【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

目前,矿山广泛使用的JH系列回柱绞车多是由JM慢速绞车演变而来的,具有速度低、结构紧凑、牵引力大等特点。主要应用于煤矿井下采煤工作面回柱放顶之用,同时也可用于上山、下山、平巷等综采工作面设备的搬迁。由于它的高度较低重量又轻,特别适用于薄煤层和急倾斜煤层采煤工作面,以及各种采煤工作面回收沉入底板或被矸石压埋的金属支柱。

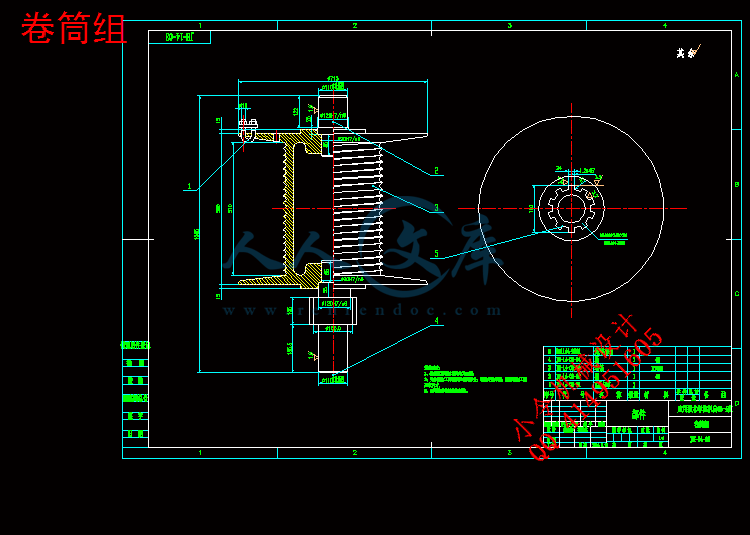

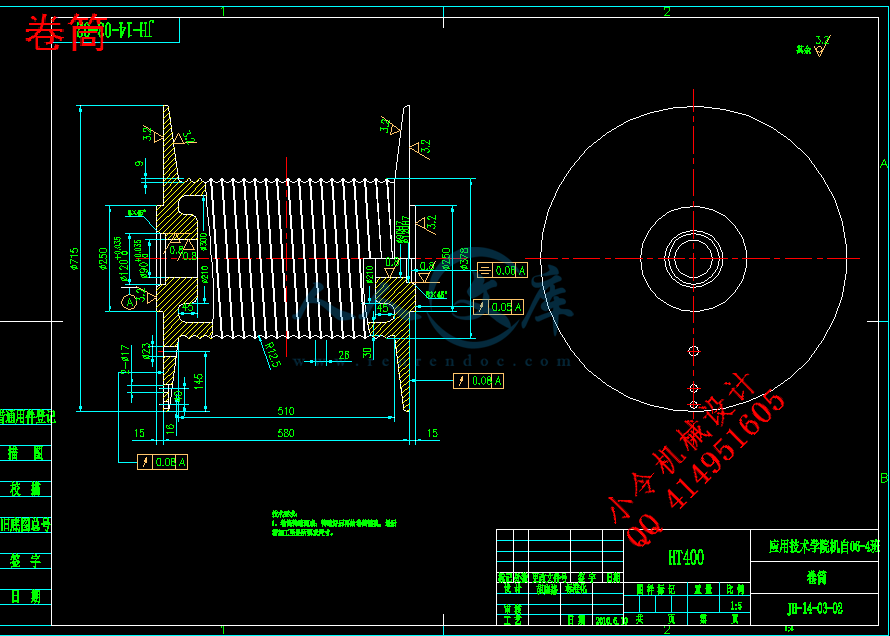

本次设计的JH-14型回柱绞车是在我去年毕业实习时所实践的回柱绞车的基础上,再查阅参考有关资料后结合我的一些想法所设计的。在减速器的设计过程中,主要采用了蜗轮蜗杆传动、双联滑移齿轮传动、圆柱齿轮传动等传动方式,利用拨叉拨动小滑移双联齿轮的方式来实现变速,而且在拨叉的设计中,我采用了手柄摇动转盘的方式来实现拨叉的水平移动。在设计卷筒时,考虑到卷筒设计精度要求不太高,因此将以往的卷筒通轴改为在卷筒两端利用过盈配合及焊接的方式来分别固定轴,避免了材料的浪费。

本次的设计主要特征就是能实现变速,既能满足不同环境下绞车的使用,也实现绞车在回绳和放绳时可以利用不同的速度达到快速回柱。

关键词:JH-14回柱绞车; 双联齿轮; 变速

ABSTRACT

At present, JH prop-drawing winch which evolved from JM Slow Speed Winch is widely in mine. This machine with advantage of slow speed, compact structure and big traction force. The prop-drawing winch is mainly used to prop drawing and caving roof in coal working face, but also can be used to relocate the equipment in fully mechanized coal face,such as uphill, downhill, and level gallery working face. Because of its low height and light weight, The prop-drawing winch is suitable for the thin coal seam and steep coal seam, and recovering the various metal pillar which Sinking into the floor or buried by gangue.

