资源目录

压缩包内文档预览:(预览前20页/共54页)

编号:15805140

类型:共享资源

大小:10.85MB

格式:ZIP

上传时间:2019-03-09

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

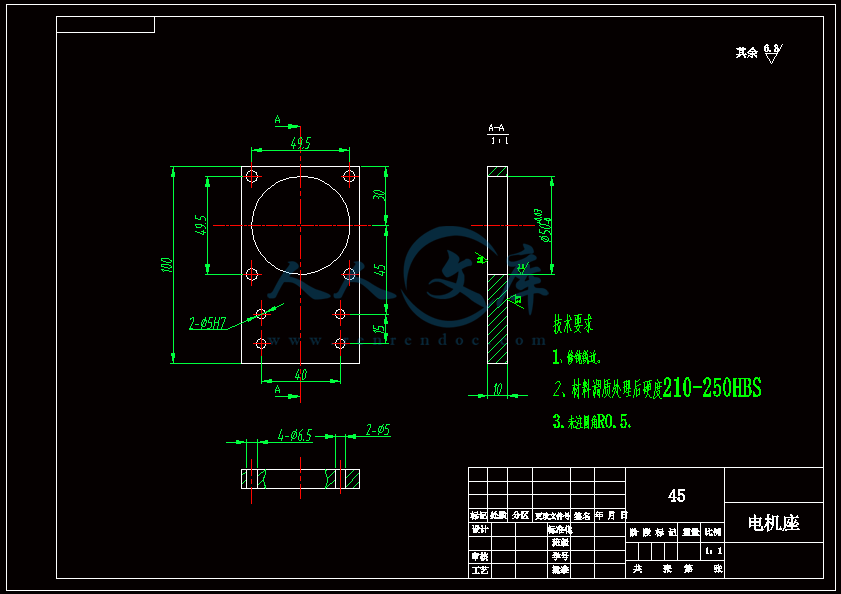

