A new generation of power supplies for electron beam welding machines.doc

4T焊接滚轮架机械设计【13张图纸】【优秀Word+CAD全套设计】

收藏

资源目录

压缩包内文档预览:

编号:447182

类型:共享资源

大小:8.14MB

格式:ZIP

上传时间:2015-07-03

上传人:小***

认证信息

个人认证

林**(实名认证)

福建

IP属地:福建

45

积分

- 关 键 词:

-

焊接

轮架

机械设计

- 资源描述:

-

摘 要

焊接装备就是在焊接生产中与焊接工序相配合,有利于实现焊接生产机械化,自动化,有利于提高装配焊接质量,促使焊接生产过程加速进行的各种辅助装置和设备。焊接滚轮架是借助主动滚轮与焊件之间的摩接力带动焊接旋转的变位机械。焊接滚轮架主要用于筒形焊件的装配与焊接。焊接滚轮架按结构形式分为两类:第一类是长轴式滚轮架。第二类是组合式滚轮架。本文主要对组合式4T焊接滚轮架进行设计,并对轴、键等主要构件进行了校核。结果表明各主要部件符合要求。该滚轮架结构简单,使用方便灵活,对焊件的适应性很强。设计中充分的考虑了滚轮架的合理性和经济性等因素。

关键词:焊接;工装夹具;滚轮架

Abstract

Welding equipment is a machine which is used in welding production and welding processes, and it is conducive to welding production mechanization and automation, to improving assembly welding-quality. Then it could prompte to speed up the process of welding production of the various assistive devices and equipment. Welding roller is used initiative and welding pieces of the wheel between the Mount relay driven welding rotating mechanical deformation. Welding roller stands for the main pieces of tube welding and welding assembly. Welding roller standing by structural form is divided into two categories : the first category is long axis-wheel frame., the second category is modular roller frame. In this paper, four pairs of modular T-welded wheel for the design, as well as axial, bond and other main component of checking. The results showed that the main components to meet the requirements. The roller frame structure is simple, flexible, adaptive welded pieces of a strong, which is the most widely used form of the structure. And it could be fully considered the roller frame reasonable and economic, and other factors.

