ZL15装载机总体及定轴变速箱的设计(3轴及齿轮)【word+3张CAD图纸全套】【优秀机械毕业设计】

【带任务书+开题报告+外文翻译+实习报告】【77页@正文33300字】【详情如下】【全套设计需要咨询请加QQ1459919609】

4.目录.doc

ZL15装载机总体及变速箱设计任务书(3轴及齿轮).doc

中文摘要.docx

参考文献.docx

实习报告.doc

开题报告.doc

正文.doc

毕业设计规定格式要求

第一章 东胜 前言.doc

第三章 东胜牵引计算.docx

第二章 东胜总体设计.doc

第五章 东胜定轴式动力换挡变速箱设计..doc

第六章 东胜毕业设计小结.docx

第四章 东胜 总体布置.docx

英文摘要.docx

英文翻译

装配图.dwg

说明书备份

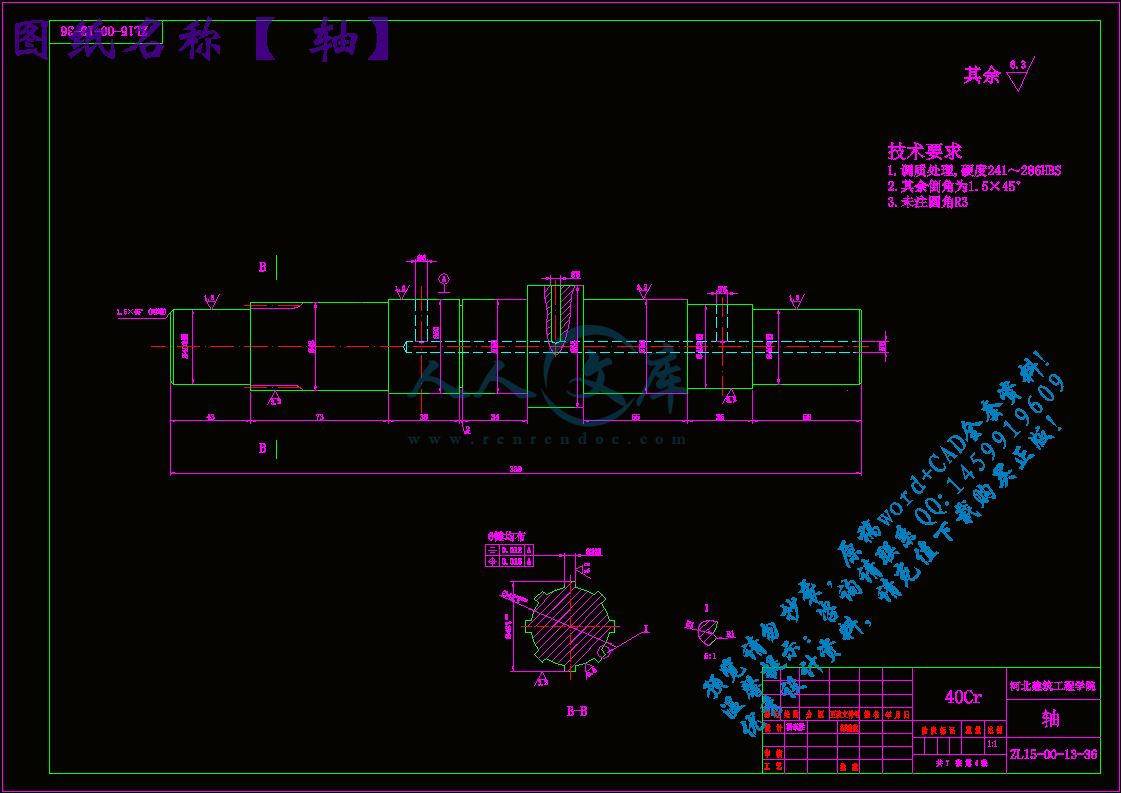

轴.dwg

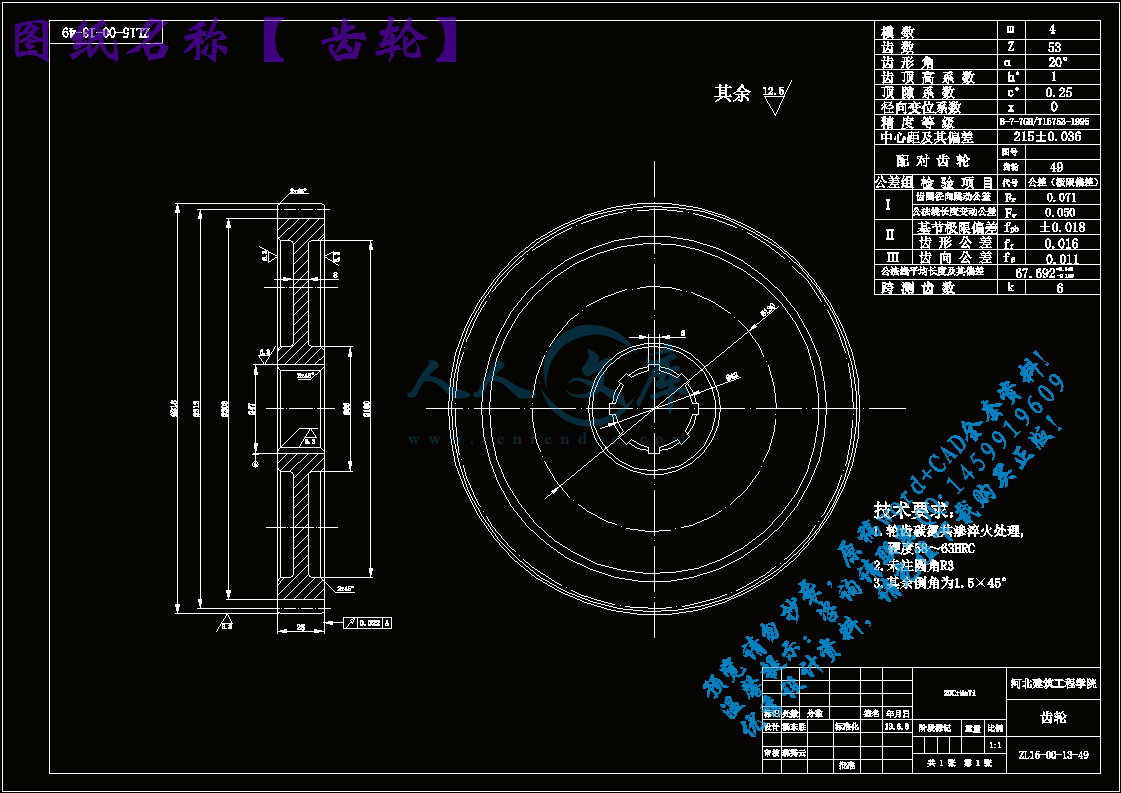

齿轮.dwg

毕业设计(论文)任务书

ZL15装载机总体及定轴变速箱设计(3轴及齿轮)

发任务书日期: 2013年 3月7日

1、本毕业设计(论文)课题应达到的目的:

本毕业设计是对机械专业学生在毕业前的一次全面训练,目的在于巩固和扩大学生在校期间所学的基础知识和专业知识,训练学生综合运用所学知识分析和解决问题的能力。是培养、锻炼学生独立工作能力和创新精神之最佳手段。毕业设计要求每个学生在工作过程中,要独立思考,刻苦钻研,有所创造的分析、解决技术问题。通过毕业设计,使学生掌握装载机的总体设计、变速箱设计、牵引计算等技术工作的实现方法,为今后步入工作岗位打下良好的基础。

2、本毕业设计(论文)课题任务的内容和要求(包括原始数据、技术要求、工作要求等):

(1)设计任务:

①总体参数选择:

1)总体方案及总体参数的确定;

2)牵引计算;

3)变速箱档位、速比的确定,动力换档变速箱型式的选定,学生要进行充分论证。

②变速箱设计(3轴及齿轮):

1)方案设计,确定传动简图;