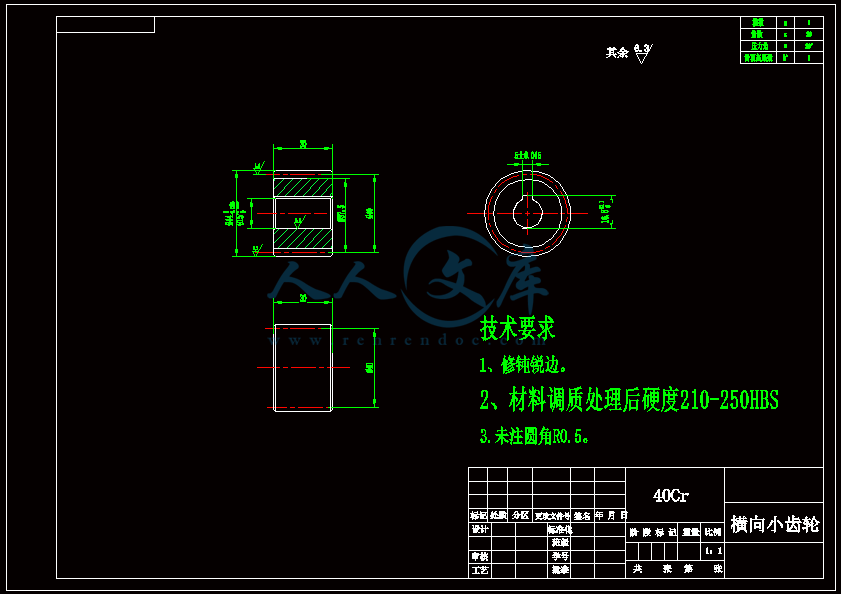

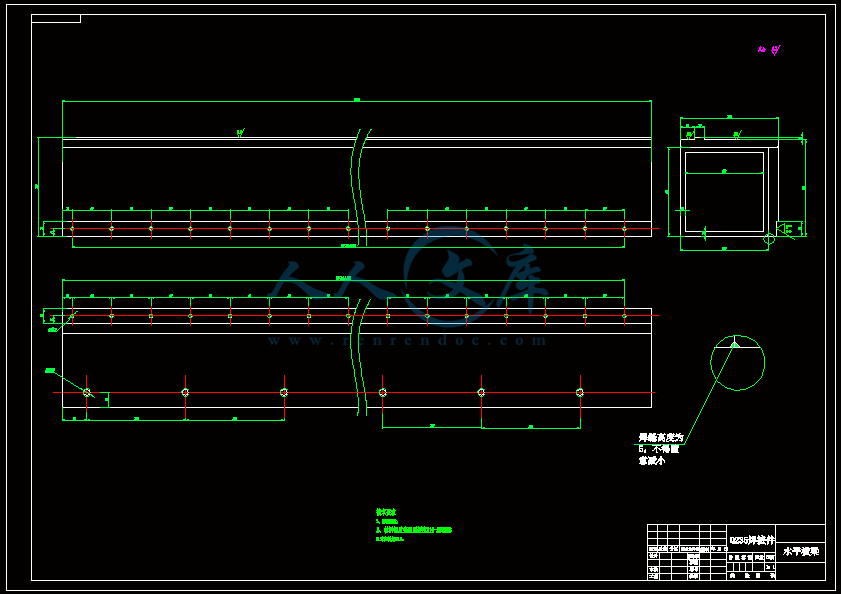

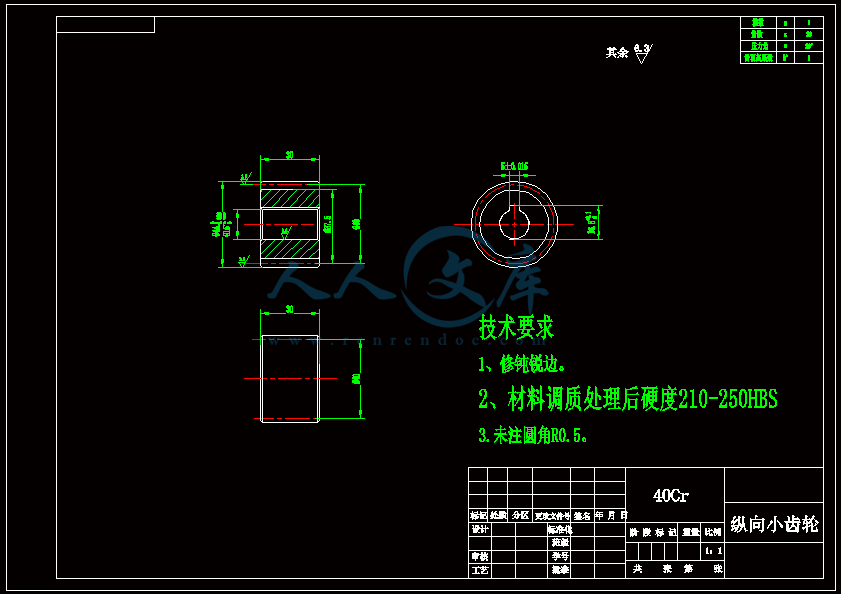

含CAD图纸、说明书

机械手设计图纸说明书

CAD图纸机械设计

CAD图纸说明

- 资源描述:

-

- 内容简介:

-

International Journal of Machine Tools received in revised form 10 May 2002; accepted 14 May 2002 Abstract Because of its excellent anodic bonding property and surface integrity, borosilicate glass is usually used as the substrate for micro-electro mechanical systems (MEMS). For building the communication interface, micro-holes need to be drilled on this sub- strate. However, a micro-hole with diameter below 200 m is diffi cult to manufacture using traditional machining processes. To solve this problem, a machining method that combines micro electrical-discharge machining (MEDM) and micro ultrasonic vibration machining (MUSM) is proposed herein for producing precise micro-holes with high aspect ratios in borosilicate glass. In the investigations described in this paper, a circular micro-tool was produced using the MEDM process. This tool was then used to drill a hole in glass using the MUSM process. The experiments showed that using appropriate machining parameters; the diameter variations between the entrances and exits (DVEE) could reach a value of about 2 m in micro-holes with diameters of about 150 m and depths of 500 m. DVEE could be improved if an appropriate slurry concentration; ultrasonic amplitude or rotational speed was utilized. In the roundness investigations, the machining tool rotation speed had a close relationship to the degree of micro- hole roundness. Micro-holes with a roundness value of about 2 m (the max. radius minus the min. radius) could be obtained if the appropriate rotational speed was employed. 2002 Elsevier Science Ltd. All rights reserved. Keywords: Borosilicate glass; Micro electrical-discharge machining; Micro ultrasonic vibration machining; Micro-hole; micro-tool; High aspect ratio 1. Introduction In packaging MEMS-related devices, such as micro valves and micro fl ow sensors etc., borosilicate glass is usually used as the substrate for bonding with silicon wafers. To build up the electrical through channel and connect the internal system between the silicon wafer and environment, micro-holes are drilled in the glass sur- face before they are bonded. Drilling these micro-holes is diffi cult with traditional machining processes. There are several methods used to manufacture micro-holes, MEDM 1,3,5,8,9,11, excimer laser drilling 6, LIGA 2,10, electrochemical discharge machining (ECDM) 12 and MUSM 4,7 etc. Because of the different work- ing mechanisms, the results produced by these methods are distinct. Correspondingauthor.Tel.:+886-3-4267353;fax:+886-3- 4254501. E-mail address: bhyen.tw (B.H. Yan). 0890-6955/02/$ - see front matter 2002 Elsevier Science Ltd. All rights reserved. PII: S0890-6955(02)00061-5 For example, in MEDM, a micro-hole with a diameter of 160 m and depth of 380 m could be drilled within 2 min 5. MEDM can be used to manufacture only con- ductive material and the recast layer on a machined sur- face, containing craters and micro cracks will cause poor surface and size accuracy. Laser micro machining tech- nology can be used to fabricate a hole under diameter