【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目 录

摘要…………………………………………………………………………………………3

第一章 绪论 ……………………………………………………………………………3

1.1 空作业车的的现状和发展趋势…………………………………………………6

1.2 课题的来源和意义………………………………………………………………8

第二章 液压系统设计 …………………………………………………………………9

2.1 本参数及主要技术性能指标 …………………………………………………9

2.1.1 行驶状态主要技术参数 …………………………………………………9

2.1.2 作业状态主要技术参数 …………………………………………………9

2.1.3 作业车平台作业工作状态图 ……………………………………………9

2.1.4 机构简述 …………………………………………………………………11

2.2 液压系统的构成…………………………………………………………………13

2.3 各系统工作原理简述……………………………………………………………13

2.4 主要机构液压回路的设计与分析………………………………………………14

2.4.1 升机构的回路设计 ………………………………………………………14

2.4.2 伸缩机构回路设计 ………………………………………………………16

2.4.3 回转机构回路设计 ………………………………………………………17

2.4.4 变幅机构回路设计 ………………………………………………………17

2.4.5 整体液压回路设计 ………………………………………………………18

2.5 主要液压元气件的选择与计算…………………………………………………20

2.5.1 液压泵的确定 ……………………………………………………………20

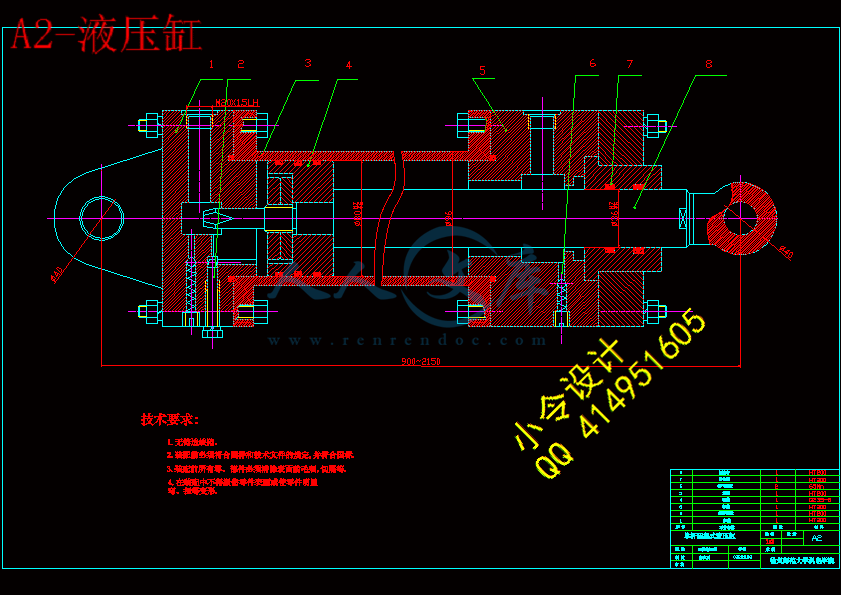

2.5.2 上下臂液压缸确定 ………………………………………………………21

2.5.3 液压马达选择 ……………………………………………………………23

2.5.4 换向阀的选择 ……………………………………………………………24

2.5.5 油箱有效容的积确定 ……………………………………………………25

第三章 电气控制系统设计 ……………………………………………………………26

3.1 电气控制方案的确定 …………………………………………………………26

3.1.1 高空作业机构的电气控制电路 …………………………………………26

3.1.2 通讯装置 …………………………………………………………………27

3.1.3 选择开关装置 ……………………………………………………………27

3.1.4 总的控制电路 ……………………………………………………………27

3.2 电气元器件的选择 ……………………………………………………………28

3.2.1 按钮的选用 ………………………………………………………………28

3.2.2 行程开关的选用 …………………………………………………………30

3.2.3 热继电器的选用 …………………………………………………………30

3.2.4 熔断器的选用 ……………………………………………………………30

3.2.5 电线的选择 ………………………………………………………………31

3.2.6 照明电器选择 ……………………………………………………………31

3.2.7 变压器的选择 ……………………………………………………………32

第四章 电气控制面板的操作……………………………………………………………33

4.1 转台处控制箱操作面板及其操作件介绍………………………………………33

4.2 平台(吊篮)控制箱操作面板及操作元件……………………………………34

4.3 高空作业电气部分操作方法……………………………………………………35

4.4 高空作业操作中注意事项………………………………………………………35

附录…………………………………………………………………………………………37

附录1 …………………………………………………………………………………37

附录2 …………………………………………………………………………………37

附录3 …………………………………………………………………………………39

附录4 …………………………………………………………………………………39

附录5 …………………………………………………………………………………40

结论…………………………………………………………………………………………42

后记…………………………………………………………………………………………43

参考文献……………………………………………………………………………………44

GKZ高空作业车液压和电气控制系统设计

摘 要

高空作业车广泛用于建筑、市政、机场、工厂、园林、住宅等场所,从事消防、抢险救灾、安装、维护等工作。本文针对徐州海伦哲工程机械有限公司GKZ14型高空作业车,进行了大量的理论研究和实验测试。

