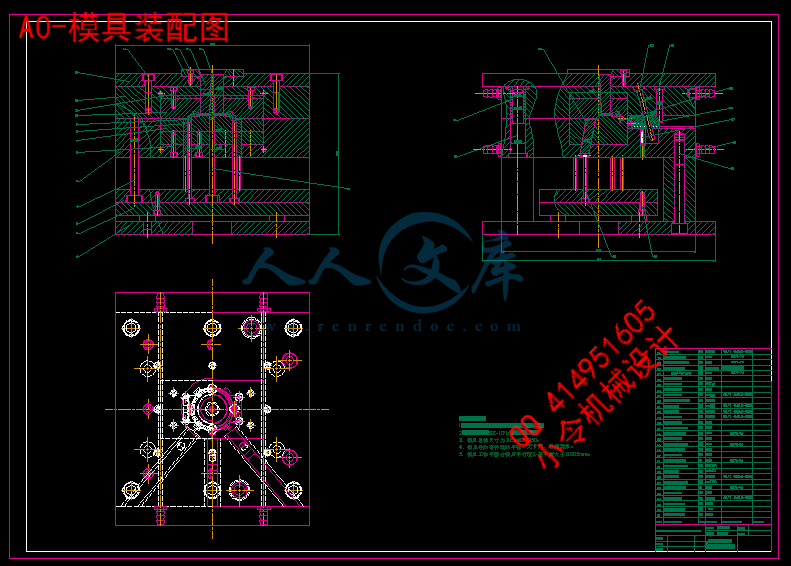

电子表外壳注塑模具设计-手表外壳塑料模【25张CAD图纸+WORD毕业论文】【抽芯】

收藏

资源目录

压缩包内文档预览:(预览前20页/共55页)

编号:408826

类型:共享资源

大小:1.36MB

格式:RAR

上传时间:2015-03-03

上传人:好资料QQ****51605

认证信息

个人认证

孙**(实名认证)

江苏

IP属地:江苏

45

积分

- 关 键 词:

-

电子表

外壳

注塑

模具设计

cad

图纸

word

毕业论文

模具

- 资源描述:

-

【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

电子表外壳注塑模具设计

摘要 本文首先分析了塑料模具的发展趋势,重点介绍了外侧抽芯结构和内侧抽芯机构。然后分析电子表壳塑件的结构特点,介绍了电子表壳体注射模结构的设计方法及模具的工作过程,以及模具设计的具体步骤和过程,并且对各个设计过程做了必要的理论说明,分析和阐述了模具零件的选材、强度和刚度的校核,电子表外壳的外侧孔采用斜导柱和斜滑块抽芯的设计方法,内凹坑采用三块式内侧抽芯机构,以及脱模机构和冷却系统的设计。

关键词 电子表外壳,注塑模,外侧抽芯,内侧抽芯

Design On Injection Mould Of Electronic Watch Shell

Abstract This text has analyzed the development trend of the plastic mould at first, focused on the outer core-pulling and medial core-pulling. Then analyzed the features of electronic watch shell plastic, introduced the design method of injection mould structure and the work process of the molding together with concrete steps and processes of mould design. This text also showed all the processes of mould design and made necessary theory instruction for every design process, analyzed and elaborated the selecting material for mould parts and the calculation of strength ang stiffness. The design method of the outside hole adopted guide pin and slide taking out core, the inside hole adopted 3-type core-pulling mechanism, and showed the design of demoulding mechanism and cooling system.

Key words Electronic watch shell, Injection mould, Outer core-pulling, Medial core-pulling

