摘要

模具设计的种类很多,其中以塑料模的设计最为主要。塑料产品的多样化和超大的市场需求量决定了塑料模设计的重要性。模具工业的发展有空间,前景很好。特别是中国加人WTO后,国际模具市场前景广阔,中国模具仍有一定的竞争优势。

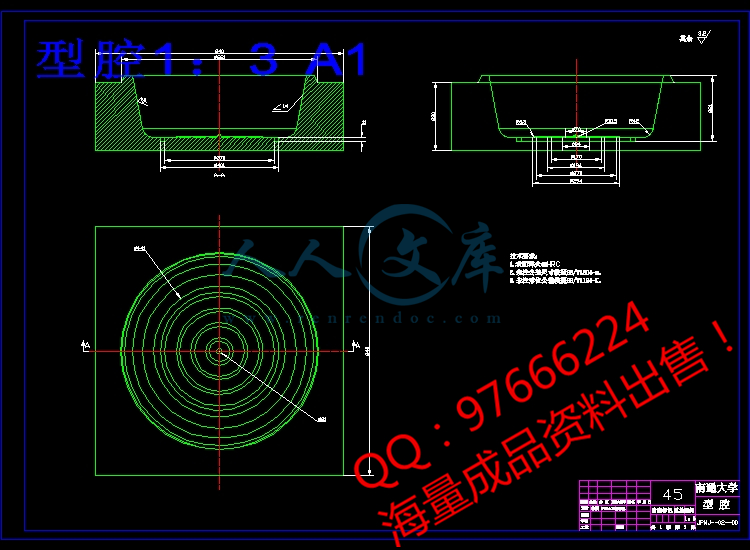

本课题以脚盆为设计对象,主要研究了该零件的3D快速模具设计技术。通过对传统的2D设计,3D设计以及最新的参数化设计做比较,发现采用SolidWorks2004的模具设计平台,可以大大提高模具设计的效率,也提高了产品快速响应市场的能力。对此课题的研究让我们初步了解了模具设计的过程,对我们今后的发展有很大的帮助。

关键字:模具设计,SolidWorks,注塑模,快速设计

Abstract

Many types of mold design, plastic mold design with the most major. Plastic product diversification and market demand for super-plastic design has determined the importance of. Mold the development of industrial space, good prospects. Especially after China's WTO plus people, the international market prospects mold, China mold there is still a competitive advantage.

This topic takes the footbath machine as the target of mold design. It is main researched the 3D fast mould designing technique of this part. Through the comparion with the designing of traditional 2D design, 3D design and the latest designing of parameterize, we can find that if adopts the mold design platform of SolidWorks2004, it can improve the efficiency of mold design greatly, and also can improve the ability that the products respond the market fast. The study on mold design lets us find out the course of the design about the mould is very helpful to our development in the future.

Key words: Mold design, SolidWorks, Injection mold, Rapid design

目录

摘要II

AbstractIII

目录IV

第1章 绪论6

1.1注塑成型6

1.2模具工业发展现状6

1.3模具发展趋势7

1.4关于SolidWorks8

1.5本文的研究目的、内容和意义8

第2章 总体设计方案的确定10

2.1设计方案的提出与比较10

2.2设计方案的确定及导入12

2.3数据准备和项目建立13

2.4 型芯型腔设计14

第3章 标准模架的选用22

3.1模板的选用22

3.2垫块的选用22

3.3导柱的选择23

3.4导套的选择24

3.5塑料注射模标准模架24

第4章 浇口与浇道的设计及计算26

4.1 添加智能螺钉26

4.2 添加定位圈27

4.3 添加浇口套27

4.4 浇口设计28

第5章 最终设计效果图29

5.1 模架最终效果图29

5.2 MasterCAM加工效果图30

第6章 总结32

参考文献33

致谢34

川公网安备: 51019002004831号

川公网安备: 51019002004831号