本设计是对该车的重要组成部分----液压系统和电气控制系统进行设计和研究,其液压系统由上车液压系统和下车液压系统组成。两者之间由中心回转接头连接(垂直升降式高空车除外),上车液压系统由变幅系统、伸缩系统和回转系统三个基本系统组成。在整个液压系统设计中,采用制动器控制克服了液压马达存在内泄而平衡阀不能锁住停在空中的重物,使重物可靠地停在空中。制动器采用恒压外控,可以进一步降低平衡阀的开启压力,提高回路效率。

从安全性、可靠性角度看,高空车不同于一般的工程机械, 其特点是作业频率不高, 负荷较小, 但要求安全性, 可靠性较高。因此, 高空车应具备紧急停止装置。高空车在各执行机构动作的终点位置设限位装置, 尤其是对于折叠臂式及混合臂式的高空车应设中臂限位装置, 以确保整车的稳定性。高空车的变幅系统和伸缩系统的速度必须加以控制, 以防止产生“超速”现象。

因此,为保证高空作业车的工作稳定、可靠、安全,作业灵活,效率高,设计出优良的液压系统和电气控制系统就显得尤为重要。

[关键词]:高空作业车;制动器;内泄;恒压外控;限位装置。

Hydraulic and electricity control system design of the high-altitude working machine

Abstract

The high-altitude working machine has been widely used in architecture, city planning, airport, factory, garden, house and other place. It plays an important role in fire protection, dealing with an emergency, construction, installation, maintenance and so on. Aiming at the GKZ14 high-altitude working machine of XhZhou HaiLun machinery Group, It does a lot of theoretical research and experiment test.

This design is carries on the design and the research to this vehicleimportant constituent ---- hydraulic system and the electricitycontrol system, its hydraulic system by boards the hydraulic systemand alights the hydraulic system to be composed. Two between (verticalfluctuation type upper air vehicle is an exception) by the centerswivel joint connection, boards the hydraulic system by the amplitudesystem, the expansion and contraction system and the rotary systemthree basic systems is composed. In the entire hydraulic systemdesign, used the brake control to overcome in the oil motor existenceto release but the by-pass valve not to be able to lock in stops inthe airborne heavy item, caused the heavy item reliably to stop inairborne. The brake uses outside the constant pressure to control, mayfurther reduce the by-pass valve to open the pressure, enhances thereturn route efficiency.

From the security, the reliable angle looked that, the upper airvehicle is different with the general project machinery, it scharacte ristic is the work frequency is not high, load smaller, butthe request security, the reliability is higher. Therefore, the upperair vehicle should have the urgent stop device. The upper air vehiclesupposes the spacing installment in each implementing agency movementend position, regarding folds the arm type and the mix arm -like upperair vehicle in particular should suppose the arm spacing installment,guarantees the entire vehicle the stability. The upper air vehicleamplitude system and the expansion and contraction system speed mustperform to control, prevents the production "overspeed" thephenomenon.

Therefore, for guaranteed work high above the ground vehicle workstable, reliable, safe, work nimble, the efficiency is high, designs the fine hydraulic system and the electricity control system appears especially importantly.

Keywords: The high-altitude working machine; braker, iternal leakage;external control with constant voltage;The installment limits the position.

第一章 绪 论

1.1高空作业车的现状和发展趋势

我国高空作业机械的生产于20世纪70年代末开始起步,发展较快,目前生产经营企业已由原来的几家迅速增加到40余家,其中与国外合资或合作生产的企业有5家。根据2004年和2005年《中国工程机械年鉴》,2003年高空作业机械工业总产值为32139万元,生产各类高空作业平台。

1906年,高空作业车740台,2004年高空作业机械工业总产值为36340万元,生产各类高空作业平台2500台,高空作业车800台。行业几个骨干企业通过近几年的技术改造,其生产规模不断扩大,形成了各自特色的产品系列,基本能满足国内市场高空作业机械的需要,企业的各项主要经济指标逐步上升,经济效益也逐年提高。

我国高空作业机械行业的一些骨干企业利用自己的技术和设备优势,通过学习引进和消化国外先进技术开发了许多新产品,其产品的技术水平和产品质量都不断提高,达到和接近了国际同类产品的水平,推动了高空作业机械行业的技术进步,在国内市场中竞争力强,市场销路好,产量增加较快。