of 4 m 6. However, laser beam machining causes deterioration and micro-cracks on the machined surface. The LIGA technique has been found suitable for produc- ing three-dimensional microstructures with micro-holes in metal, polymers and ceramics 2,10. However, the LIGA method affects the confi guration precision in micro-hole machining with high aspect ratios because of light diffraction (such as X-ray). ECDM can improve the material removal rate (MRR) and surface roughness to 1.5 mm/min and 0.08 m, respectively 12, but as with chemical etching, the walls of the micro-holes will be over etched due to the ECDM process. MUSM has been proved successful in hard and brittle material. Masuzawa et al. demonstrated that micro-holes as small as 5 m 1106B.H. Yan et al. / International Journal of Machine Tools OS, optical scale; OP, optical scale counter; X, Y and Z, motors for x-, y- and z-axes movement; Cu (copper plate), EDM electrode; H, rotating chuck holder; t, micro-tool; D, computer controlled display; C, motor for c-axis rotation; ID, interface circuit and motor driver; G, function generator; CPU, computer. and back direction using motor X and moved up and down using motor Y. The micro tool was clamped into a horizontal chuck rotated by motor C and directed left and right by motor Z. The movement resolutions of motors X, Y and Z were 0.2 m, 0.2 m and 0.5 m, respectively. To enable removing the debris easily from the micro-holes during MUSM, the machining operation was performed horizontally. The ultrasonic machining unit (frequency, 30 kHz) included an electronic gener- ator, a transducer and horn-tool combination equipment. The tool was a cylindrical rod screwed onto the horn tip. A small piece of borosilicate glass was chemically glued onto a small rectangular plate 4 attached to the tool tip (as shown in Fig. 2). 2.2. Materials Borosilicate glass (Pyrex, Corning 7740) is a silica composition with excellent anodic bonding property, surface integrity, thermal properties and acid resistance. This glass has always served as the substrate for micro sensors. Because borosilicate glass is hard and brittle, it is very suitable for micro-hole drilling using the MUSM method. For maintaining precise micro-hole sizes and shapes, the micro-tools must have high wear resistance and rigidity. A circular tungsten carbide rod with a diam- eter of 0.3 mm was selected as the MEDM and MUSM tool 4. Micro-hole precision can be improved by using oil as the slurry medium 1315. Silicon carbine grains, suspended in kerosene, were chosen as the working slurry whose concentrations were 10%, 20% and 30% in the MUSM process. And the averaged abrasive sizes were 1.2 m (about 75% particle sizes were from 0.9 to 1.5 m) and 3 m (about 75% particle sizes were from 2.6 to 3.4 m). 