目 录

1 前言 1

1.1 塑料模具行业的概述 1

1.2 模具行业的发展现状及其发展趋势 1

1.3 侧抽芯机构的的应用 2

2 塑件分析 4

2.1 塑件的结构 4

2.2 工艺分析和尺寸精度 5

2.3 塑件材料成型特性及工艺参数 5

3 设备的选择 7

3.1 塑件体积的计算 7

3.2 注射机的选择 7

3.3 锁模力的校核 7

3.4 开模行程的校核 8

3.5 注射机的校核 8

4 浇注系统的设计 10

4.1 分型面的选择 10

4.2 主流道的设计 10

4.3 浇口的设计 11

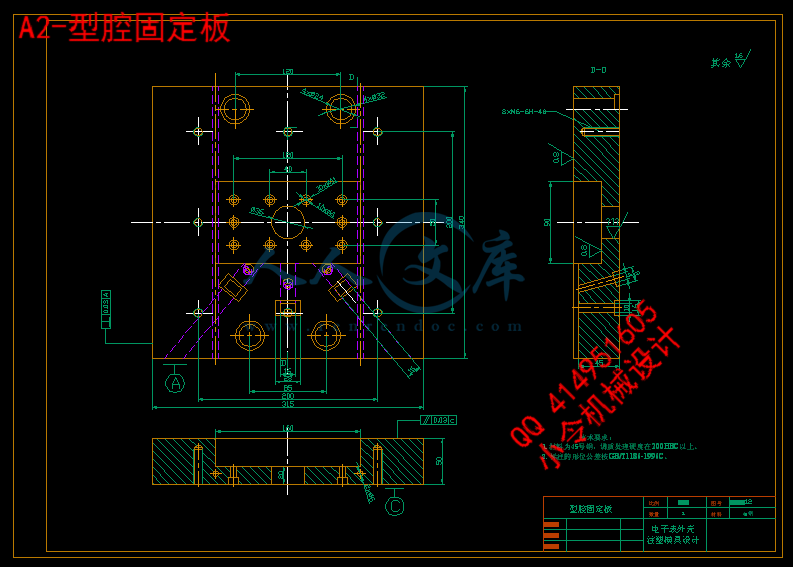

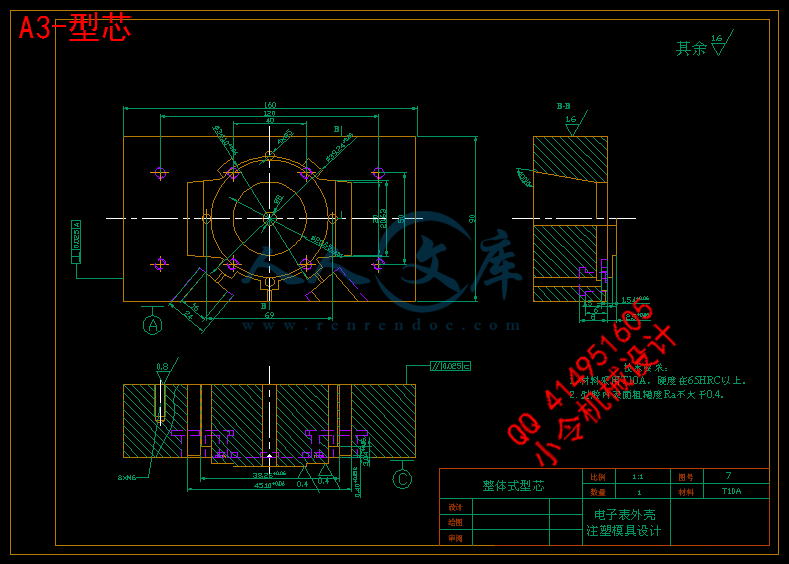

5 成型零部件的设计 13

5.1 型腔尺寸的计算 13

5.2 型腔侧壁厚度的计算 26

5.3 底板厚度的计算 26

5.4 型芯尺寸的计算 27

5.4.1 型芯径向尺寸1计算 27

5.4.2 型芯高度1的计算 27

5.4.3 型芯径向尺寸2的计算 28

5.4.4 型芯高度2的计算 28

5.4.5 型芯径向尺寸3的计算 29

5.4.6 型芯高度3的计算 29

5.5 侧型芯尺寸的计算 33

5.5.1 侧型芯直径的计算 33

5.5.2 侧型芯高度的计算 33

5.6 内型芯径向尺寸的计算 34

5.6.1 内型芯径向尺寸1的计算 34

5.6.2 内型芯径向尺寸2的计算 34

5.6.3 内型芯径向尺寸3的计算 35