【Key words】:weld, frock clamp, turning rolls

目 录

第一章 文献综述1

1.1焊接的应用1

1.2焊接机械装备1

1.2.1焊接机械设备的分类2

1.2.2焊接机械装备对焊接生产的作用2

1.3焊接自动化:3

1.4焊接工装夹县4

1.4.1焊接工装夹具的特点5

1.4.2焊接工装夹具的分类6

1.4.3对焊接工装夹具的设计要求6

1.4.4焊件在焊接工装夹具中的定位方法7

1.5焊接变位机械8

1.5.1焊接变位机械的分类8

1.5.2焊接变位机械应具备的性能9

1.6几类焊接机械设备的具体介绍10

1.6.1焊接变位机10

1.6.2焊接翻转机11

1.6.3焊接操作机12

1.6.4焊接滚轮架13

1.6.5关于滚轮架轴向窜动的问题16

第二章 方案的选择与确定18

2.1组合式滚轮架的特点:18

2.2滚轮驱动方案20

2.3减速器的选择:20

2.4连轴器的选用:21

2.5滚轮架滚轮的设计21

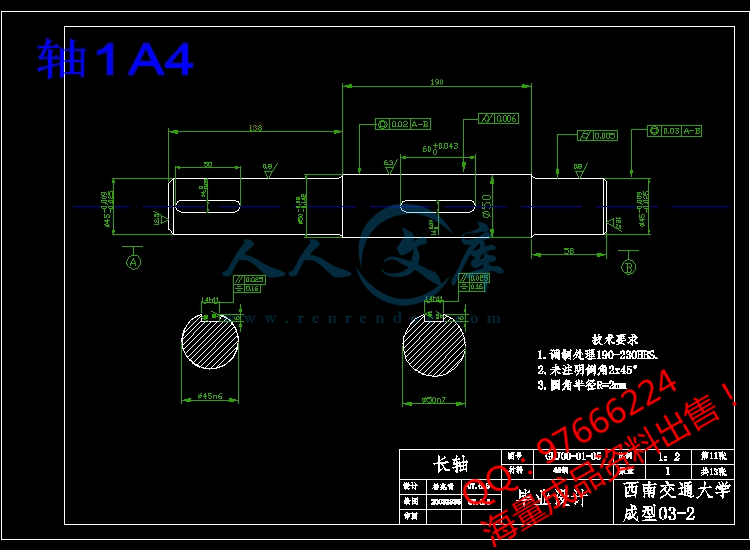

2.6轴的设计23

2.7轴承的选用24

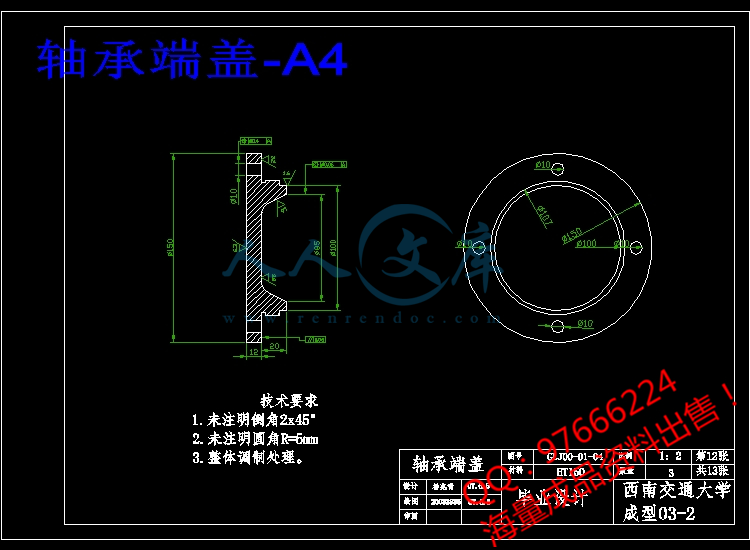

2.8轴承端盖的设计25

2.9丝杠的设计26

2.10键的设计27

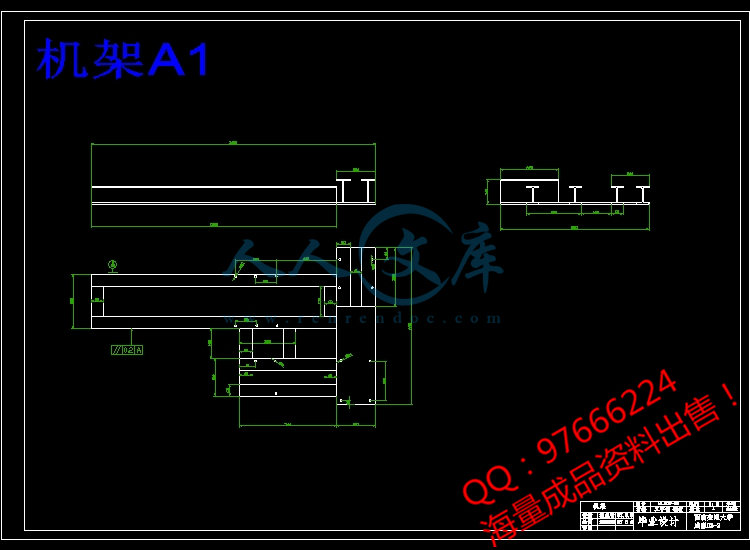

2.11机架的设计27

2.12表面粗糙度29

第三章 计算与校核30

3.1焊接滚轮架的设计计算30

3.1.1驱动圆周力与支反力的分析及中心角的确定30

3.1.2 焊接滚轮架的受力分析33

3.1.3滚轮支反力的计算34

3.2电动机的选定36

3.3轴的校核37

3.4滚轮处键的校核38

3.5轴承寿命计算38

3.6轴承的强度计算39

结论41

致谢42

参考文献43

- 内容简介:

-

A new generation of power supplies for electron beam welding machines Jerzy Doraa, Jan Felbab, , and Wiktor Sielankoc aDORA POWER SYSTEM, ul. Wyszyskiego 110, 50-307 Wrocaw, Poland bFaculty of Microsystem Electronics and Photonics, Wrocaw University of Technology, ul. Grabiszyska 97, 53-439 Wrocaw, Poland cIndustrial Institute of Electronics, ul. Duga 44/50, 00-241 Warszawa, Poland Received 31 August 2004; accepted 10 September 2004. Available online 10 November 2004. Abstract Widely used electron beam welding machines are equipped with heavy power supplies, located in a special oil tank and connected with an electron gun to a high-voltage cable. A special system detects electric discharges in the electron gun space, which may arise during welding and then it tries to switch off the high voltage to interrupt an electric arc. Such disadvantages have been eliminated with the novel power supply described here. The Q of resonance circuit of this supply is stabilized and as a result circulating power appears. During an electric discharge in the gun, power is not sent to the electron gun but circulates between the electronic parts of the resonance circuit without losses and “waits” for the break in the short circuit. The power supply is much smaller and lighter than supplies of similar rating used nowadays. It is connected directly to the electron gun chamber without a high-voltage cable. The first construction of the supply was designed for electron beam welding machine of 5 kW power and 60 kV accelerating voltage. ntsTests of the new power supply in laboratory and industrial conditions have shown its usefulness for electron beam welding. Keywords: Electron beam; Electron beam welding ; Power supply Article Outline 1. Introduction 2. State-of-the-art of a power supply 3. Power supply consideration 4. Model of the new power supply 5. Power supply in use 6. Conclusions References 1. Introduction Since the pioneering work on the development of high-power electron beam welding, the main effort of welding machine designers and constructors has been concentrated on the design of the electron beam generator. It consist of three distinct parts: the electron gun, where electrons are emitted, accelerated and formed into an electron beam, the gun power supplies and a beam transport system. These requirements of electron beam technology and possibility of modelling the electron trajectories defined the principles of electron gun construction. Free electrons (emitted or extracted from heated, cold ntsor plasma cathodes) acquire kinetic energy when they cross the electric field created between cathode and anode, which is usually connected to the ground. An additional electrode influences the shape of the electric field and controls the current of the electron beam. The guns electrodes receive energy and power from a power supply unit. The beam transport systems facilitate the concentration of the energy of the beam to provide the deep penetration, necessary for welding, and play an important role in electron beam technology. The system deflects the beam and is able to acquire information from the welding point to give automatic focusing, seam tracing and power control of the beam. The progress in systems operation has been determined mainly by the developments in modern electronic devices and controlling computers. Possible discharges in the electron gun space are some of the most important problems of electron beam welding. As a result of arcing a weld process may be discontinued. The repair of welded parts (if possible) is time and labour consuming. In order to prevent interruptions caused by arcing, constructors have proposed methods which limit the flow of metal vapour and gas into the gun space 1. Much more effective results seem to be attainable if the power supply functions properly. This problem is driving the progress in constructions of power supply design for the next generation. 2. State-of-the-art of a power supply The discharge between gun electrodes can be classified as micro-arcing, single or multi-arcing and a soft vacuum discharge. Conventional power sources are already practically resistant to micro-arcing. Also single and multi-arcing do not interrupt the welding process. Almost all charges are discharged in the output filter capacitors of such supplies and soon the gun recovers. Unfortunately, during a soft vacuum discharge, ntsthe breakdown has not been recovered by the time the power supply is restarted (several milliseconds) and the process of welding can be stopped. Prevention of interruptions because of such a discharge has been possible by making the arcing as short as possible, having lower stored energy and by resupplying power to the gun in a very short time. There have been some systems constructed which meet the requirements. Paton Electric Welding Institute proposed a system in which the surge energy at arcing is absorbed by a vacuum tube 2. The regulating lamp is controlled along a channel which protects the source of accelerating voltage and restricts the beam current. Such power sources have been used extensively in recent years 3. As an alternative to a power supply with a tube, high frequency or switch-mode systems to decrease arcing energy were developed. MELCO proposed a system in which the period of interruption of power supply by arcing was extremely short. The system consists of a high-frequency power source to decrease the arcing energy and a transient signal controller which controls feedback signals at arcing and supplies power continuously and stably 4. A switch mode accelerating voltage regulator, developed by Ferranti Sciaky, enabled a fast response and low-stored energy power supply to withstand arcing 5. Generally, power supplies for welding machines working according to the above-mentioned principles have been in common use. The high-voltage part of the main and auxiliary supplies are located in a special heavy oil tank connected with an electron gun by a high-voltage cable. A large source of new high sophisticated electronic components and the idea of transferring some auxiliary supplies directly into the gun (e.g. TWI, Cambridge 6) has made units become smaller, more reliable and resistant to arcing. Nevertheless, stored energy in a high-voltage tank ntsand a cable is very detrimental to the operation of an electron beam gun and may have an influence on the welding process. Such disadvantages have been eliminated with the novel power supply described below. 