汽车举升机的设计

机械式汽车举升机的设计

双柱机械式汽车举升机设计【优秀举升机械装置设计+6张CAD图纸】

【任务书+开题报告+文献综述+外文翻译+专题报告+54页@正文16000字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】.bat

专题报告.doc

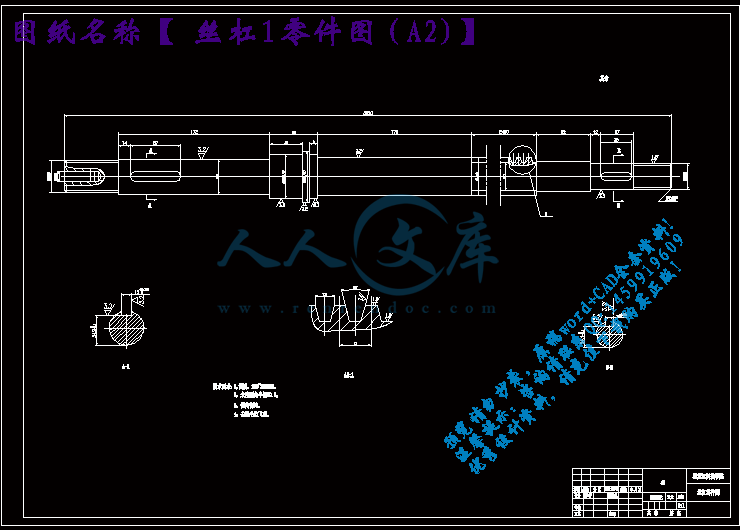

丝杠1零件图(A2).dwg

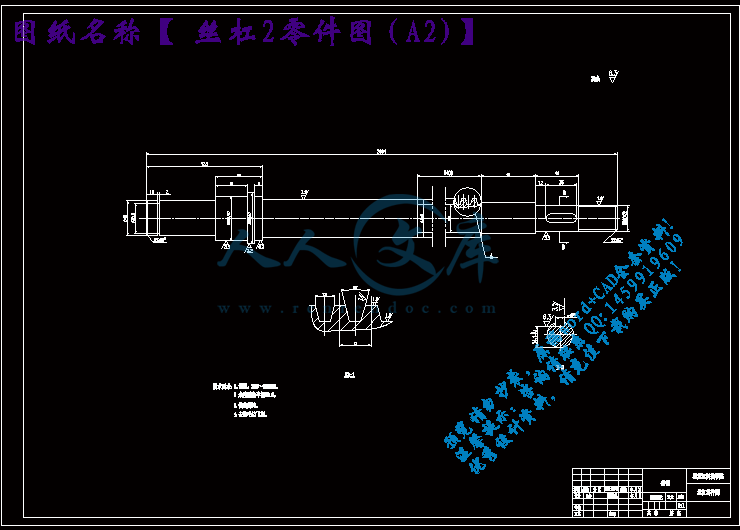

丝杠2零件图(A2).dwg

任务书.doc

升举机支撑装置(A0).dwg

双柱机械式汽车举升机的设计正文.doc

外文原文.pdf

外文译文.doc

开题报告.doc

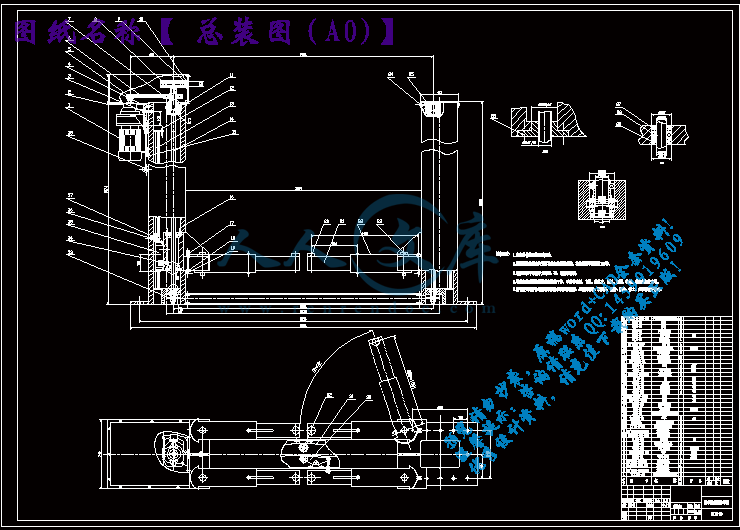

总装图(A0).dwg

文献综述.doc

皮带轮(A2).dwg

英文翻译.doc

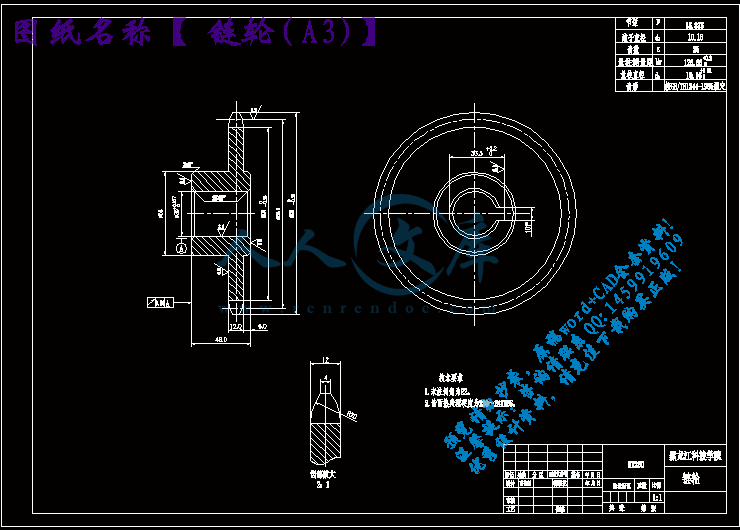

链轮(A3).dwg

毕业设计(论文)任务书

一、设计(论文)题目:双柱机械式汽车举升机