5.6.4 内型芯高度的计算 36

6 合模导向机构的设计 37

6.1 导柱的设计 37

6.2 导柱的布置 37

6.3 导套的设计 38

7 顶出机构设计 39

7.1 脱模力的计算 39

7.2 顶杆的结构 40

7.3 顶杆的校核 40

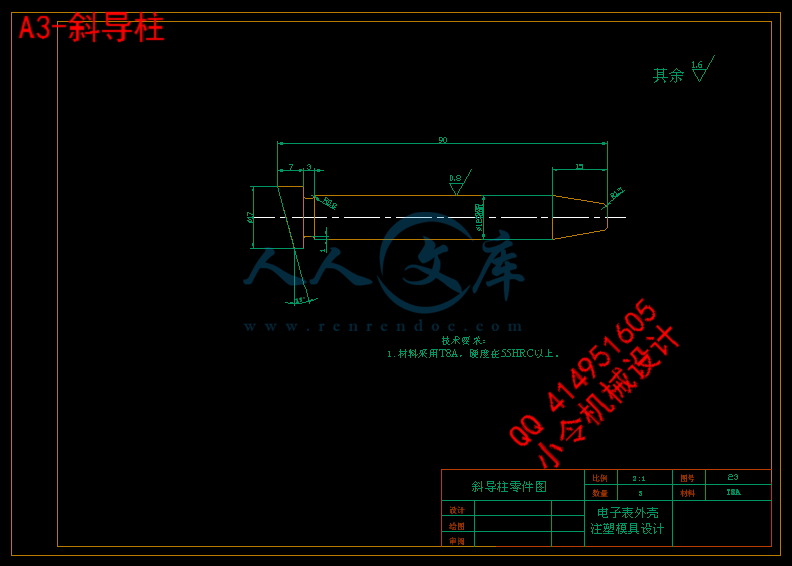

8 侧向分型抽芯机构设计 41

8.1 侧向抽拔距的计算 41

8.2 斜导柱受力分析 41

8.3 斜导柱直径的校核 42

8.4 斜导柱的结构 42

8.5 滑块的结构 43

8.6 导滑槽的结构 43

8.7 斜导柱分型抽芯机构的设计 44

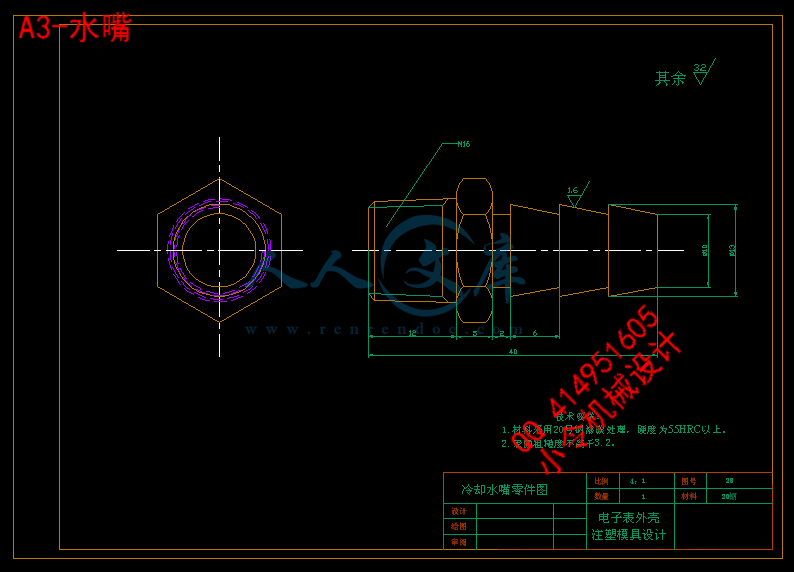

9 冷却系统的设计 45

9.1 冷却时间的确定 45

9.2 冷却参数的确定 45

9.3 冷却水管总长度 46

10 模具动作原理 48

参考文献 50

致谢 51

1 前言

1.1 塑料模具行业的概述

近年来,随着塑料制品的广泛应用,塑料模具的设计及制造也相应的迅猛发展。全球制造业正以垂直的模式向亚太及中国转移,中国正在成为世界制造业的重要基地[1]。制造业模式的变化,必将对新技术的需求有所提高,也必将导致CAD技术的发展;同时,由于网络技术的大面积应用,正如10年前由于成本的大幅度下降,使得微机进入千家万户,已经改变我们的生活一样,网络应有的普及将在更大的程度上改变制造业的模式。随着中国加入WTO,成为世界制造业的重要基地,将要求我国的产品有创新性,并且要有更高

- 内容简介:

-

Int J Adv Manuf Technol (2000) 16:739747 2000 Springer-Verlag London LimitedAutomated Assembly Modelling for Plastic Injection MouldsX. G. Ye, J. Y. H. Fuh and K. S. LeeDepartment of Mechanical and Production Engineering, National University of Singapore, SingaporeAn injection mould is a mechanical assembly that consists ofproduct-dependent parts and product-independent parts. Thispaper addresses the two key issues of assembly modellingfor injection moulds, namely, representing an injection mouldassembly in a computer and determining the position andorientation of a product-independent part in an assembly. Afeature-based and object-oriented representation is proposedto represent the hierarchical assembly of injection moulds.This representation requires and permits a designer to thinkbeyond the mere shape of a part and state explicitly whatportions of a part are important and why. Thus, it providesan opportunity for designers to design for assembly (DFA). Asimplified symbolic geometric approach is also presented toinfer the configurations of assembly objects in an assemblyaccording to the mating conditions. Based on the proposedrepresentation and the simplified symbolic geometric approach,automatic assembly modelling is further discussed.Keywords: Assemblymodelling;Feature-based;Injectionmoulds; Object-oriented1.IntroductionInjection moulding is the most important process for manufac-turing plastic moulded products. The necessary equipment con-sists of two main elements, the injection moulding machineand the injection mould. The injection moulding machines usedtoday are so-called universal machines, onto which variousmoulds for plastic parts with different geometries can bemounted, within certain dimension limits, but the injectionmould design has to change with plastic products. For differentmoulding geometries, different mould configurations are usuallynecessary. The primary task of an injection mould is to shapethe molten material into the final shape of the plastic product.This task is fulfilled by the cavity system that consists of core,cavity, inserts, and slider/lifter heads. The geometrical shapesCorrespondence and offprint requests to: Dr Jerry Y. H. Fuh, Depart-ment of Mechanical and Production Engineering, National Universityof Singapore (NUS), 10 Kent Ridge Crescent, Singapore 119260.E-mail: mpefuhyhK.sgand sizes of a cavity system are determined directly by theplastic moulded product, so all components of a cavity systemare called product-dependent parts. (Hereinafter, product refersto a plastic moulded product, part refers to the component ofan injection mould.) Besides the primary task of shaping theproduct, an injection mould has also to fulfil a number oftasks such as the distribution of melt, cooling the moltenmaterial, ejection of the moulded product, transmitting motion,guiding, and aligning the mould halves. The functional partsto fulfil these tasks are usually similar in structure and geo-metrical shape for different injection moulds. Their structuresand geometrical shapes are independent of the plastic mouldedproducts, but their sizes can be changed according to theplastic products. Therefore, it can be concluded that an injectionmould is actually a mechanical assembly that consists ofproduct-dependent parts and product-independent parts. Figure1 shows the assembly structure of an injection mould.The design of a product-dependent part is based on extractingthegeometryfrom theplasticproduct.Inrecentyears,CAD/CAM technology has been successfully used to helpmould designers to design the product-dependent parts. TheMouldMouldbaseCoolFillLayoutPlugSocketCav_1Cav_2CA-plateGuild-bushTCP-plateBep-plateCb-plateEa-plateEb-plateGuid-pinIp-plateRet-pinSliderbodyguideStop-blkHeel-blkheadCoreCavityProduct-independent partProduct-dependent partMove-halfFixed-halfFig. 1. Assembly structure of an injection mould.740X. G. Ye et al.automatic generation of the geometrical shape for a product-dependent part from the plastic product has also attracted alot of research interest 1,2. However, little work has beencarried out on the assembly modelling of injection moulds,although it is as important as the design of product-dependentparts. The mould industry is facing the following two difficult-ies when use a CAD system to design product-independentparts and the whole assembly of an injection mould. First,there are usually around one hundred product-independent partsin a mould set, and these parts are associated with each otherwith different kinds of constraints. It is time-consuming forthe designer to orient and position the components in anassembly. Secondly, while mould designers, most of the time,think on the level of real-world objects, such as screws, plates,and pins, the CAD system uses a totally different level ofgeometrical objects. As a result, high-level object-oriented ideashave to be translated to low-level CAD entities such as lines,surfaces, or solids. Therefore, it is necessary to develop anautomatic assembly modelling system for injection moulds tosolve these two problems. In this paper, we address the follow-ing two key issues for automatic assembly modelling: rep-resenting a product-independent part and a mould assembly ina computer; and determining the position and orientation of acomponent part in an assembly.This paper gives a brief review of related research inassembly modelling, and presents an integrated representationfor the injection mould assembly. A simplified geometric sym-bolic method is proposed to determine the position and orien-tation of a part in the mould assembly. An example of auto-matic assembly modelling of an injection mould is illustrated.2.Related ResearchAssembly modelling has been the subject of research in diversefields, such as, kinematics, AI, and geometric modelling. Lib-ardi et al. 3 compiled a research review of assembly model-ling. They reported that many researchers had used graphstructures to model assembly topology. In this graph scheme,the components are represented by nodes, and transformationmatrices are attached to arcs. However, the transformationmatrices are not coupled together, which seriously affects thetransformation procedure, i.e. if a subassembly is moved, allits constituent parts do not move correspondingly. Lee andGossard 4 developed a system that supported a hierarchicalassembly data structure containing more basic informationabout assemblies such as “mating feature” between the compo-nents. The transformation matrices are derived automaticallyfrom the associations of virtual links, but this hierarchicaltopology model represents only “part-of” relations effectively.Automatically inferring the configuration of components inan assembly means that designers can avoid specifying thetransformation