摘要

Zl50装载机是我国轮式装载机系列中的中型产品,该机是一种较大型的以装卸散状物料为主的工程机械,广泛应用于矿山、基建、道路修筑、港口、货场、煤场等地进行装载、推土、铲挖、起重、牵引等作业。

本设计的步骤简单如下:1.对装载机的总体进行分析,确定总体参数;2.牵引计算,确定出各档及各档传动比;3.对装载机进行整体布置,并绘出总体布置图;4.变速箱的设计,这是本设计中最主要的部分,确定传动比,设计传动简图,配齿计算,得出齿圈、行星轮、太阳轮的齿数,并验算其合理性。然后进行齿轮设计;5.对离合器,轴、轴承的设计及选择。

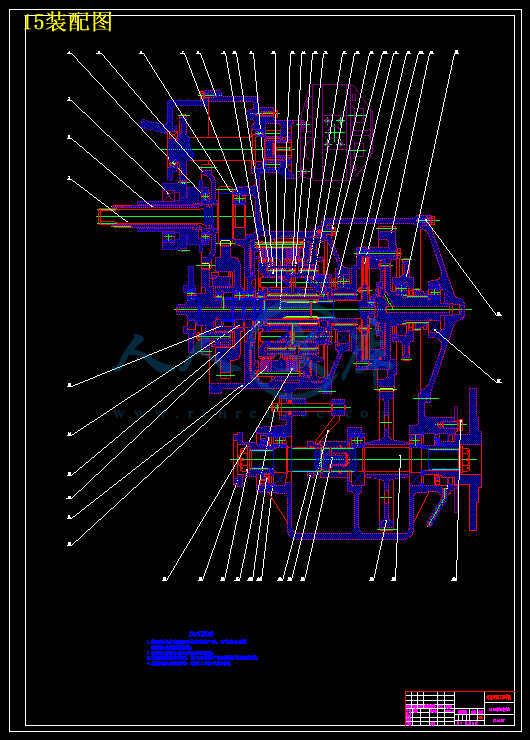

此设计中,主要任务是设计变速箱及第二行星排,设计中采用了行星式动力换挡变速箱,它具有3个离合器和3根轴,且轴安装在壳体内,使变速箱结构简单、便于维修。变速箱具有两个前进挡和一个后退档,可以产生三个速度。

关键词: 装载机 液力机械传动系统 行星式动力换挡变速箱

ABSTRACT

The loader ZL50 iswheel type and it is more bigger among the series made in our country.It is suitable for loading discharging materials and it applies for mine、capital contuction、road builing 、port、field、coalfield and carries loading 、pushing dust 、diging rising weight

The design of the simple steps are as follows: 1.the overall loader analysis , to determine the overall parameters; 2. traction calculation, determine the gear and the gear ratio; 3 .to loader for the overall layout, and draw the overall layout; 4.design of gearbox ,and it is the design of the main parts determination of design, transmission ratio, transmission diagram, gear tooth number calculation, the ring gear, a planet wheel, sun wheel, and check the rationality. Then the design of the clutch gear; 5. design and selection of shaft, bearing.

In my design, I adopt counter shaft power shift transmission’s construction is simple and maincenance is easy .the transmission has two forward and one reverse gear ,it can provide three speeds

KEY WORDS: lorder liquid engine driving system

Hydraulic torque conventer power shift gearbox

目录

第1章 前言········································································· 1

第2章 总体设计·································································· 2

2.1 概述··········································································· 2

2.2 选择确定总体参数··························································· 2

2.3 装载机底盘部件型式设计·················································· 11

第3章 牵引计算································································ 22

3.1 柴油机与变矩器联合工作的输入与输出特性曲线······················· 22

3.2 确定档位及各档传动比···················································· 28

3.3 运输工况牵引特性曲线···················································· 31

3.4 求出各档最高车速并分析牵引特性······································· 33

第4章 总体布置································································ 35

4.1 总体布置草图的基准······················································· 35

4.2 各组成部件的位置························································· 35

4.3 计算平衡重·································································· 39

4.4 桥荷的分配································································· 40

4.5 验算轮胎载荷······························································· 42

4.6 总体布置图·································································· 43

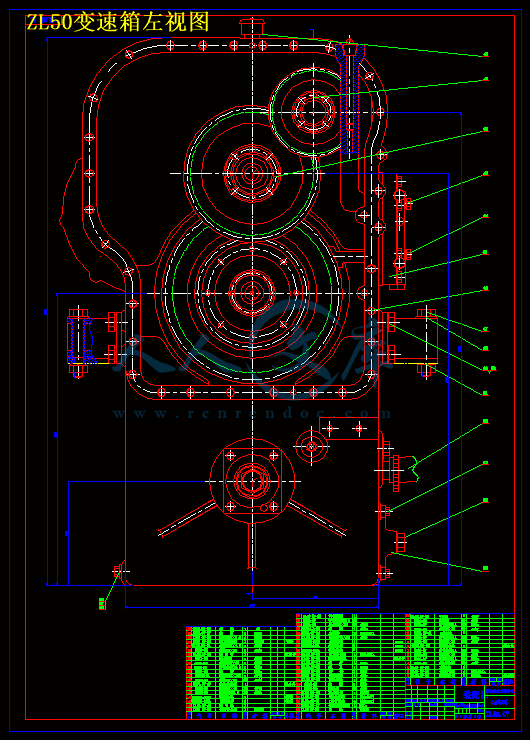

第5章 行星式动力换挡变速箱设计········································ 43

5.1 传动比的确定 ······························································ 44

5.2 传动简图设计 ······························································ 45

5.3 配齿计算 ··································································· 47

5.4 离合器设计·································································· 53

5.5 齿轮设计····································································· 56

5.6 轴的设计····································································· 59

5.7 轴承的选择计算····························································· 64

第6章 毕业设计小节··························································· 66

参考文献············································································68

毕业实习报告····································································· 69

附:英文翻译

英文原文

第1章前言

ZL50轮式装载机是一种较大型的以装卸散状物料为主的工程机械,因其具有作业速度快、效率高、机动性好、操作轻便等优点,所以对于加快工程建设速度,减轻劳动强度,提高工程质量,降低工程成本都发挥着重要的作用,是现代机械化施工中不可缺少的装备之一。

ZL50轮式装载机是高效率、用途广泛的工程机械,广泛应用于建筑、矿山、道路、水电和国防建设等国民经济各个部门,不仅对松散的堆积物料可以进行装、运、卸等作业,还可以对岩石、硬土进行轻度挖掘工作。

ZL50轮式装载机属于ZL系列,采用轮式行走系,液力机械传动系,铰接式车架工作装置采用液压操纵。此类装载机具有机动性好、转向灵活、生产率高、操纵轻便等特点,一般后桥布置为摆动桥,增加了整机的稳定性,所以该机的安全性好。

ZL50轮式装载机为四轮驱动装载机,作业时以全轮驱动,空车运输时,为防止寄生功率,仅用前轮驱动,因此后桥的传动可以用啮合套脱开。ZL50装载机采用液压与液力机械传动,具有变速平稳、传动比大、作业效率高和无级变速等特点,应用十分广泛。其变速器采用行星齿轮变速器,换档操纵为液压式。ZL50装载机的主要特点:采用双涡轮变矩器、具有两个前进档一个倒退档的双行星传动动力换档变速器,以及能实现脱起动,内燃机熄火转向,排气制动的“三合一”机构。

川公网安备: 51019002004831号

川公网安备: 51019002004831号