一些企业利用自身的优势,在原有产品的基础上根据国内底盘品种的发展和基础零部件的更新,不断加大新产品的开发力度,走企业横向联合多种经营的综合开发道路,不但使企业自身的生产和销售步入了良性循环轨道,还带动了附属企业和国内相关产品的销售发展。

高空作业行业作为城市建设的新型产业,必须调整产品结构。要抓好供电用高空作业机械产品、建筑用自行式登高作业机械及带电绝缘高空作业机械产品的开发,室内外轻型作业平台和25M以上消防救援高空作业车的开发和应用。总的发展趋势是致力于扩大高空作业机械的作业范围,满足不同作业的需要;确保使用人员的作业安全;提高操纵和使用性能。高空作业平台产品以往国内大多以手推式为主,体积大、质量重,更换工作场地非常困难,给用户使用带来不便,而发达国家在产品上早已更新。因此,开发轻便的铝合金平台和自行式平台有着广阔的前景,从国内近几年开发的铝合金平台销量来看也证明了这一点。应该优先进行高空作业机械的自动控制和安全保护技术、室内外轻型作业平台及自行式作业平台和大作业幅度平台及新型多功能高空作业车的研究、开发。

要提高我国高空作业车的技术水平,首先必须解决工程车辆底盘问题。我国目前正在努力提高汽车工业的整体水平,走集团化规模道路,并积极引进国外资金及技术,但还只限于轻型底盘。汽车制造厂家应该在此基础上根据高空作业车的具体要求,专门设计轻型、中型和重型的工程车底盘以供高空作业车的改装之用。

我国高空机械的使用范围还比较窄,使用较多的主要有路灯、道路交通、园林部门、国内大多厂家把用户集中在车站、地铁、商店、工厂、供电、路灯等部门,其市场远远没有挖掘和培育出来。高空作业机械在有发展前途的电力、电信及有线电视系统使用较少,究其原因是国内产品技术性能及参数还不能完全满足上述三大系统使用的要求,在产品用途和功能上还需更新。如将高空作业机械用在建筑施工中以替代某些脚手架施工、建筑物外墙表面的装饰、清洗和维护等;绝缘架线和维修;消防救援及大型物体(船舶、飞机)维护检查等,但开发以上这些产品需要从产品的适应性、技术性能上进行较大的突破。

随着我国经济的发展,停电对工农业生产和人民生活带来的损失不可估量,国家已经开始实行《电力法》对供电可靠性要求越来越高,在电力系统创一流企业活动中要求供电可靠率达到99.9%所以如何解决不停电检修----带电作业的问题已经非常突出。这就要求不但能登高作业,还要具有绝缘性能好的高空作业车。这种新型高空作业车要打破常规的格局,工作斗,臂架要采用非金属的高性能绝缘材料,工作斗对整个作业的控制不能采用一般的电控和液控,还要具有起吊能力。并有更可靠的安全性、平稳性、微调性。电信和有线电视系统使用的高空作业车要求小巧灵活,能走街穿巷,操作方便、乘坐舒适。这就要求设计小型先进的汽车底盘,并解决动力输出问题。应该特别注意的是,高空作业车新产品的开发不能限制在汽车上,应该考虑它是一种工程机械,以适应用户的需要为前提,行走方式可以采用电动自行式、液控自行式、轮胎自行式、履带自行式等。我国船舶行业对轮胎液控自行式高空作业车的需求量很大,建筑行业对履带自行式产品也将产生需求,室内装修、清洗行业大量需要电机自行式高空作业车。随着高速公路、高架桥的出现,逐步需要具有负低空作业性能的高空作业车,以解决高架路桥的维修问题,这种特殊的高空作业车在国外早已出现,但在我国还刚刚起步。[1]

1.2课题的来源和意义

本课题以徐州海伦哲工程机械有限公司研制开发 “GKZ14型高空作业车” 为研究对象,对该车高空作业机构的液压电气系统进行设计。

此型号高空作业车除高空作业机构外还设有起重装置,一机多用。液压系统在高空作业车里占重要地位,如起重工件装置主要由起升,变幅,吊臂升缩和回转等机构组成,这些机构都靠液压系统驱动,实现作业要求。随着经济技术的快速发展,国内外起重机市场和高空作业车市场对这两种产品的需求越来越大,我国近年来通过实行积极的财政政策和内需拉动等手段,加强和改善宏观调控,集中液压系统设计在整个高空作业车的设计里具有重要的意义,它使整个机必要力量建设一批大型工程,“GKZ14型高空作业车”将有广阔的应用前景,将产生巨大的社会经济效益。

川公网安备: 51019002004831号

川公网安备: 51019002004831号