matrices directly. Moreover, the position of acomponent will change whenever the size and position of itsreference component are modified. There exist three techniquesto infer the position and orientation of a component in theassembly: iterative numerical technique, symbolic algebraictechnique, and symbolic geometric technique. Lee and Gossard5 proposed an iterative numerical technique to compute thelocation and orientation of each component from the spatialrelationships. Their method consists of three steps: generationof the constraint equations, reducing the number of equations,and solving the equations. There are 16 equations for “against”condition, 18 equations for “fit” condition, 6 property equationsfor each matrix, and 2 additional equations for a rotationalpart. Usually the number of equations exceeds the number ofvariables, so a method must be devised to remove the redundantequations. The NewtonRaphson iteration algorithm is used tosolve the equations. This technique has two disadvantages:first, the solution is heavily dependent on the initial solution;secondly, the iterative numerical technique cannot distinguishbetween different roots in the solution space. Therefore, itis possible, in a purely spatial relationship problem, that amathematically valid, but physically unfeasible, solution canbe obtained.Ambler and Popplestone 6 suggested a method of comput-ing the required rotation and translation for each componentto satisfy the spatial relationships between the components inanassembly.Sixvariables(threetranslationsandthreerotations) for each component are solved to be consistent withthe spatial relationships. This method requires a vast amountof programming and computation to rewrite related equationsin a solvable format. Also, it does not guarantee a solutionevery time, especially when the equation cannot be rewrittenin solvable forms.Kramer 7 developed a symbolic geometric approach fordetermining the positions and orientations of rigid bodies thatsatisfy a set of geometric constraints. Reasoning about thegeometric bodies is performed symbolically by generating asequence of actions to satisfy each constraint incrementally,which results in the reduction of the objects available degreesof freedom (DOF). The fundamental reference entity used byKramer is called a “marker”, that is a point and two orthogonalaxes. Seven constraints (coincident, in-line, in-plane, parallelFz,offsetFz, offsetFx and helical) between markers are defined.For a problem involving a single object and constraints betweenmarkers on that body, and markers which have invariant attri-butes, action analysis 7 is used to obtain a solution. Actionanalysis decides the final configuration of a geometric object,step by step. At each step in solving the object configuration,degrees of freedom analysis decides what action will satisfyone of the bodys as yet unsatisfied constraints, given theavailable degrees of freedom. It then calculates how that actionfurther reduces the bodys degrees of freedom. At the end ofeach step, one appropriate action is added to the metaphoricalassembly plan. According to Shah and Rogers 8, Kramerswork represents the most significant development for assemblymodelling. This symbolic geometric approach can locate allsolutionsto constraintconditions, andis computationallyattractive compared to an iterative technique, but to implementthis method, a large amount of programming is required.Although many researchers have been actively involved inassembly modelling, little literature has been reported on fea-ture based assembly modelling for injection mould design.Kruth et al. 9 developed a design support system for aninjection mould. Their system supported the assembly designfor injection mouldsthrough high-level functionalmouldobjects (components and features). Because their system wasAutomated Assembly Modelling741based on AutoCAD, it could only accommodate wire-frameand simple solid models.3.Representation of Injection MouldAssembliesThe two key issues of automated assembly modelling forinjection moulds are, representing a mould assembly in com-puters, and determining the position and orientation of a pro-duct-independent part in the assembly. In this section, wepresent an object-oriented and feature-based representation forassemblies of injection moulds.The representation of assemblies in a computer involvesstructural and spatial relationships between individual parts.Such a representation must support the construction of anassembly from all the given parts, changes in the relativepositioning of parts, and manipulation of the assembly as awhole. Moreover, the representations of assemblies must meetthe following requirements from designers:1. It should be possible to have high-level objects ready touse while mould designers think on the level of real-world objects.2. The representation of assemblies should encapsulate oper-ational functions to automate routine processes such aspocketing and interference checks.To meet these requirements, a feature-based and object-orientedhierarchical model is proposed to represent injection moulds.An assembly may be divided into subassemblies, which in turnconsists of subassemblies and/or individual components. Thus,a hierarchical model is most appropriate for representing thestructural relations between components. A hierarchy impliesa definite assembly sequence. In addition, a hierarchical modelcan provide an explicit representation of the dependency ofthe position of one part on another.Feature-based design 10 allows designers to work at asomewhat higher level of abstraction than that possible withthe direct use of solid modellers. Geometric features areinstanced, sized, and located quickly by the user by specifyinga minimum set of parameters, while the feature modeller worksout the details. Also, it is easy to make design changes becauseof the associativities between geometric entities maintained inthe data structure of feature modellers. Without features,designers have to be concerned with all the details of geometricconstruction procedures required by solid modellers, and designchanges have to be strictly specified for every entity affectedby the change. Moreover, the feature-based representation willprovide high-level assembly objects for designers to use. Forexample, while mould designers think on the level of a real-world object, e.g. a counterbore hole, a feature object of acounterbore hole will be ready in the computer for use.Object-oriented modelling 11,12 is a new way of thinkingabout problems using models organised around real-world con-cepts. The fundamental entity is the object, which combinesboth data structures and behaviour in a single entity. Object-oriented models are useful for understanding problems