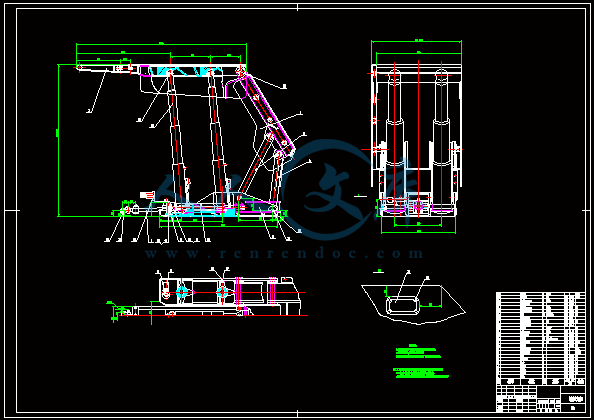

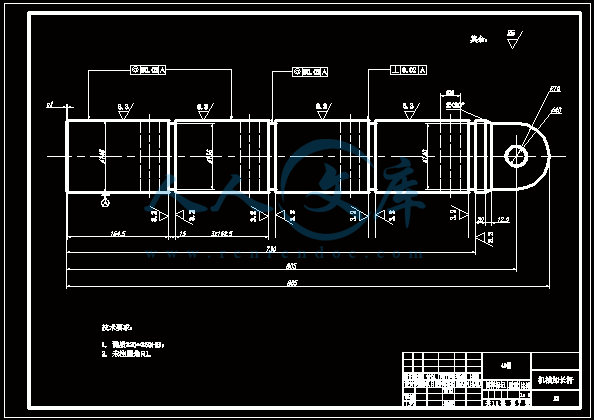

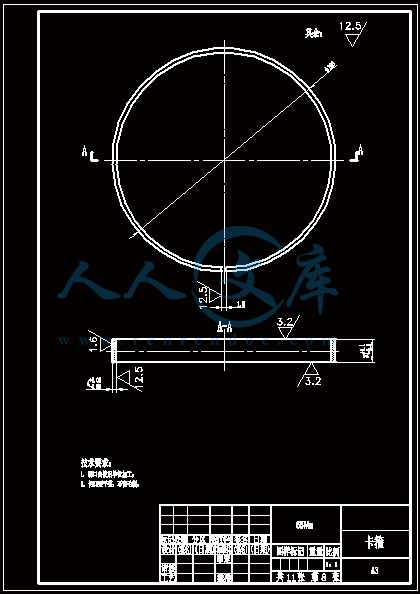

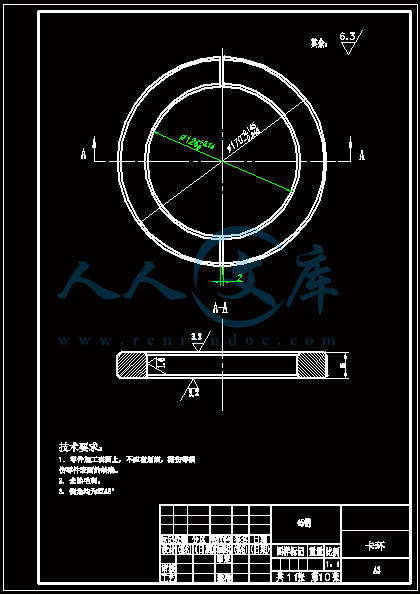

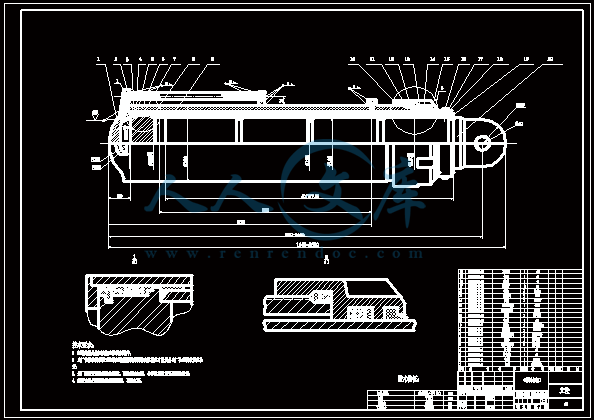

低位放顶煤液压支架的设计(全套含CAD图纸)

