Optimization of Gate, Runner and Sprue in Two-Plate FamilyPlastic Injection Mould..pdf

双盖注塑模具设计【优秀含10张CAD图纸+塑料模具全套毕业设计】

收藏

资源目录

压缩包内文档预览:

编号:479262

类型:共享资源

大小:1.96MB

格式:ZIP

上传时间:2015-10-07

上传人:小***

认证信息

个人认证

林**(实名认证)

福建

IP属地:福建

45

积分

- 关 键 词:

-

注塑

模具设计

优秀

优良

10

cad

图纸

塑料模具

全套

毕业设计

- 资源描述:

-

!【详情如下】【注塑塑料模具课题】CAD图纸+word设计说明书.doc[11000字,32页]【需要咨询购买全套设计请加QQ97666224】.bat

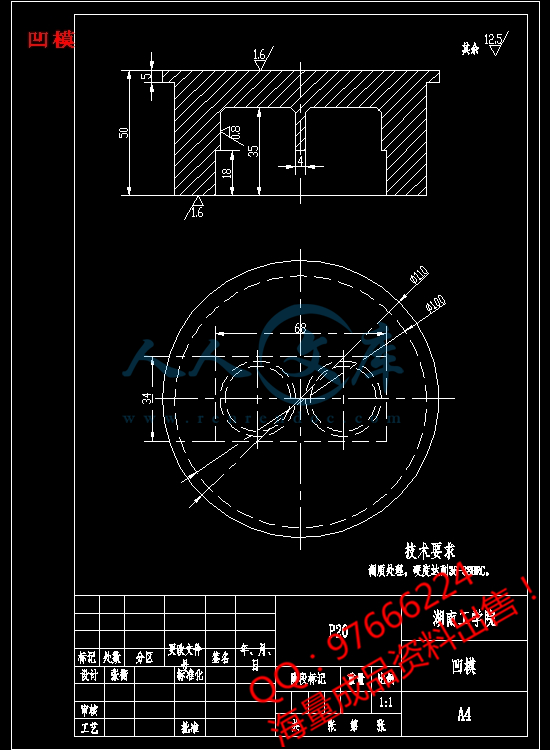

凹模.dwg

型芯.dwg

型芯固定板.dwg

塑件图.dwg

定模座板.dwg

定模板.dwg

推件板.dwg

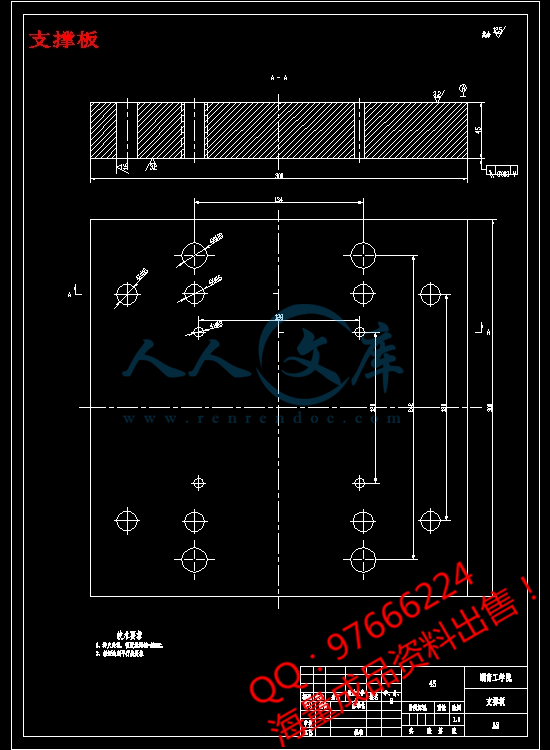

支撑板.dwg

浇口套.dwg

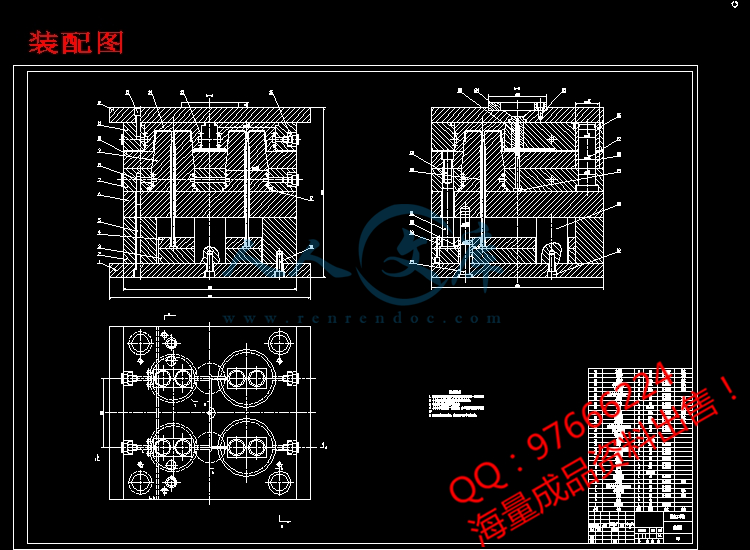

装配图.dwg

设计任务书.doc

设计说明书.doc[11000字,32页]

开题报告和中期检查表.doc

外文翻译

摘 要

本课题主要是针对塑料盖的模具设计,通过对塑件进行工艺的分析和比较,最终设计出一副注塑模。该课题从产品结构工艺性,具体模具结构出发,对模具的浇注系统、模具成型部分的结构、顶出系统、冷却系统、注塑机的选择及有关参数的校核都有详细的设计,同时并简单的编制了模具的加工工艺。通过整个设计过程表明该模具能够达到此塑件所要求的加工工艺。根据题目设计的主要任务是塑料盖注塑模具的设计。也就是设计一副注塑模具来生产盒盖塑件产品,以实现自动化提高产量。

关键词:塑料盖;注塑模;模具结构;浇注系统;注塑机

ABSTRACT

This topic mainly aimed at the mold design of plastic lid. Through the analysis and comparison of the plastic product , the plastic injection mold was designed. This topic came from the technology capability of product, the structure of the mold embarks, the gating system, the injection