anddesigning programs and databases. In addition, the object-oriented representation of assemblies makes it easy for a“child” object to inherit information from its “parent”.Figure 2 shows the feature-based and object-oriented hier-archical representation of an injection mould. The represen-tation is a hierarchical structure at multiple levels of abstraction,from low-level geometric entities (form feature) to high-levelsubassemblies. The items enclosed in the boxes represent“assembly objects” (SUBFAs, PARTs and FFs); the solid linesrepresent “part-of” relation; and the dashed lines representother relationships. Subassembly (SUBFA) consists of parts(PARTs). A part can be thought of as an “assembly” of formfeatures (FFs). The representation combines the strengths of afeature-based geometric model with those of object-orientedmodels. It not only contains the “part-of” relations betweenthe parent object and the child object, but also includes aricher set of structural relations and a group of operationalfunctions for assembly objects. In Section 3.1, there is furtherdiscussion on the definition of an assembly object, and detailedrelations between assembly objects are presented in Section Definition of Assembly ObjectsIn our work, an assembly object, O, is defined as a unique,identifiable entity in the following form:O = (Oid, A, M, R)(1)Where:Oid is a unique identifier of an assembly object (O).A is a set of three-tuples, (t, a, v). Each a is called anattribute of O, associated with each attribute is a type,t, and a value, v.M is a set of tuples, (m, tc1, tc2, %, tcn, tc). Eachelement of M is a function that uniquely identifies amethod. The symbol m represents a method name; andmethods define operations on objects. The symbol tci(iFig. 2. Feature-based, object-oriented hierarchical representation.742X. G. Ye et al.= 1, 2, %, n) specifies the argument type and tc specifiesthe returned value type.R is a set of relationships among O and other assemblyobjects.Therearesixtypesofbasicrelationshipsbetween assembly objects, i.e. Part-of, SR, SC, DOF,Lts, and Fit.Table 1 shows an assembly object of injection moulds, e.g.ejector. The ejector in Table 1 is formally specified as:(ejector-pinF1, (string, purpose, ejecting moulding),(string, material, nitride steel), (string, catalogFno,THX),(checkFinterference(), boolean), (pocketFplate(), boolean),(part-of ejectionFsys), (SR Align EBFplate), (DOF Tx,Ty).In this example, purpose, material and catalogFno areattributes with a data type of string; checkFinterference andpocketFplate are member functions; and Part-of, SR and DOFare relationships.3.2Assembly RelationshipsThere are six types of basic relationships between assemblyobjects, Part-of, SR, SC, DOF, Lts, and Fit.Part-ofAn assembly object belongs to its ancestor object.SRSpatial relations: explicitly specify the positionsandorientationsofassemblyobjectsinanassembly.Foracomponentpart,itsspatialrelationship is derived from spatial constraints(SC).SCSpatial constraints: implicitly locate a componentpart with respect to the other parts.DOFDegrees of freedom: are allowable translational/rotational directions of motion after assembly, withor without limits.LtsMotion limits: because of obstructions/interferences,the DOF may have unilateral or bilateral limits.FitSize constraint: is applied to dimensions, in orderto maintain a given class of fit.Table 1. Definition of an assembly object-ejector.Object Oidejector-pinF1Instance-ofEjectorFpinDerived from ejector classAPurpose “ejecting moulding” Type stringMaterial “nitrided steel”Type stringCatalogFno “THX”Type stringMCheckFinterferenceCheck interference(coolFobj)between ejectors andcooling linesPocketFplate()Make a hole on plate toaccommodate ejector pinsRPart-ofejectorFsysSRalign with EBplateDOFTx, TyAmong all the elements of an assembly object, the relation-ships are most important for assembly design. The relationshipsbetween assembly objects will not only determine the positionof objects in an assembly, but also maintain the associativitiesbetween assembly objects. In the following sub-sections, wewill illustrate the relationships at the same assembly level withthe help of examples.3.2.1Relationships Between Form FeaturesMould design, in essence, is a mental process; mould designersmost of the time think on the level of real-world objects suchas plates, screws, grooves, chamfers, and counter-bore holes.Therefore, it is necessary to build the geometric models of allproduct-independent parts from form features. The moulddesigner can easily change the size and shape of a part,because of the relations between form features maintained inthe part representation. Figure 3(a) shows a plate with acounter-bore hole. This part is defined by two form features,i.e. a block and a counter-bore hole. The counter-bore hole(FF2) is placed with reference to the block feature FF1, usingtheir local coordinates F2and F1, respectively. Equations (2)(5) show the spatial relationships between the counter-borehole (FF2) and the block feature (FF1). For form features,there is no spatial constraint between them, so the spatialrelationships are specified directly by the designer. The detailedassembly relationships between two form features are definedas follows:SR(FF2, FF1):F2i= F1i(2)F2j= F1j(3)Fig. 3. Assembly relationships.Automated Assembly Modelling743F2k= F1k(4)r2F= r1F+ b22*F1j+ AF1*F1i(5)DOF:ObjFhasF1FRDOF(FF2, F2j)The counter-bore feature can rotate about axis F2j.LTs(FF2, FF1):AF1, b11 0.5*b21(6)Fit (FF2, FF1):b22= b12(7)WhereF and r are the orientation and position vectors of fea-tures.F1= (F1i, F1j, F1k),F2= (F2i, F2j, F2k).bijis the dimension of form features, Subscript i isfeature number, j is dimension number.AF1is the dimension between form features.Equations (2)(7) present the relationships between the formfeature FF1and FF2. These relationships thus determine theposition and orientation of a form feature in the part. Takingthe part as an assembly, the form feature can be consideredas “components” of the assembly.The choice of form features is based on the shape character-istics of product-independent parts. Because the form featuresprovided by the Unigraphics CAD/CAM system 13 can meetthe shape requirements of parts for injection moulds and thespatial relationships between form features are also maintained,we choose them to build the required part models. In additionto the spatial relationships, we must record LTs, Fits relation-ships for form features, which are essential to check thevalidity of form features before updating the models in theCAD system.3.2.2Relationships Between PartsIn an assembly, the position and orientation of a part is usuallyassociated with another part. Figure 3(b) shows a plate (PP1)and a screw (PP2). The relative