2.3. Machining procedures The machining processes were divided into two main parts. First, the tungsten carbide rod was fashioned into a micro-tool using a copper plate as electrode in the MEDM step. This tool was then used with the MUSM procedure to drill a micro-hole in the borosilicate glass. The above procedures are described in detail below: To EDM the micro-tool, the circular tungsten carbide rod was fi xed at horizontal direction and rotated clock- wise. At the same time, a copper plate was fastened to a jig and moved vertically up and down automatically. The diameter of the tool was reduced by the moving plate edge (as shown in Fig. 3(a) and the EDM dielec- tric was sprayed to the working area when MEDM was beginning. The completed micro-tool was 2 mm long and diameter 150 m. To produce high stress concen- tration in the workpiece during MUSM, the front end of the micro-tool was reduced in diameter to 20 m and length 0.2 mm. Fig. 3(b) displays the fi nished micro- 1107B.H. Yan et al. / International Journal of Machine Tools ? (fi nish) The open load voltage (V)100 Working voltage (V)25 Discharge current (A)0.95, 1.45 Pulse duration (s)4, 10 Off time (s)4, 10 ized to manufacture the glass with ultrasonic vibration (as shown in Fig. 2). The fl ow rate of slurry was 450 ml/min. Table 2 lists the experimental parameters for the MUSM processes. 3. Experimental results In addition to evaluating the size accuracy of high pre- cision micro-holes, the shape precision and surface roughness was estimated. Hence, the following dis- cussion is organized into three main parts: (A) diameter variation between the entrance and exit (DVEE), (B) roundness and (C) surface roughness. The factors affect- ing the precision of micro-holes include the slurry con- centration, abrasive grain size and the MUSM machin- ing parameters. 3.1. DVEE of micro holes In the MUSM processes, the micro-feeding method of micro-tool was applied to manufacture the micro-holes. In machining micro-holes with high aspect ratios, the tools could touch the walls of the holes for a long time, causing abrasion to the sides of the tools, or inducing irregular expansion of the micro-holes. These conditions will reduce the accuracy of the holes. DVEE of the micro-holes is an essential element in the MUSM pro- cess. The following sections utilize several MUSM para- meters to study the DVEE forming effects. Table 2 The experimental MUSM parameters Ultrasonic vibration directionLongitudinal Ultrasonic vibration frequency30 kHz Ultrasonic vibration amplitude (m)1.2, 1.4, 1.6, 1.8,2.0, 2.2 Rotational speed of micro tool (rpm)50, 100, 150, 200, 250 Feed rate (m/min)6, 6.7, 7.5, 8.6, 10 Concentration of slurry (wt %)10%, 20%, 30% Averaged abrasive size (m)1.2, 3 1108B.H. Yan et al. / International Journal of Machine Tools the front end of the tool produced more abrasion during this machining process. Hence, the DVEE became large. Fig. 9 shows a SEM photograph of the worn micro-tool. Fig. 9(a) represents the small circular step at the front end of the micro-tool seriously abraded from a larger feed rate machining (8.6 m/min). The tool suffered less wear at the same position when a smaller feed rate was used (6 m/min), as shown in Fig. 9(b). 