPLASTICCOMPOSITESAREDICULTTOMOLDSUCCESSFULLYTHEREMOVALOFWATERAFTERMOLDINGISALSOACHALLENGEFORTHISNOVELTECHNOLOGYTABLE1LISTSTHEADVANTAGESANDLIMITATIONSOFWATERASSISTEDINJECTIONMOLDINGTECHNOLOGYWATERASSISTEDINJECTIONMOLDINGHASADVANTAGESOVERITSBETTERKNOWNCOMPETITORPROCESS,GASASSISTEDINJECTIONMOLDING5,BECAUSEITINCORPORATESASHORTERCYCLETIMETOSUCCESSFULLYMOLDAPARTDUETOTHEHIGHERCOOLINGCAPACITYOFWATERDURINGTHEMOLDINGPROCESSTHEINCOMPRESSIBILITY,LOWCOST,ANDEASEOFRECYCLINGTHEWATERMAKESITANIDEALMEDIUMFORTHEPROCESSSINCEWATERDOESNOTDISSOLVEANDDIUSEINTOTHEPOLYMERMELTSDURINGTHEMOLDINGPROCESS,THEINTERNALFOAMINGPHENOMENON6THATUSUALLYOCCURSINGASASSISTEDINJECTIONMOLDEDPARTSCANBEELIMINATEDINADDITION,WATERASSISTEDINJECTIONMOLDINGPROVIDESABETTERCAPABILITYOFMOLDINGLARGERPARTSWITHASMALLRESIDUALWALLTHICKNESSTABLE2LISTSACOMPARISONOFWATERANDGASASSISTEDINJECTIONMOLDINGWITHINCREASINGDEMANDSFORMATERIALSWITHIMPROVEDPERFORMANCE,WHICHMAYBECHARACTERIZEDBYTHECRITERIAOFLOWERWEIGHT,HIGHERSTRENGTH,ANDAFASTERANDCHEAPEPRODUCTIONCYCLETIME,THEENGINEERINGOFPLASTICSISAPROCESSTHATCANNOTBEIGNOREDTHESEPLASTICSINCLUDETHERMOPLASTICANDTHERMOSETPOLYMERSINGENERAL,THERMOPLASTICPOLYMERSHAVEANADVANTAGEOVERTHERMOSETPOLYMERSINTERMSOFHIGHERIMPACTSTRENGTH,FRACTURERESISTANCEANDSTRAINSTOFAILURETHISMAKESTHERMOPLASTICPOLYMERSVERYPOPULARMATERIALSINSTRUCTURALAPPLICATIONSPOLYBUTYLENETEREPHTHALATEPBTISONEOFTHEMOSTFREQUENTLYUSEDENGINEERINGTHERMOPLASTICMATERIALS,WHICHISFORMEDBYPOLYMERIZING14BUTYLENEGLYCOLANDDMTTOGETHERFIBERREINFORCEDCOMPOSITEMATERIALSHAVEBEENADAPTEDTOIMPROVETHEMECHANICALPROPERTIESOFNEATPLASTICMATERIALSTODAY,SHORTGLASSBERREINFORCEDPBTISWIDELYUSEDINELECTRONIC,COMMUNICATIONANDAUTOMOBILEAPPLICATIONSTHEREFORE,THEINVESTIGATIONOFTHEPROCESSINGOFBERREINFORCEDPBTISBECOMINGINCREASINGLYIMPORTANT710THISREPORTWASMADETOEXPERIMENTALLYSTUDYTHEWATERASSISTEDINJECTIONMOLDINGPROCESSOFPOLYBUTYLENETEREPHTHALATEPBTMATERIALSEXPERIMENTSWERECARRIEDOUTONAN80TONINJECTIONMOLDINGMACHINEEQUIPPEDWITHALABSCALEWATERINJECTIONSYSTEM,WHICHINCLUDEDAWATERPUMP,APRESSUREACCUMULATOR,AWATERINJECTIONPIN,AWATERTANKEQUIPPEDWITHATEMPERATUREREGULATOR,ANDACONTROLCIRCUITTHEMATERIALSINCLUDEDAVIRGINPBTANDA15GLASSBERLLEDPBTCOMPOSITE,ANDAPLATECAVITYWITHARIBACROSSCENTERWASUSEDVARIOUSPROCESSINGVARIABLESWEREEXAMINEDINTERMSOFTHEIRINUENCEONTHELENGTHOFWATERPENETRATIONINMOLDEDPARTS,WHICHINCLUDEDMELTTEMPERATURE,MOLDTEMPERATURE,MELTLLINGSPEED,SHORTSHOTSIZE,WATERPRESSURE,WATERTEMPERATURE,WATERHOLDANDWATERINJECTIONDELAYTIMEMECHANICALPROPERTYTESTSWEREALSOPERFORMEDONTHESEMOLDEDPARTS,ANDXRDWASUSEDTOIDENTIFYTHEMATERIALANDSTRUCTURALPARAMETERSFINALLY,ACOMPARISONWASMADEBETWEENWATERASSISTEDANDGASASSISTEDINJECTIONMOLDEDPARTS2EXPERIMENTALPROCEDURE21MATERIALSTHEMATERIALSUSEDINCLUDEDAVIRGINPBTGRADE1111FB,NANYAPLASTIC,TAIWANANDA15GLASSBERLLEDPBTCOMPOSITEGRADE1210G3,NANYAPLASTIC,TAIWANTABLE3LISTSTHECHARACTERISTICSOFTHECOMPOSITEMATERIALS22WATERINJECTIONUNITALABSCALEWATERINJECTIONUNIT,WHICHINCLUDEDAWATERPUMP,APRESSUREACCUMULATOR,AWATERINJECTIONPIN,AWATERTANKEQUIPPEDWITHATEMPERATUREREGULATOR,ANDACONTROLCIRCUIT,WASUSEDFORALLEXPERIMENTS3ANORICETYPEWATERINJECTIONPINWITHTWOORICES03MMINDIAMETERONTHESIDESWASUSEDTOMOLDTHEPARTSDURINGTHEEXPERIMENTS,THECONTROLCIRCUITOFTHEWATERINJECTIONUNITRECEIVEDASIGNALFROMTHEMOLDINGMACHINEANDCONTROLLEDTHETIMEANDPRESSUREOFTHEINJECTEDWATERBEFOREINJECTIONINTOTHEMOLDCAVITY,THEWATERWASSTOREDINATANKWITHATEMPERATUREREGULATORFOR30MINTOSUSTAINANISOTHERMALWATERTEMPERATURE23MOLDINGMACHINEANDMOLDSWATERASSISTEDINJECTIONMOLDINGEXPERIMENTSWERECONDUCTEDONAN80TONCONVENTIONALINJECTIONMOLDINGMACHINEWITHAHIGHESTINJECTIONRATEOF109CM3/SAPLATECAVITYWITHATRAPEZOIDALWATERCHANNELACROSSTHECENTERWASUSEDINTHISSTUDYFIG2SHOWSTHEDIMENSIONSOFTHECAVITYTHETEMPERATUREOFTHEMOLDWASREGULATEDBYAWATERCIRCULATINGMOLDTEMPERATURECONTROLUNITVARIOUSPROCESSINGVARIABLESWEREEXAMINEDINTERMSOFTHEIRINUENCEONTHELENGTHOFWATERPENETRATIONINWATERCHANNELSOFMOLDEDPARTSMELTTEMPERATURE,MOLDTEMPERATURE,MELTLLPRESSURE,WATERTEMPERATUREANDPRESSURE,WATERINJECTIONDELAYTIMEANDHOLDTIME,ANDSHORTSHOTSIZEOFTHEPOLYMERMELTTABLE4LISTSTHESEPROCESSINGVARIABLESASWELLASTHEVALUESUSEDINTHEEXPERIMENTS24GASINJECTIONUNITINORDERTOMAKEACOMPARISONOFWATERANDGASASSISTEDINJECTIONMOLDEDPARTS,ACOMMERCIALLYAVAILABLEGASINJECTIONUNITGASINJECTIONPPC1000WASUSEDFORTHEGASASSISTEDINJECTIONMOLDINGEXPERIMENTSDETAILSOFTHEGASINJECTIONUNITSETUPCANBEFOUNDINTHEREFS1115THEPROCESSINGCONDITIONSUSEDFORGASASSISTEDINJECTIONMOLDINGWERETHESAMEASTHATOFWATERASSISTEDINJECTIONMOLDINGTERMSINBOLDINTABLE4,WITHTHEEXCEPTIONOFGASTEMPERATUREWHICHWASSETAT2025XRDINORDERTOANALYZETHECRYSTALSTRUCTUREWITHINTHEWATERASSISTEDINJECTIONMOLDEDPARTS,WIDEANGLEXRAYDIRACTIONXRDWITH2DDETECTORANALYSESINTRANSMISXRDSAMPLES,THEEXCESSWASREMOVEDBYPOLISHINGTHE40KVAND40MAMORESPECICALLY,THEMEASUREMENTSWEREPERFORMEDONTHEMOLDSIDEANDWATERSIDELAYERSOFTHEWATERASSISTEDINJECTIONMOLDEDPARTS,WITHTHE2HANGLERANGINGFROM7TO40THESAMPLESREQUIREDFORTHESEANALYSESWERETAKENFROMTHECENTERPORTIONOFTHESEMOLDEDPARTSTOOBTAINTHEDESIREDTHICKNESSFORTHESIONMODEWEREPERFORMEDWITHCUKARADIATIONATSAMPLESONAROTATINGWHEELONAROTATINGWHEEL,RSTWITHWETSILICONCARBIDEPAPERS,THENWITH300GRADESILICONCARBIDEPAPER,FOLLOWEDBY600AND1200GRADEPAPERFORABETTERSURFACESMOOTHNESS26MECHANICALPROPERTIESTENSILESTRENGTHANDBENDINGSTRENGTHWEREMEASUREDONATENSILETESTERTENSILETESTSWEREPERFORMEDONSPECIMENSOBTAINEDFROMTHEWATERASSISTEDINJECTIONMOLDEDPARTSSEEFIG3TOEVALUATETHEEECTOFWATERTEMPERATUREONTHETENSILEPROPERTIESTHEDIMENSIONSOFSPECIMENSFORTHEEXPERIMENTSWERE30MM10MM1MMTENSILETESTSWEREPERFORMEDINALLOYDTENSIOMETERACCORDINGTOTHEASTMD638MTESTA25KNLOADCELLWASUSEDANDTHECROSSHEADSPEEDWAS50MM/MINBENDINGTESTSWEREALSOPERFORMEDATROOMTEMPERATUREONWATERASSISTEDINJECTIONMOLDEDPARTSTHEBENDINGSPECIMENSWEREOBTAINEDWITHADIECUTTERFROMPARTSSUBJECTEDTOVARIOUSWATERTEMPERATURESTHEDIMENSIONSOFTHESPECIMENSWERE20MM10MM1MMBENDINGTESTSWEREPERFORMEDINAMICROTENSILETESTERACCORDINGTOTHEASTMD256TESTA200NLOADCELLWASUSEDANDTHECROSSHEADSPEEDWAS50MM/MIN3CONCLUSIONSTHISREPORTWASMADETOEXPERIMENTALLYSTUDYTHEWATERASSISTEDINJECTIONMOLDINGPROCESSOFPOLYBUTYLENETEREPHTHALATEPBTCOMPOSITESTHEFOLLOWINGCONCLUSIONSCANBEDRAWNBASEDONTHECURRENTSTUDY1WATERASSISTEDINJECTIONMOLDEDPBTPARTSEXHIBITTHENGERINGPHENOMENONATTHECHANNELTOPLATETRANSITIONAREASINADDITION,GLASSBERLLEDCOMPOSITESEXHIBITMORESEVEREWATERNGERINGSTHANTHOSEOFNONLLEDMATERIALS2THEEXPERIMENTALRESULTSINTHISSTUDYSUGGESTTHATTHELENGTHOFWATERPENETRATIONINPBTCOMPOSITEMATERIALSINCREASESWITHWATERPRESSUREANDTEMPERATURE,ANDDECREASESWITHMELTLLPRESSURE,MELTTEMPERATURE,ANDSHORTSHOTSIZE3PARTWARPAGEOFMOLDEDMATERIALSDECREASESWITHTHELENGTHOFWATERPENETRATION4THELEVELOFCRYSTALLINITYOFMOLDEDPARTSINCREASESWITHTHEWATERTEMPERATUREPARTSMOLDEDBYWATERSHOWALOWERLEVELOFCRYSTALLINITYTHANTHOSEMOLDEDBYGAS5THEGLASSBERSNEARTHESURFACEOFMOLDEDPBTCOMPOSITEPARTSWEREFOUNDTOBEORIENTEDMOSTLYINTHEOWDIRECTION,ANDORIENTEDSUBSTANTIALLYPERPENDICULARTOTHEOWDIRECTIONWITHINCREASINGDISTANCEFROMTHESKINSURFACEPBT玻璃纤维增强复合材料水辅注塑成型的实验研究摘要本报告的目的是通过实验研究聚对苯二甲酸丁二醇复合材料水辅注塑的成型工艺。实验在一个配备了水辅注塑统的80吨注塑机上进行,包括一个水泵,一个压力检测器,一个注水装置。实验材料包括PBT和15玻璃纤维填充PBT的混合物以及一个中间有一个肋板的空心盘。实验根据水注入制品的长度的影响测得了各种工艺参数以及它们的机械性能。XRD也被用来分别材料和结构参数。最后,作了水辅助和气体辅助注塑件的比较。实验发现熔体压力,熔融温度,及短射类型是影响水注塑行为的决定性参数。材料在模具一面比在水一面展示了较高的结晶度。气辅成型制品也要比水辅成型制品结晶度高。另外,制品表面的玻璃纤维大部分取向与流动方向一致,而随着离制品表面距离的增加,越来越多的垂直与流动方向。关键词水辅注塑成型,玻璃纤维增强PBT,工艺参数,机械性能,结晶,1前言依靠重量轻,成型周期短,消耗低,水辅注塑成型技术在塑料制品制造方面已经取得了突破。在水辅注塑成型中,模具行腔被部分注入聚合物熔体,而后向这些聚合物中心注入水。水辅注塑成型的原理如图1图1水辅注塑成型的原理如图水辅注塑成型能够在更短的循环时间内生产出收缩小,翘曲小,表面质量好的各种薄厚的制品。水辅注塑成型工艺也可根据工具及设备的承受压力在设计,节省材料,减轻重量,减少成本方面取得更大的自由。典型的应用有棒,管材,水路管网建设用的大型复合结构管。另一方面,尽管有很多优势,由于加入了额外的工艺参数,模具和工艺控制变的更加严峻和困难。水也可能腐蚀模具钢,同时一些材料包括热塑性塑料难以成型。成型后水的清除也是对这个新技术的一个挑战。表1列出了水辅注塑成型技术的优势和局限性。优势局限性1,成型周期短2,成本低(水更便宜而且可方便地循环利用)3,制品内部不产生泡沫现象。1,水腐蚀模具2,需要较大的注塑元件。(容易陷入聚合物熔体)3,一些材料难以成型(尤其是非晶态热塑性材料)4,成型后需要清除水表1水辅注塑成型有优势超过它更有名的竞争对手,气辅注塑成型,因为依靠水在成型过程中更好的冷却能力,水辅注塑成型获得了更短的成型周期。它的不可压缩性,低成本以及易循环利用,水成为这一过程的理想媒介。既然水不会溶解和扩散到聚合物熔体中,那么经常在气辅成型工艺出现的气泡现象也便消除了。另外,水辅注塑成型能更好的用小剩余壁厚成型大型制件。表2是对水辅和气辅成型工艺的一个比较。表2水辅和气辅成型工艺比较。水辅气辅1成型周期2介质成本3气泡现象5残余壁厚6表面粗糙度7表面光泽短低无小小高长高有大高低8指形效应9非均匀穿透10制品透明度11内表面(热塑性半晶)12内表面(热固性)大稳定高平滑粗糙小不稳定低粗糙平滑随着对密度小,强度高,价格便宜,成型周期短的优良性能材料需求的增加,塑料工程是一个不可忽视的工艺。这些塑料包括热塑性和热固性塑料。一般来说,热塑性塑料以其更高的冲击强度,断裂阻力,疲劳强度而更有优势。这使得热塑性塑料在工程建设中广泛使用。PBT是广泛使用的热塑性工程塑料之一,它有1,4丁烯乙2醇和DMT聚合而成。玻纤增强混合材料适用于提高原材料的机械性能。今天,短玻璃纤维增强PBT已被广泛应用与电子,通信,汽车领域。所以,对玻璃纤维增强PBT的研究更加重要了。本文是通过实验研究聚对苯二甲酸丁二醇水辅注塑的成型工艺,实验在一个配备了水辅注塑统的80吨注塑机上进行,包括一个水泵一个压力检测器,一个注水装置。实验材料包括PBT和15玻璃纤维填充PBT的混合物以及一个中间有一个肋板的空心盘。实验根据水注入制品的长度的影响测得了各种工艺参数以及它们的机械性能。XRD也被用来分别材料和结构参数。最后,作了水辅助和气体辅助注塑件的比较。2实验步骤21材料实验材料包括PBT(牌号1111FB,南亚塑料,台湾)和15玻璃纤维填充PBT的混合物(牌号1210G3,南亚塑料,台湾)。表3列出了此混合材料的特征。表3纤维增强PBT复合材料特征性质ASTMPB

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号