资源目录

压缩包内文档预览:

编号:6894926

类型:共享资源

大小:8.96MB

格式:RAR

上传时间:2018-01-02

上传人:优***

认证信息

个人认证

罗**(实名认证)

广西

IP属地:广西

50

积分

- 关 键 词:

-

ve

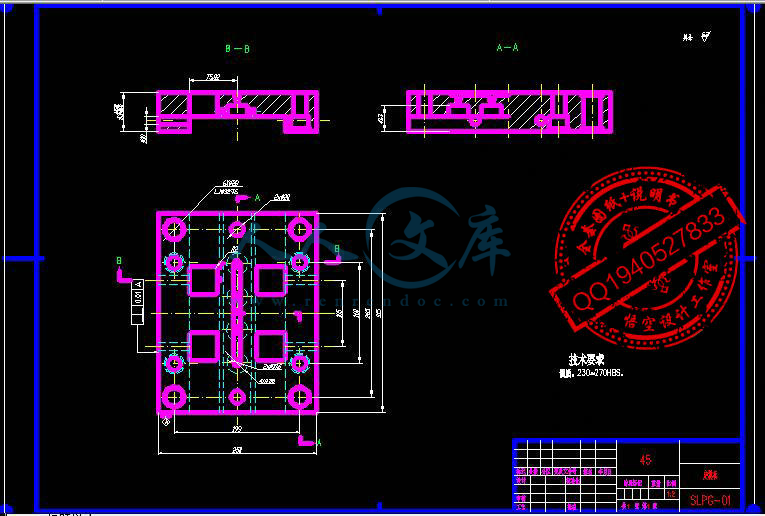

瓶盖

注塑

模具设计

及其

仿真

加工

- 资源描述:

-

- 内容简介:

-

JournalofUniversityofScienceandTechnologyBeijingVolume13,Number3,June2006,Page240Correspondingauthor:YingTang,E-mail:tangydlMaterialsOptimizationstrategyinendmillingprocessforhighspeedmachiningofhardeneddie/moldsteelYingTangMechanicalEngineeringSchool,UniversityofScienceandTechnologyBeijing,Beijing100083,China(Received2005-02-21)Abstract:Anoptimizationstrategyforhighspeedmachiningofhardeneddie/moldsteelbasedonmachiningfeatureanalysiswasstudied.Itisafurtherextensionofthepreviouslypresentedstudyonthethermalmechanismofendmillingandconstantcuttingforcecontrol.Anobjectivefunctionconcerningmachiningcostandassociatedoptimizationalgorithmbasedonmachiningtimeandcuttinglengthcalculationwasproposed.Constraintstosatisfyspecificmachiningstrategieswhenhighspeedmachiningthehardeneddie/moldsteel,trochoidtoolpathpatterninslotendmillingtoavoidover-heatandfeedrateadaptationtoavoidover-load,werealsodiscussed.Asacasestudy,thetoolselectionproblemwhenmachiningadiepartwithmultiplemachiningfeatureswasinvestigated.Keywords:optimizationalgorithm;hardeneddie/moldsteel;machiningcost;machiningfeature1.IntroductionTheintroductionofadvancedcuttingtoolslikeAlTiN-coatedmicro-graincarbideendmillsincethe1990shaschangedthetrendindie/moldmanufacturingtowardshardmachiningbothinroughingandfinishing1.Nowadays,highspeedmachiningofhardeneddieandmoldsteelsisaproventechnologyalready,wheremanyspecificmachiningconceptsandstrategiesaredevelopedtofacilitateit2.Representatively,ma-chiningfeaturesthataredefinedasdistinctivevolumetricshapetoberemovedbydistinctivema-chiningoperations(i.e.cuttingtoolandtoolpathpat-tern),isputforwardtoeaseNC(numericalcontrol)programming3.Usuallytoolpathpatternforeachfeaturetypecanbestandardizedandfixed.Oncemachiningfeaturesandrelevanttoolpathpat-ternarefixed,itbecomesabsolutelynecessarytoopti-mizeotheroperationparametersbecausewhenweconsiderbothproductivityandtoolcost,thelattercontributestoasmuchas20%ofthetotalcostofdieandmoldmanufacturing.Suchoptimizationismadepossiblewithmachiningfeatureandfixedtoolpathpatternanalysis,whichreducesthenumberofvariablesthathavetobeconsideredatthesametime.Productiv-ityandtoolcostcanbetreatedasfunctionsoftheseindependentcuttingconditionvariablessothattheimpactofthesevariablesontheproductivityandtoolcostorthecombinedobjectivefunctionofthesetwocanbecalculatedandoptimized.Thispaperisorganizedasfollows:anobjectivefunctionconcerningmachiningcostanditsassociatedoptimizationalgorithmisproposedinSection2,fol-lowedbyacasestudytousetheproposedalgorithmfortoolselectioninendmillingdiepartwithmultiplemachiningfeaturesinSection3.Constraintsfacedinattemptingtosatisfyspecificmachiningstrategieswhenhighspeedmachiningthehardeneddie/moldsteelarediscussedinthesamesection.ConclusionsarepresentedinSection4basedontheresultsofthecasestudy.2.OptimizationstrategyAsconcerningproductivity,thetimeinvolvedinmachiningprocessneedstobecalculated.Thema-chiningtimemTconsideredincludesthecuttingtimecTandtheaircuttingtimencT.Basically,theexactcuttingtimecTiscalculatedbyaddingthetimesspentoneverychipandtheaircuttingtimencTisthetotaltimeofaircuttinginthetoolpath,whichcannormallybecalculatedwitheasebasedonfixedtoolpathpattern,mcncnczeiiiLTTTTf=+=+(1)wherethecuttinglengthiLofthei-thchipiscalculat-edbasedontheengagementgeometrybetweentheworkpieceandthecuttingtool,andzeifistheinstantfeedoftoolwhencuttingthechip.Inthecaseofendmillingconcavecontour,iL,zeifandotherparametersY.Tang,Optimizationstrategyinendmillingprocessforhighspeedmachining241associatedwithitareshowninFig.1.Fig.1.Tool-workengagementinconcavecontourend-millingprocess.tmimaximumuncutthicknessofthei-thchip;Licuttinglengthofthei-thchip;fziinstantfeedpertoothatthetoolcenter;fzeiinstantfeedpertoothatthetooltip;iangleformedbyfziandfzei;enicutting-relatedangle;Rdiradialdepthofcut;rendmillradius;Rconcavecontourradius.Indieandmoldindustry,thetoollifefLisoftenmeasuredbythetotallengththatatoolisengagedincuttingtillitfails.ThevalueoffLcanbeobtainedfromthetoolmanufacturerdirectlyorthroughtoollifeexperiments.Ifthetotalcuttinglengthatanygiventimeduringthetoollife,tL,canbeintegratedbyad-dingallthechiplengthsundercuttilltheconsideredtimepoint,tiiLL=(2)thentheratiooftLtofLindicatesthetoollifethathasbeenconsumed.Theoptimizationstrategycouldbetominimizethemachiningtimeormaximizethetoollifeforacertainwork.Amoregeneralobjectivefunctionisthema-chiningcost,whichisacombinationofboth.Machin-ingprocessinvolvesvariousmiscellaneouscosts;butinthisstudywetakeintoconsiderationonlythema-chiningtimecostandthetoolcost,whichareidentifiedasthemajorcostsfordieandmoldmachiningproc-esses.Thetotalcost(C)formachiningoneworkpieceistmmtfLCcTcL=+(3)wheremcisthecostperunitmachinetimeandtcisthepricepertool.TheoptimizationwithminimumCsuggestsadesiredbalancebetweensavedmachiningtimeandreducedtoolcost.3.Casestudyfortoolselectioninhighspeedmachiningofhardeneddie/moldsteelAsacasestudy,thetoolselectionproblemfacedwhenmachiningadiepartwithmultiplemachiningfeatureswasinvestigated.Supposethattwoslotsof100mminlength,10mmindepthand50mmand15mminwidth,respectively,needtobemachinedonadiework(Fig.2).TheworkpiecematerialisJISSKC61diesteelofHRC53inhardness.AlTiN-coatedmicro-graincarbideendmillcutterswithsixbladeswereusedtoimplementtheslotendmilling.Endmillcuttersunderconsiderationareof6,8,10,12,14and18mmindiameter.Theaimistoseekanoptimaltoolselectiontoachievetheminimummachiningcosttoremovethetwoslots.Fig.2.Diepartwithtwoslotstobemachined.Themodelandcalculationpresentedinthispaperaresubjecttocertainconstraintsdiscussedasfollows:theneedtosatisfyspecificmachiningstrategiesindieandmoldindustryandalsomethodsthatareinaccor-dancewithstate-of-the-artunderstandingofhighspeedmachininghardeneddie/moldsteel.(1)Slotendmillingwithtrochoidtoolpathpattern.Fromthemachiningpointofview,machiningfea-turesinmillingcanusuallybeclassifiedintofivecate-gories:hole,pocket,openpocket,faceandboss3.SlotmachininginFig.2belongstothesortofopenpocket,whichischaracterizedbytwoopensidessothatcuttingtoolcanapproachpartfromoneofthetwosides.Aconventionalwayofslotendmillinginvolvesusingthefulldiameteroftheendmillinthematerial.Inthiscase,theteethwillcontactwiththepartresultinginbuild-upofheatduring50%oftherevolution,andthencooldownduringtheremaining50%oftherevo-lution.Thetoollifewillbedrasticallyreducedduetoexcessiveheatbuild-uponthecuttingteeth,ifthereisnoenoughtimeforthecuttingteethtocooldown,accordingtothethermalmechanisminendmilling242J.Univ.Sci.Technol.Beijing,Vol.13,No.3,Jun2006processpresentedinpreviousworks4-5.Itbecomesessentialtoseekaspecificmachiningstrategytore-ducecuttingheataccumulationforimprovingtoollife.Thekeyissueliesinthelimitationofcontactbetweenthetoolandthepartperrevolution.Trochoidtoolpathpatternwithsuccessivetrochoidcyclesofthesamepitch,showninFig.3,issuchasubstitutedesignedforendmillingaslotintothehardenedsteelathighspeed6.Bymaintainingalimitedpitch,thearcofcontactisminimized.Incon-junctionwithproperfeedsandspeeds,endmillinginthismannercanremovealargeamountofmaterialwithoutthegenerationofexcessiveheat.Fig.3.Slotendmillingwithtrochoidtoolpathpattern.Bisaslotofgivenwidth.(2)Feedrateadaptationtokeepconstantcuttingforce.Anotherconcepttakenasabasisforhardeneddiesteelendmillingistomaintainthecuttingforcecon-stantunderasafetylimitespeciallyinroughingorintermediateroughingoperation,becausechippingoccurssoonifexcessivecuttingforcesatthecuttingedgearepresent.Chippingononecuttingedgecancauseacascadeeffectofsuccessivechippingontheremainingintactcuttingedges.Thismakesthetoolunusableveryquickly.Astraightforwardapproachtokeepconstantcuttingforceistoadaptfeedratealongtoolpath.Thebasicprincipleofthestrategyistosolvetheinstantfeedrateaccordingtotool-workengagementgeometrywithasecondorderforcemodel,whichwaspresentedinpreviousworks7-8,220112211221212YXXXXX=+(4)whereYdenotestheaveragecuttingforcevalueinXY-planexyF.ThecontroltargetforceYisdeter-minedfromexperiences.1Xand2Xarethenormal-izedmaximumuncutchipthicknessmitandchipcut-tinglengthiLrespectively.Thesixcoefficients(012,)areidentifiedbyconductingasetofpre-processexperimentsofstraightcutbyusingleastsquaresmethod.Undertheseconstraints,thesimulationwascon-ductedfirstlytoseektheoptimalcutterdiameterDwhenamachiningfeature,aslotofgivenwidthB,neededtobemachined.Fig.4istheB-Dplaneofthecontourplotofmachiningcostwhenmachinedwithapitchof0.5mmandaspindlespeedof9600r/min.Thetargetcuttingforcesareequaltothevaluesmeasuredincuttingexperimentswithdifferentdiametercutterstocutalongstraightcontoursatthesamepitchandspin-dlespeed.ThetoollifefL=112mm/bladeandcostpermachiningtimemc=750yuanRMB/hweredeter-minedaccordingtoourindustrialpartnersexperience.Cuttercostswerenamedaccordingtotheirmarketprices.Fig.4.MachiningcostConB-Dplaneinthecaseofone-slotendmillingwithtrochoidtoolpath.Theblackdottedlineacrossmachiningcostcon-toursontheB-DplaneinFig.4indicatestheoptimaltooldiameterDtotheminimumcostachievementforthegivenslotwidthB.Forexample,a10mmcuttershouldbeusedtocutthe50mm-widthslot,whilea6mmcuttertocutthe15mm-widthslot.Inotherwords,twocuttersareneededifcutterdiameterselectionisconsideredseparatelyforeachmachiningfeature.Asalsoseeninthefigure,theblackdottedlinelocatedintheleftendoftheB-Dplaneimpliesthatsmallendmillcuttersof6,8and10mmindiameterarepreferredinslotend-millingmachining.Ithastobepointedoutthatthesimulationisconductedundertheassumptionthattheslotcanberemovedinonelayerwithallendmillcutters.Inthecaseofdeepslot,morelayerswillbeneededifasmallerdiametercutterisused.Theresult-ingmachiningcostincreasewillpushoptimalcutterdiameterpositionstotherightendinFig.4.Further-more,thesimulationisconductedundertheassump-tionthattheslotisnarrow,sothetrochoidtoolpathpatternneedstobeused.Forawideslothowever,acombinationoftrochoidtoolpathpatterntomachineY.Tang,Optimizationstrategyinendmillingprocessforhighspeedmachining243intothepartfirstandthenasidetoolpathpatterntoremoveleftstockwillsavetimeandthusismoreprac-ticable.Inthepracticeofdie/moldmanufacturingindustryhowever,asingleendmillcutterisgenerallyexpectedtofinishallmachiningfeaturesonapart,onaccountofthetimetakentoexchangethecutterandalltheassoci-atedcutterandholderpreparations.Thatmeanstoolselectionshouldnotbeundertakenforeachmachiningfeatureseparatelybutforallfeaturesasawhole.Fig.5illustratesthemachiningcostinvolvedinthetwo-slotmachiningprocessbyusingonecutterof6,8and10mmrespectively.Themachiningcostwhenusingthe6mmendmilltoremovea15mm-widthslotandthe10mmendmilltoremovea50mm-widthslotisshowninthesamefigureforcomparison.Datainthebottomcolumnsdenotethemachiningcoststoremovethe50mm-widthslot,whiledatainthetopcolumnsdenotethemachiningcoststoremovethe15mm-widthslot.Anddataabovecolumns,thesumofthemrespec-tivelyarethetotalmachiningcosts.Fig.5.Machiningcostwhenendmillingtwoslotsatdiffer-enttoolselections.SeenintheFig.5,themachiningcostwithtwocut-tersissmallerthanthatwithonecutter.ItsaresultthatcoincideswiththesimulationanddiscussionofFig.4.Fig.5alsoshowsifonlyonecutterisneeded,the8mmcuttercanprovidelessmachiningcostthanthe10mmor6mmcutter.Machiningcostdifferencebe-tweenthetwo-cutterselectionandtheoptimalone-cutterselectionis4.2yuanRMB.However,thema-chiningcosthereincludesonlythemachiningtimecostandthecutterswearcost.Ifthetimecostofcuttertransportandexchangeandtheassociatedcostoncut-terandholderpreparationetc.areincluded,thenitisexpectedthatthecostdifferencecanbecompensated.4.ConclusionsAnoptimizationstrategyforhighspeedmachiningofhardenedDie/Moldsteelisstudied.Anobjectivefunctionconcerningmachiningcostandassociatedoptimizationalgorithmbasedonmachiningtimeandcuttinglengthcalculation,areproposed.Constraintstosatisfyspecificmachiningstrategieswhenhighspeedmachiningthehardeneddie/moldsteel,trochoidtoolpathpatterninslotendmillingtoavoidover-heatandfeedrateadaptationtoavoidover-load,arealsodis-cussed.Asacasestudy,thetoolselectionproblemwhenamachiningdiepartwithmultiplemachiningfeaturesisinvestigated.Simulationsshow:(1)Theoptimizationwithminimummachiningcostsuggestsadesiredbalancebetweensavedmachiningtimeandreducedtoolcost.(2)Withtheproposedoptimizationalgorithm,theplotofmachiningcostcontoursontheB-Dplaneisobtained,whichcanbeusedtoseektheoptimalcutterdiameterDforagivenslotwidthBwhenslotendmillingisrequired.(3)Theoptimizationwhenallmachiningfeaturesaretakenintoconsiderati

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号