摘 要

数控机床即数字程序控制机床,是一种自动化机床,数控技术是数控机床研究的核心,是制造业实现自动化、网络化、柔性化、集成化的基础。随着制造技术的发展,现代数控机床借助现代设计技术、工序集约化和新的功能部件使机床的加工范围、动态性能、加工精度和可靠性有了极大的提高。

本文主要对XK5040数控立式铣床及控制系统进行设计,首先分析立式铣床的加工特点和加工要求确定其主参数,包括运动和动力参数;根据主参数和设计要求进行主运动系统、进给系统设计。主要进行主运动系统和进给系统的机械结构设计及滚珠丝杠和步进电机的选型和校核。

关键词 数控技术;立式铣床;结构设计

Abstract

The numerical control engine bed is the digital process control engine bed, is one kind of automated engine bed, the numerical control technology is the core which the numerical control engine bed studies, is the manufacturing industry realization automation, the network, the flexibility, the integrated foundation. Along with the manufacture technology development, the modern numerical control engine bed with the aid of the modern design technology, the working procedure intensification and the new function part caused the engine bed the processing scope, the dynamic performance, the processing precision and the reliability had the enormous enhancement .

This article mainly carries on the design to the XK5040 numerical control vertical milling machine , first analyzes the vertical milling machine the processing characteristic and the processing request determines its host parameter, including movement and dynamic parameter; Carry on the host kinematic scheme according to the host parameter and the design request, enters for the system and the control system hardware circuit design. Mainly carries on the host kinematic scheme and enters for the system mechanism design and the ball bearing guide screw and electric stepping motor shaping and the examination;