3. Power supply consideration The new power supply for electron beam welding machines is absolutely resistant to arcing, has exceptionally low dimensions and operates without a heavy oil tank, high-voltage cable or any special system to detect electric discharges. The novelty of the presented supply is based on the resonance circuit 7. In high-frequency resonance circuits, as a result of non-matching, reflected power is created. In the present case, the so-called circulating power appears due to the substitution of the reflected power by DC power which returns to the power supply. If no stabilization of the resonance circuit takes place, the power circulates between the electronic parts of the resonance circuit and causes almost no losses in it. In the case of the electron beam welding process, all the power supply is used as the effective power. Each mismatch between the electron gun and the output of the power supply reflects circulating power. The maximum value of this power is when the soft vacuum discharge in the gun chamber occurs. This arcing may arise between cathode or control electrode and anode, as well as between all possible parts of the gun and insulator at high-voltage potential and the ground. As the power is not sent to the electron gun but circulates and is stored in the supply, the short circuit is immediately quenched. The power supply has two parts. The high-voltage part, in the form of a cylinder filled with silicon oil, is joined mechanically with the electron gun chamber and connected with gun electrodes by vacuum ntsculverts. The low-voltage unit can be installed directly within reach of the operator. Both parts are connected using an optical waveguide and conductors with breakdown voltage isolation less than 500 V. The supplies of the indirectly heated cathode and control electrode are located in the high-voltage cylinder. For cathode heating a resonance circuit has also been used but, in this case, it is only there to give the possibility of calculating the feedback resonance between the primary and secondary winding of the heating transformer into the resonance circuit. Thus, the control electrode takes energy from the cathode supply. A schematic diagram of all units is presented in Fig. 1. The circuit diagram is available on the internet site 8. Display Full Size version of this image (46K) Fig. 1. Schematic diagram of power supply. 4. Model of the new power supply The new unit was designed with a power supply of 5 kW and 60 kV accelerating voltage for a triode electron gun with a directly heated cathode. The shapes of gun electrodes and distances between them had been optimized by measuring the electron beam emittance, which is a very sensitive figure-of-merit to detect any influence of geometrical and electrical gun factors on the quality of the electron beam 9. The optimization procedure (applying the Taguchi method of experimental ntsdesign) was to decrease the normalized emittance of the electron beam 10. The heating of the tantalum cathode with 22 mm emitting surface in the gun needs power of 150 W, while the control electrode is supplied up to 2 kV. The power supply was constructed in the form of a cylinder of 160 mm diameter and 600 mm long (the high-voltage part) and 6U standard unit. Tests were performed on an electron beam welding machine of 10 kW and 80 kV designed and constructed by Wroclaw University of Technology. The results of the tests are given in Table 1. Table 1. Results of the tests Type of test Test result Short-time stabilization test (60 kV, 3.6 kW, 15 min) Voltage stability 0 to +0.3%, Short-time stabilization test (60 kV, 3.6 kW, 15 min) Current stability 0.5% to +0 Long-term stabilization test (60 kV, 1.2 kW, 1 h) Voltage stability 0.2% to +0 Long-term stabilization test (60 kV, 1.2 kW, 1 h) Current stability 0.5% to +0 Repeatability in cyclic work (60 kV, 4.5 kW, 2 min work +1 min break, 90 min) Voltage stability 0.3% to +0 Repeatability in cyclic work (60 kV, 4.5 kW, 2 min work +1 min break, 90 min) Current stability 0.2% to +0 Shape of welds (60 kV, different beam power, different welding speed, stainless steel) Statistically the same as with standard power supply (400 Hz frequency motor generator) of the welding machine Resistance to arcing (even with welding of high-pressure-vapor Short brakes in generating of electron beam have been visually observed, but without interrupting of the ntsType of test Test result alloys, e.g. brass) welding process, and with no disadvantageous effects to the weld. All tests show the usefulness of the new power supply for electron beam welding. A power supply of 15 kW power and 120 kV accelerating voltage is now under design. It is estimated that it will be located in a cylinder of 300 mm600 mm (the high-voltage part) and two 6U standard units. 5. Power supply in use The power supply was adapted to the new electron beam welding machine, constructed by the Industrial Institute of Electronics in Warsaw. It is a fully automated unit for welding torsional vibration dampers for crankshafts of diesel engines with a yield of 50 000 pieces a year 11. The device was installed in industry for mass production in 2001 and until now the reliability of the power supply is very high. 6. Conclusions After testing the new power supply in laboratory and industrial conditions, it can be concluded that: all operating data of the supply are at least not worse than those for supplies presently in use, it is resistant to every kind of arcing which may appear in the electron gun space during the welding process, it operates without both a heavy oil tank and costly high-voltage cable, nts it is much smaller, lighter and cheaper than supplies of similar output presently in use. References 1 Fritz D, Nazarenko OK, Irie H, Abe N, Ohmine M. Proce

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

|

2:不支持迅雷下载,请使用浏览器下载

3:不支持QQ浏览器下载,请用其他浏览器

4:下载后的文档和图纸-无水印

5:文档经过压缩,下载后原文更清晰

|

川公网安备: 51019002004831号

川公网安备: 51019002004831号