The JH-14 prop-drawing winch is designed based on my Practice on graduation practice last years and consulting large numbers of information, Which also combines many of my new ideas. The design process in the speed reducer, mainly used in the worm-gear transmission, double-slip gear transmission and column gear transmission etc transmission way. slide the small double-gear with the fork-lever to achieve Speed Change. But also in the fork-lever of the design, I used the handle shake rotary table to achieve the fork-lever horizontal movement. The prop-drawing winch drum in the design, taking into account the design precision need not too high,so I put a drum axis change into connection of drum and axis with interference fitting and welding in Both ends of the drum, reduced the Materials of axis, to avoid the waste of materials.

The main features of the design is to achieve speed change, it can satisfy the different working environment, but also to make the prop-drawing winch use different speeds to achieve the rapid return to prop drawing in the back rope and up rope.

Keywords:JH-14 prop-drawing winch;double-slip gear;speed change目 录

1 绪论……………………………………………………………………………………………1

1.1 引言………………………………………………………………………………………1

1.2 概述………………………………………………………………………………………1

1.2.1 绞车概况……………………………………………………………………………1

1.2.2 回柱绞车概况………………………………………………………………………2

1.3 国内外绞车的发展………………………………………………………………………3

1.4 JH-14型回柱绞车的技术特点……………………………………………………………4

2 总体设计………………………………………………………………………………………4

2.1设计总则…………………………………………………………………………………5

2.2 设计条件…………………………………………………………………………………5

2.3 传动方案的设计…………………………………………………………………………5

2.4电动机的设计选择………………………………………………………………………5

2.4.1电动机输出功率的计算………………………………………………………………5

2.4.2确定电动机的型号……………………………………………………………………6

2.4.3牵引钢丝绳直径的确定及滚筒直径的确定…………………………………………7

2.5滚筒的设计计算…………………………………………………………………………8

2.5.1滚筒直径……………………………………………………………………………8

2.5.2滚筒宽度……………………………………………………………………………8

2.5.3滚筒的外径………………………………………………………………………9

2.5.4验算滚筒的平均速度…………………………………………………………………9

3 减速器设计…………………………………………………………………………………10

3.1 减速器总体设计…………………………………………………………………………10

3.1.1 减速器概述…………………………………………………………………………10

3.1.2 减速器设计…………………………………………………………………………10

3.2 减速器参数确定…………………………………………………………………………10

3.2.1 总传动比及传动比分配……………………………………………………………11

3.2.2 传动装置运动参数的计算…………………………………………………………11

3.3 圆弧蜗轮蜗杆的设计计算………………………………………………………………12

3.3.1 蜗杆传动概述………………………………………………………………………12

3.3.2 蜗杆传动的失效形式………………………………………………………………13

3.3.3 蜗杆传动的材料选定………………………………………………………………13

3.3.4 蜗杆传动的结构……………………………………………………………………14

3.3.5 蜗杆传动的主要参数和几何尺寸计算……………………………………………15

3.3.6 蜗杆传动的润滑……………………………………………………………………18

3.4 滑移齿轮的设计计算……………………………………………………………………18

3.4.1 齿轮传动类型………………………………………………………………………18

3.4.2 滑移齿轮概述………………………………………………………………………20

3.4.3 滑移齿轮传动设计计算及强度校核………………………………………………20

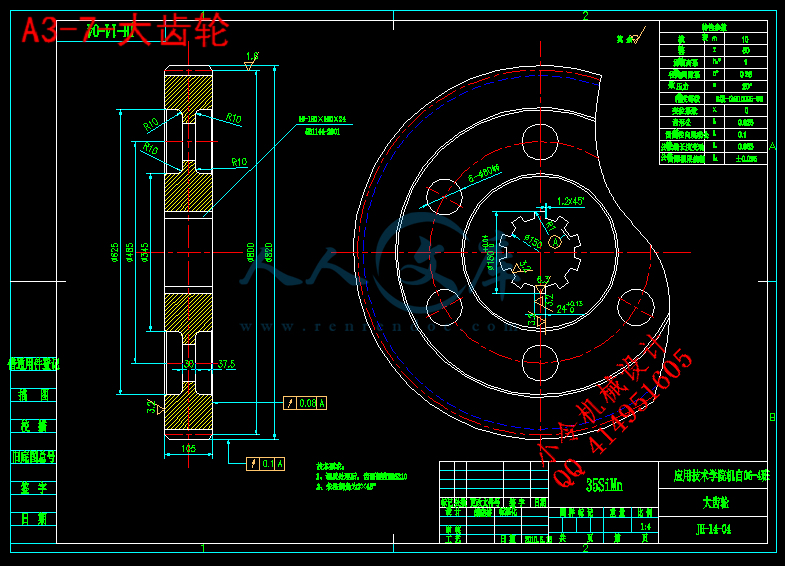

3.5 大小齿轮的设计计算……………………………………………………………………26

3.5.1 齿轮传动概述………………………………………………………………………26

3.5.2 齿轮材料选择………………………………………………………………………27

3.5.3 齿轮传动设计及强度校核…………………………………………………………28

3.6 过桥齿轮的设计计算……………………………………………………………………33

3.7 减速器传动轴的设计与校核……………………………………………………………33

3.7.1 蜗杆轴的设计计算…………………………………………………………………33

3.7.2 蜗轮轴的设计计算…………………………………………………………………39

3.8 键的选择及强度校核……………………………………………………………………45

3.8.1 蜗轮轴小滑移齿轮处………………………………………………………………46

3.8.2 蜗轮轴蜗轮处………………………………………………………………………46

3.8.3 大滑移齿轮轴大滑移齿轮处………………………………………………………47

3.8.4 大滑移齿轮轴小齿轮处……………………………………………………………47

3.8.5 第四轴轴过桥齿轮处………………………………………………………………48

3.9 轴承的选择及强度校核…………………………………………………………………48

3.9.1 蜗杆轴上轴承的选择及强度校核…………………………………………………49

3.9.2 蜗轮轴上轴承的选择及强度校核…………………………………………………52

3.9.3 其它轴上轴承的选择………………………………………………………………55

3.10 减速器中拨叉的设计…………………………………………………………………56

3.11 减速器其他部件的设计………………………………………………………………57

3.11.1 通气器……………………………………………………………………………57

3.11.2 油标………………………………………………………………………………57

3.11.3 减速器箱体的设计………………………………………………………………57

4 卷筒齿轮设计………………………………………………………………………………58

4.1 总体设计…………………………………………………………………………………58

4.2 卷筒轴的设计及校核……………………………………………………………………59

4.3 卷筒轴轴承的选择及校核………………………………………………………………64

4.4 大齿轮处键的选择………………………………………………………………………67

5 回柱绞车其它部件…………………………………………………………………………67

5.1 联轴器……………………………………………………………………………………67

5.2 制动器……………………………………………………………………………………68

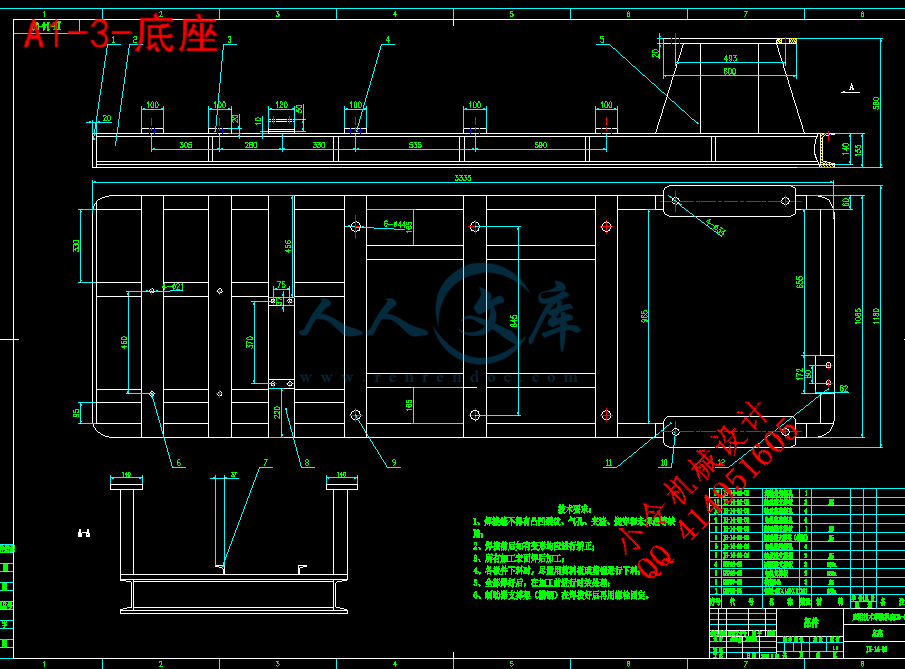

5.3 底座………………………………………………………………………………………69

6 回柱绞车的润滑与密封……………………………………………………………………69

7 回柱绞车的安装、操作与维护………………………………………………………………70

7.1 回柱绞车的装配、调整及试运转………………………………………………………70

7.2 回柱绞车的安装、固定与操作…………………………………………………………72

7.2.1 回柱绞车的安装与固定……………………………………………………………72

7.2.2 回柱绞车的操作规程………………………………………………………………73

7.3 绞车的维护、拆卸与修理………………………………………………………………75

参考文献………………………………………………………………………………………76

英文原文………………………………………………………………………………………77

中文译文………………………………………………………………………………………81

致 谢…………………………………………………………………………………………87

川公网安备: 51019002004831号

川公网安备: 51019002004831号