【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目 录

摘 要................................................................Ⅰ

Abstract.............................................................Ⅱ

第1章 绪论..........................................................1

1.1 本课题研究的背景..........................................1

1.2 本课题研究的内容和方法....................................1

1.3国内外的发展现状...........................................1

1.31液压传动发展现状..........................................1

1.3.2 PLC的发展现状...........................................2

第2章 液压传动系统的设计

2.1液压系统工况的分析.........................................2

2.1.1 位移循环图L—t..........................................3.

2.1.2速度循环图v—t...........................................3

2.2液压缸的设计................................................3

2.2.1液压缸的负载分析..........................................3

2.2.2初步确定液压缸的工作压力..................................4

2.2.3液压缸的尺寸计算..........................................5

2.2.4 液压缸流量的计算..........................................5

2.3液压泵的确定与所需功率的计算................................5

2.4阀类元件的选择..............................................6

2.5滤油器的选型................................................8

2.6油箱的设计..................................................8

2.6.1油箱设计要点 .............................................9

2.6.2油箱容量计算..............................................9

第 3 章 滚轮电机的选择和调速 ...........................................9

3.1滚轮电机的选型及计算.........................................9

3.2变频器的选用................................................11

3.3滚轮电机的调速..............................................12

3.3.1三相异步的调速方式........................................12

3.3.2变频器的调速原理..........................................15

第4章 PLC的控制设计..................................................16

4.1 PLC的特点..................................................16

4.2 PLC的选型原则..............................................16

4.3机型的选择.................................................17

4.4控制要求...................................................17

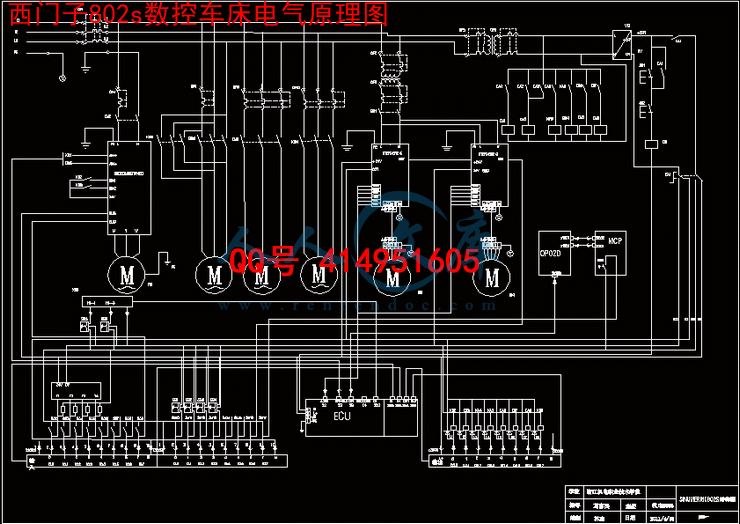

4.5电气原理图..................................................18

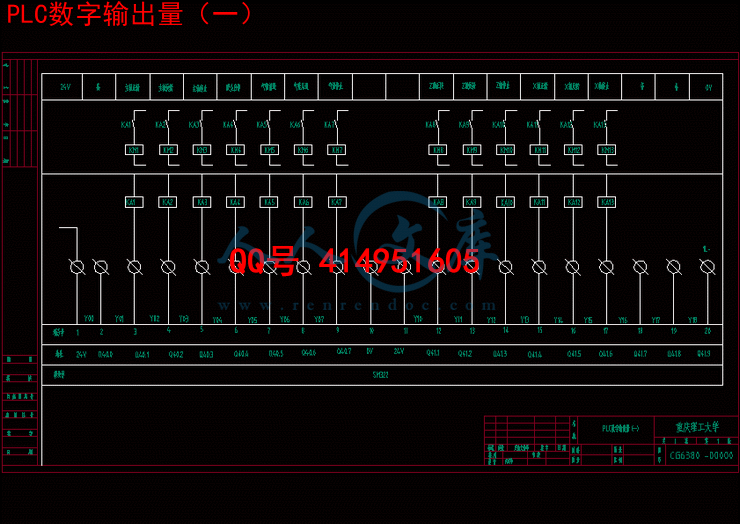

4.6I/O端口分配表..........................................20

4.7电器元件的选型.........................................21

4.8程序设计与系统流程图...................................23

4.9程序设及分析...............................................25

第5章 三菱编程软件和仿真软件.........................................29

5.1三菱编程软件...............................................35

5.2三菱仿真软件...............................................30

结论...................................................................42

致谢...................................................................43

参考文献...............................................................44

摘要

本文介绍了无心外圆磨床的上下料系统控制的原理和特点,主要是通过PLC控制液压系统实现对工件上料和收料的控制。先根据的已知条件计算并选择液压系统各个元件,如液压泵、电磁阀、流量控制阀等,再设计连接液压回路,形成液压的传动系统。由液压系统的不同控制控制方式、如手动控制和自动控制,选择合适的PLC,编写程序,绘制电气接线图,并在运行过程中不断的调整和优化。而且在整个过程中会有变频器对电机的调速和传感器的检测,这些也有赖于PLC的控制,总之,最后由PLC程序控制液压系统形成一个统一的控制系统整体,达到控制液压系统完成特定的工作行程的目的。

关键词:PLC 液压系统 变频器

第一章 绪论

1.1 本课题研究的目的和意义

1.2 本课题研究的内容

1.3 国内外研究情况及其发展

液压系统工况分析

2.1 位移循环图L—t

2.2速度循环图v—t

2.3液压缸的负载分析

第三章液压元件的计算和选型

3.1液压缸的设计计算

3.2液压泵的确定与所需功率的计算

3.3阀类元件的选择

3.4管道的选择

3.5滤油器的选择

3.6油箱的设计

川公网安备: 51019002004831号

川公网安备: 51019002004831号