二、设计的目的和意义:现代汽车工业随着科学技术的飞速发展而日新月异, 新工艺、新材料、新技术广泛运用, 特别是电子技术、液压技术在汽车上应用, 使当今的汽车是集各种先进技术的大成, 新颖别致的汽车时时翻新。而现代汽车的故障诊断不再是眼看、耳听、手摸, 汽车维修也不再是师傅带徒弟的一门手艺, 而是利用各种新技术的过程。随着汽车技术的快速发展, 日益呈现出汽车维修的高科技特征, 与其同时汽车维修理念也不断更新。为此,为了提高其维修的快速发展,有必要设计一套新型的汽车举升机。

三、设计(论文)主要内容:双柱机械式汽车举升机,它包括两个框形举升柱,两个垂直滑动在该框形举升柱上的升降滑架,两个托臂和两个轨道式托板,其特征在于所述框形举升柱是由结构在下部的底板升底梁升矩形齿轮箱及矩齿轮箱两侧短边向上延伸的方形导柱连接上部的横梁构成的整体;所述框形举升柱下面的矩形齿轮箱其中一个是安装电动机的驱动箱;而所述升降滑架是由两个平行固定在其上的托臂穿过所述轨道式托板上滑套的孔位相互连接。其中包括两张A0图纸,三张A1图纸和一张A2图纸,总和三张多A0图纸,毕业设计论文1.5万字左右。

四、设计目标:满足现代的汽车维修需要,尽可能的节省时间,提高汽车维修的效率。

五、进度计划: 2008年3月13日至3月31日进行为期3周的生产实习;4月1日至4月10日完成对设计题目的资料收集与查询;4月11日至6月10日完成对设计图纸的绘制;5月11日至6月10日完成毕业设计说明书的编写;6月11日至6月25日最后的审稿及说明书和图纸的打印。

六、参考文献资料:

[1]《机床设计手册》编写组.《机床设计手册》第1册.机械工业出版社,1986年

[2] 《机床设计手册》编写组.《机床设计手册》第2册.机械工业出版社,1986年

[3] 《机床设计手册》编写组.《机床设计手册》第3册.机械工业出版社,1986年

[4]《机床设计手册》编写组.《机床设计手册》第4册.机械工业出版社,1986年

[5]《机床设计手册》编写组.《机床设计手册》第5册.机械工业出版社,1986年

[6] 朱龙根、黄雨华.机械系统设计.机械工业出版社,1980年

[7] 《机械设计手册》编写组.《机械设计手册》第1册.机械工业出版社,1988年

[8] 《机械设计手册》编写组.《机械设计手册》第2册.机械工业出版社,1988年

[9] 《机械设计手册》编写组.《机械设计手册》第3册.机械工业出版社,1988年

[10] 《机械设计手册》编写组.《机械设计手册》第4册.机械工业出版社,1988年

[11] 《机械设计手册》编写组.《机械设计手册》第5册.机械工业出版社,1988年

[12] 黄祖尧、肖正义.精密丝杆副的选用计算.《机床》1989年第6期

[13] 上海金属切削技术协会.《金属切削手册》第2册.兵器工业出版社,1986年

摘要

双柱机械式汽车举升机,它包括两个框形举升柱,两个垂直滑动在该框形举升柱上的升降滑架,两个托臂和两个轨道式托板,其特征在于所述框形举升柱是由结构在下部的底板升底梁升矩形齿轮箱及矩齿轮箱两侧短边向上延伸的方形导柱连接上部的横梁构成的整体;所述框形举升柱下面的矩形齿轮箱其中一个是安装电动机的驱动箱;而所述升降滑架是由两个平行固定在其上的托臂穿过所述轨道式托板上滑套的孔位相互连接。

关键词 滑动螺旋副 导轨 丝杠 制动器 组合开关

Abstract

Shuangzhu mechanical vehicle lift, which includes two box-shaped Jusheng pillar, two vertical sliding in the box-shaped piece of Jusheng-piece aircraft, two up and two track-holding arm, their identity is in Jusheng pillar box-shaped structure in part by the end of Liang-bed or carpenter's square or rectangle gear boxes and gear boxes on both sides of a square-short margin upward extension of the upper beam connecting a pillar overall; Jusheng pillar box is described below rectangle gear boxes installed electric motors is one of the driving boxes; and the piece-by-two parallel fixed in its orbit above the occasional arm-supporting, through the Hua Tao Kong spaces interlinked.

Key words Glide the spiral pair and lead the track, silk to carry on the shoulder, make to move the machine and combine the switch