2)技术设计;

3)强度、刚度计算。

③变速箱操纵液压系统原理图设计。

(2)技术参数

①额定载重量:1.5T

②工作重量:≯5.5T

③最高车速:≮20km/h

④空载牵引力:3.5~4.4T

⑤爬坡能力:≮20°

⑥最大卸载高度:≮2.35m;最小卸载距离:≮0.75m

⑦掘起力:≮4T

(3)设计要求:

①主要任务:学生应在指导教师指导下独立完成一项给定的设计任务,编写符合要求的设计说明书,并正确绘制机械与电气工程图纸或独立撰写一份毕业论文,并绘制有关图表。

②知识要求:学生在毕业设计工作中,应综合运用多学科的理论、知识与技能,分析与解决工程问题。通过学习、研究与实践,使得理论认识深化、知识领域扩展、专业技能延伸。

③能力培养要求:学生应学会依据技术课题任务,进行资料的调研、收集、加工与整理和正确使用工具书;培养学生掌握有关工程设计的程序、方法与技术规范,提高工程设计计算、图纸绘制、编写技术文件的能力;培养学生掌握实验、测试等科学研究的基本方法;锻炼学生分析与解决工程实际问题的能力。

④综合素质要求:通过毕业设计,学生应能树立正确的设计思想;培养学生严肃认真的科学态度和严谨求实的工作作风;在工程设计中,应能树立正确的生产观点、经济观点与全局观点。

⑤设计成果要求:

1)凡给定的设计内容,包括说明书、计算书、图纸等必须完整,不得有未完成的部分,不应出现缺页、少图纸现象。

2)对设计的全部内容,包括设计计算、机械构造、工作原理、液压系统、整机布置等,均应有清晰的了解。对设计过程、设计步骤有明确的概念,能用图纸完整地表达机械结构与工艺要求,有比较熟练的认识图纸能力。对运输、安装、使用等亦应有一般了解。

3)说明书、计算书内容要精炼,表述要清楚,取材合理,取值合适 ,设计计算步骤正确,数字计算准确,各项说明要有依据,插图、表格及字迹均应工整、清楚、不得随意涂改。制图要符合机械制图标准,且清洁整齐。

4)对国内外装载机情况有一般的了解,对各种装载机有一定的分析、比较能力。

5)其它各项应符合本资料有关部分提出的要求。

3、对本毕业设计(论文)课题成果的要求(包括图表、实物等硬件要求):

①计算说明书一份

内容包括:设计任务要求的选型论证、设计计算内容,毕业实习报告等。做到内容完整,论证充分(包括经济性论证),字迹清楚,插图和表格正规(分别进行统一编号)、准确,字数要求不少于2万字。查阅文献15篇以上,翻译机械类外文资料,译文字数不少于3000字;撰写中英文摘要;并引导学生应用计算机进行设计、计算与绘图。

②图纸一套(折合不少于3张0号图)

1)总体布置图一张(0号);

2)变速箱传动简图一张(1号);

3)变速箱装配图二张(两个视图)(0号二张);

4)变速箱操纵液压系统原理图一张(1号);

5)零件图二张(2号二张);

4、主要参考文献:

要求按国标GB 7714—87《文后参考文献著录规则》书写。

【1】同济大学主编. 铲土运输机械. 北京: 中国建筑工业出版社,1987

【2】吉林工业大学主编. 轮式装载机设计. 北京: 中国建筑工业出版社,1989

【3】杨晋生主编. 铲土运输机械. 北京: 机械工业出版社, 1987

【4】同济大学主编. 工程机械底盘构造与设计. 北京: 中国建筑工业出版社, 1987

【5】诸文农主编. 底盘设计(上、下). 机械工业出版社,1981年7月

【6】许镇宇,邱宣怀主编.机械零件(修订版)[M] .北京:人民教育出版社,1981

【7】吉林工业大学主编. 工程机械液压与液力传动. 机械工业出版社,1979

【8】东北工学院主编. 机械零件设计手册. 冶金工业出版社,1997

【9】黄谊主编. 液压与气压传动(第一版). 北京:机械工业出版社, 2000年5月

【10】成大光主编. 机械设计手册(第一卷). 北京:化学工业出版社, 2003年9月

成大光主编. 机械设计手册(第二卷). 北京:化学工业出版社, 2003年9月

成大光主编. 机械设计手册(第三卷). 北京:化学工业出版社, 2003年9月

成大光主编. 机械设计手册(第四卷). 北京:化学工业出版社, 2003年9月

成大光主编. 机械设计手册(第五卷). 北京:化学工业出版社, 2003年9月

【11】董刚, 李建功, 潘凤章主编. 机械设计.北京:机械工业出版社, 1998年7月

【12】刘鸿文主编. 材料力学(第四版). 高等教育出版社, 2004年1月

【13】路凤仪主编. 机械原理课程设计. 北京:机械工业出版社, 2002年6月

5、本毕业设计(论文)课题工作进度计划:

起 迄 日 期工 作 内 容

2013.2.25-2013.3.4

2013.3.5-2013.3.16

2013.3.17-2013.4.9

2013.4.10-2013.4.16

2013.4.17-2013.5.1

2013.5.2-2013.5.11

2013.5.12-2013.5.19

2013.5.20-2013.5.26

2013.5.27-2013.6.2

2013.6.3-2013.6.16

2013.6.17-2013.6.28

毕业实习及熟悉整理资料并写开题报告

总体方案选择及总体设计

牵引计算

进行总体布置并绘制总体布置图

变速箱设计

绘制传动简图、液压系统图

绘制变速箱装配图

典型零件设计及有限元分析

完善计算书、图纸 准备和进行答辩

修改设计图、计算书 完善设计成果

教研室审查意见:

摘要

我所设计的ZL15装载机既保留了传统装载机的优点,而且具有新的性能和优点。

本次设计主要进行的是变速箱的设计。ZL15装载机属于小型土方机械,广泛应用于城市建设工地及货场、煤场、仓库等装载及堆放松散货料的场所,并且可以用来完成轻度的挖掘及平整场地作业。

ZL15型装载机属于ZL系列,采用轮式行走系,液力机械传动系,铰接式车架,所以该机具有机动性好、转向灵活、生产率高、操纵轻便等优点。另外,该机后桥布置为摆动桥,增加了整机的稳定性,所以该机的安全性好。

ZL15型装载机采用定轴式变速箱,结构简单,制造成本较低,维修方便,特别是采用离合器外置式时,变速箱体尺寸小,便于总体布置。本机在设计中,参考同类机型,选用最佳传动方案,使机构简单,操作方便,并满足作业要求。定轴式变速箱采用动力换挡,使驾驶室操作便捷,减少劳动强度。

变速箱设计包括:变速箱型式的选择、传动比最终的确定、传动简图设计(前三后三档位)、所有齿轮的配齿计算、Ⅰ轴和Ⅱ轴离合器设计、结构设计(包括轴、轴承以及齿轮的选择校核计算)。最后还运用有CATIA对输出轴的受力情况进行了有限元分析。

【关键词】轮式装载机 定轴式变速箱 换挡离合器 有限元分析

ABSTRACT

This type of ZL15 loader that I have designed has the common virtues of the traditional loaders.And it has some new-improved virtues and function.

In my design progress,I put emphasis on the gearbox design. The ZL15 loader belongs to pint-size earthmoving machine.It is suitable for the construction site, the freight yard and so on, where the bulk materials are placed. Other more, it can dig and level lightly.

ZL15 loader belongs to ZL series, using wheeled walking system, hydro mechanical drive, articulated car frame, so the loader has many advantages, such as good maneuverability、turning agility、high productivity、operate portability, and so on. In addition, setting the latter bridge as Swing Bridge increases the overall stability and the safety of the machine.

