资源目录

压缩包内文档预览:(预览前20页/共33页)

编号:6975947

类型:共享资源

大小:10.47MB

格式:ZIP

上传时间:2018-01-05

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

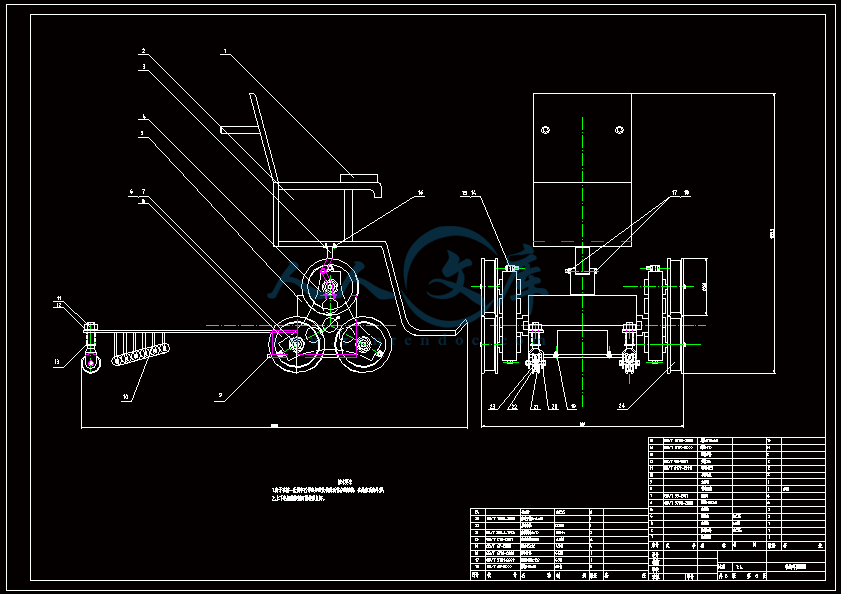

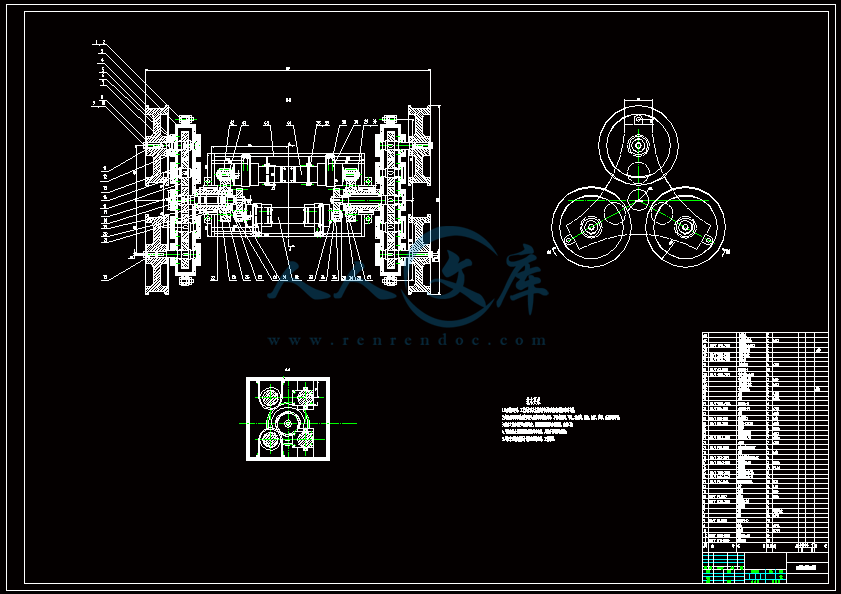

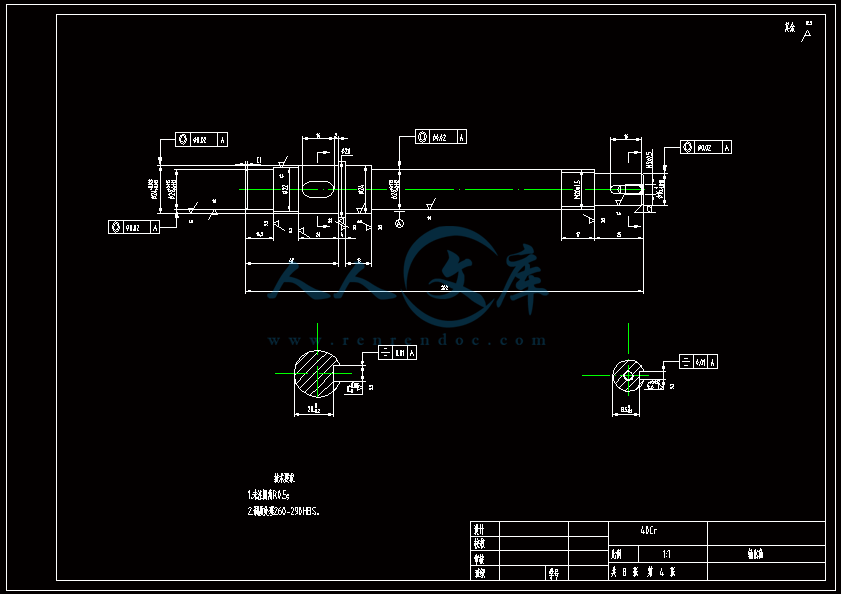

楼梯

自行

轮椅车

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

DOI101007/S0017000318433ORIGINALARTICLEINTJADVMANUFTECHNOL200525551559SHMASOODBABBASESHAYANAKARAANINVESTIGATIONINTODESIGNANDMANUFACTURINGOFMECHANICALCONVEYORSSYSTEMSFORFOODPROCESSINGRECEIVED29MARCH2003/ACCEPTED21JUNE2003/PUBLISHEDONLINE23JUNE2004SPRINGERVERLAGLONDONLIMITED2004ABSTRACTTHISPAPERPRESENTSTHERESULTSOFARESEARCHINVESTIGATIONUNDERTAKENTODEVELOPMETHODOLOGIESANDTECHNIQUESTHATWILLREDUCETHECOSTANDTIMEOFTHEDESIGN,MANUFACTURINGANDASSEMBLYOFMECHANICALCONVEYORSYSTEMSUSEDINTHEFOODANDBEVERAGEINDUSTRYTHEIMPROVEDMETHODOLOGYFORDESIGNANDPRODUCTIONOFCONVEYORCOMPONENTSISBASEDONTHEMINIMISATIONOFMATERIALS,PARTSANDCOSTS,USINGTHERULESOFDESIGNFORMANUFACTUREANDDESIGNFORASSEMBLYRESULTSOBTAINEDONATESTCONVEYORSYSTEMVERIFYTHEBENEFITSOFUSINGTHEIMPROVEDTECHNIQUESTHEOVERALLMATERIALCOSTWASREDUCEDBY19ANDTHEOVERALLASSEMBLYCOSTWASREDUCEDBY20COMPAREDTOCONVENTIONALMETHODSKEYWORDSASSEMBLYCOSTREDUCTIONDESIGNDFADFMMECHANICALCONVEYOR1INTRODUCTIONCONVEYORSYSTEMSUSEDINTHEFOODANDBEVERAGEINDUSTRYAREHIGHLYAUTOMATEDCUSTOMMADESTRUCTURESCONSISTINGOFALARGENUMBEROFPARTSANDDESIGNEDTOCARRYPRODUCTSSUCHASFOODCARTONS,DRINKBOTTLESANDCANSINFASTPRODUCTIONANDASSEMBLYLINESMOSTOFTHEPROCESSINGANDPACKAGINGOFFOODANDDRINKINVOLVECONTINUOUSOPERATIONSWHERECARTONS,BOTTLESORCANSAREREQUIREDTOMOVEATACONTROLLEDSPEEDFORFILLINGORASSEMBLYOPERATIONSTHEIROPERATIONSREQUIREHIGHLYEFFICIENTANDRELIABLEMECHANICALCONVEYORS,WHICHRANGEFROMOVERHEADTYPESTOFLOORMOUNTEDTYPESOFCHAIN,ROLLERORBELTDRIVENCONVEYORSYSTEMSINRECENTYEARS,IMMENSEPRESSUREFROMCLIENTSFORLOWCOSTBUTEFFICIENTMECHANICALCONVEYORSYSTEMSHASPUSHEDCONVEYORMANUFACTURERSTOREVIEWTHEIRCURRENTDESIGNANDASSEMBLYMETHODSANDLOOKATANALTERNATIVEMEANSTOMANUFACTUREMOREECONOMICALANDRELIABLECONVEYORSFORTHEIRCLIENTSATPRESENT,SHMASOODA117BABBASESHAYANAKARAINDUSTRIALRESEARCHINSTITUTESWINBURNE,SWINBURNEUNIVERSITYOFTECHNOLOGY,HAWTHORN,MELBOURNE3122,AUSTRALIAEMAILSMASOODSWINEDUAUMOSTMATERIALHANDLINGDEVICES,BOTHHARDWAREANDSOFTWARE,AREHIGHLYSPECIALISED,INFLEXIBLEANDCOSTLYTOCONFIGURE,INSTALLANDMAINTAIN1CONVEYORSAREFIXEDINTERMSOFTHEIRLOCATIONSANDTHECONVEYORBELTSACCORDINGTOTHEIRSYNCHRONISEDSPEEDS,MAKINGANYCHANGEOVEROFTHECONVEYORSYSTEMVERYDIFFICULTANDEXPENSIVEINTODAYSRADICALLYCHANGINGINDUSTRIALMARKETS,THEREISANEEDTOIMPLEMENTANEWMANUFACTURINGSTRATEGY,ANEWSYSTEMOPERATIONALCONCEPTANDANEWSYSTEMCONTROLSOFTWAREANDHARDWAREDEVELOPMENTCONCEPT,THATCANBEAPPLIEDTOTHEDESIGNOFANEWGENERATIONOFOPEN,FLEXIBLEMATERIALHANDLINGSYSTEMS2HOANDRANKY3PROPOSEDANEWMODULARANDRECONFIGURABLE2DAND3DCONVEYORSYSTEM,WHICHENCOMPASSESANOPENRECONFIGURABLESOFTWAREARCHITECTUREBASEDONTHECIMOSAOPENSYSTEMARCHITECTUREMODELITISNOTEDTHATTHERESEARCHINTHEAREAOFIMPROVEMENTOFCONVEYORSYSTEMSUSEDINBEVERAGEINDUSTRYISVERYLIMITEDMOSTOFTHEPUBLISHEDRESEARCHISDIRECTEDTOWARDSIMPROVINGTHEOPERATIONSOFCONVEYORSYSTEMSANDINTEGRATIONOFSYSTEMTOHIGHLYSOPHISTICATEDSOFTWAREANDHARDWARETHISPAPERPRESENTSARESEARCHINVESTIGATIONAIMEDATIMPROVINGTHECURRENTTECHNIQUESANDPRACTICESUSEDINTHEDESIGN,MANUFACTURINGANDASSEMBLYOFFLOORMOUNTEDTYPECHAINDRIVENMECHANICALCONVEYORSINORDERTOREDUCETHEMANUFACTURINGLEADTIMEANDCOSTFORSUCHCONVEYORSAPPLYINGTHECONCEPTOFCONCURRENTENGINEERINGANDTHEPRINCIPLESOFDESIGNFORMANUFACTURINGANDDESIGNFORASSEMBLY4,5,SEVERALCRITICALCONVEYORPARTSWEREINVESTIGATEDFORTHEIRFUNCTIONALITY,MATERIALSUITABILITY,STRENGTHCRITERION,COSTANDEASEOFASSEMBLYINTHEOVERALLCONVEYORSYSTEMTHECRITICALPARTSWEREMODIFIEDANDREDESIGNEDWITHNEWSHAPEANDGEOMETRY,ANDSOMEWITHNEWMATERIALSTHEIMPROVEDDESIGNMETHODSANDTHEFUNCTIONALITYOFNEWCONVEYORPARTSWEREVERIFIEDANDTESTEDONANEWTESTCONVEYORSYSTEMDESIGNED,MANUFACTUREDANDASSEMBLEDUSINGTHENEWIMPROVEDPARTS2DESIGNFORMANUFACTURINGANDASSEMBLYDFMAINRECENTYEARS,RESEARCHINTHEAREAOFDESIGNFORMANUFACTURINGANDASSEMBLYHASBECOMEVERYUSEFULFORINDUSTRIESTHATARECON552SIDERINGIMPROVINGTHEIRFACILITIESANDMANUFACTURINGMETHODOLOGYHOWEVER,THEREHASNOTBEENENOUGHWORKDONEINTHEAREAOFDESIGNFORCONVEYORCOMPONENTS,ESPECIALLYRELATEDTOTHEISSUEOFINCREASINGNUMBERSOFDRAWINGDATAANDREENGINEERINGOFTHEPROCESSOFCONVEYORDESIGNBASEDONTRADITIONALMETHODSAVASTAMOUNTOFPAPERSHAVEBEENPUBLISHEDTHATHAVEINVESTIGATEDISSUESRELATEDTODFMAANDAPPLIEDTOVARIOUSMETHODOLOGIESTOACHIEVERESULTSTHATPROVEDECONOMICAL,EFFICIENTANDCOSTEFFECTIVEFORTHECOMPANIESUNDERINVESTIGATIONTHEMAINCLASSIFICATIONSOFDFMAKNOWLEDGECANBEIDENTIFIEDAS1GENERALGUIDELINES,2COMPANYSPECIFICBESTPRACTICEOR3PROCESSANDORRESOURCESPECIFICCONSTRAINTSGENERALGUIDELINESREFERTOGENERALLYAPPLICABLERULESOFTHUMB,RELATINGTOAMANUFACTURINGDOMAINOFWHICHTHEDESIGNERSHOULDBEAWARETHEFOLLOWINGLISTHASBEENCOMPILEDFORDFMGUIDELINES6DESIGNFORAMINIMUMNUMBEROFPARTSDEVELOPAMODULARDESIGNMINIMISEPARTVARIATIONSDESIGNPARTSTOBEMULTIFUNCTIONALDESIGNPARTSFORMULTIUSEDESIGNPARTSFOREASEOFFABRICATIONAVOIDSEPARATEFASTENERSMAXIMISECOMPLIANCEDESIGNFOREASEOFASSEMBLYMINIMISEHANDLINGDESIGNFORHANDLINGPRESENTATIONEVALUATEASSEMBLYMETHODSELIMINATEADJUSTMENTSAVOIDFLEXIBLECOMPONENTSTHEYAREDIFFICULTTOHANDLEUSEPARTSOFKNOWNCAPABILITYALLOWFORMAXIMUMINTOLERANCEOFPARTSUSEKNOWNANDPROVENVENDORSANDSUPPLIERSUSEPARTSATDERATEDVALUESWITHNOMARGINALOVERSTRESSMINIMISESUBASSEMBLIESFIG1LAYOUTOFCONVEYORSYSTEMFORLABELLINGPLASICBOTTLESEMPHASISESTANDARDISATIONUSETHESIMPLESTPOSSIBLEOPERATIONSUSEOPERATIONSOFKNOWNCAPABILITYMINIMISESETUPSANDINTERVENTIONSUNDERTAKEENGINEERINGCHANGESINBATCHESTHESEDESIGNGUIDELINESSHOULDBETHOUGHTOFAS“OPTIMALSUGGESTIONS”THEYTYPICALLYWILLRESULTINAHIGHQUALITY,LOWCOST,ANDMANUFACTURABLEDESIGNOCCASIONALLYCOMPROMISESMUSTBEMADE,OFCOURSEINTHESECASES,IFAGUIDELINEGOESAGAINSTAMARKETINGORPERFORMANCEREQUIREMENT,THENEXTBESTALTERNATIVESHOULDBESELECTED7COMPANYSPECIFICBESTPRACTICEREFERSTOTHEINHOUSEDESIGNRULESACOMPANYDEVELOPS,USUALLYOVERALONGPERIODOFTIME,ANDWHICHTHEDESIGNERISEXPECTEDTOADHERETOTHESEDESIGNRULESAREIDENTIFIEDBYTHECOMPANYASCONTRIBUTINGTOIMPROVEDQUALITYANDEFFICIENCYBYRECOGNISINGTHEOVERALLRELATIONSHIPSBETWEENPARTICULARPROCESSESANDDESIGNDECISIONSCOMPANIESUSESUCHGUIDELINESASPARTOFTHETRAININGGIVENTODESIGNERSOFPRODUCTSREQUIRINGSIGNIFICANTAMOUNTSOFMANUALASSEMBLYORMAINTENANCENOTETHATMOSTOFTHEMETHODOLOGIESAREGOODATEITHERBEINGQUICKANDEASYTOSTARTORBEINGMOREFORMALANDQUANTITATIVEFOREXAMPLE,GUIDELINESBYBOOTHROYDANDDEWHURST8ONDFAARECONSIDEREDASBEINGQUANTITATIVEANDSYSTEMATICWHEREASTHEDFMGUIDELINES,WHICHAREMERELYRULESOFTHUMBDERIVEDFROMEXPERIENCEDPROFESSIONALS,AREMOREQUALITATIVEANDLESSFORMAL93CONVENTIONALCONVEYORSYSTEMDESIGNDESIGNANDMANUFACTURINGOFCONVEYORSYSTEMSISAVERYCOMPLEXANDTIMECONSUMINGPROCESSASEVERYCONVEYORSYSTEMISACUSTOMMADEPRODUCT,EACHPROJECTVARIESFROMEVERYOTHERPROJECTINTERMSOFSIZE,PRODUCTANDLAYOUTTHESYSTEMDESIGN553ISBASEDONCLIENTREQUIREMENTSANDPRODUCTSPECIFICATIONSMOREOVER,THESYSTEMLAYOUTHASTOFITINTHESPACEPROVIDEDBYTHECOMPANYTHEPROCESSOFDESIGNINGALAYOUTFORACONVEYORSYSTEMINVOLVEREVISIONSANDCOULDTAKEFROMDAYSTOMONTHSORINSOMEINSTANCESYEARSONEWITHTHEMINIMUMCOSTANDMAXIMUMCLIENTSUITABILITYISMOSTLIKELYTOGETAPPROVALFIGURE1SHOWSASCHEMATICLAYOUTOFATYPICALCONVEYORSYSTEMINSTALLEDINAPRODUCTIONLINEUSEDFORLABELLINGOFPLASTICBOTTLESDIFFERENTSECTIONSOFTHECONVEYORSYSTEMAREIDENTIFIEDBYSPECIFICTECHNICALNAMES,WHICHARECOMMONLYUSEDINSIMILARINDUSTRIALAPPLICATIONTHE“SINGLIZER”SECTIONENABLESTHEPRODUCTTOFORMINTOONELANEFROMMULTIPLELANESTHE“SLOWDOWNTABLE”REDUCESTHESPEEDOFPRODUCTONCEITEXITSFROMFILLER,LABELLER,ETCTHE“MASSFLOW”SECTIONISUSEDTOKEEPUPWITHHIGHSPEEDPROCESS,EG,FILLER,LABELLER,ETCTHE“TRANSFERTABLE”TRANSFERSTHEDIRECTIONOFPRODUCTFLOWTHEPURPOSEOFTHESEDIFFERENTCONVEYORSECTIONSISTHUSTOCONTROLTHEPRODUCTFLOWTHROUGHDIFFERENTPROCESSINGMACHINESATYPICALMECHANICALCONVEYORSYSTEMUSEDINFOODANDBEVERAGEAPPLICATIONSCONSISTSOFOVERTWOHUNDREDMECHANICALANDELECTRICALPARTSDEPENDINGONTHESIZEOFTHESYSTEMSOMEOFTHECOMMONBUTESSENTIALCOMPONENTSTHATCOULDBESTANDARDISEDANDACCUMULATEDINTOFAMILIESOFTHECONVEYORSYSTEMARESIDEFRAMES,SPACERBARS,ENDPLATES,COVERPLATES,INSIDEBENDPLATES,OUTSIDEBENDPLATES,BENDTRACKSANDSHAFTSDRIVE,TAILANDSLAVETHESIZEANDQUANTITYOFTHESEPARTSVARYACCORDINGTOTHELENGTHOFCONVEYORSECTIONSANDNUMBEROFTRACKSCORRESPONDINGTOTHEWIDTHANDTYPESOFCHAINSREQUIREDTHEPROBLEMSANDSHORTCOMINGSINTHECURRENTDESIGN,MANUFACTURINGANDASSEMBLYOFMECHANICALCONVEYORSAREVARIED,BUTINCLUDEOVERDESIGNOFSOMEPARTSHIGHCOSTOFSOMECOMPONENTSLONGHOURSINVOLVEDINASSEMBLY/MAINTENANCEUSEOFNONSTANDARDPARTSTABLE1CONVEYORCRITICALPARTSBASEDONPARTSCOSTANALYSISPRODUCTDESCRIPTIONQTYMATERIALUSEDCOSTIMPROVEMENTPOSSIBLEYES/NOLEGSET68PLASTICLEGSSTUBE2022YESSIDEFRAME8025MMSS1607YESSUPPORTCHANNEL400CCHANNELSS1500YESBENDTRACKS8PLASTIC1436NORTROLLERSHAFT13920DIASSSHAFT670YESTAILSHAFT3935DIASTAINLESSSTEEL627NOSPACERBAR13550X50X6SS543YESSUPPORTWEARSTRIP4004010MMPLASTIC536YESSUPPORTSIDEWEARSTRIP132PLASTIC301YESENDPLATE3925MM/SS188YESCOVERPLATE3916MMS/S157NOBENDPLATES825MM/SS129YESTORQUEARMBRACKET186MMS/SPLATE121YESSLOTCOVER97STAINLESSSTEEL097YESINSIDEBENDPLATE825MM/SS066YESTOTAL10000CRITICALPARTS4AREASOFIMPROVEMENTINORDERTOIDENTIFYTHEAREASOFCOSTREDUCTIONINMATERIALANDLABOUR,ACOSTANALYSISOFALLMAINCONVEYORPARTSWASCONDUCTEDTOESTIMATETHEPERCENTAGEOFCOSTOFEACHPARTINRELATIONTOTHETOTALCOSTOFALLSUCHPARTSTHEPURPOSEOFTHISANALYSISWASTOIDENTIFYTHECRITICALPARTS,WHICHAREMAINLYRESPONSIBLEFORINCREASINGTHECOSTOFTHECONVEYORANDTHEREBYINVESTIGATEMEANSFORREDUCINGTHECOSTOFSUCHPARTSTABLE1SHOWSTHECOSTANALYSISOFA50SECTIONCONVEYORSYSTEMTHEANALYSISREVEALSTHAT12OUTOF15PARTSCONSTITUTE79OFTHETOTALMATERIALCOSTOFTHECONVEYORSYSTEM,WHEREFURTHERIMPROVEMENTSINDESIGNTOREDUCETHECOSTISPOSSIBLEOUTOFTHESE,SEVENPARTSWEREIDENTIFIEDASCRITICALPARTSSHOWNBYANASTERISKINTABLE1CONSTITUTINGMAXIMUMNUMBEROFCOMPONENTSINQUANTITYANDCOMPRISINGOVER71OFOVERALLMATERIALCOSTAMONGTHESE,THREECOMPONENTSLEGSET,SIDEFRAMEANDSUPPORTCHANNELWEREFOUNDTOACCOUNTFOR50OFTHETOTALCONVEYORMATERIALCOSTADETAILEDANALYSISOFEACHOFTHESE12PARTSWASCARRIEDOUTCONSIDERINGTHEPRINCIPLESOFCONCURRENTENGINEERING,DESIGNFORMANUFACTUREANDDESIGNFORASSEMBLY,ANDANEWIMPROVEDDESIGNWASDEVELOPEDFOREACHCASE10DETAILSOFDESIGNIMPROVEMENTOFSOMESELECTEDMAJORCOMPONENTAREPRESENTEDBELOW5REDESIGNOFLEGSETASSEMBLYINACONVEYORSYSTEM,THELEGSAREMOUNTEDONTHESIDEFRAMETOKEEPTHEENTIRECONVEYORSYSTEMOFFTHEFLOORTHEEXISTINGDESIGNOFCONVEYORLEGSWORK,BUTTHEYARECOSTLYTOMANUFACTURE,THEYHAVESTABILITYPROBLEMS,ANDCAUSEDELAYSINDELIVERIESTHEDELAYISUSUALLYCAUSEDBYSOMEOFTHEPARTSNOTARRIVINGFROMOVERSEASSUPPLIERSONTIMETHEMOSTCRITICALSPECIFICATIONSREQUIREDFORTHECONVEYORLEGSARE554STRENGTHTOCARRYCONVEYORLOADSTABILITYEASEOFASSEMBLYEASEOFFLEXIBILITYFORADJUSTINGHEIGHTFIGURE2INDICATESALLTHEPARTSFORTHEEXISTINGDESIGNOFTHECONVEYORLEGTHEINDICATEDNUMBERSARETHEPARTNUMBERSDESCRIBEDINTABLE2,WHICHALSOSHOWSABREAKDOWNOFCOSTANALYSISCOMPLETEWITHTHELABOURTIMEREQUIREDTOASSEMBLEACOMPLETESETOFLEGSTHEEXISTINGLEGSETUPCONSISTSOFPLASTICLEGBRACKETSORDEREDFROMOVERSEAS,STAINLESSSTEELLEGTUBES,WHICHARECUTINTOSPECIFIEDSIZES,LEGTUBEPLASTICADJUSTMENTS,WHICHARECLIPPEDONTOTHELEGTUBEATTHEBOTTOMASSHOWNINFIG2LUGS,WHICHARECUTINSQUARESIZES,DRILLEDANDWELDEDTOTHELEGTUBETOBOLTTHEANGLECROSSBRACINGANDBACKINGPLATETOSUPPORTLEGBRACKETSBOLTSTHEOFPARTSINTABLE2SIGNIFIESTHENUMBEROFCOMPONENTSINEACHPARTNUMBERANDTHEQUANTITYISTHECONSUMPTIONOFEACHPARTINTHELEGDESIGNCOMPANIESHAVEUSEDTHISDESIGNFORMANYYEARSBUTONEOFTHECOMMONCOMPLAINTSREPORTEDBYTHECLIENTSWASOFTHEINSTABILITYOFLEGSFROMANINITIALINVESTIGATION,ITBECAMECLEARTHATTHECONNECTIONBETWEENTHESTAINLESSSTEELTUBEANDPLASTICLEGSBRACKETPARTFIG2EXISTINGLEGDESIGNASSEMBLYWITHPARTNAMESSHOWNINTABLE1TABLE2COSTANALYSISFOROLDLEGDESIGNASSEMBLYPARTNOPARTDESCRIPTIONOFPARTSQTYCOSTSOURCE1PLASTICLEGBRACKET223000OVERSEAS5,6LEGTUBEPLASTICADJUSTMENT422800OVERSEAS4LUG22400INHOUSE7ANGLECROSSBRACING11500INHOUSE2BACKINGPLATE22400INHOUSE3LEGTUBE222500INHOUSE8BOLTS66300INHOUSETOTALASSEMBLYCOSTWELDING1500INHOUSETOTAL1917114001ANDPART3INFIG2WASNOTRIGIDENOUGHTHECONNECTIONSFORTHESEPARTSAREONLYASINGLE6MMBOLTATTIMES,WHENTHECONVEYORSYSTEMWASCARRYINGFULLPRODUCTLOADS,ITWASOBSERVEDTHATTHECONVEYORLEGSWEREUNSTABLEANDCAUSEDMECHANICALVIBRATIONONEOFTHEMAINREASONSFORTHISWASDUETOASINGLEBOLTCONNECTIONATEACHENDOFTHELUGSINPART3ANDPART7THESTABILITYOFTHECONVEYORISCONSIDEREDCRITICALMATTERANDREQUIRESRECTIFICATIONIMMEDIATELYTOSATISFYCUSTOMEREXPECTATIONSCONSIDERINGTHEPROBLEMSOFTHEEXISTINGCONVEYORLEGDESIGNANDTHECLIENTSPREFERENCES,ANEWDESIGNFORTHECONVEYORLEGWASDEVELOPEDGENERALLYTHESTABILITYANDTHESTRENGTHOFTHELEGSWERECONSIDEREDASTHEPRIMARYCRITERIAFORIMPROVEMENTINTHENEWDESIGNPROPOSALBUTOTHERCONSIDERATIONSWERETHESIMPLICITYOFDESIGN,MINIMISATIONOFOVERSEASPARTSANDEASEOFASSEMBLYATTHEPOINTOFCOMMISSIONINGFIGURE3SHOWS,THENEWDESIGNOFTHECONVEYORSLEGASSEMBLY,ANDTABLE3GIVESADESCRIPTIONANDTHECOSTOFEACHPARTFIGURE3SHOWSTHATTHENEWDESIGNCONSISTSOFONLYFIVEMAINPARTSFORTHECONVEYORSLEGCOMPAREDTOEIGHTMAINPARTSINTHEOLDDESIGNINTHEOLDDESIGN,THEPLASTICLEGBRACKET,THELEGTUBEPLASTICADJUSTMENTANDTHELEGTUBEWERETHEMOSTEXPENSIVEITEMSACCOUNTINGFOR72OFTHECOSTOFLEGASSEMBLYINTHENEW555FIG3NEWDESIGNFORLEGASSEMBLYWITHPARTNAMESINTABLE3TABLE3COSTANALYSISFORNEWDESIGNLEGASSEMBLYPARTNOPARTDESCRIPTIONOFPARTSQTYCOSTSOURCE1STAINLESSSTEELANGLE50503MM222400INHOUSE3LEGPLASTICADJUSTMENT221000OVERSEAS4CROSSBRASSING11700INHOUSE5BOLTS84400INHOUSE2BACKINGPLATE22400INHOUSETOTALASSEMBLYCOST1000INHOUSETOTAL15115900DESIGN,THOSEPARTSHAVEBEENREPLACEDBYASTAINLESSSTEELANGLEANDANEWPLASTICLEGADJUSTMENTREDUCINGTHECOSTOFLEGASSEMBLYBYALMOST50THUSTHETOTALNUMBERSOFPARTSINTHELEGHAVEBEENREDUCEDFROM19TO15ANDTHETOTALCOSTPERLEGSETUPHASBEENREDUCEDBY55INTHENEWDESIGNTHENEWCONVEYORLEGDESIGN,WHENTESTED,WASFOUNDTOBEMORESECUREANDSTABLETHANTHEOLDDESIGNTHEELIMINATIONOFPARTNUMBER1AND5FROMOLDCONVEYORDESIGNHASMADETHENEWDESIGNMORESTABLEANDRIGIDINADDITION,THEWIDTHOFTHECROSSBRACINGHASALSOBEENINCREASEDWITHTWOBOLTSMOUNTINSTEADOFONEINOLDDESIGNTHISHASPROVIDEDTHEENTIRECONVEYORLEGSETUPANADDITIONALSTRENGTH6REDESIGNOFTHESIDEFRAMESTHESIDEFRAMEISTHEPRIMARYSUPPORTOFACONVEYORSYSTEMTHATPROVIDESPHYSICALSTRENGTHTOCONVEYORSANDALMOSTALLTHEPARTSAREMOUNTEDONITTHESIDEFRAMEISALSOEXPECTEDTOHAVEARIGIDSTRENGTHTOPROVIDESUPPORTTOALLTHELOADSCARRIEDONTHECONVEYORITALSOACCOMMODATESALLTHEASSOCIATEDCONVEYORCOMPONENTSFORTHEASSEMBLYTHECRITICALCONSIDERATIONSOFSIDEFRAMEDESIGNARESIZEOFSIDEFRAMEDEPTHSTRENGTHOFTHEMATERIALEASEFORASSEMBLYEASEFORMANUFACTURINGFIGURE4SHOWSTHESIDEFRAMEDIMENSIONANDPARAMETERSTHESIDEFRAMEUSEDINEXISTINGDESIGNAPPEARSTOBEOFREASONABLEDEPTHINSIZEDIMENSIONHINFIG4FROMTHEINITIALINVESTIGATION,ITWASFOUNDTHATTHEDISTANCEBETWEENSPACERBARHOLESANDRETURNSHAFTDIMENSIONSGANDFINFIG4COULDBEREDUCED,ASTHEREWASSOMEUNNECESSARYGAPBETWEENTHOSETWOCOMPONENTSTHEIMPORTANTPOINTTOCHECKBEFOREREDEFININGTHEDESIGNPARAMETERSWASTOMAKESURETHATAFTERBRINGINGTHOSETWOCLOSER,THERETURNCHAINSWOULDNOTCATCHTHESPACERBARWHILETHECONVEYORISRUNNINGTHEMODELOFTHENEWSIDEFRAMEDESIGNWASDRAWNONCADTOENSUREALLTHESPECIFICATIONSARESOUNDANDTHEPARTSAREPLACEDINTHEPOSITIONTOCHECKTHECLEARANCESANDTHEFITSUSINGTHEPRINCIPLEOFDESIGNFORMANUFACTURINGTHENEWSIDEFRAMEDESIGNWASMADESYMMETRICALSOTHATITAPPLIESTOALLTYPESOFSIDEFRAMESTHISCHANGEISEXPECTEDTOREDUCETHESIZEOFSIDEFRAMESIGNIFICANTLYFORALLSIZESOFCHAINSTABLE4SHOWSACOMPARISONOFDIMENSIONSINTHEOLDDESIGNANDTHENEWDESIGNOFSIDEFRAMESFORTHESAMECHAINTYPEIT556FIG4SIDEFRAMEDIMENSIONSTABLE4NEWANDOLDSIDEFRAMEDIMENSIONPARAMETERSOLDDESIGNCHAINTYPEABCDEFGHIJKL325PRIMEPRIMELF/SSSTR/LBP/MAG319271196651052112411365885196TAB2283621875696202232127NEWDESIGNCHAINTYPEABCDEFGHIJKL325PRIMEPRIMELF/SSSTR/LBP/MAG/TAB311007317367107167199925885152ISNOTEDTHATTHEOVERALLSIZEDEPTHOFTHECONVEYORHASBEENREDUCEDFROM241MMTO199MMDIMENSIONH,WHICHGIVESASAVINGOF42MMOFSTAINLESSSTEELONEVERYSIDEFRAMEMANUFACTUREDTHUS,FROMASTAINLESSSTEELSHEET15003000MM,THEOLDDESIGNPARAMETERSALLOWEDONLYSIX3MLONGSIDEFRAMESBUTWITHTHENEWDESIGNPARAMETERNOWITWASPOSSIBLETOPRODUCESEVENSIDEFRAMESOF3MLONGFROMTHESAMESHEETSIZETHEAMOUNTOFMATERIALUSEDFORSIDEFRAMESWASALSOREVIEWEDFORFURTHERINVESTIGATIONITISESTIMATEDTHATABOUT55OFTHETOTALCOSTOFTHECONVEYORSYSTEMISSPENTONMATERIALSTHECURRENTMATERIALUSEDFORSIDEFRAMESIS25MMTHICKSTAINLESSSTEELFOODGRADE304CURRENTLY,THEREAREOTHERMATERIALSAVAILABLEINTHEMARKETWITHALTERNATIVETHICKNESSTHATCOULDBECONSIDEREDASANOPTIONFORTHIS,ADEFLECTIONANALYSISHASBEENCONDUCTEDTOESTIMATEIFTHEREWASANYOTHERTYPEOFMATERIALSUITABLETOREPLACETHEEXISTINGMATERIALSOTHATITDOESNOTFAILITSSTRENGTHCRITERIA61DEFLECTIONANALYSISFORSIDEFRAMESFIGURE5SHOWSTHEEXPERIMENTALSETUPTODETERMINETHEDEFLECTIONOFNEWSIDEFRAMEINXANDYDIRECTIONUNDERDIFFERENTLOADINGCONDITIONSWITHTHENEWDESIGNPARAMETERSASETOFSIDEFRAMESWEREMANUFACTUREDTOINVESTIGATETHEDEFLECTIONON16MMTHICKSTAINLESSSTEELSIDEFRAMESASECTIONOFSIDEFRAMEBOLTEDWITHSPACERBARANDRETURNSHAFTWASASSEMBLEDFORTESTINGWITHTHEEXPERIMENTTHERESULTSFORDEFLECTIONWEREOBTAINEDBYAPPLYINGVARIABLELOADSONASECTIONOFTHESIDEFRAMEVIAAHYDRAULICPRESSASSHOWNINFIG5,THEDEFLECTIONGAUGESAREPLACEDONVERTICALYANDHORIZONTALXAXESTOMEASUREANYREADINGOBSERVEDONTHESIDEFRAMESTHELOADSAREAPPLIEDONSIDEFRAMEVIATHEHYDRAULICPRESSINDOWNWARDDIRECTIONTHESIDEFRAMESARESUPPORTEDBYSTANDSFROMTHESAMEPOSITIONWHERETHELEGSAREMOUNTEDONTHESIDEFRAMESTHREESETSOFEXPERIMENTSARECONDUCTEDONFOUR,SIXANDEIGHTTRACKSOFCONVEYORSECTIONSTOOBSERVEANYABNORMALITIESUNDERBIGLOADSTHELOADSAPPLIEDONTHEEXPERIMENTALCONVEYORSECTIONSAREOVERESTIMATEDANDAREHIGHERTHANACTUALLOADCONDITIONSFORCONVEYORSYSTEMINREALAPPLICATIONSTHECONVEYORSAREUSUALLYDESIGNEDTOCARRYLOADUNDERONETONNEPERMETREFORINDUSTRYAPPLICATIONINTHEFOODANDBEVERAGEINDUSTRYTHEPURPOSEOFAPPLYINGABIGLOADWASTOESTIMATETHEPOINTOFDEFLECTIONFORSIDEFRAMEUNDERHIGHLOADSFIGURES6AND7SHOWTHERESULTSOFTHEEXPERIMENTSFORTHECONVEYORSECTIONSOFFOURTRACKSANDSIXTRACKS,RESPECTIVELYFROMTHERESULTSOBTAINED,ITISOBSERVEDTHATUNDER2KNOFLOADS,THEDEFLECTIONVALUESAREALMOSTUNDER2MMFORALLFIG5EXPERIMENTALSETUPTOINVESTIGATEDEFLECTIONONNEWSIDEFRAMEDESIGN557FIG6DEFLECTIONRESULTSFOR4TRACK16MMSTAINLESSSTEELSIDEFRAMEFIG7DEFLECTIONRESULTSFOR6TRACK16MMSTAINLESSSTEELSIDEFRAMETYPESOFSECTIONSUNDERTHEGIVENCIRCUMSTANCES,THE16MMSTAINLESSSTEELSIDEFRAMEDESIGNCANBEAPOSSIBLEALTERNATIVETOTHEEXISTINGCONVEYORSIDEFRAMEDESIGNITISEXPECTEDTHATWITHWIDERCONVEYORSECTIONS,THEDEFLECTIONSONSIDEFRAMEWILLSTAYWITHINTHEALLOWABLELIMITS,THATIS,5MMTHEMAINREASONWHYTHISEXPERIMENTWASCONDUCTEDISTOENSURETHATTHESIDEFRAMESDONOTBUCKLEUNDERHIGHLOADSTHUSTHEREWASNOEVIDENCEOFBUCKLINGOCCURRENCEFORANYOFTHETYPESOFCONVEYORSECTIONSUSEDITISALSOEXPECTED,BASEDONTHEEXPERIENCESOFENGINEERSANDTHEINVESTIGATIONDURINGTHECURRENT

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号