3.2. Roundness In the USM processes, tool rotation or not, defi nitely infl uences the roundness of the holes 15,18. Tool rotation aids the suspended particles to enter the holes, thereby increasing the working effi ciency of the USM. Rotating tools can also induce the particles to grind the holes, thereby improving the roundness of the holes. In Fig. 8.The feed rate effect on DVEE via MUSM. 1110B.H. Yan et al. / International Journal of Machine Tools (c) was fi nished using an averaged grain of 1.2 m. These two fi gures clearly illustrate that the working sur- face still has a few craters and is not very smooth when the large grain size was used. The surface was very smooth with almost no craters when the small grain size was applied. Hence, the smaller abrasive particle sizes have a better effect on the micro-hole surface roughness. Fig. 12.The cross section and the surfaces of micro-holes via MUSM. (a) A cross section of micro-hole. (b) The surface of micro- hole produced using averaged size 3 m. (c) The surface of micro- hole produced using averaged size 1.2 m. 4. Conclusions For drilling micro-holes with high aspect ratios in borosilicate glass, a working method combining MEDM with MUSM was developed. Because the micro-tool was not dismantled from the clamping apparatus through varied working processes, a good tool concentricity level could be maintained in the machining procedures. Highly accurate micro-holes with diameters of about 150 m and depth of 500 m were manufactured via the MUSM method. The experiments revealed that the DVEE is infl uenced by the slurry concentration, ultrasonic vibration ampli- tude or rotational speed of the micro-tool. Values of these parameters exist at which DVEE is a minimum. Larger or smaller values cause DVEE to increase. Fur- thermore, smaller particle sizes or micro-tool feed rates produced better DVEE. In the MUSM processes, the micro-hole roundness had a close relationship to the micro-tool rotational speed. Experiments show the rotational speed effect on roundness is similar to the rotational speed effect on DVEE. Hence, for better micro-hole roundness, choos- ing the proper rotational speed is important. Moreover, the surface roughness of micro-holes was clearly affected by the size of the abrasive particles. Results obtained show that a fi ner surface roughness could be obtained when smaller abrasive particle sizes were used. Acknowledgements The authors would like to thank the National Science Council of the Republic of China for fi nancially support- ing this research under Contract No. NSC 89-2212-E- 008-049. References 1 K. Kagaya, Y. Oishi, K. Yada, Micro-electro discharge machin- ing using water as a working fl uid: micro-hole drilling, Precision Engineering 8 (3) (1986) 156162. 2 W. Ehrfeld, H. Lehr, Deep X-ray lithography for the production of three-dimensional microstructures from metals, polymers and ceramics, Radiation Physics and Chemistry 45 (3) (1995) 349 365. 3 D.M. Allen, A. Lecheheb, Micro electro-doscharge machining of ink jet nozzles: optimum selection of material and machining parameters, Journal of Materials Processing Technology 58 (1996) 5366. 