molding system and the related parameter examination, the mold took shape the partial structures, the against system, the cooling system ,the injection molding machine all had the detailed design, at the same time , the processing craft of the mold were simply established. Through the entire process of the design indicated this mold can achieve the processing craft which the plastic lid requested.

Key words:plastic lid;plastic injection mold;the structure of the mold embarks;gating systerm; injection molding machine

目 录

前言1

1 塑件成型的工艺性分析4

1.1塑件的分析4

1.2 PP的性能分析4

1.3聚丙烯的成型工艺4

2 注射机的型号和规格选择及校核6

2.1 注射机的选用6

2.2 注射压力的校核7

2.3 锁模力的校核7

3 分型面的选择8

3.1 分型面的形式8

3.2 分型面的选择原则8

3.3 水平分型面的选择8

4 型腔数目的决定及排布9

4.1 型腔数目的确定:9

4.2 多型腔的排列:9

4.3 模具结构的初步确定9

5 浇注系统的设计10

5.1主流道设计:10

5.2分流道的设计11

5.3浇口的设计:13

5.4 校核主流道的剪切速率13

5.5冷料穴的设计13

6 成型零件的工作尺寸计算14

6.1 凹模的结构形式14

6.2 凸模的结构设计14

6.3 成型零件的工作尺寸计算15

6.3.1 凹模径向尺寸计算15

6.3.2 凹模深度尺寸的计算16

6.3.3 型芯径向尺寸计算16

6.3.4 型芯高度尺寸的计算17

6.3.5型腔的壁厚和底板厚度的计算17

7 模架的确定18

7.1各模板尺寸的确定18

8 导柱导向机构的设计19

9 脱模推出机构的设计20

9.1 脱模力的计算20

9.2 推出方式的确定20

9.3 脱模机构的设计原则20

10 温度调节系统的设计21

10.1 冷却系统设计21

10.2 冷却时间的确定21

10.3 冷却系统设计原则21

10.4 冷却系统的计算22

11模具安装23

设计总结24

参考文献25

致 谢26

- 内容简介:

-

Optimization of Gate, Runner and Sprue in Two-Plate Family Plastic Injection Mould M.A. Amran*, M. Hadzley, S. Amri, R. Izamshah, A. Hassan, S. Samsi, and K. Shahir1Faculty of Manufacturing Engineering, Universiti Teknikal Malaysia (UTeM), Locked Bag 1200, Hang Tuah Jaya, Ayer Keroh, Melaka, Malaysia *Email: mohdamran.my Abstract. This paper describes the optimization size of gate, runner and sprue in two-plate family plastic injection mould. An Electronic Cash Register (ECR) plastic product was used in this study, which there are three components in electronic cast register plastic product consist of top casing, bottom casing and paper holder. The objectives of this paper are to find out the optimum size of gate, runner and sprue, to locate the optimum layout of cavities and to recognize the defect problems due to the wrong size of gate, runner and sprue. Three types of software were used in this study, which Unigraphics software as CAD tool was used to design 3D modeling, Rhinoceros software as post processing tool was used to design gate, runner and sprue and Moldex software as simulation tool was used to analyze the plastic flow. As result, some modifications were made on size of feeding system and location of cavity to eliminate the short- shot, over filling and welding line problems in two-plate family plastic injection mould. Keywords: Computer Modeling; Flow Simulation; Optimization PACS: 07.05Tp 1. INTRODUCTION The plastic injection generally has three phase processes comprising filling, packing and cooling phases. The introduction of simulation software has made a significant impact in the mould making industry with the increasing use of computers in design engineering, the amount of commercially available software on the market has also increased 1. The ECR plastic product uses same material and colour, however different size of part. Each part has it own mould but on this research, all the parts used family mould. The difficult stage to design family mould is to decide the mould layout, injection location, size of gate, runner, sprue and location of water holes 2, 6, 7. To investigate the flow behaviour the Moldex software as simulation software was used to analyze the plastic flow. 2. METHODOLOGY This study started from design 3D modeling of ECR product using Unigraphic software and then the files were transferred into Rhinoceros software for post processing. In Rhinoceros software the feeding system such as gates, runners, sprues, 309ntswaterholes and mould base were designed. Finally, Moldex software is used by importing file from Rhinoceros software. Plastic materials, processing conditions were decided before filling, packing, cooling and warpage analysis. If results do not satisfy, the modification will be done again as shown in Figure 1. EndInterperet data &make conclusionYESRun analysisSelect materialSet processing conditionTransfer file to Moldex softwareDesign water holes systemDesign rectangular edge gate Design circular cross section runner Design direct sprueDesign circular layoutNOTransfer file to Rhinoceros softwareMeshing part surfaceDesign part in 3D using UnigraphicStartFIGURE 1. Methodology of analysis. 3. DESIGN OF TWO PLATE MOULD All ECR files consist of top casing, bottom casing and paper holder which they were exported from Unigraphic software to the Rhinoceros software through step one by one. The files were saved under DXF extension which it can be read by Rhinoceros software. Initially, the top casing file was opened in Rhinoceros software which it was converted from solid modeling into mesh modeling as shown in Figure 2(a). Further, Figure 2(b) shows the early stage of imported file of bottom casing from Unigraphic software to Rhinoceros software. The refine mesh of bottom casing has been made until the fine mesh of surface is achieved. The cavity surface was remained after core side had been deleted by removing the mesh. The same method was done for paper holder as shown in Figure 2(c). 