目 录

摘要1

Abstract2

第一章 绪论5

1.前言5

2.举升机概述6

第二章 升举装置的总体设计7

1.设计题目7

2.设计方案7

3.方案选择7

4.实习考察7

5.确定总设计计划7

6.方案的实施8

第三章 机械传动系统9

1.方案的拟定9

2.在拟定机械传动系统方案时,应考虑以下原则10

3.传动类型选择的依据10

4.滑动螺旋传动的特点及计算14

第四章 滚动直线导轨套副19

1.导轨的类型及其特点20

2.导轨的设计要求20

3.导轨的设计程序及内容20

4.精密导轨的设计原则20

5.导轨类型的选择原则21

第五章 丝杠同步转动的链传动24

1.滚子传动的设计25

2.滚子链传动的设计计算25

3.滚子链的静强度计算29

4.滚子链的使用寿命计算30

5.滚子链链轮33

6.滚子链链轮的基本参数和主要尺寸34

第六章 带传动及其有关计算35

1.带传动35

2.带和带传动的形式35

3. V带传动35

5.基准宽度制带传动的设计计算36

6. 带传动的效率40

7. V带带轮41

8.带轮的结构41

9.带轮的技术要求41

10.带轮的技术要求42

11.V带传动的主要失效形式43

第二部分 机电控制系统44

第一章 制动器的选择及其计算44

1制动器44

2 制动器的分类、特点及应用44

3.制动器的选择44

4.制动器的性能参数及主要尺寸45

第二章 开关的选择46

1.HZ5B-1型组合开关47

2.LXJ6系列接近开关47

第三部分 使用及其效益47

1.使用时注意事项48

2.升举机安全操作规程48

第二章 经济效益分析48

结论49

谢 辞51

第一章 绪论

1.前言

现代汽车工业随着科学技术的飞速发展而日新月异, 新工艺、新材料、新技术广泛运用, 特别是电子技术、液压技术在汽车上应用, 使当今的汽车是集各种先进技术的大成, 新颖别致的汽车时时翻新。而现代汽车的故障诊断不再是眼看、耳听、手摸, 汽车维修也不再是师傅带徒弟的一门手艺, 而是利用各种新技术的过程。随着汽车技术的快速发展, 日益呈现出汽车维修的高科技特征, 与其同时汽车维修理念也不断更新。

随着汽车技术的发展, 维修设备也随之产生了质的变化。汽车保修设备的生产, 也不再是多以机具类为主。20世纪90年代以来, 一批批先进的进口汽车检测设备和仪器涌入国门。四轮定位仪、解码器、汽车专用示波器、汽车专用电表、发动机分析仪、尾气测试仪及电脑动平衡机等,这些昔日人们十分陌生的检测设备, 已经成为现代维修企业的必备工具。而这些检测设备, 本身就是高科技化的产品, 是电子检测技术、电脑技术的高级集成物。要熟练地操作使用这些检测设备, 技术人员需要经过严格的培训, 并要掌握外语和电脑技术, 才能掌握正确的使用方法, 充分发挥检测设备的各项功能。这种高科技化的现代汽车检测设备, 使现代汽车维修的科技含量大为提高。

加入WTO对中国汽车维修业的影响是巨大的。为了适应售后服务的要求, 国外汽车维修业将相继进入中国市场, 国外汽车维修业的介入给中国汽车维修市场提供了一个较为先进的高效的国际技术环境, 对促进国内汽车维修业的更新改造、加速汽车维修业技术进步的进程, 将起到良好的推动作用。

传统的汽车维修方式、维修制度以及经营模式必然被现代汽车维修方式所代替。以往的汽车维修往往就维修谈维修, 现代汽车维修是汽车销售、零件销售、资讯及售后服务四位一体紧密结合。汽车维修的新趋势是维修对象的高科技化、维修设备现代化、维修咨询网络化、维修诊断专家化、维修管理电脑化及服务对象的社会化。国外汽车维修企业以汽车服务贸易的形式进入国内市场, 使我国汽车维修行业将面临严峻形势, 而在汽车维修企业发展要素中, 起主导作用的因素将是: 管理、技术、装配和信息。倡导汽车维修行业的服务优质化、品牌化、现代化, 势在必行。

参考文献:

[1] 《机床设计手册》编写组.《机床设计手册》第1册.机械工业出版社,1986年

[2] 《机床设计手册》编写组.《机床设计手册》第2册.机械工业出版社,1986年

[3] 《机床设计手册》编写组.《机床设计手册》第3册.机械工业出版社,1986年

[4]《机床设计手册》编写组.《机床设计手册》第4册.机械工业出版社,1986年

[5]《机床设计手册》编写组.《机床设计手册》第5册.机械工业出版社,1986年

[6] 朱龙根、黄雨华.机械系统设计.机械工业出版社,1980年

[7] 《机械设计手册》编写组.《机械设计手册》第1册.机械工业出版社,1988年

[8] 《机械设计手册》编写组.《机械设计手册》第2册.机械工业出版社,1988年

[9] 《机械设计手册》编写组.《机械设计手册》第3册.机械工业出版社,1988年

[10] 《机械设计手册》编写组.《机械设计手册》第4册.机械工业出版社,1988年

[11] 《机械设计手册》编写组.《机械设计手册》第5册.机械工业出版社,1988年

[12] 黄祖尧、肖正义.精密丝杆副的选用计算.《机床》1989年第6期

[13] 上海金属切削技术协会.《金属切削手册》第2册.兵器工业出版社,1986年

川公网安备: 51019002004831号

川公网安备: 51019002004831号