placement of the screw isconstrained by the counter-bore hole on the plate. The relation-ships between the screw and the plate are defined as follows:SR(PP2, PP1):P2= MpP1(8)r2= Mrr1(9)SC(PP2, PP1):mate(f1,f2) axisFalign(axisF1, axisF2)DOF:ObjFhasF1FRDOF(PP2, P2j)The screw can rotate about P2jof the plate.LTs(PP2, PP1):A22, A12(10)Fits(PP2, PP1):A13= A21+ cc(11)Where:P1and P2are the orientation vectors of the plate andthe screw, and P1= (P1i, P1j, P1k), P2= (P2i, P2j, P2k).Mpand Mrare the transformation matrix between thescrew and the plate. is a Boolean operator.mate and axisFalign are constraints (detailed discussionabout them are given in the next section).r is a position vector.Aijis dimension of parts. Subscript i is part number, andj is dimension number.cc is the clearance between the screw and the plate.As we can see in Eqs. (8) and (9), it is essential to calculatethe matrix Mpand Mrto determine the position and orientationof the screw with reference to the plate. Mpand Mrcan bederived from the spatial constraints (SC). This derivationrequires the task of inferring the configuration of a part in anassembly, which will be discussed in the next section.We have presented a representation of the injection mouldassembly in a computer. At this stage, it might be worthwhileto summarise the benefits of this representation. Assembliesare represented as a collection of subassemblies that in turnmay consist of subassemblies and/or component parts, and acomponent part can further be considered as the assembly ofform features. Such hierarchical relationships imply an orderingon the assembly sequence and a parentchild link. The feature-based representation not only allows designers to work at ahigh-level of abstraction while designing individual parts, butalso extends the feature paradigm to assembly modelling,because this representation allows a component to be changedparametrically with the other components consequently havingtheir positions changed accordingly. The object-oriented rep-resentation can combine both the data structure and operationin an object. The encapsulated operational functions in anassembly object can help to automate the routine processessuch as the pocketing and interference check.4.Inferring Part Configuration in theAssemblyAs we can see from Eqs (8) and (9), the positions andorientations of parts in an assembly are eventually representedby the transformation matrices. For the sake of convenience,the spatial relationships are usually specified by the high-levelmating conditions such as “mate”, “align” and “parallel”. Thus,it is essential to derive automatically the explicit transformationmatrices between parts from implicit constraint relationships.Three techniques to infer the configurations of parts in anassembly have been discussed in Section 2. Because the sym-bolic geometric approach can locate all solutions to constraintequations withpolynomial time complexity, we use thisapproach to determine the positions and orientations of partsin an assembly. To implement this approach in assemblymodelling software, a large amount of programming is required.Therefore, a simplified geometric approach is proposed todetermine the positions and orientations of parts in an assembly.744X. G. Ye et al.In the symbolic geometric approach, determining positionsand orientations of parts is performed symbolically by generat-ing a sequence of actions to satisfy each constraint incremen-tally. The information required to satisfy each constraintincrementally is stored in a table of “plan fragments”. Eachplan fragment is a procedure that specifies a sequence ofmeasurements and actions that move parts in such a way asto satisfy the corresponding constraint. The plan fragment alsorecords the objects new degrees of freedom (DOFs) andassociated geometric invariants. Conceptually, Kramers planfragment table is a 3D dispatch table. We use TDOF torepresent translational degrees of freedom and RDOF to rep-resent rotational degrees of freedom. Then an entry in the planfragment table has the following form:planFfragment: kTDOF, RDOF, constraintFtypelTDOF = 0, 1, 2, 3RDOF = 0, 1, 2, 3constraintFtype=coincident,in-line,in-plane,parallelFz, offsetFz, offsetFx and helicalThe plan fragment table is an exhaustive enumeration of allthe states in the search space for the problem of moving anobject to satisfy a series of constraints between markers onthe object and markers fixed in the global coordinate frame.To enumerate the combination of different values of the abovethree parameters, 82 entries will be generated 7. If the searchspace for the problem can be reduced the number of entriesin a plan fragment table will decrease. To achieve this, thenumber of enumerate values for entry parameters must bedecreased. For example, for a specified constraint type, if theenumeration values of TDOF change from 0,1,2,3 to 0,3,then the search space is reduced.After a careful analysis of the constraints between compo-nents of an injection mould, four basic primitive constraints areintroduced: in-line, parallelFz, parallelFz1 and parallelFoffset.Their definitions and algebraic equations are as follows:in-line(M1, M2): M1lies on the line through M2parallel to theZ-axis of M2.ugmp(M1) gmp(M2)u gmz(M2)u = 0(12)parallelFz(M1, M2): the Z-axes of markers M1and M2areparallel and have the same direction.gmz(M1) gmz(M2) = 1(13)parallelFz1(M1, M2): the Z-axes of markers M1and M2areparallel and have the opposite direction.gmz(M1) gmz(M2) = 1(14)paralleFoffset(M1, M2, d): Applicable only in conjunctionwith parallelFz or parallelFz1, specifies the distancebetween M1position and M2position.gmp(M1) gmp(M2) = d(15)Where:M1and M2are markers.gmp(M) is the global marker position.gmz(M) is the global marker Z-axis.gmx(M) the global marker X-axis.d is the distance between M1and M2.In our simplified symbolic geometric approach, the enumer-ation vales of constraint types are inFline, parallelFz, par-relFz1, paralleFoffset. Compared with Kramers symbolic geo-metric approach, our constraint types are reduced from sevento four. This simplification will reduce the number of entriesin the plan fragment table. Based on these four primitiveconstraints, three high-level constraints were synthesised fortheusersconvenience.Theyaremate(M1,M2,d),planeFalign(M1, M2, d), and axisFalign(M1, M2). Their defi-nitions are given as follows:mate(M1, M2, d):parallelFz1(M1, M2) parallelFoffset(M1, M2, d)planeFalign(M1, M2, d):parallelFz(M1, M2) parallelFoffset(M1, M2, d)axisFalign(M1, M2):parallelFz(M1, M2) inFline(M1, M2)The assembly objects in an injection mould can have one,two or three synthesised constraints. For two and three syn-thesised constraints, the constraint sequence is further restricted.The sequences are as