4 X.-Q. Sun, T. Masuzawa, M. Fjino, Micro ultrasonic machining and its applications in MEMS, Sensors and Actuators A57 (1996) 159164. 5 D. Reynaerts, P.H. Heeren, H. Van Brussel, Microstructuring of silicon by electro-discharge machining (EDM) Part I: theory, Sensors and Actuators A60 (1997) 212218. 6 S.S. Choi, M.Y. Jung, D.W. Kim, M.A. Yakshin, J.Y. Park, Y. 1112B.H. Yan et al. / International Journal of Machine Tools & Manufacture 42 (2002) 11051112 Kuk, Fabrication and microelectron gun arrays using laser micromachining,MicroelectronicEngineering41-42(1998) 167170. 7 K. Egashira, T. Masuzawa, Microultrasonic machining by the application of workpiece vibration, Annals of the CIRP 48 (1) (1999) 131134. 8 H.M. Chow, C.T. Yang, B.H. Yan, F.Y. Huang, Fabrication of micro electrode of carbide and micro machining characteristics of Ti6Al4V alloy by electrical discharge machining, Journal of Japan institute of Light Metal 49 (1) (1999) 27. 9 B.H. Yan, F.Y. Huang, H.M. Chow, J.Y. Tsai, Micro-hole mach- ining of carbide by electrical discharge machining, Journal of Materials Processing Technology 87 (1999) 139145. 10 R.K. Kupka, F. Bouamrance, C. Cremers, S. Megtert, Mircofabr- ication: LIGA-X and applications, Applied Surface Science 164 (2000) 97110. 11 C. Zhang, H. Onmori, W. Li, Precision shaping of small diameter wheels using microelectric discharge truing (MEDT) and hole- machining of Al2O3material, International Journal of Machine Tool & Manufacture 40 (2000) 661674. 12 C.T. Yang, S.S. Ho, B.H. Yan, Micro hole machining of borosil- icateglassthroughelectrochemicaldischargemachining (ECDM), Key Engineering Material 196 (2001) 149166. 13 D.C. Kennedy, R.J. Grieve, Ultrasonic machininga review, The Prod. Engineer 54 (9) (1975) 481486. 14 D. Kremer, The state of the art of ultrasonic machining, Annals of the CIRP 30 (1) (1981) 107110. 15 T.B. Thoe, D.K. Aspinwall, M.L.H. Wise, Review on ultrasonic machining, International Journal of Machine Tools & Manufac- ture 38 (1998) 239255. 16 J.A. McGeough, Advanced methods of machining, pp. 170-198 Chapman and Hall, London, 1988. 17 G.W. Chang, B.H. Yan, R.T. Hsu, Study on cylindrical magnetic abrasive fi nishing using unbonded magnetic abrasives, Inter- national Journal of Machine Tools & Manufacture 42 (2002) 575583. 18 M. Komaraiah, P. Narasimha, Reddy, A study on the infl uence of workpiece properties in ultrasonic machining, International Journal of Machine Tools & Manufacture 33 (3) (1993) 495505. 研究精密小孔的硼硅玻璃使用microEDM结合微超声振动加工文摘由于其优良的阳极键合性能和表面完整性、硼硅玻璃通常用作的基质微机电系统(MEMS)。为构建通信接口,需要钻小孔衬底。 然而,微孔直径低于200年m很难生产使用传统加工过程。来解决这个问题,一种加工方法,结合微电火花加工(MEDM)和微超声振动生产加工(MUSM)提出本精密小孔高硼硅玻璃的纵横比。在本文中描述的调查,一个圆形的试件进行生产使用MEDM过程。这个工具被用来钻一个洞在玻。实验表明,使用合适的加工参数,直径出入口之间的差异(DVEE)可能达到的值约2m小孔直径约150500mm和深度。DVEE可以改善如果适当的泥浆浓度;超声振幅或转速是利用。圆度调查,旋转速度有密切的关系程度的微观孔的圆度。小孔的圆度值约2m(max。减去分钟半径)可以获得采用适当的转速。2002爱思唯尔的科学有限公司版权所有。关键词:硼硅玻璃;微电火花加工;微超声振动加工;微孔;试件;高纵横比1.介绍 在包装MEMS-related设备,例如微阀和微流量传感器等,硼硅玻璃通常是用作键与硅衬底晶片。建立电气通过通道和连接硅片之间的内部系统和环境,小孔钻在玻璃表面保税。钻井这些困难与传统加工过程。有几种方法用来制造小孔,MEDM(1、3、5、8、9、11,准分子激光钻井6,联赛(2、10),电化学放电加工(ECDM)12和MUSM(4、7)等。