310nts (a) Top Casing (b) Bottom Casing (c) Paper Holder FIGURE 2. Mesh modeling of ECR. 3.1 Rectangle Edge Gate Two sizes of rectangular edge gate need to decide which are depth and width. The depth of these parts are calculated using formula h = nt, where h is depth of gate (mm), t is wall section thickness (mm) and n is material constant 3. Calculation from this formula the depth of top casing and bottom gate are 1.2 mm and paper holder is 1.8 mm. The width of edge gate is derived from equation 1 4. W= n x A / 30 (1) Where, W is gate width (mm); A is surface area of cavity (mm2) and n is material constant. From calculation surface area of top casing is 84,648 mm2,the width is 5.8 mm. Further calculation, bottom casing width is 5.9 mm and paper holder is 1.27 mm. 3.2 Circular Runner Diameter runner was calculated by taking the weight of part from volume multiply density and distance part from centre of mould as equation 2 4. D = W x L / 30 (2) Where, D is runner diameter, W is part weight and L is distance part to centre mould. Volume of top casing was taken from Rhinoceros software is 78,202 mm3and the weight is 0.08 kg so the diameter of runner is 6.5 mm. Further calculation, the diameter of bottom casing is 6.7 mm and paper holder is 1.5 mm. 3.3 Sprue The sprue size was decided by taking the thickness cavity plate mouldbase and given angle one degree from diameter 7 mm. Initial cold slug well is 7 mm and base cold slug well is 10 mm. Figure 3 shows the location of top casing, bottom casing and paper holder together with feeding system. FIGURE 3. Layout of two-plate mould. 311nts4. FILLING ANALYSIS OF TWO PLATE MOULD Result from filling analysis shows that the total filling period is 1.041 seconds. At the stage, 100% there were two results where the top casing was short shot and the plastic cannot flow to the impression of paper holder as shown in Figure 4. FIGURE 4. Filling process The top casing was redesigned because of the meeting area of flow front situated at side body, as result a welding line was developed on that area as shown in Figure 5. Welding line is the result of a flow front, which easily breaks up into two separate parts. When the two fronts meet, they try to welding back together again so as result form a single front line which it can be easily broken down 5. FIGURE 5. Welding line at top casing 4.1 Modification on Two-Plate Mould Modification was done on gate of bottom casing by decreasing 25% from 5.9 mm to 4.3 mm and runner from 6.7 mm to 5 mm due to over filling. Location of paper holder was moved from 50 mm from center of mould to 25 mm and increase runner size by 25%. A set of groove was added on surface of top casing to ensure the plastic flow toward corner of top casing as shown in Figure 6. FIGURE 6. Modification of Two-Plate mould. 312nts4.2 Filling process after Modification Result from filling analysis after modification shows the melt of plastic of three components were balance on each other. The total filling melt front time is 7.804x10-1seconds. The welding line has been eliminated on the centre side body of top casing and as result melt plastic flows towards on the corner as shown in Figure 7. FIGURE 7. Filling process after modification 5. DISCUSSION The size of runner of paper holder was increased and shifted to eliminate the unfilling. Gate and runner of bottom casing were decreased due to the over filling. Top casing was redesigned by adding a set of groove on the top surface of top casing to eliminate the welding line. As the result the welding line on centre side body of top casing was eliminated. From results it was found that the size of gate and runner in two-plate mould for paper holder increased by 25% due to the short shot problem and gate and runner for bottom casing reduced by 25% due to the over filling. 6. CONCLUSION This study was success on analyzing the flow of plastic materials in two-plate mould. The modifications was done on layout of cavities and feeding system as result improved the quality of the product. Furthermore, the defects of plastic product on short shot, over filling and welding line were eliminated before the actual mould is fabricated. REFERENCES 1. S.S.S. Imehezri., S.M. Sapuan, S. Sulaiman, Journal Material and Design, volume 26, pp. 157 166, 2005. 2. L.T. Manzione

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

|

2:不支持迅雷下载,请使用浏览器下载

3:不支持QQ浏览器下载,请用其他浏览器

4:下载后的文档和图纸-无水印

5:文档经过压缩,下载后原文更清晰

|

川公网安备: 51019002004831号

川公网安备: 51019002004831号