follows:mate(M1, M2, d) planeFalign(M3, M4, d2)mate(M1, M2, d1) axisFalign(M3, M4)planeFalign(M1, M2, d) axisFalign(M3, M4)mate(M1,M2,d1)axisFalign(M3,M4,d2)axisFalign(M5, M6).Because of these restrictions on the constraint sequences,the number of entries in our plan fragment table is substantiallyreduced. To solve for one, two or three constraints allowed inour system, only nine entries are required. For interactiveaddition of components to the assembly, more constraint typesand free sequences will increase the flexibility for users. How-ever, in automatic assembly modelling for an injection mould,as the spatial relationships are predefined in assembly objects,some of the sequence restrictions do not matter. With theabove-defined synthesised constraints, the structural relation-ships of a component part can be specified in the database ofthe components. When adding a component part to the mouldassembly, the system will first decompose the synthesisedconstraints into primitive constraints, then generate a groupof fragment plans to orient and position the component inthe assembly.5.Automated Assembly Modelling ofInjection MouldsAnyassemblyofinjectionmouldsconsistsofproduct-independent parts and product-dependent parts. The design ofindividual product-dependent parts is based on the geometryof the plastic part 1,2. Usually the product-dependent partshave the same orientation as that of the top-level assembly,and their positions are specified directly by the designer. Asfor the design of product-independent parts, conventionally,mould designers select the structures from the catalogues,Automated Assembly Modelling745build the geometric models for selected structures of product-independent parts, and then add the product-independent partsto the assembly of the injection mould. This design process istime-consuming and error-prone. In our system, a database isbuiltforallproduct-independentpartsaccordingtotheassembly representation and object definition described in Sec-tion 3. This database not only contains the geometric shapesand sizes of the product-independent parts, but also includesthe spatial constraints between them. Moreover, some routinefunctions such as interference check and pocketing are encapsu-lated in the database. Therefore, the mould designer must selectthe structure types of product-independent parts from the userinterfaces, and then the software will automatically calculatethe orientation and position matrices for these parts, and addthem to the assembly.5.1Mould Base SubassemblyAs can be seen from Fig. 1, the product-independent parts canbe further classified as the mould base and standard parts. Amould base is the assembly of a group of plates, pins, guidebushes, etc. Besides shaping the product, a mould has to fulfila number of functions such as clamping the mould, leadingand aligning the mould halves, cooling, ejecting the product,etc. Most moulds have to incorporate the same functionality,which results in a similarity of the structural build-up. Someform of standardisation in mould construction has been adopted.A mould base is the result of this standardisation.According to the feature-based and object-oriented assemblyrepresentation, the feature-based solid models for componentparts of the mould base are first constructed; next, the assemblyobjectsaredefinedbyestablishingrelationshipsbetweencomponents and encapsulating some functions in the componentparts; then, using these assembly objects, a hierarchical subas-sembly object a mould base can be formed. This mouldbase object can be instantiated by a group of data from thecatalogue database. Figure 4 shows the instantiation of themould base object to generate the specified mould base. Thisspecified mould base instance can be added automatically tothe mould assembly. The structural relations between the mouldbase subassembly and top assembly can be expressed by Eqs.(8) and (9), where Mpand Mrare the unit matrices.5.2Automatic Addition of Standard PartsA standard part is an assembly object. It can be definedaccording to Eq. (1) in Section 3.1. In the database, the spatialconstraints are specified by mate, planeFalign and axisFalign,but unlike the mould base, the position and orientation matricesof a standard part are left unknown. During instantiation,the software then automatically infers the explicit structuralrelationshipsbyusingthesimplifiedsymbolicgeometricapproach described in Section 4.5.3Pocketing for Assembly ObjectsOne of the important issues for automatic assembly design isthe automation of the pocketing process. Pocketing is anFig. 4. Instantiation of mould base.operation that makes an empty space in corresponding compo-nents to accommodate the inserted components. When an ejec-tor is added to the assembly, an empty space is required onthe EA plate to accommodate the ejector, as shown in Fig. 5.Since an object-oriented representation is adopted, eachassembly object can be represented by two solids, the realobject and the virtual object. The virtual object is modelledaccording to the space that a real object will occupy. Wheneveran assembly object is added to an assembly, its virtual objectisalsoaddedtotheassembly.TheoperationfunctionpocketFplate() in M of O will subtract the virtual object fromthe corresponding components (see Eq. (1) and Table 1).Moreover, because there are associativities between the virtualobject and real object, the pockets on the corresponding compo-nents will change with the modification of the real object.Fig. 5. Pocketing of assembled objects.746X. G. Ye et al.This automatic pocketing function further demonstrates theadvantage of an object-oriented representation.6.System ImplementationBased on the Unigraphics system 13, the proposed feature-based and object-oriented assembly scheme and automation ofassembly modelling have been implemented in the IMOLDsystem 14 developed at the National University of Singapore.The Unigraphics system provides a user-friendly applicationprogramming interface (API). Through this interface, the userscan call Unigraphics internal functions such as adding parts toan assembly, modifying parameters, etc. Although Unigraphicsprovides functions for mating conditions, the proposed approachis still needed to infer the component configuration, becauseit is necessary to calculate the degrees of freedom, and checkthe validity of mating conditions before the component can beadded to the assembly. The proposed synthesised constraintsare compatible with Unigraphics constraints.Figure 6 shows an injection moulded product, and thedesigned injection mould assembly for this product is shownin Fig. 7(a). The corresponding parentchild relationships forfix-half subassembly are shown in Fig. 7(b). This assembly is

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号