收藏

资源目录

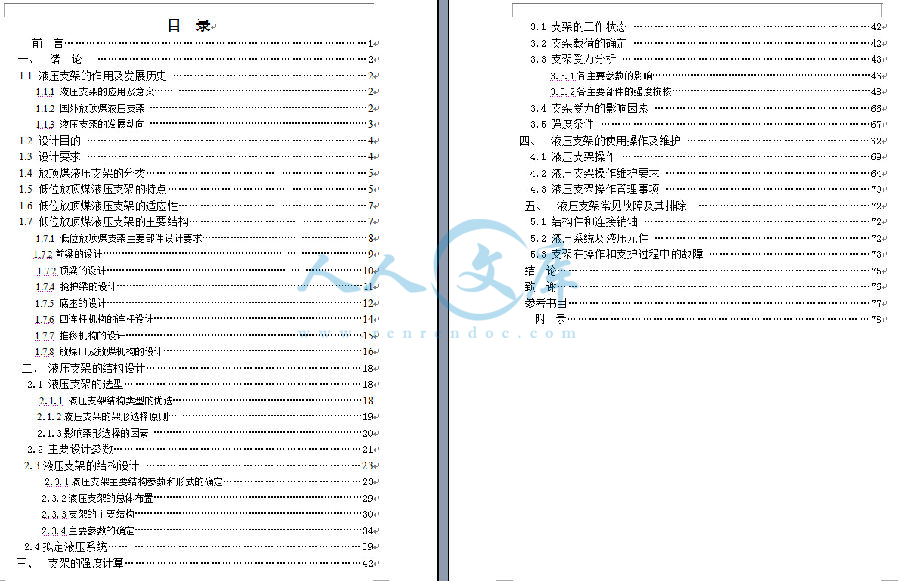

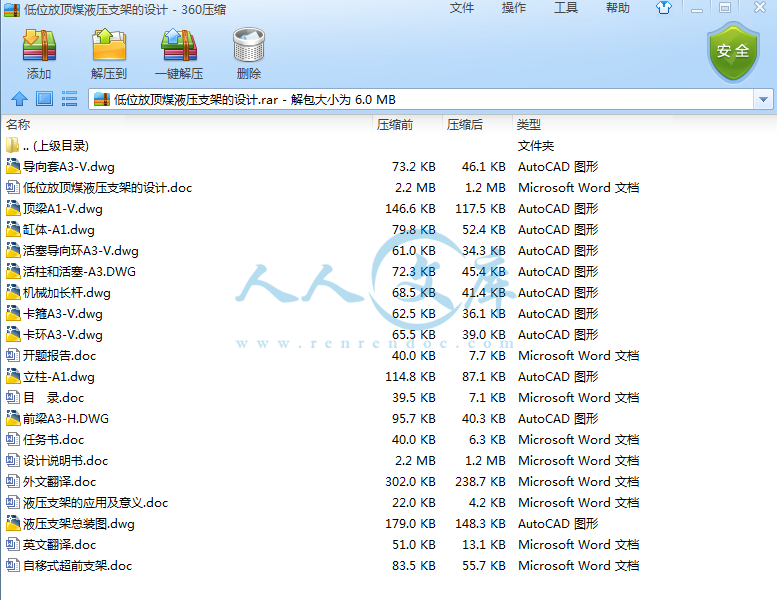

压缩包内文档预览:

编号:9644670

类型:共享资源

大小:3.59MB

格式:ZIP

上传时间:2018-03-19

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

低位

放顶煤

液压

支架

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

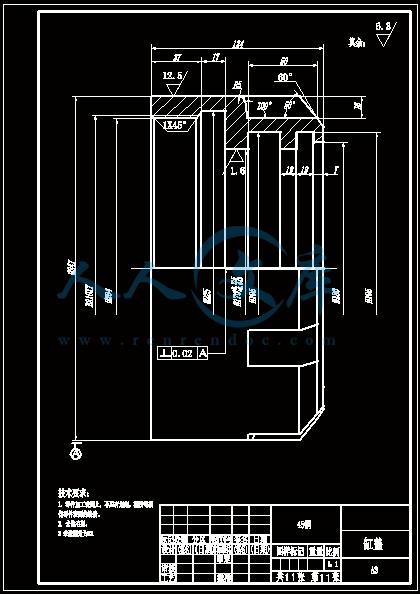

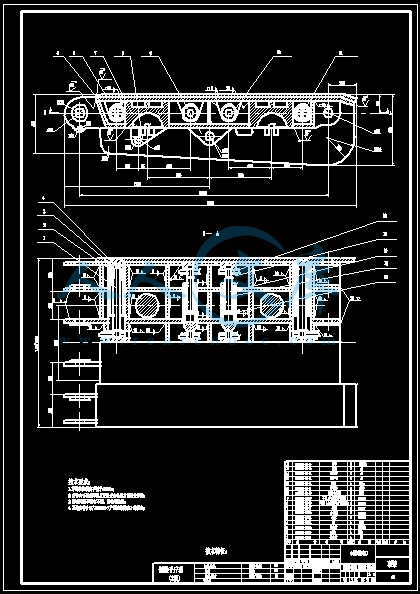

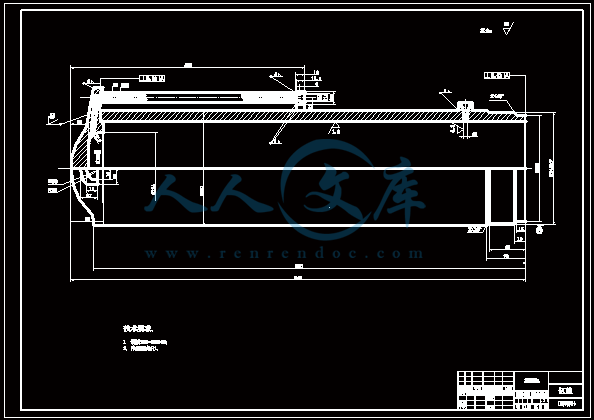

英文原文POWEREDSUPPORTSPOWEREDROOFSUPPORTSAREUSEDTOSUPPORTTHEROOFATTHEFACETHEYWORKINSEVERALSTEPSMOSTLYINTHEIMMEDIATEFORWARDSUPPORTIFSTYPEINORDERTOSUPPORTTHENEWLYEXPOSEDROOFASSOONASPOSSIBLEINNORMALSUPPORTINGCONDITIONTHECANOPYOFTHESUPPORTISSETTIGHTLYAGAINSTTHEROOFSTRATA,BYTHESUPPORTINGRESISTANCESOFTHEHYDRAULICLEGSWHENTHECUTTINGMACHINECUTSANDPASSESSEVERALSUPPORTUNITSBEYONDTHESUPPORTINQUESTION,THESUPPORTLEGSARELOWEREDANDPULLEDFORWARDFORADISTANCEEQUALTOTHEWIDTHOFCUTWEBBYRETRACTINGTHEHYDRAULICADVANCINGRAMTHEADVANCINGRAMACTSAGAINSTTHEFACECONVEYORPANLINE,WHOSEPOSITIONISHELDUNCHANGEDBYTHEADVANCINGRAMS,FORCESOFTHESUPPORTSTHATARESETONBOTHSIDESOFTHESUPPORTTOBEADVANCEDASSOONASTHESUPPORTHASBEENADVANCEDTOTHEDESIGNEDPOSITION,THESUPPORTISIMMEDIATELYRESETAGAINSTTHEROOFFINALLY,THEADVANCINGRAMOFTHESUPPORTINQUESTIONISEXTENDEDTOPUSHTHECONVEYORFORWARDANDBECOMESREADYFORTHENEXTCUTTHESEQUENTIALSTEPSDESCRIBEDAREFORTHEADVANCEOFANINDIVIDUALSUPPORTINTHEDIRECTIONPERPENDICULARTOTHEFACELINEBUTALONGTHEFACELINEDIRECTION,THECONVEYORCANNOTBEADVANCEDINASHARPSTEPIMMEDIATELYAFTERTHESHEARERHASPASSEDIT,DUETOTHERIGIDITYOFTHEPANLINETHUSTHEFOURTHSTEPISUSUALLYSOMETIMEAFTERTHESHEARER,SPASS,RESULTINGINACURVEDORSNAKEDSECTIONDURINGPANELDEVELOPMENTTHEPANELENTRIESAREROOFBOLTEDASUSUALBUTINTHETAILENTRYONEORTWOROWSOFCRIBSAREERECTEDTOSUPPLEMENTTHEROOFBOLTINGDURINGRETREATINGMINING,THEROOFATTHEHEADENTRYTJUNCTIONAREAUPTO500FT152MOUTBYTHEFACEISGENERALLYREINFORCEDWITHSUPPORTSOFSOMETYPETOINCREASESUPPORTDENSITYTOCOPEWITHTHEMOVINGFRONTANDSIDEABUTMENTPRESSURESMODERNLONGWALLMININGEMPLOYSHYDRAULICPOWEREDSUPPORTSATTHEFACEAREATHESUPPORTSNOTONLYHOLDSUPTHEROOF,PUSHESTHEFACECHAINCONVEYORAFC,ANDADVANCESITSELF,BUTALSOPROVIDESASAFEENVIRONMENTFORALLASSOCIATEDMININGACTIVITIESTHEREFOREITSSUCCESSFULSELECTIONANDAPPLICATIONARETHEPREREQUISITEFORSUCCESSFULLONGWALLMININGFURTHERMORE,DUETOTHELARGENUMBEROFUNITSREQUIRED,THECAPITALINVESTEDFORTHEPOWERSUPPORTUSUALLYACCOUNTSFORMORETHANHALFOFTHEINITIALCAPITALFORALONGWALLFACETHEREFOREBOTHFROMTECHNICALANDECONOMICPOINTSOFVIEW,THEPOWEREDSUPPORTISAVERYIMPORTANTPIECEOFEQUIPMENTINALONGWALLFACECLASSIFICATIONOFPOWEREDSUPPORTSTHEAPPLICATIONOFMODERNPOWEREDSUPPORTSCANBETRACEDBACKTOEARLY1950SSINCETHEN,FOLLOWINGITSADOPTIONINEVERYPARTOFTHEWORLD,THEREHAVEBEENCOUNTLESSMODELSDESIGNANDMANUFACTUREDINVARIOUSCOUNTRIESBUTUNFORTUNATELY,THERESTILLISNOUNIFORMSYSTEMOFCLASSIFICATIONINTHISSECTIONASIMPLIFIEDCLASSIFICATIONISUSEDSINCEAPOWEREDSUPPORTCONSISTSOFFOURMAJORCOMPONENTSIE,CANOPY,CAVINGSHIELD,HYDRAULICLEGSANDPROPS,ANDBASEPLATE,THEWAYSBYWHICHTHEYAREINTERRELATEDAREUSEDFORCLASSIFICATIONINTHISRESPECT,TWOFACTORSAREMOSTIMPORTANTAPRESENCEORABSENCEOFCAVINGSHIELDIFACAVINGSHIELDISINCLUDED,THESUPPORTISA“SHIELD”TYPE,OTHERWISE,AFRAMEORACHOCKBNUMBERANDTYPEOFARRANGINGTHEHYDRAULICLEGSSINCESUPPORTCAPACITYISGENERALLYPROPORTIONALTONUMBEROFHYDRAULICLEGS,ITISIMPORTANTTOSPECIFYTHENUMBEROFHYDRAULICLEGSTHATASUPPORTHASFURTHERMORE,THEWAYTHEHYDRAULICLEGSAREINSTALLEDISIMPORTANTFOREXAMPLE,AVERTICALINSTALLATIONBETWEENTHEBASEANDTHECANOPYHASTHECAVINGSHIELDHASTHELEASTEFFICIENCYINSUPPORTINGTHEROOFBASEDONTHISCONCEPT,THEREAREFOURTYPESOFPOWEREDSUPPORT,THATIS,THEFRAME,CHOCK,SHIELDANDCHOCKSHIELD,INORDEROFEVOLUTIONOFTHEIRDEVELOPMENTHOWEVER,ITMUSTBENOTEDTHATTHETRENDOFDEVELOPMENTINEACHTYPEISSUCHTHATITBECOMESLESSDISTINGUISHABLEINTERMSOFAPPLICATIONTHEFOURTYPESOFROOFSUPPORTSCANBEOBTAINEDFOREITHERLONGWALLRETREATINGORADVANCINGSYSTEMS,ANDTHEYAREAVAILABLEINSTANDARD,ONEWEBBACK,ANDIMMEDIATEFORWARDSUPPORTIFSVERSIONSWITHTHESTANDARDSYSTEM,THEWININGMACHINETAKESACUTORASLICE,ANDTHEARMOREDFACECONVEYORISPUSHEDOVERBYTHEHYDRAULICRAMSTHATAREFIXEDTOTHESUPPORTUNITSTHESUPPORTUNITSTHENAREADVANCEDSEQUENTIALLYTOTHECONVEYORWITHTHEONEWEBBACKSYSTEM,ASUPPORTISSETBACKFROMTHECONVEYORBYADEVICETHATAUTOMATICALLYKEEPSTHELEADINGEDGEOFTHESUPPORTATAFIXDISTANCEFROMTHECONVEYORTHISALLOWSEASYACCESSTHOUGHTHEFACEANDEMPLOYSTHESTANDARDMETHODOFADVANCINGIE,PUSHINGTHECONVEYORFIRST,ANDTHENADVANCINGTHESUPPORTWITHTHEIFSSYSTEM,THESUPPORTUNITSISADVANCEDTOTHECONVEYORIMMEDIATELYAFTERTHECUTTINGMACHINEHASPASSED,ANDTHEFORWARDCANOPYOFTHESUPPORTUNITSISLONGENOUGHTOTHESUPPORTBOTHTHERECENTLYANDNEWLYEXPOSEDROOFSECTIONSAFTERTHESUPPORTSHAVEBEENADVANCED,THECONVEYORISPUSHEDOVERFRAMETHEFRAMESUPPORTISANEXTENSIONOFTHESINGLEHYDRAULICPROPSCONVENTIONALLYUSEDUNDERGROUNDTHUSITISTHEFIRSTTYPEDEVELOPEDINMODERNSELFADVANCINGHYDRAULICPOWEREDSUPPORTSITINVOLVESSETTINGUPTWOHYDRAULICPROPSORLEGSVERTICALLYINTANDEMTHATARECONNECTEDATTHETOPBYASINGLEORTWOSEGMENTEDCANOPIESTHETWOSEGMENTEDCANOPIESCANBEHINGEJOINTEDATANYPOINTBETWEENTHELEGSORINFRONTOFTHEFRONTLEGTHEBASEOFTHETWOHYDRAULICLEGSMAYBEACIRCULARSTEELSHOEWELDEDATBOTTOMOFEACHLEGORSOLIDBASECONNECTINGBOTHLEGSGENERALLY,AFRAMESUPPORTCONSISTSOFTWOORTHREESETSOFHYDRAULICLEGSTHESETMOVINGFIRSTISTHESECONDARYSET,THESETMOVINGLATERISTHEPRIMARYSETTHEREISADOUBLEACTINGRAMINSTALLEDBETWEENEACHSETTHEPISTONOFTHERAMISCONNECTEDTOTHESECONDARYSETANDTHECYLINDERTOTHEPRIMARYSETDURINGSUPPORTADVANCE,THEPRIMARYSETISSETAGAINSTTHEROOFWHILETHESECONDARYSETISLOWEREDANDPUSHEDFORWARDBYTHEPISTONHAVINGREACHEDTHENEWPOSITION,THESECONDARYSETISAGAINSTTHEROOFWHILETHEPRIMARYSETISLOWEREDANDPULLEDFORWARDBYTHECYLINDERTHEDISTANCEOFEACHADVANCERANGESFROM20TO36IN050091MTHEFRAMESUPPORTISVERYSIMPLE,BUTMOREFLEXIBLEORLESSSTABLESTRUCTURALLYTHEREARECONSIDERABLEUNCOVEREDSPACESBETWEENTHETWOPIECESOFCANOPYWHICHALLOWSBROKENROOFROCKTOFALLTHROUGHCONSEQUENTLY,THEFRAMESUPPORTISNOTSUITABLEFORAWEAKROOFFRAMESHAVEBECOMESELDOMUSEDBECAUSETHEYARELESSSTABLEANDREQUIREFREQUENTMAINTENANCECHOCKINACHOCKSUPPORT,THECANOPYISASOLIDPIECEANDTHEBASEMAYBEEITHERASOLIDORPIECEORTWOSEPARATEPARTSCONNECTEDBYSTEELBARSATTHEREARAND/ORTHEFRONTENDSINBOTHCASESALARGEOPENSPACEISLEFTATTHECENTERFORLOCATINGTHEDOUBLEACTINGHYDRAULICRAMWHICHISUSEDTOPUSHANDPULLTHECHAINCONVEYORANDTHECHOCKINAWHOLEUNIT,RESPECTIVELY,ADISTINCTIVEDIFFERENCEFROMTHEFRAMESUPPORTTHISSETUPISALSOUSEDINTHESHIELDSANDCHOCKSHIELDSAGAIN,ALLHYDRAULICLEGSAREINSTALLEDVERTICALLYBETWEENTHEBASEANDTHECANOPYTHENUMBEROFLEGSRANGESFROMTHREETOSIX,BUTTHEFOURLEGCHOCKSAREBYFARTHEMOSTPOPULARONESTHESIXLEGCHOCKSAREDESIGNEDFORTHINSEAMSWITHTWOLEGSINTHEFRONTANDFOURLEGSINTHEREAR,SEPARATEDBYAWALKWAYFORTHESIXLEGCHOCKS,THECANOPYISGENERALLYHINGEJOINTEDABOVETHEWALKWAYMOSTCHOCKAREALSOEQUIPPEDWITHAGOBWINDOWHANGINGATTHEREARENDOFTHECANOPYTHEGOBWINDOWCONSISTSOFSEVERALRECTANGULARSTEELPLATESCONNECTEDHORIZONTALLYATBOTHENDSINMOSTCHOCKSUPPORTS,THEREAREHINGEJOINTCONNECTIONSBETWEENTHELEGSANDTHECANOPYANDBETWEENTHELEGSANDTHEBASEBUTINORDERTOINCREASETHELONGITUDINALSTABILITY,ITISREINFORCEDMOSTLYWITHABOXSHAPEDSTEELFRAMEBETWEENTHEBASEANDEACHLEGALEGRESTORINGDEVICEISINSTALLEDAROUNDEACHLEGATTHETOPOFTHEBOXSHAPEDSTEELFRAMETHECHOCKSARESUITABLEFORMEDIUMTOHARDROOFWHENTHEROOFOVERHANGSWELLINTOTHEGOBANDREQUIRESINDUCEDCAVING,THECHOCKSCANPROVIDEACCESSTOTHEGOBSHIELDSHIELDS,ANEWENTRYINTHEEARLYSEVENTIES,ARECHARACTERIZEDBYTHEADDITIONOFACAVINGSHIELDATTHEREARENDBETWEENTHEBASEANDTHECANOPYTHECAVINGSHIELDS,WHICHINGENERALAREINCLINED,AREHINGEJOINTEDTOTHECANOPYANDTHEBASEMAKINGTHESHIELDAKINEMATICALLYSTABLESUPPORT,AMAJORADVANTAGEOVERTHEFRAMESANDTHECHOCKSITALSOCOMPLETELYSEALSOFFTHEGOBANDPREVENTSROCKDEBRISFROMGETTINGINTOTHEFACESIDEOFTHESUPPORTTHUSTHESHIELDSUPPORTEDFACEISGENERALLYCLEANTHEHYDRAULICLEGSINTHESHIELDSAREGENERALLYINCLINEDTOPROVIDEMOREOPENSPACEFORTRAFFICBECAUSETHECANOPY,CAVINGSHIELD,ANDBASEAREINTERCONNECTED,ITCANWELLRESISTTHEHORIZONTALFORCEWITHOUTBENDINGTHELEGSTHUS,UNLIKETHESOLIDCONSTRAINTINTHEFRAME/CHOCKSUPPORTS,THEPINCONNECTIONSBETWEENTHELEGSANDTHECANOPY,ANDBETWEENTHELEGSANDTHEBASEINASHIELDSUPPORTMAKEITPOSSIBLETHATTHEANGLEOFINCLINATIONOFTHEHYDRAULICLEGSVARIESWITHTHEMININGHEIGHTSSINCEONLYTHEVERTICALCOMPONENTOFHYDRAULICLEGPRESSUREISAVAILABLEFORSUPPORTINGTHEROOF,THEACTUALLOADINGCAPACITYOFTHESHIELDALSOVARIESWITHTHEMININGHEIGHTSTHEREAREMANYVARIATIONSOFTHESHIELDSUPPORTSINTHEFOLLOWING,SIXITEMSAREUSEDTOCLASSIFYTHESHIELDS,WHICHENABLESAUNIFIEDTERMINOLOGYTOBEDEVELOPEDFORALLKINDSOFSHIELDSTHETYPESOFMOTIONALTRACESOFTHECANOPYTIP,LEGPOSITIONSANDORIENTATION,NUMBEROFLEGS,CANOPYGEOMETRY,ANDOTHEROPTIONALDESIGNSANDDEVICESCANBECLEARLYSPECIFIEDBYTHETERMINOLOGYTYPESOFMOTIONALTRACESFORTHELEADINGEDGEOFTHECANOPYTHISISTHEMOSTCOMMONLYRECOGNIZEDWAYOFCLASSIFYINGTHESHIELDBASEDONTHISCRITERION,THEREARETHREETYPES,LEMNISCATE,CALIPER,ANDELLIPSELEMNISCATETHISISTHEMOSTPOPULARTYPETHECAVINGSHIELDANDTHEBASEAREJOINTEDBYTWOLEMNISCATEBARSWHICHHAVEATOTALOFFOURHINGESASTHEHYDRAULICLEGSARERAISEDANDLOWERED,THEDIMENTIONSOFTHELEMNISCATEBARSARESELECTEDSUCHTHATTHELEADINGEDGEOFTHECANOPYMOVESUPANDDOWNNEARLYVERTICALLY,THUSMAINTAININGANEARLYCONSTANTUNSUPPORTEDDISTANCEBETWEENTHEFACELINEANDTHELEADINGEDGEOFTHECANOPYTHISISAFEATURETHATISWIDELYCONSIDEREDMOSTDESIRABLEFORGOODROOFCONTROLTHEREARECLEARLIMITSOFMININGHEIGHTWITHINWHICHTHELEADINGEDGEOFTHECANOPYMOVESNEARLYVERTICALLYTHESELIMITSARESTRICTLYCONTROLLEDBYTHEDIMENTIONALANDPOSITIONALARRANGEMENTSOFTHECANOPY,CAVINGSHIELD,LEMNISCATEBARS,ANDTHEBASEBEYONDTHESELIMITS,THEEDGESWILLMOVERAPIDLYAWAYFROMTHEFACELINECREATINGALARGEUNSUPPORTEDAREACALIPERINACALIPERSHIELD,THECAVINGSHIELDANDTHEBASEARECONNECTEDBYASINGLEHINGEWHENTHEHYDRAULICLEGSARERAISED,THELEADINGEDGEOFTHECANOPYMOVESINANARCAWAYFROMTHEFACE,THUSINCREASINGTHEUNSUPPORTEDAREATHISISCONSIDEREDBYMOSTUSERSTHELEASTDESIRABLEFEATUREOFTHECALIPERSHIELDBUTINPRACTICEIFTHESEAMTHICKNESSVARIESLITTLE,THEDIMENTIONALANDPOSITIONALARRANGEMENTOFCANOPY,CAVINGSHIELD,ANDTHEBASECANBESODESIGNEDTHATTHEDISTANCECHANGEOFUNSUPPORTEDAREAWILLNOTBESIGNIFICANTONTHEOTHERHAND,WHENTHELEGSARELOWERED,ITREDUCESTHEUNSUPPORTEDAREAELLIPSEINTHISTYPETHECAVINGSHIELDANDTHEBASEARESOCONNECTEDTHATWHENTHEHYDRAULICLEGSAREMOVEDUPANDDOWN,THELEADINGEDGEOFTHECANOPYFOLLOWSANELLIPTICALTRACETHISTYPEISSELDOMUSEDCHOCKSHIELDTHECHOCKSHIELDCOMBINESTHEFEATURESOFTHECHOCKSANDTHESHIELDSASSUCHITPOSSESSESTHEADVANTAGESOFBOTHIFALLOFTHEFOURORSIXLEGSAREINSTALLEDBETWEENTHECANOPYANDTHEBASE,ITISCALLEDACHOCKSHIELDTHEREAREREGULARFOURORSIXLEGCHOCKSHIELDSINWHICHALLLEGSAREVERTICALANDPARALLELOTHERSFORMVORXSHAPESSOMECANOPIESAREASINGLEPIECEANDSOMEARETWOPIECESWITHAHYDRAULICRAMATTHEHINGEJOINTTHECHOCKSHIELDHASTHEHIGHESTSUPPORTINGEFFICIENCYTHEYARESUITABLEFORHARDROOFCOMMONELEMENTSOFPOWEREDSUPPORTSTHEMODERNPOWERDSUPPORTS,REGARDLESSOFTHETYPES,CONSISTOFTHEFOLLOWINGFIVECOMMONCOMPONENTS1LOADBEARINGUNITSTHESEINCLUDETHECANOPY,BASEPLATE,CAVINGSHIELD,LEMNISCATEBARS,ANDJOINTPINS2HYDRAULICRAMSTHESEINCLUDETHEHYDRAULICRAMSFORAPUSHINGTHECHAINCONVEYORANDADVANCINGTHEPOWEREDSUPPORT,BOPERATINGTHEFRONTCANOPYORFACEGUARDS,CBALANCINGORLIMITINGTHEPOSITIONOFTHECANOPY,ANDDOPERATINGOTHERAUXILIARYEQUIPMENTSUCHASLEGRECOVERINGDEVICESANDSIDESHIDEDS,ANDABOVEALL,OPERATINGTHELEGS3CONTROLANDOPERATINGUNITSTHESEINCLUDEINTERNALCONTROLVALVESSUCHASCHECKANDYIELDVALVESINTHEHYDRAULICLEGS,UNITCONTROLVALVE,ANDHIGHPRESSUREHYDRAULICTUBINGS4AUXILIARYDEVICESTHESEINCLUDESUPPORTADVANCING,LEGRECOVERING,GOBWINDOWS,FACEGUARDS,BASELIFTING,LIGHTING,ANDSOON5HYDRAULICFLUIDTHISISTHEEMULSIONFOROPERATINGTHEPOWEREDSUPPORTS中文译文液压支架液压支架被用来支护工作面顶板。他们在立即前移支护系统里通常从事以下几步工作,为了尽可能快地支撑新暴露空间。在正常的支撑重要条件下,支架的顶梁是通过立柱的支撑阻力紧紧地靠着来阻止顶板岩层。当切割和通过几个支撑单位超过支架时,立柱降柱和向前移动一段距离,通过液压推进油缸的缩回来达到与切割的深度相等。