Key words Numerical control technology; Vertical milling machine; Design

目 录

摘 要I

AbstractII

第1章 总体设计1

1.1铣床简介1

1.2 XK5040型数控铣床的总体布局主要技术参数及总传动系统图1

1.2.1 XK5040型数控铣床的总体布局1

1.2.2 XK5040型数控铣床的主要技术参数3

1.2.3 总传动系统图4

第2章 主运动系统设计 6

2.1 传动系统设计6

2.1.1参数的拟定6

2.1.2 传动结构或结构网的选择6

2.1.3 转速图拟定7

2.1.4齿轮齿数的确定及传动系统图的绘制10

2.2传动件的估算与验算14

2.2.1传动轴的估算和验算14

2.2.2齿轮模数的估算17

2.3 展开图设计 22

2.3.1结构实际的内容及技术要求22

2.3.2齿轮块的设计24

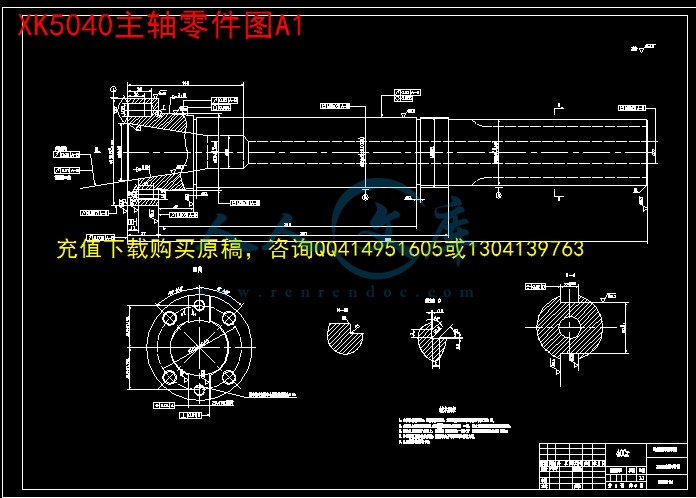

2.3.3传动轴设计26

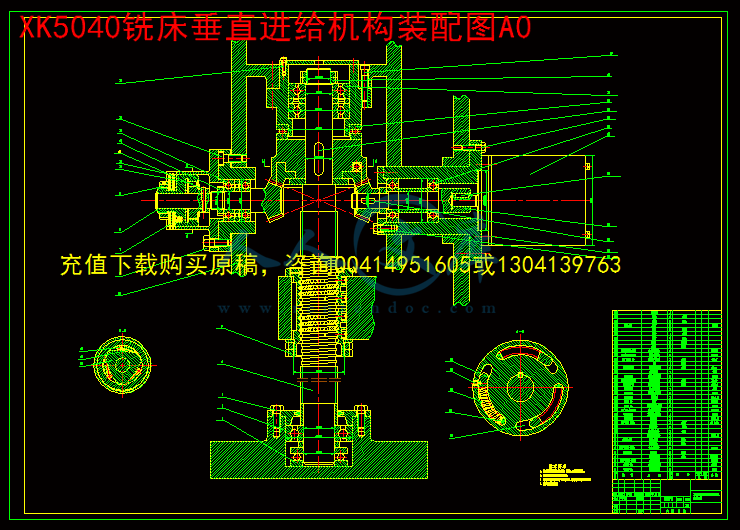

2.3.4主轴组件设计29

2.4制动器设计35

2.4.1按扭矩选择35

2.5截面图设计37

2.5.1轴的空间布置37

2.5.2操纵机构38

2.5.3润滑38

2.5.4箱体设计的确有关问题39

第3章 进给系统设计40

3.1总体方案设计40

3.1.1对进给伺服系统的基本要求40

3.1.2进给伺服系统的设计要求40

3.1.3总体方案40

3.2进给伺服系统机械部分设计41

3.2.1确定脉冲当量计算切削力41

3.2.2滚珠丝杆螺母副的计算和造型43

3.2.3齿轮传动比计算53

3.2.4步进电机的计算和选型54

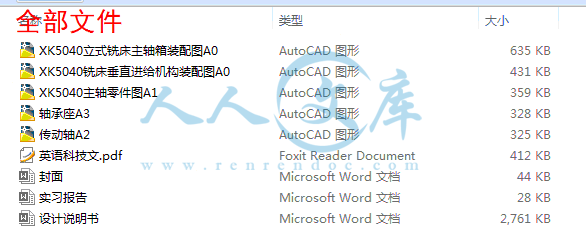

3.2.5进给伺服系统机械部分结构设计65

结论69

致谢70

参考文献71

附录172

附录274

第1章 总体设计

1.1铣床简介

铣床是一种用途广泛的机床。它可以加工平面(水平面、垂直面等)、沟槽(键槽、T型槽、燕尾槽等)、多齿零件上齿槽(齿轮、链轮、棘轮、花键轴等)、螺旋形表面(螺纹和螺旋槽)及各种曲面。此外,它还可以用于加工回转体表面及内孔,以及进行切断工作等。

由于铣床使用旋转的多齿刀具加工工件,同时有数个刀齿参加切削,所以生产效率高,但是,由于铣刀每个刀齿的切削过程是断续的,且每一个的切削厚度又是变化的,这就使切削力相应地发生变化,容易引起机床振动,因此,铣床在结构上要求有较高的刚度和抗振性。

铣床的类型很多,主要类型有:卧式升降台铣床、立式升降台铣床、龙门铣床、工具铣床和各种专门化铣床等。

随着科学技术的进步,数控铣床得到了越来越广泛的应用,它一般分为立式和卧式两种,一般数控铣床是指规格较小的升降台数控铣床,其工作台宽度多在400mm以下,规格较大的数控铣床,例如工作台宽度在500mm以上的,其功能已向加工中心靠近,进而演变成柔性制造单元。数控铣床多为三坐标、两轴联动的机床,也称两轴半控制,即X、Y、Z三个坐标轴中,任意两个都可以联动。一般情况下,在数控铣床上只能用来加工平面曲线的轮廓。对于有特殊要求的数控铣床,还可以加进一个回转的A坐标或C坐标,即增加一个数控分度头或数控回转工作台,这是机床的数控系统为四坐``标的数控系统,它可用来加工旋转槽、叶片等立体曲面零件。

我们本次设计过程中要接触到的为XK5040数控立式铣床。它的工作台宽度为400mm。

川公网安备: 51019002004831号

川公网安备: 51019002004831号