The ZL15 loader is adopted fixed-axis gear-box, which can simplifies the structure of the whole machine, lowers production costs and make it easier for general service. In the design, after referring to the same type machine, the best transmission scheme is adopted finally, which can minimize the number of the parts and makes the machine has reasonable transmission ratio, so as to satisfy the demand of operation. The fixed-axis gear-box adopts dynamic gear-shifting, which makes the operation of the cab handier, and reduces the intensity of labor.

Gearbox design, including: the choice of transmission type, to determine the final drive ratio, transmission schematic design (three after three stalls), all gears with teeth, Ⅰaxis and Ⅱaxis clutch design, structural design (including the axis , the choice of bearings and gears check prices). Finally I use CATIA to analyze the stress situation of the output axis.

【KEY WORDS】 wheeled loader fixed-axis gear-box Gear-shifting sleeve

Finite element

目 录

第1章 前言1

第2章 总体设计2

2.1 概述2

2.2 选择确定总体参数2

2.3 装载机底盘部件型式选择12

第3章 牵引计算20

3.1 柴油机与变矩器联合工作的输入与输出特性曲线20

3.2 确定档位及各档传动比24

3.3 运输工况牵引特性曲线27

3.4 求出各档最高车速并分析牵引特性29

第4章 总体布置35

4.1 估计各部件重量(可根据样机定),并确定部件位置坐标35

4.2 各部件布置35

4.3平衡重计算39

4.4 验算轮胎载荷40

第5章 定轴式动力换档变速箱设计42

5.1 传动比的确定43

5.2 传动简图设计45

5.3 配齿计算48

5.4 离合器设计50

5.5 结构设计53

第6章 毕业设计小结70

参考文献72

第一章 前言

装载机属于铲土运输机械类,是一种通过安装在前端一个完整的铲斗支撑结构和连杆,随机器向前运动进行装载或挖掘,以及提升、运输和卸载的自行式履带或轮胎机械,它广泛应用于公路、铁路、建筑和矿山等工程建设。装载机具有作业速度快、效率高、机动性好、操作轻便等优点,因此成为工程建设中土石方施工的主要机种之一,对于加快工程建设速度,减轻劳动强度,提高工程质量,降低工程成本都发挥着重要的作用,是现代机械化施工中不可缺少的装备之一。

ZL15装载机是小型土力机械,广泛应用于城市建设工地及货场、煤场、仓库等装载及堆放松散物料的场所,工作在密实的土壤,并且可以用来完成轻度挖掘及平整场地的作业。

ZL15装载机属于ZL系列,采用轮式行走系;液力机械传动系;铰接式车架;工作装置采用液压操纵,所以该机具有机动性好,转向灵活、生产率高、操纵轻便等优点。另外,该机后桥布置为摆动桥,增加了整车的稳定性,所以,该机安全性好。

ZL15装载机现在普遍采用的设计是分动装置、变矩器和变速箱“三合一”布置。变速箱采用定轴式动力换挡变速箱,动力装置采用高速柴油机。驱动桥为一级减速主传动,轮边行星减速,且采用双桥驱动,采用钳盘式制动器,工作装置采用反转连杆机构。为了适应工作要求,适应生产要求,并尽力向ZL标准系列靠拢,我们在设计过程中,将采用最先进的型式和技术。

第2章 总体设计

2.1 概述

总体设计是机械设计中极为关键的环节,它是对所设计机械的总的设想。总体设计的成败,关系到整部机械的经济技术指标,直接决定了机械设计的成败。

总体设计指导机构设计和部件设计的进行,一般由主任工程师(或总工程师)主持进行。在接受设计任务以后,应进行深入细致的调查研究,收集国内外同类机械的有关资料。了解当前国内外装载机的使用、生产、设计和科研情况,并进行分析比较,制定总的设计原则。设计原则应当保证所设计机型符合有关的方针、政策。在满足使用要求的基础上,力求结构合理,技术先进,经济性好,寿命长。

总体设计原则:

1.遵循三化:零件标准化、产品系列化、部件通用化。

2.采用四新:新技术、新结构、新材料、新工艺。

3.满足三好:好制造、好使用、好维修。

4.对零部件设计负责。

制定设计总则以后,便可以编写设计任务书,在调研的基础上,运用所学知识,从优选择确定总体方案,保证设计的成功。

2.2 选择确定总体参数

目前,装载机的总体设计中有计算法、类比法及综合运用计算法和类比等三种设计方法。限于我们的条件,我们的设计采用计算法和类比法综合运用的方法。

总体参数的确定包括以下内容(其余见任务书):

2.2.1轴距及轮距

轴距和轮距的大小可以影响装载机的使用性能,因此总体设计中的参数,一般是参考同类机型初选,然后通过绘制总体布置图才能准确地选定轴距。

1.轴距L—它的改变会影响以下几个方面的整机性能:

A:影响前后桥轴荷的分配。当各总成(除后桥外)相对于前桥的前后位置不变时,轴距的改变会使前后轴的载荷发生变化。如图2-1所示,后桥载荷 ,如保持整车重心位置G不变,则增大L,后桥载荷必减小,反之,则增大。因此,改变轴距可调整轴荷分配。

B:影响装载机的纵向稳定性。轴距增大,有利于提高整车的纵向稳定性,如图(2)所示,取临界平衡状态(前桥为支点) ,如保持前后桥轴荷不变,则增大轴距L值,必增大 值,即增加抗整机绕前轴倾翻的力矩(G)。轴距增大还可以减少装载机在行驶中的前后颠簸,提高行驶平稳性,减少司机疲劳。

C:影响最小转弯半径。轴距增大,最小转弯半径增大。

此外,轴距的改变,还会影响车架受力和整机通透性。考虑以上因素,参考天津市政工程机械厂和江西工程机械厂生产的ZL15同类机型。初选轴距L=2050mm。

2.轮距B:

大部分装载机前后轮距相同,且前后轮使用相同轮胎。

A:轮距增加,提高装载机的横向稳定性,但最小转弯半径增加。

B:轮距增大会造成铲斗宽度增加,这样将降低单位斗刃长度上的插入力。

设计中尽可能希望轮距小些。

参考同类机型,选取轮距W=1440mm

2.2.2初选轮胎

轮胎是行走系的主要部件,承担着繁重而复杂的载荷,它对装载机的技术性能和工作指标影响很大,并且还直接影响装载机的安全行驶;从经济指标上看,轮式装载机的轮胎费用占整机购置费的10-15%,占装载机使用费用的25-50%,因此,合理而正确的选择轮胎对扩大装载机的使用范围、降低装载机的使用成本具有很大的意义。

装载机的作业条件是选择其轮胎的重要依据,用于土方工程的装载机常在比压小的软基路面和凹凸不平的路面上行驶作业。另外,装载机的行走装置一般都是与车架刚性连接。所以,在选择轮胎时,除了满足一定的承载能力外,还需要有好的耐磨性、牵引性、通过性及缓冲性能。

1.机构形式的选择

目前装载机广泛采用低压、宽基系列轮胎。

低压轮胎的外形尺寸较大,弹性较好,能增大接

地面积,减少接地比压,所以它能在比压小的软基路面上行驶,下陷小,降低滚动阻力,通过性好;在凹凸路面或碎石路面行驶时,能很好地吸收冲击与振动,缓冲性能好。

宽基轮胎比标准轮胎宽度大,从而接地比压小,在软基路面上通过性能好,牵引力也大。另外具有在同样载荷下使用较低气压的优点。同时又能改善驾驶性能及行驶的稳定性,所以为轮式装载机所广泛采用。

2.轮胎花纹的选用

轮胎胎面上有不同形状的花纹,轮胎花纹的主要作用是保证轮胎和道路之间的良好附着性,传递机械的牵引力与制动力。在本设计中采用混合花纹:中间部分是纵向而两臂部分是横向花纹,其花纹占接地面积的30%,中间纵向花纹可保证纵向稳定,而两臂花纹可提供驱动力与制动力,并且有较好的耐磨性。

3.轮胎尺寸对装载机性能有很大影响,它影响传动系传动比的选择,整机重心高度、离地间隙以及各部件的总体布置等。轮胎尺寸增加,可以增加轮胎的承载能力,能有效地改善附着性能,但它引起机器成本的增加和整机重心的提高。

综合考虑以上因素,参考同类机型,由《工程机

械轮胎手册》表2-3-6和表1-1-5查得:

轮胎型号最大负荷充气压力外直径断面宽度

11.00-202945Kgf7.0

Kg/cm2 1090mm2875mm

2.2.3初定斗宽和斗型

1.斗宽的确定

斗宽B=轮距+轮胎宽+2a (参见设计指导书)

由以上设计知轮距为1440mm,轮胎宽为290mm,取a=50~100mm,则斗宽

B=1440+290+2×(50~100)=1830~1930mm

取斗宽B=1900mm。

2.斗型的确定

铲斗是铲装物料的工具,它的斗型与结构是否合理,直接影响装载机的生产率。在设计工作装置连杆机构之前,首先要确定铲斗的几何形状和尺寸,因为它与连杆机构的设计有密切联系。

铲斗首先要有合理的斗型,减少切削和装料阻力,提高作业生产年率,其次是在保证铲斗具有足够强度和刚度的前提下,尽量减少自重;同时也应考虑到更换工作装置和修复易损零件的方便。

铲斗有普通形式的铲斗、蛙式、侧卸式和强制卸料等。普通铲斗有直刀刃、V形刀刃、带斗齿和V形刀刃带斗齿铲斗。直线型斗刃适于装载轻质和松散小颗粒物料,并可利用刀刃作刮平、清理场地工作;V形刀刃便于插入物料堆,有利于改善作业装置的偏载,适宜铲装较密实物料;带斗齿铲斗具有较大的插入料堆的能力,适宜于铲装矿石和坚实物料。齿型的选择应考虑插入阻力和耐磨两个因素,并且要便于更换。尖齿插入力较强,但不耐磨,纯齿则较耐磨,然而插入阻力大,一般轮式装载机多用于前者,大型装载机则常用分体式。这种连接方式便于更换。

ZL15装载机属于中小型装载机,据作业要求,并参考一些同类产品,本机选用直刀刃尖齿铲斗。

参考文献

【1】 同济大学主编.铲土运输机械. 北京:中国建筑工业出版社,1987.

【2】 吉林工业大学编.轮式装载机设计. 北京:中国建筑工业出版社,1989.

【3】 杨晋生主编.铲土运输机械. 北京:机械工业出版社,1987.

【4】 同济大学主编.工程机械底盘构造与设计. 北京:中国建筑工业出版社,1987.

【5】 诸文农编.底盘设计(上下). 北京:机械工业出版社,1981.

【6】 许镇宇,邱宣怀主编.机械零件(修订版)[M] .北京:人民教育出版社,1981

【7】 吉林工业大学主编. 工程机械液压与液力传动. 机械工业出版社,1979

【8】 东北工学院主编. 机械零件设计手册. 冶金工业出版社,1997

【9】 黄谊主编. 液压与气压传动(第一版). 北京:机械工业出版社, 2000年5月

【10】 成大光主编. 机械设计手册(第一卷). 北京:化学工业出版社, 2003年9月

成大光主编. 机械设计手册(第二卷). 北京:化学工业出版社, 2003年9月

成大光主编. 机械设计手册(第三卷). 北京:化学工业出版社, 2003年9月

成大光主编. 机械设计手册(第四卷). 北京:化学工业出版社, 2003年9月

成大光主编. 机械设计手册(第五卷). 北京:化学工业出版社, 2003年9月

【11】 董刚, 李建功, 潘凤章主编. 机械设计. 北京:机械工业出版社, 1998年7月

【12】 刘鸿文主编. 材料力学(第四版). 高等教育出版社, 2004年1月

【13】 路凤仪主编. 机械原理课程设计. 北京:机械工业出版社, 2002年6月

【14】 青风,国内轮式装载机的现状和发展趋势,机电信息,2004年第八期

川公网安备: 51019002004831号

川公网安备: 51019002004831号