推进油缸靠在工作面输送镏槽上,它的位置是通过支架的推进油缸的推进力来保持不变,作用在支架的两边。支架一推进到设计的位置,支架就立即重新靠在顶板上。最后,支架的推力油缸试图向前推进输送机和为下一次切割做准备。描述的顺序步骤就是为了单个支架的推移,在方向上要垂直于工作线。但是沿着工作线的方向,在采煤机通过输送机之后,输送机不会立即推移很大一段距离,由于镏槽的刚性。因此第四步通常是在采煤机通过之后的一段时间,导致了弯曲或矩形的方向。在采区推进期间,镏槽向导通常是锚杆支架。但是在尾部巷道一排或两排垛子被支撑去辅助顶板螺栓。在后退式采煤期间,在下顺槽T型接口的顶板(伸出工作面的距离达到了152M)一般是通过某些类型的支架来进行加固,以提高支护密度来处理向前移动和向旁边移动的支座压力。现代长壁采煤工作面使用自移式液压支架(这种支架在这本书中通常被称为液压支架)。液压支架不仅支撑顶板,推移工作面刮板输送机,和它自己的移动前进,而且为了所有相互联系的采煤活动提供安全的环境。因而液压支架成功的选择和应用是长壁开采成功的选择和应用是长壁开采成功的前提条件。此外,由于需要大量的液压支架,为液压支架所投入的资金通常超过为长壁工作面所投入的初期资金的一半。因而从技术和经济两方面观点看,液压支架是长壁工作面非常重要的设备。液压支架的分类现代液压支架的使用可以追溯到20世纪50年早期。自从那时起,随着液压支架在世界上的应用,在不同的国家已经有了不计其数的设计模型和不计其数的液压支架被制造。但是不幸的是液压支架仍然没有一致的分类体系。在这一段一个简化的分类被使用。液压支架是由四大主要部分组成(顶梁、掩护梁、立柱和底座)。这些组成部分的使用是相互联系的,为了便于分类。在这一方面,两个因素是最重要的(A)是否存在掩护梁如果包括掩护梁,那么这种支架就是掩护型的,否则它就是节式或垛式支架;(B)立柱的数量和类型立柱的负载量通常与立柱的数量成正比例,因而确定支架的立柱数量是重要的。此外,立柱被安装的方式是重要的;例如,在支护顶板方面,在顶梁和底座之间垂直的安装立柱有最高的应用效率然而在底座和掩护梁之间倾斜的安装立柱却有着最低的效梁。根据这个概念,有四种类型匠液压支架,那就是,节式,垛式,掩护式和支撑掩护式,随着他们的发展演变而来的。然而,必须强调的是每种类型的发展趋势都是为了在应用方面让液压支架变的容易区分。这四种类型的液压支架不仅可以用于后退式长壁回采工作面和前进式开采工作面,还可以用于标准方式、滞后支护方式和即时支护方式。对于标准支护方式,采煤机作切割或分段运动,工作面输送机由装在液压支架上的推移千斤顶推动前进。液压支架比输送机先移动。对于滞后式支护方式,支架不可能靠近输送机,因为有一个装置自动的使支架前端与输送机保持一定的距离。这就要求要有贯穿工作面的缓沟,并且采用前进式标准支护,比如先推动刮板输送机,然后再让液压支架前进。对于即时支护方式,液压支架在截煤机过去之后立即跟随刮板输送机前进,液压支架前面的顶板有足够的长度来支护采过和将要采的顶板部分。在液压支架前进以后,刮板输送机也被推移前进。节式支架节式支架是通常使用在地下的单体液压支柱的扩展。因此节式支架是在现代自移式液压支架中发展出的第一种类型的液压支架。它包含两排串列的液压支柱,在顶部由单个或两个扇形顶梁所连接。两个扇形顶梁可以在两个立柱之间或前柱的前面以任意的角度铰接。两个液压支柱的底座可能是一个环形的钢铁滑必履焊接在每个立柱的底部或整个底座连接两个立柱。如果钢铁滑履被使用,那么弹簧板连接着立柱就用来提高稳定性。通常节式支架包含两排或三排立柱。首先移动的那排立柱是辅助的立柱,后来移动的是主要的立柱。有一个双作用油缸安装在每排立柱之间。油缸的活塞连接到了辅助立柱上,气缸连接到了主要立柱上。在支架推移期间,主要立柱支撑顶板而辅助立柱是低的并且通过活塞向前推。达到了新的位置时,辅助立柱支撑顶板而主要立柱是低的并且通过气缸向前推。每次前移的距离是在20到36英寸之间。因此节式支架是非常简单的,不仅不是更加的灵活而且结构上不稳固。在两块顶梁之间有相当大的地方,不允许破落的顶板石块落在那里。因此,节式支架不适合用在支撑力弱的顶板上。节式支架已经变的极少使用因为它们不稳固而且需要经常维修。垛式支架在垛工支顶架里,顶梁是一整块和底座可能是一整块也可能是由后端梁和前端梁上的钢铁杆连接的两个分开的零件。在这两种情况里,一块大的空地方是在中心的左边,为了定位双作用液压缸,用来在整个机构里推拉刮板输送机和垛式支架。都分别不同于节式支架,这个装置也用在掩护工和支撑掩护式支架中。此外,所有的立柱都垂直地安装在底座和顶数值之间。立柱的三到六个,但是四柱的垛式支架是远远落后于最流行的垛式支架。六柱垛式支架的前面两个立柱和后面四个立柱都设计的有细小缝隙,被一个通道分开。因为六柱垛式支架也在顶兴的后部安装一个挡矸板。挡矸板由几个矩形的铁板组成,水平的连接在两端。在大多娄的垛式支架里,在立柱和顶梁,立柱和底座之间都有铰接的连接口。但是为了增加纵向的稳定性,在底座和每个立柱之间用一个箱形的铁架来进行加固。在箱形铁架的顶部,每个立柱的周围都安装一个立柱复位装置。垛式支架适用于中硬顶板。当顶板外伸进了采空区并且要求人工放顶,垛式支架就会给采空区提供通道。掩护式支架掩护式支架,

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号