由于不同的工作机制,这些方法产生的结果是截然不同的。例如,MEDMm 160微孔的直径和深度380m可以钻在2分钟内5。MEDM只能用于生产导电材料在加工和重铸层表面,含有陨石坑和微裂缝会导致表面和尺寸精度差。激光微加工技术可用于制造下一个洞直径4m6。然而,激光加工造成恶化和加工表面的微裂纹。西甲技术被发现适合生产三维微观结构与小孔金属、聚合物和陶瓷2、10。然而,联赛方法影响配置精密微孔加工高纵横比的,因为光的衍射(如x射线)。ECDM可以提高材料去除率(MRR)和表面粗糙度1.5毫米/分钟和0.08m分别12,但与化学腐蚀,墙上的小孔将被证明是成功的在困难和脆性材料。Masuzawa等人证明了小孔小至5m(深度10m)和三维微机器可以创建通过结合线电火花磨削(WEDG放电),MEDM和MUSM(4、7)。因为MUSM依赖于微机械力量去除材料,对于高纵横比的微孔加工,小型机械力量的变化可以有重大的后果对制造业的稳定性和精度。此外,机械力量主导的精度。此外,机械力量主导MUSM参数。尚未进行深入研究这些参数如何影响制造业的稳定性和准确性。加工方法结合MEDM和MUSM设计完成高纵横比的小孔。在整个加工过程中,微刀相同的夹具,所以工具偏心问题是可以避免的。避免在制造过程 微刀振荡或打破,超声波仪器成立震动工件。 这种安排选举中小孔的加工精度。2.方法2.1. 试验装置实验设备由EDM机,作为选取控制系统和超声加工单位(如图1所示)。选取控制系统固定到EDM工作台。这里的硼硅玻璃或铜盘沿前后方向移动使用电动机X和上下移动使用电动机Y .微观工具被夹成水平卡盘旋转由电动机电动机C和定向左派和右派Z汽车的运动分辨率X,Y,Z是0.2mmm 0.2和0.2,分别。图1.MEDM和MUSM设备的配置:U,超声振动设备;操作系统,光学规模;OP,光学规模计数器;X,Y和Z,汽车forx - Y -和z-axes运动;铜(铜板)、EDM电极;H,旋转卡盘夹;t,试件;D,计算机控制显示,C,c-axis旋转电动机;ID、接口circuitand电机驱动;G函数发生器;CPU、电脑。启用删除碎片很容易从小孔MUSM期间,进行加工操作水平。超声波加工单位(包括频率、30千赫)电子发生器,传感器和horn-tool组合设备。该工具是一个圆柱形杆螺纹角尖。一小块的硼硅玻璃化学粘到一个小矩形板4在工具提示(如图2所示)。2.2. 材料硼硅玻璃(Pyrex,康宁7740)是一种硅成分具有优良的阳极键合性能,表面完整性、热性能和耐酸性。这个玻璃一直担任微传感器衬底。 因为硼硅玻璃是硬和脆,它的方法。维持精确的微孔大小,非常适合微孔钻井使用MUSM工具4。微孔精度可以提高通过使用石油作为泥浆介质(13 - 15)。硅卡宾枪谷物,悬浮在煤油,被选为工作泥浆的浓度是10%,20%和30%的MUSM过程。和平均磨料尺寸1.2m(大约75%的粒子大小从0.9到0.9m)和3m(大约75%的粒子大小从2.6到2.6m)。2.3. 加工过程被分成两个主要的加工流程部分。首先,碳化钨杆制成试件用铜版的电极MEDM一步。 这个工具是与MUSM然后使用硼硅玻璃的微孔钻探的过程。上面的程序详细描述如下:电火花加工试件,循环碳化钨杆是固定在水平方向和旋转时钟-明智的。与此同时,一个铜板被绑跳汰机和自动上下垂直移动。的直径降低了移动的工具板边(如图3所示(一个)和EDM介质喷洒到工作区域MEDM时开始。完成的试件进行长约2毫米,直径150m。产生高应力集中在工件MUSM,前端电路的试件直径减少到20m和长度0.2毫米。图3(b)显示微刀完成。实验参数MEDM流程表1中列出。查克的试件,微孔使用MUSM钻的玻璃。减少工具的磨损在低级别(15),该工具可以-之前没有接触到工件加工过程开始,所以它存在之间的工具,约0.1毫米玻璃表面加工过程时,开始宁。微孔加工过程中,微观喂养工具伴随着喷浆与超声振动利用制造玻璃(如图2所示)。砂浆的流量是450毫升/分钟。表2列出了实验参数MUSM流程。图2.实验仪器的细节图MUSM过程。图3。试件加工过程和试件在MEDM过程完成。(b)完成试件形状。表1 表2实验MEDM参数 实验MUSM参数工件的圆杆,碳化钨(甘蓝型) 纵向超声振动方向铜电极 超声振动频率30千赫工作煤油 超声振动振幅(m)1.2,1.4,1.6,1.8,2.0,2.2转速150 微工具转速(rpm)50,100,150,200,200工件(rpm) 进给速率(m /分钟),6.7,7.5,8.6,10极性+(粗糙);(完成) 浆浓度(wt %)10%,20%,30%打开负载电压(100 V) 平均磨料尺寸(m)1.2,3工作电压(V)25放电电流(A)0.95、1.45脉冲持续时间(s)4、10时间(s)4、103.实验结果除了评估精度的高精度微孔大小,形状精度和表面粗糙度估计。因此,下面的讨论分为三个主要部分:(A)的入口和出口之间的DVEE,(B)圆度和(C)表面粗糙度。 微孔的精度影响。因素包括浆浓度、磨料粒度和MUSM加工参数。3.1.1.磨料浆浓度和粒径的影响磨料浆的浓度和粒度是最重要的影响因素MUSM加工精度。磨料浆浓度高、材料被加工表面的研磨谷物将快于泥浆浓度越低。快速除材料之间的摩擦将会减少微刀前端和加工过程。DVEE将使用泥浆浓度高时低。图4显示,平均磨料尺寸是否1.2mor3m DVEE泥浆浓度会发生小于20%浆浓度10%。但DVEE泥浆浓度达到30%时变得更大。20%浓度提供了几乎两倍磨料粒子制造孔比10%浓度的平均大小1.2m,导致DVEE变得更小。然而,由于微孔加工是设置在横向模式下,磨料磨具洞入口之间的聚集和工具,这些粒子被旋转工具,被送入洞超声波振幅。但这将阻碍研磨剂进入洞时的粒子之间的聚集太多洞入口和工具,从而影响微孔DVEE的。浆浓度30%,这种情况将变得清晰,所以效果明显降低。此外,平均晶粒尺寸(3m)比超声波振幅(1.8m),诱导磨料磨具在MUSM很难进入洞。所以DVEE加工影响并不明显比小的晶粒尺寸。图4还表明,采用平均1.2m 大小创建DVEE比3m平均粒子的大小。在同一浓度,小颗粒更均匀悬浮在泥浆和容易进入比大一个洞。然而,MRR并不为每个谷物。因此,平滑的加工表面,更直的交叉截面微孔可以获得,提高DVEE小孔。获得更好的完成效果,以下实验使用粒子浓度20%的平均直径1.2m。3.1.2.超声振动振幅的影响在超声电机程序,大型加工工具导致更高的MRR(15、16)。加工工具可能弯曲在钻井过程中超声振动时振幅很大。这将影响到精确的漏洞。 在MUSM这种现象更明显。在这些实验中,超声波振幅测量使用工具显微镜(1000)三次(在空气中),然后把平均工作振幅。图5给出了超声振动振幅对DVEE的影响。图中显示,DVEE随振幅增加而降低mm从1.2到1.2。DVEE增加当振幅增加从1.8mm到2.2。这表明适当的振幅会增加小孔的严谨。然而,利用较小的振幅制造小孔将增加试件的加工时间和导致更多的磨损,产生更大的DVEE。此外,加工时间变得更短的振幅。是增加了。这

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号